Spray-needle buckled type quick connector for bottle washing machine

A technology of quick connection and bottle washing machine, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of secondary pollution, cleaning dead corners, etc., and achieve the effect of ensuring quality and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

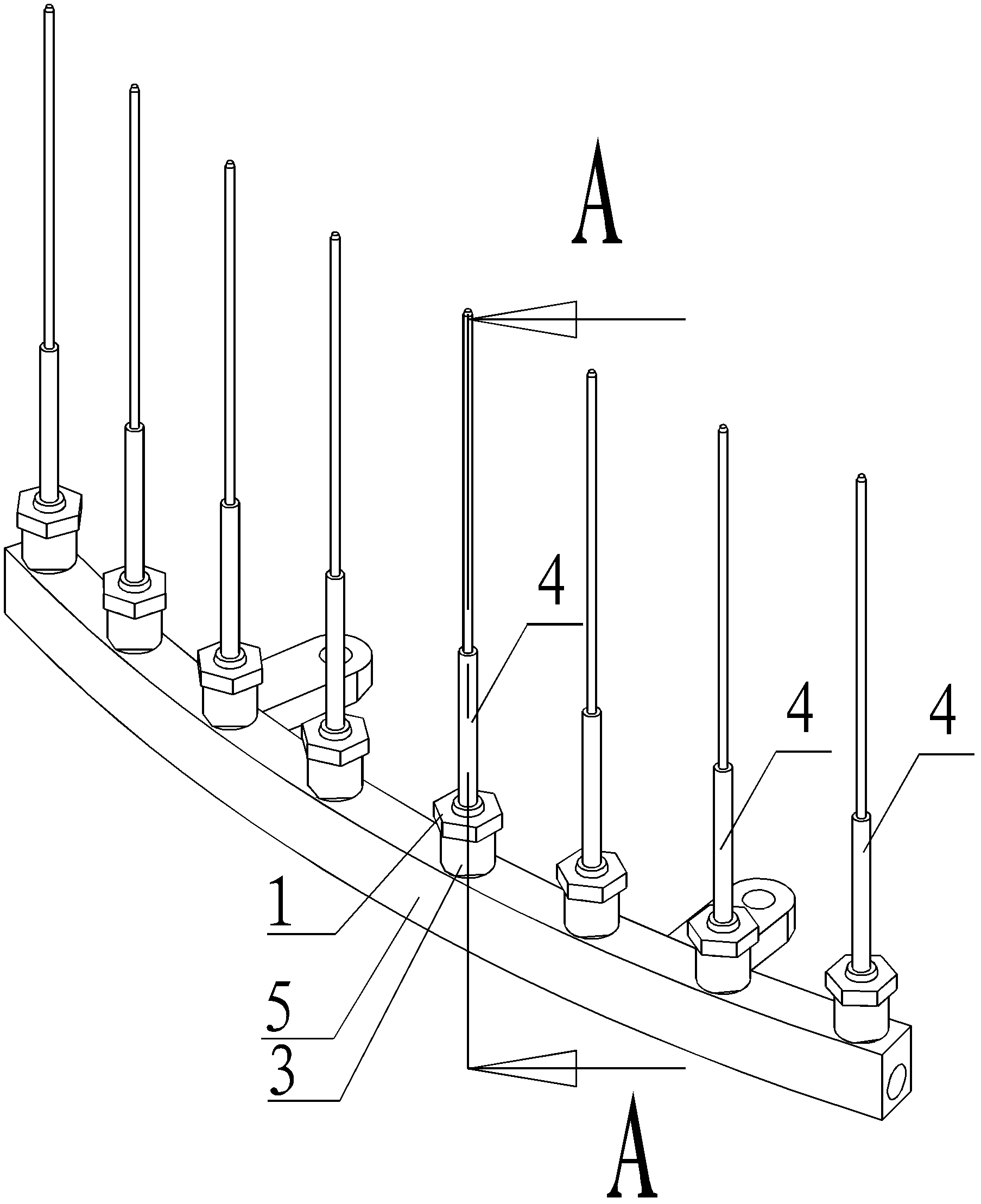

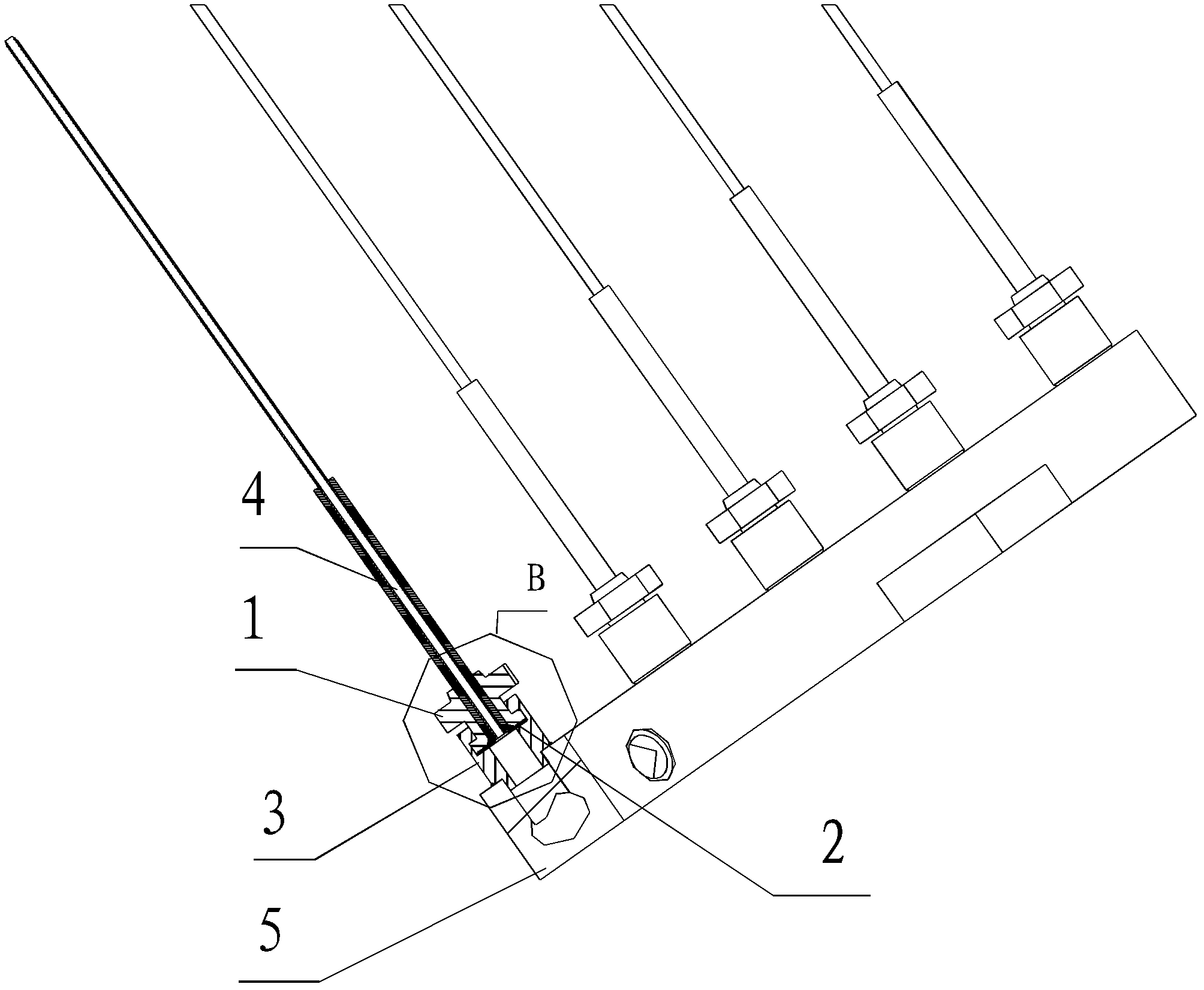

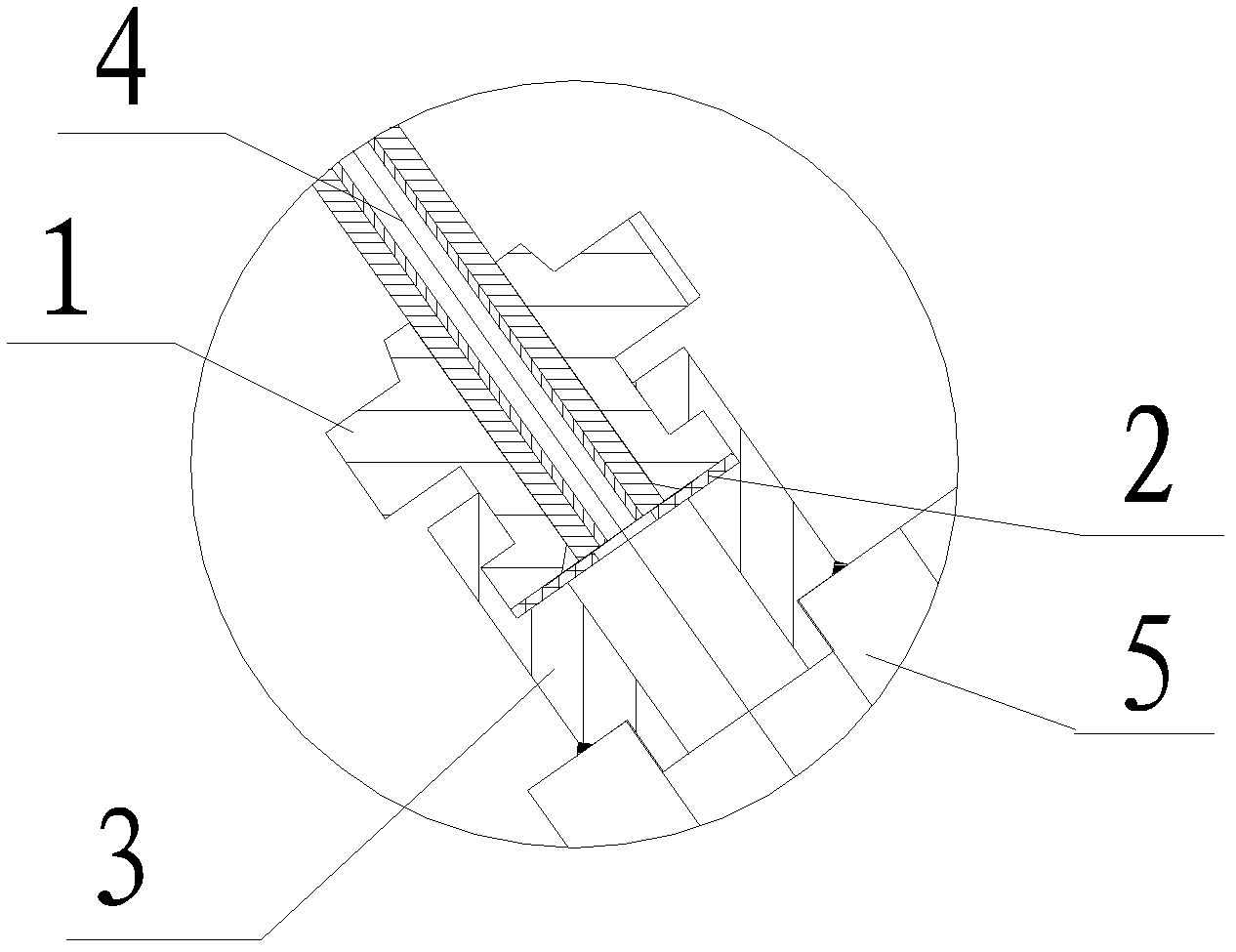

[0014] figure 1 It is a structural schematic diagram of the present invention, figure 2 is the invention figure 1 A-A view of the, image 3 is the invention figure 2 The enlarged picture of B, such as Figure 1-3 As shown: the present invention includes a spray needle, a spray needle holder and a sealing gasket. The spray needle includes a welded convex spray needle seat 1 and a needle tube 4, and the spray needle holder includes a welded concave head spray needle seat 3 and a bracket 5 , the gasket 2, which plays the role of sealing and shock absorption, is installed at the junction of the spray needle and the spray needle holder. The outer convex surface of the needle needle seat 1 with the convex head is a V-shaped outer tapered surface, and two symmetrical lugs are provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com