Permanent magnet synchronous motor fault simulation system and fault diagnosis method

A permanent magnet synchronous motor, fault simulation technology, applied in the direction of motor generator testing, measuring electricity, measuring electrical variables, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

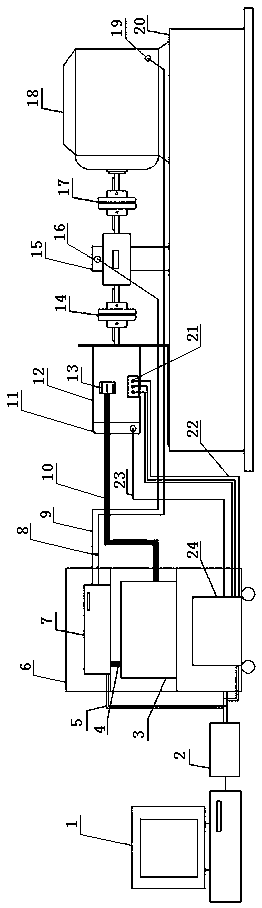

[0020] A kind of permanent magnet synchronous motor fault simulation system, its composition comprises: permanent magnet synchronous motor 12, described permanent magnet synchronous motor one end is equipped with rotor position detector 11, and the other end is connected with torque sensor 15 by coupling I14, The torque sensor is connected to the dynamometer 18 through the coupling II17, the lower end of the dynamometer has a signal output terminal 19, and is transmitted to the data acquisition and control system 7 through the signal feedback cable 8, and the rotor The position detector is transmitted to the motor controller 24 through the rotor position signal rotor position signal line 23, the fault point 13 on the permanent magnet synchronous motor is connected with the short circuit fault simulation actuator 3 through the cable 10, and the permanent magnet synchronous The power input terminal 21 under the motor is connected with the motor controller through a cable 22 .

Embodiment 2

[0022] According to the permanent magnet synchronous motor fault simulation system described in embodiment 1, the motor controller, the short-circuit fault simulation actuator, and the data acquisition and control system are installed in the cabinet 6 in sequence, and the data The acquisition and control system is connected with the short-circuit fault simulation actuator through the control line, the data acquisition and control system 4 is connected with the CAN analyzer 2 through the CAN bus 5, and the CAN analyzer is connected with the industrial computer through the USB interface 1 connection, the CAN analyzer is connected with the motor controller through the CAN bus.

Embodiment 3

[0024] According to the permanent magnet synchronous motor fault simulation system described in embodiment 1, the described torque sensor has a signal output terminal 16 and passes through the torque signal feedback cable 9 to the described data acquisition and control system, and the described dynamometer . The torque sensor is fixed on the upper plane of the base 20 through a bracket, and the right end of the permanent magnet synchronous motor is fixed on the base through a bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com