Filling action mechanism of filling machine

A technology of action mechanism and filling machine, applied in packaging, bottle filling, liquid bottling, etc., to achieve the effect of stable movement path, compact structure and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

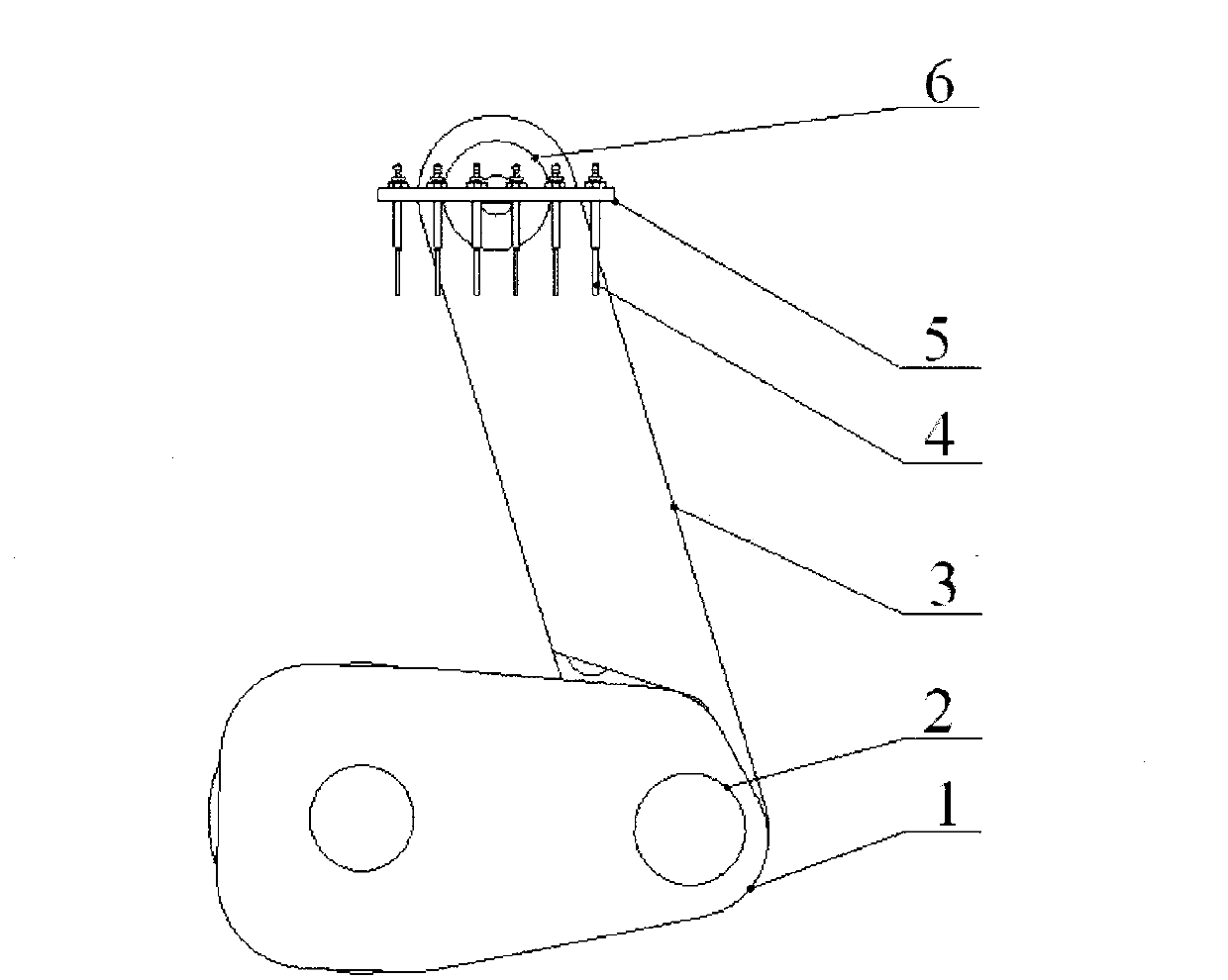

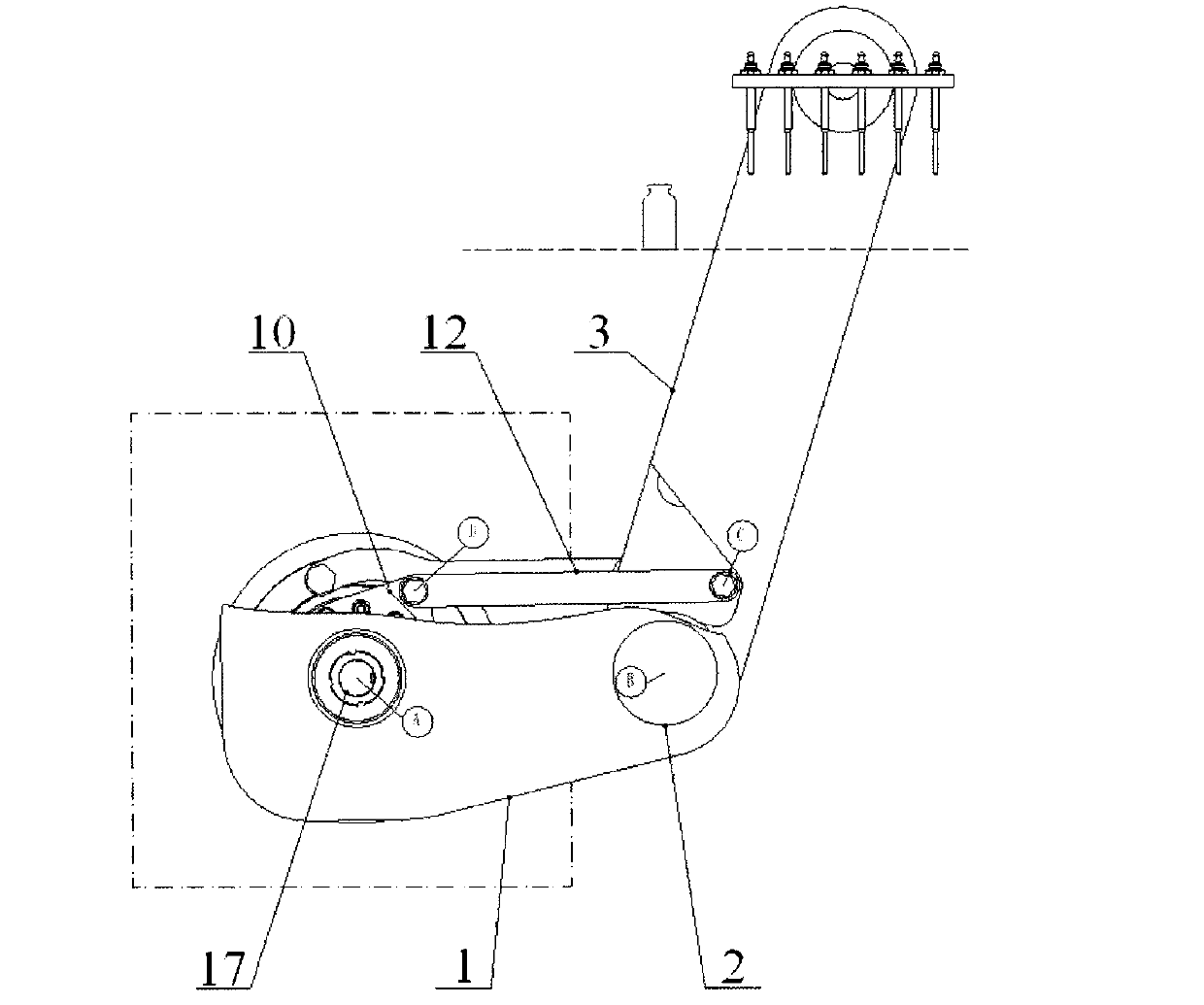

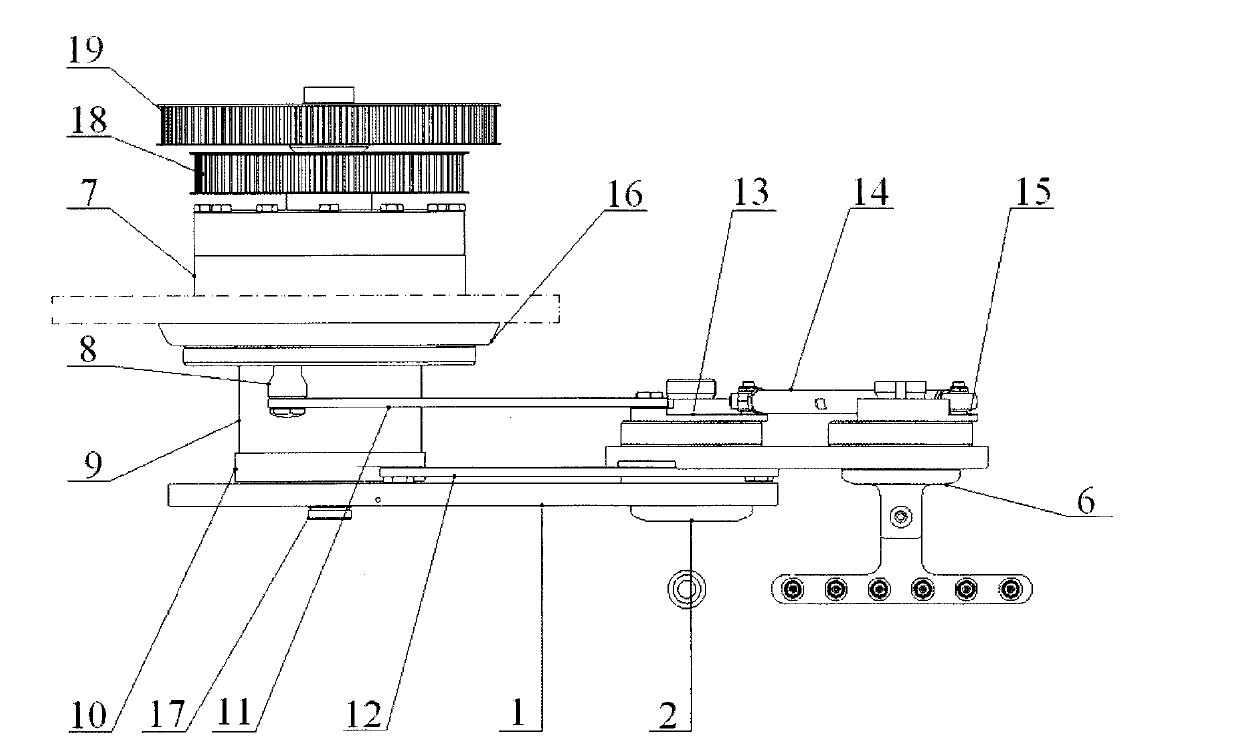

[0020] The present invention is a filling action mechanism of a filling machine, such as Figure 1-Figure 5 As shown, it includes a manipulator main shaft 17, one end of the manipulator main shaft 17 passes through the boom pulley 19, the forearm pulley 18, the hollow reducer 7, the fixed plate 16, the connecting joint 9, and the arm 1 One end is connected, the other end of the manipulator arm 1 is connected to one end of the manipulator arm 3 through the manipulator secondary shaft 2, and the output end of the hollow reducer 7 is connected to the manipulator through the connecting joint 9, the first movable joint 10, and the second link 12 The small arm 3 is connected, and a needle holder fixed shaft 6 is installed on the other end of the small arm 3 of the manipulator. One end of the first movable joint 10 is connected to the robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com