Online monitoring tubular centrifugal machine and separation monitoring process thereof

A tubular centrifuge and monitoring process technology, applied to centrifuges with rotating drums, centrifuges, etc., can solve problems that affect material quality and production, and have no monitoring means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

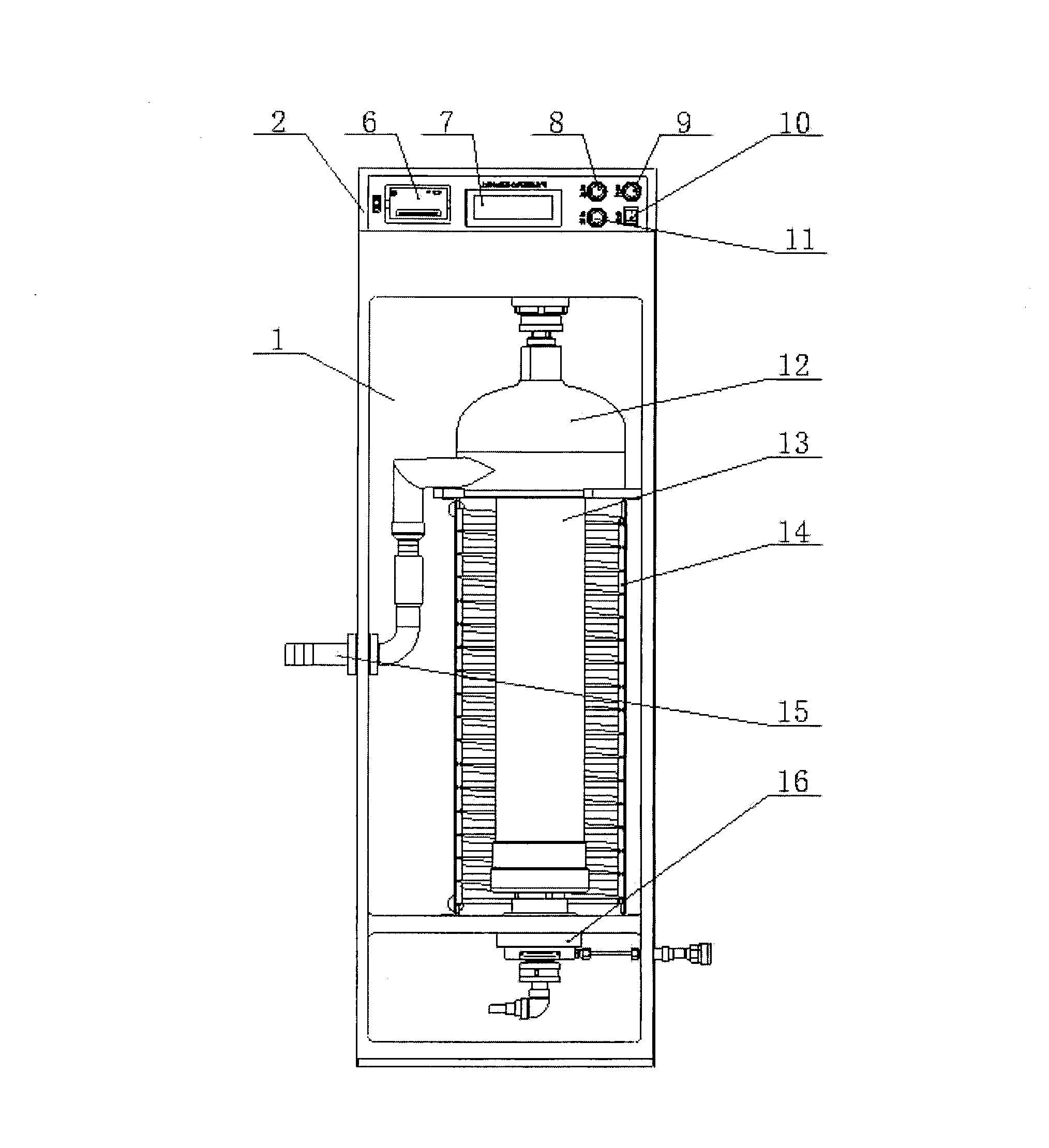

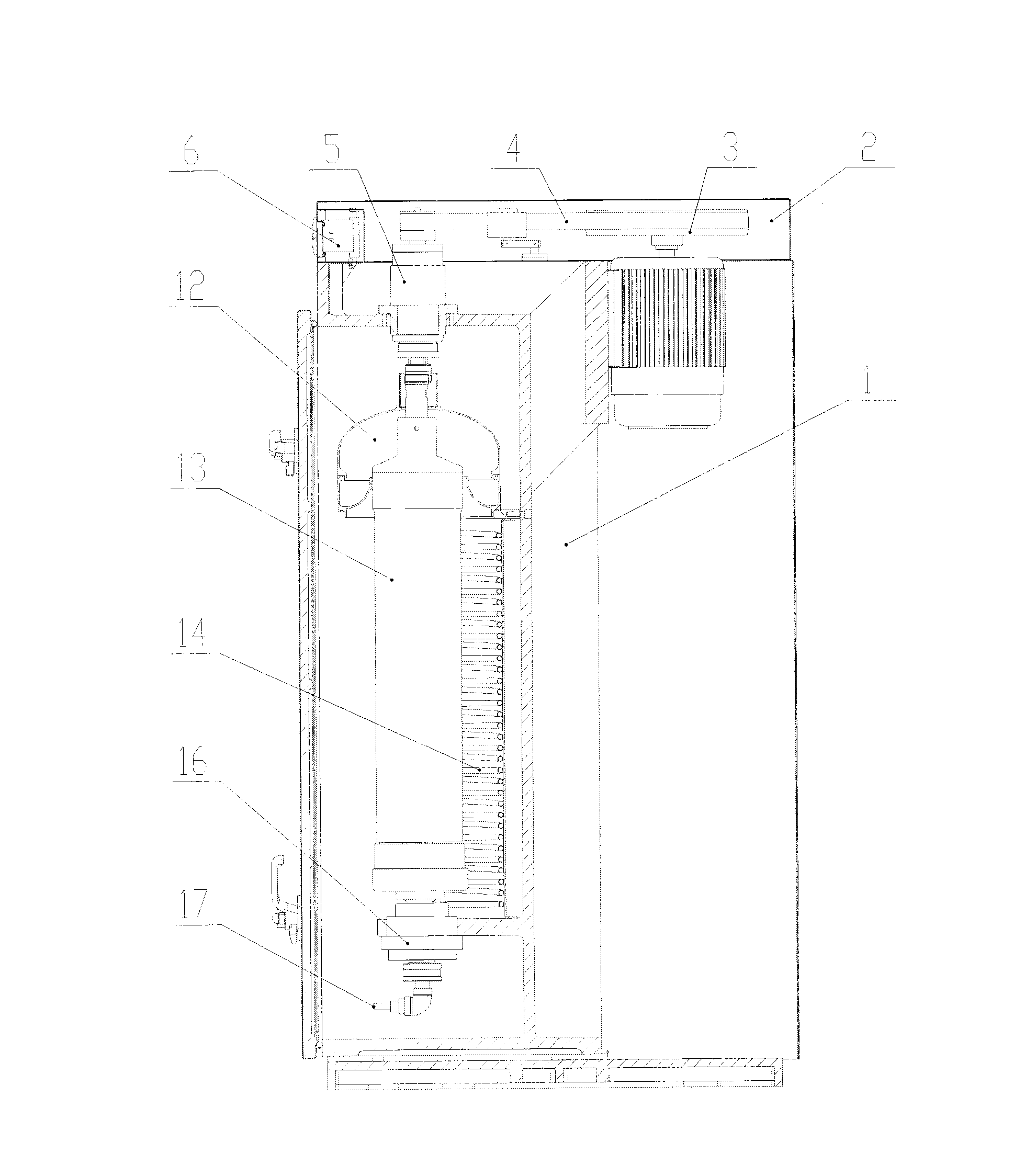

[0008] See attached figure 1 , 2 , the whole machine is located in the body 1, the lower part of the body 1 is fixed with a lower damper 16, the upper part of the lower damper 16 is connected to the drum 13 through a bearing, and the drum 13 is covered with an effusion plate 12, and the drive shaft of the machine head 5 passes through The effusion pan 12 is connected to the drum 13 through bearings, the effusion pan 12 is connected with a discharge pipe 15, a condensation pipe 14 is fixed on the outside of the drum 13, and the feed pipe 17 extends into the cavity of the drum 13 through the lower damper 16, Condenser pipe 14 is provided on the outside of drum 13; the upper part of the body is fixed on machine head 5, and the pulley at the upper end of machine head 5 is connected to the main motor through transmission belt 4 and large pulley 3; the monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com