Trimetazidine hydrochloride tablets and preparation method thereof

A technology selected from trimetazidine hydrochloride, which is applied in the field of trimetazidine hydrochloride tablets and its preparation, can solve the problems of difficult molding and poor compressibility, and achieve increased fluidity, reduced myocardial oxygen consumption and Cardiac energy, the effect of reducing the workload of the heart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

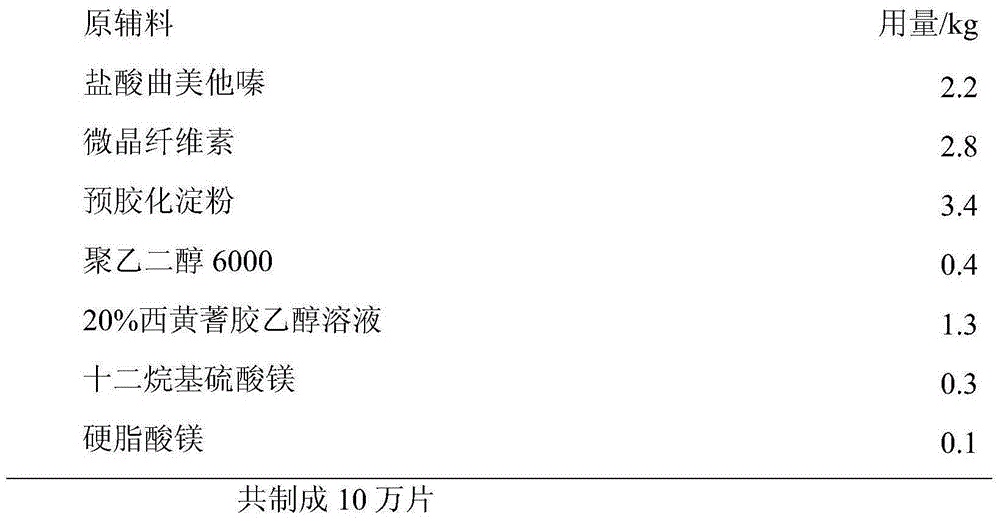

[0025] 1. Prescription

[0026]

[0027] 2. Process

[0028] Trimetazidine hydrochloride was passed through a 22-mesh mesh sieve. Weigh 2.2kg trimetazidine hydrochloride, 2.8kg microcrystalline cellulose, 3.4kg pregelatinized starch and 0.4kg polyethylene glycol 6000 according to the prescription and mix them evenly. Add 1.3 kg of tragacanth gum ethanol solution with a concentration of 20%, granulate with an 18-mesh sieve, dry and granulate. Add 0.3kg lauryl magnesium sulfate and 0.1kg magnesium stearate and mix and then compress into tablets to obtain the trimetazidine hydrochloride tablet of the present invention.

Embodiment 2

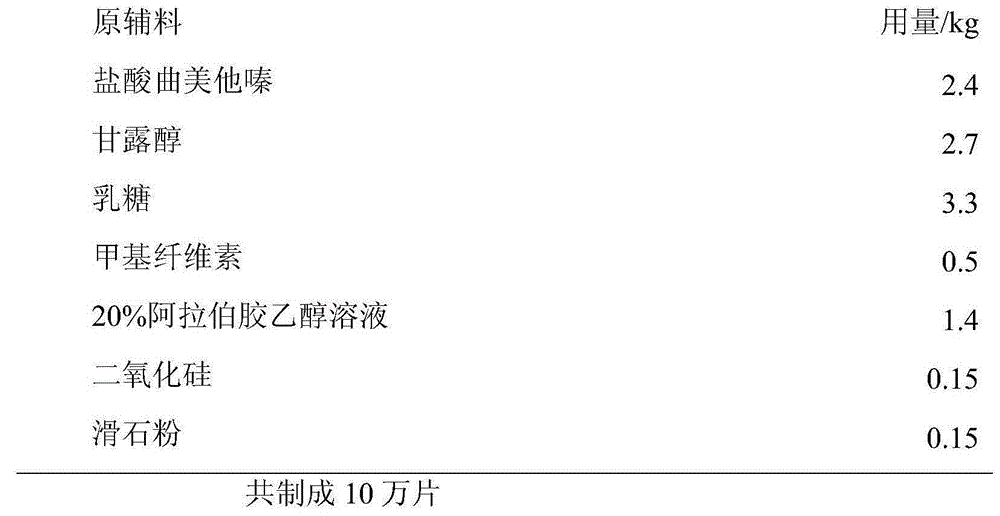

[0030] 1. Prescription

[0031]

[0032] 2. Process

[0033] Trimetazidine hydrochloride was passed through a 22-mesh mesh sieve. Take by weighing 2.4kg of trimetazidine hydrochloride, 2.7kg of mannitol, 3.3kg of lactose and 0.5kg of methylcellulose and mix them evenly. Add 1.4kg concentration of 20% ethanol solution of gum arabic, granulate with 18 mesh sieve, dry and granulate. Add 0.15kg of silicon dioxide and 0.15kg of talcum powder for total mixing and then compress into tablets to obtain the trimetazidine hydrochloride tablet of the present invention.

Embodiment 3

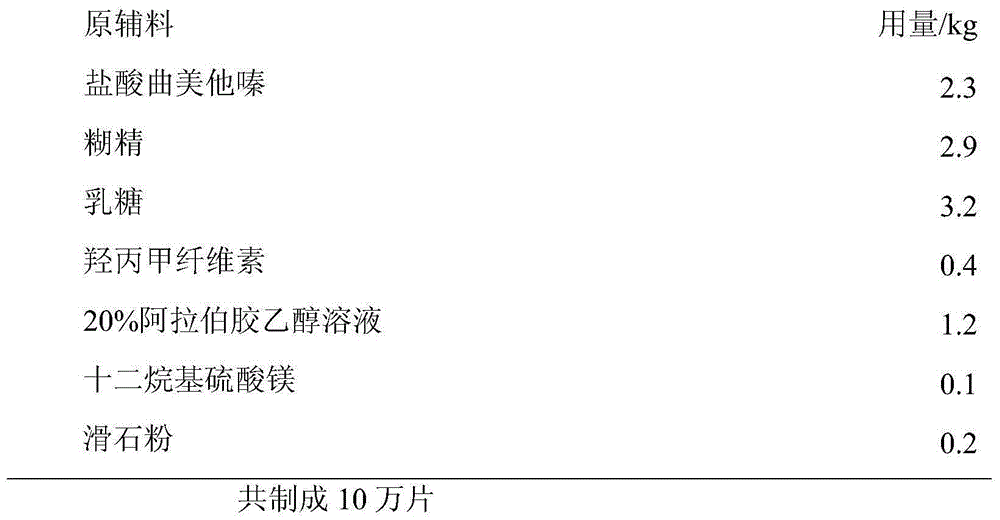

[0035] 1. Prescription

[0036]

[0037] 2. Process

[0038] Trimetazidine hydrochloride was passed through a 22-mesh mesh sieve. Take by weighing 2.3kg trimetazidine hydrochloride, 2.9kg dextrin, 3.2kg lactose and 0.4kg hypromellose and mix uniformly according to the prescription. Add 1.2 kg of 20% ethanol solution of gum arabic, granulate with 18 mesh sieve, dry and granulate. Add 0.1kg lauryl magnesium sulfate and 0.2kg talcum powder and mix and compress into tablets to obtain the trimetazidine hydrochloride tablet of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com