Single-head filling and capping machine

A technology of stoppering machine and filling machine, which is applied in the field of filling, can solve the problems of low-speed use of high-speed equipment, restricting the development of pharmaceutical companies, and high cost, and achieves the effects of low cost, overcoming substandard sanitation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

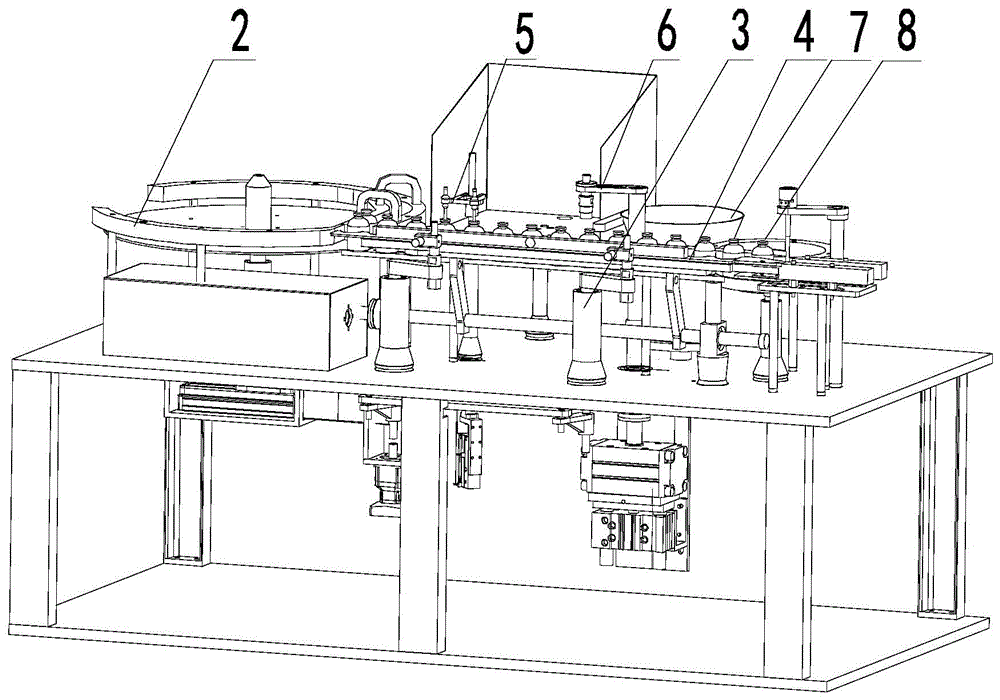

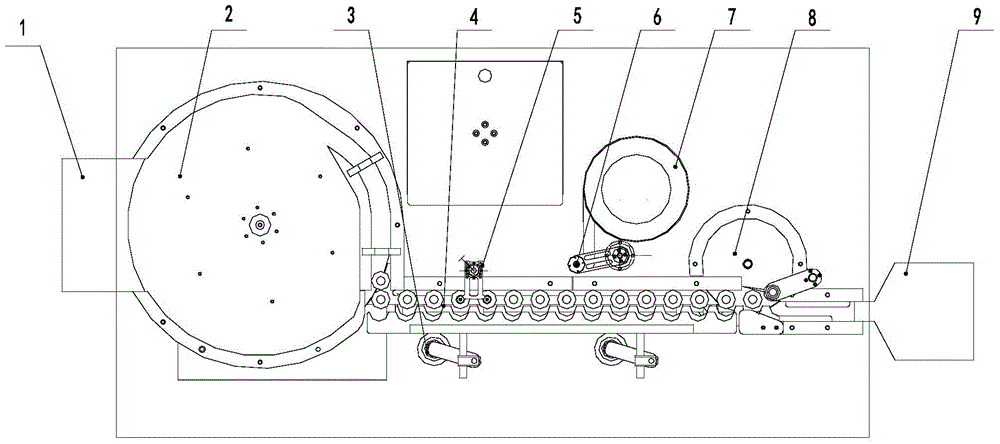

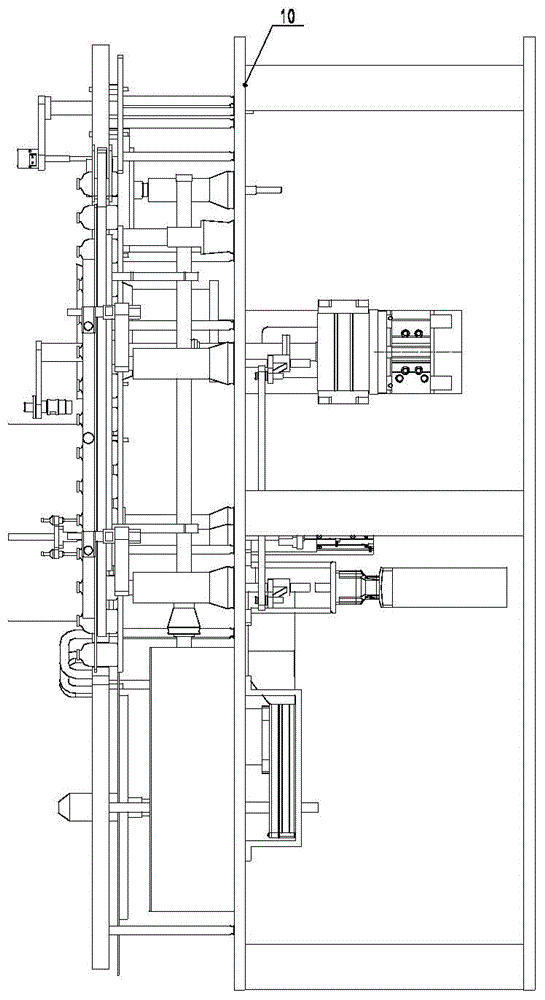

[0012] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a single-head filling and corking machine, which comprises a frame 10, a bottle feeding tray 1, a bottle unscrambling part 2, a medicine bottle positioning part 3, a bottle feeding part 4, a filling part 5, a corking part Part 6, cork unscrambling part 7, waste rejecting part 8 and bottle output part 9, the bottle feeding tray 1 is connected with the bottle unscrambling part 2, the bottle feeding part 4 is located below and connected with the bottle unscrambling part 2, and the bottle feeding part 4 A medicine bottle positioning part 3 is arranged on one side close to the bottle unscrambling part 2, a filling part 5 is arranged on the other side of the bottle conveying part 4, and a filling part 5, a stoppering part 6, a pick-off The waste part 8 and the bottle outlet part 9, the cork unscrambling part 7 and the cork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com