Adjustable automatic belt punching synchronous machine and belt punching method

An adjustable and synchronous machine technology, applied in the direction of metal processing, to achieve the effect of satisfying the drilling accuracy, reasonable and convenient use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

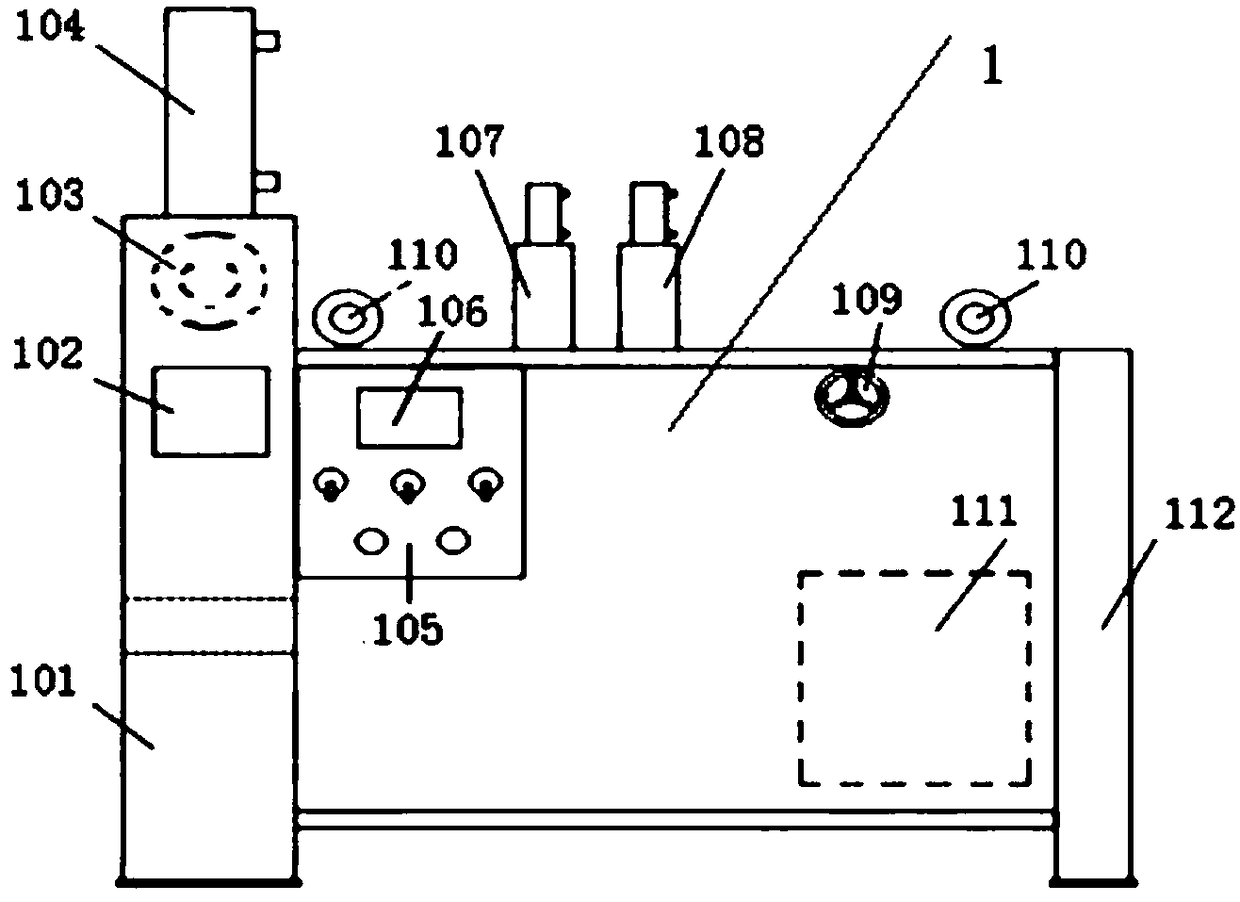

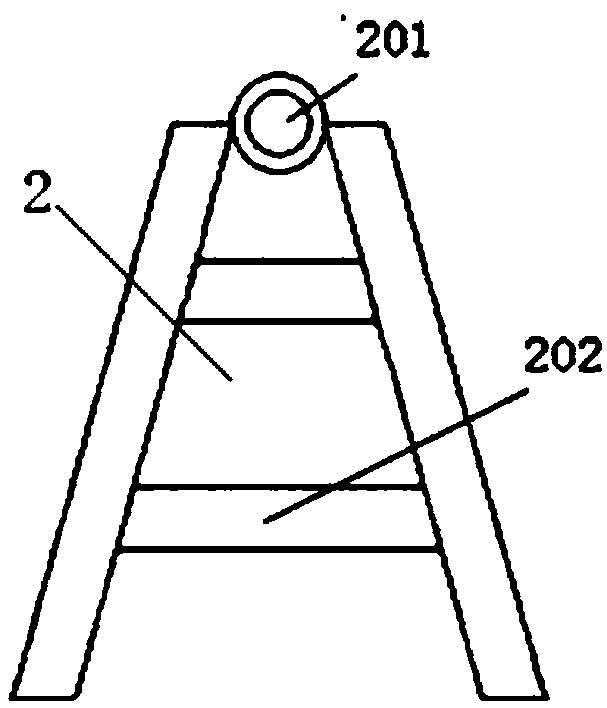

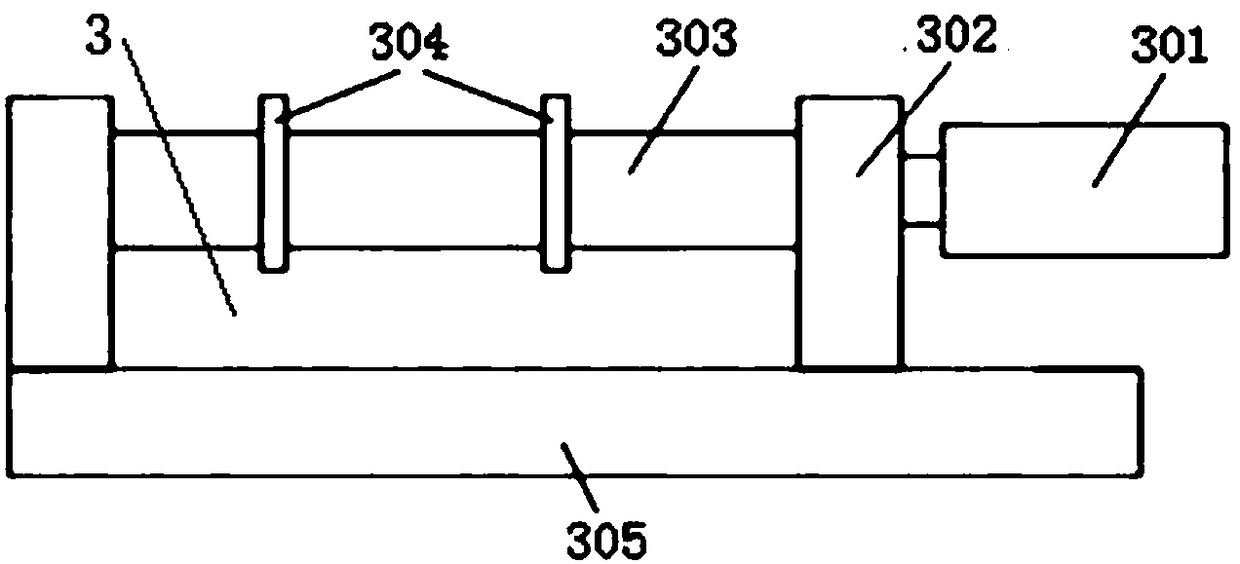

[0033] Such as Figure 1~4 , an adjustable belt automatic punching synchronous machine, the adjustable belt automatic punching synchronous machine includes a belt release bracket 2, a workbench 1 and a belt collection bracket 3 arranged in sequence, and the upper part of the workbench 1 is provided with a porous synchronous Punch device 4, the workbench 1 is also provided with the meter wheel 109 for measuring the length of the belt and the guide wheel 110 for fixing the belt. The front of the workbench 1 is equipped with an equipment electrical control box 105. On the face of the control box, an operating The buttons and the parameter liquid crystal display screen 106 are internally equipped with a hydraulic oil tank 111 for providing hydraulic oil to the oil cylinder.

[0034] Described porous synchronous punch device 4 comprises a fixed porous synchronous punch device 107, a movable porous synchronous punch device 108, base plate 401, side plate 402 and upper plate 403, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com