The preparation method of theophylline sustained-release tablet

A technology for sustained-release tablets and theophylline, which is applied in the field of medicine, can solve the problems of poor reproducibility of sustained-release tablets, differences in release rate and dissolution, and achieve the effects of improving use value, stable quality, and avoiding toxic and side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

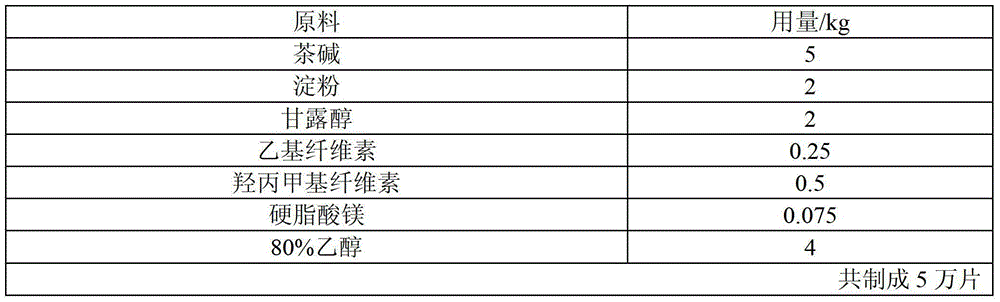

[0033] Table 1 The raw materials and proportions of theophylline sustained-release tablets (100mg)

[0034]

[0035] The preparation method is as follows:

[0036] (1) Add ethyl cellulose, hydroxypropyl methyl cellulose and 80% ethanol of recipe quantity in the wet mixing granulator, stir and shear at normal temperature for 30 minutes, and make a uniformly dispersed binder for subsequent use;

[0037] (2) Add theophylline, binding agent, starch and mannitol of recipe quantity in granulator again, make soft material;

[0038] (3) After replacing the granulator with a 16-mesh stainless steel mesh, use the granulator to granulate;

[0039] (4) The prepared wet granules are pumped into the fluidized bed, and the wet granules are vacuum pumped into the fluidized bed to dry to a moisture content of 4%, and then the granules are sized with a crushing and sizing machine, and magnesium stearate is added to mix evenly and then pressed The tablets are dried to obtain theophylline su...

Embodiment 2

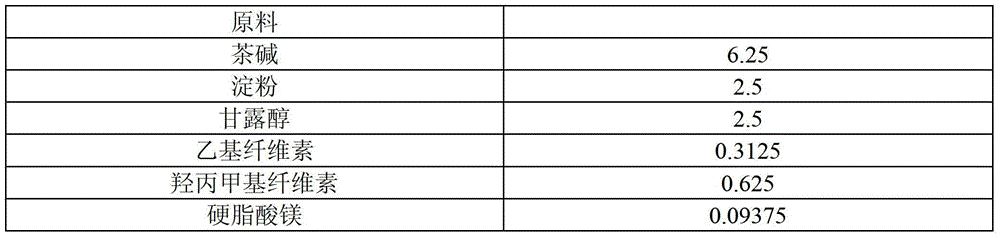

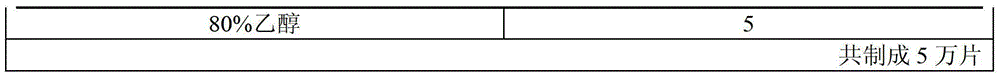

[0041] Table 2 Theophylline Sustained-release Tablets (125mg) Raw Materials and Proportioning

[0042]

[0043]

[0044] The preparation method is as follows:

[0045] (1) Add povidone K30, methyl cellulose and 80% ethanol of recipe quantity in the wet mixing granulator, stir and shear at normal temperature for 25 minutes, make the uniformly dispersed adhesive for subsequent use;

[0046] (2) Add theophylline, binding agent, starch and mannitol of recipe quantity in granulator again, make soft material;

[0047] (3) After replacing the granulator with 18-mesh stainless steel mesh, use the granulator to granulate;

[0048] (4) The prepared wet granules are pumped into the fluidized bed, and the wet granules are vacuum pumped into the fluidized bed to dry to 5% moisture, and then the granules are sized with a crushing and sizing machine, and magnesium stearate is added to mix evenly and then pressed The tablets are dried to obtain theophylline sustained-release tablets. ...

Embodiment 3

[0050] Table 3 The raw materials and proportions of theophylline sustained-release tablets (200mg)

[0051] raw material

Dosage / kg

Theophylline

5

starch

4

Ethyl cellulose

0.25

carbomer

0.1

Hypromellose

0.5

Magnesium stearate

0.01

stearic acid

0.075

80% ethanol

4

A total of 25,000 pieces were made

[0052] The preparation method is as follows:

[0053] (1) Add sodium alginate, hydroxypropyl methylcellulose and 80% ethanol in the wet mixing granulator, stir and shear at room temperature for 30 minutes, and make a uniformly dispersed adhesive for subsequent use;

[0054] (2) Add theophylline, binding agent, starch and mannitol of recipe quantity in granulator again, make soft material;

[0055] (3) After replacing the granulator with a 19-mesh stainless steel mesh, use the granulator to granulate;

[0056] (4) The prepared wet granules are pumped into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com