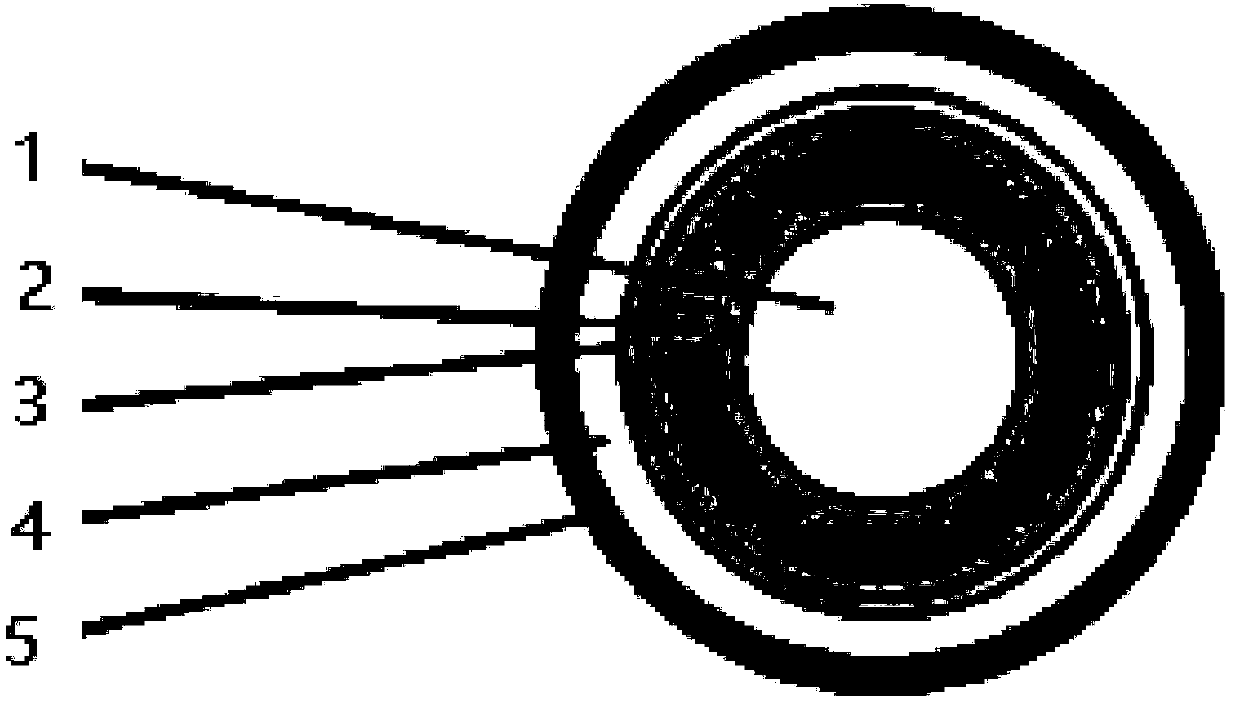

Potassium chloride sustained-release pellet and preparation method and application thereof

A technology for slow-release pellets and potassium chloride pellets, which is applied to the active ingredients of alkaline/alkaline earth metal chlorides, pharmaceutical formulations, microcapsules, etc. Excellent water permeability, good release reproducibility, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

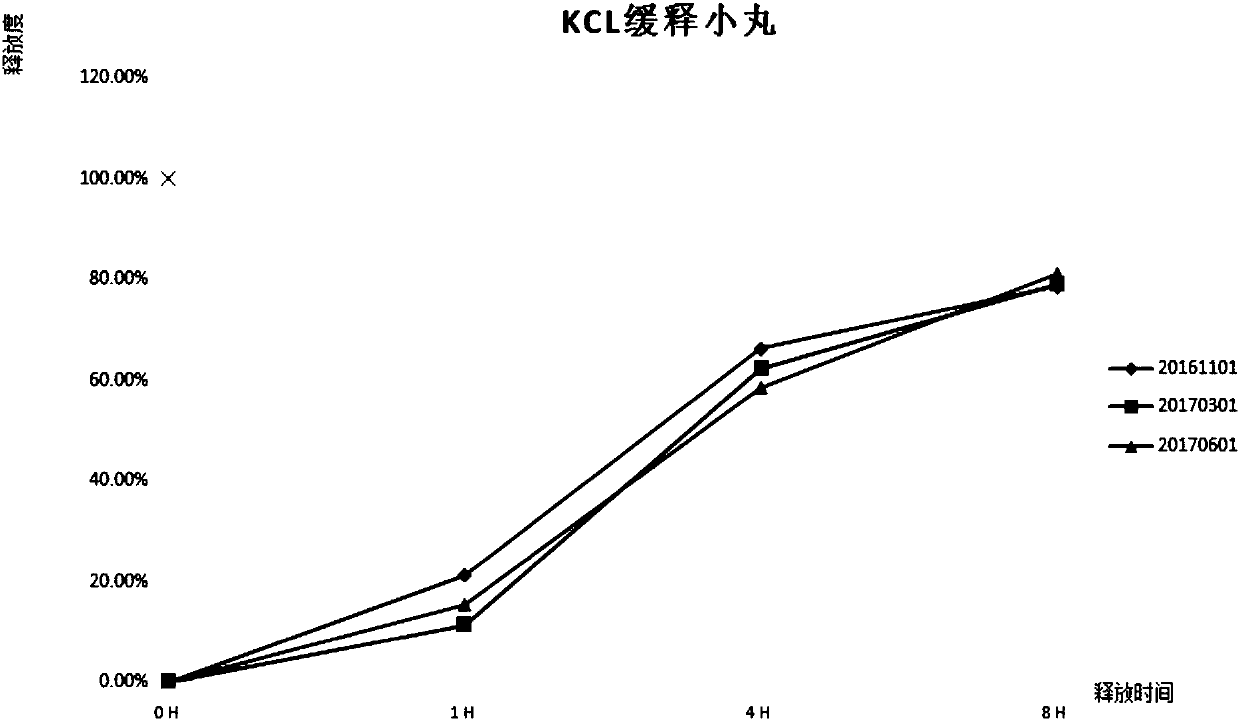

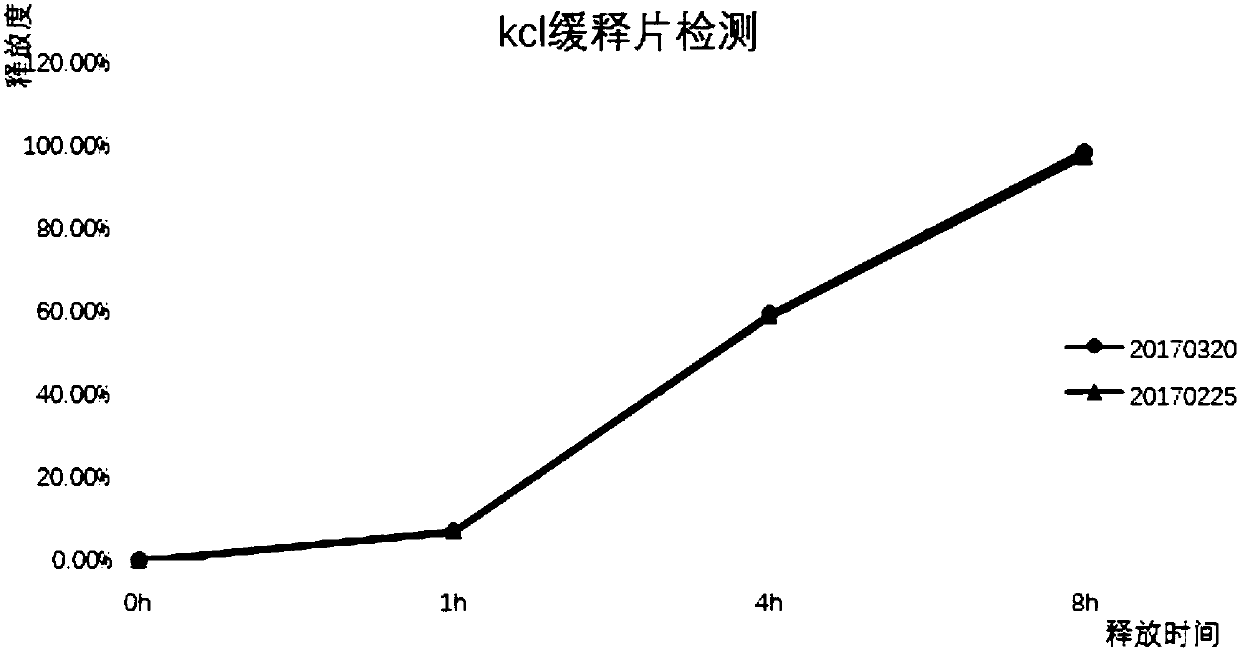

Examples

Embodiment 1

[0062] Step 1: Making the pellet core:

[0063] In terms of weight percentage: take starch: 20%, sucrose: 70%, dextrin: 9%, and 30% syrup solution as binder.

[0064] a. The sucrose is crushed and processed into powder with less than 80 meshes, starch is added, and dextrin is uniformly mixed through a mixer to make a mixed powder of sugar, starch and dextrin.

[0065] b. Put the mixed powder in the coating granulator, and start the main machine of the coating granulator at 80r / min. Air pressure of blower: 0.03Kpa. The 30% syrup solution passes through a peristaltic pump at a speed of 50r / min, and is atomized and sprayed onto the rotating mixed powder through a spray gun to form sugar pills. Put the sugar pellets in a fluidized bed to boil and dry, control the inlet air temperature at 90-110 degrees, and dry for 30-40 minutes with a moisture content of ≤5%. After sieving, they will become sugar pellets with a target particle size of 0.2-0.4mm.

[0066] Step 2: Making the main medicin...

Embodiment 2

[0085] Step 1: Making the pellet core:

[0086] In terms of weight percentages: starch: 25%, sucrose: 65%, dextrin: 10%, and purified aqueous solution as a binder.

[0087] a. The sugar is crushed and processed into powder with less than 80 mesh.

[0088] b. Add starch, dextrin is mixed evenly through a mixer to make sugar, starch, dextrin mixed powder.

[0089] c. Put the mixed powder in the coating granulator to start the coating granulator with a speed of 70r / min. Air pressure of blower: 0.04Kpa. The purified water solution is atomized and sprayed into the rotating mixed powder through the spray gun through the peristaltic pump at a speed of 45r / min to form sugar pellets. The sugar pellets are placed in a fluidized bed to boil and dry, and the inlet air temperature is controlled to 90-110 degrees, and the drying is 35-40. Minutes, dried in a fluidized bed, moisture content ≤5%, and sieved to make it into a sugar pill with a target particle size of 0.2-0.4mm.

[0090] Step 2: Makin...

Embodiment 3

[0109] Step 1: Making the pellet core:

[0110] According to weight percentage: take starch: 20%, sugar: 70%, dextrin; 9%, 50% syrup solution as binder.

[0111] a. The sugar is crushed and processed into powder with less than 80 mesh, starch is added, and dextrin is mixed evenly through a mixer to make a mixed powder of sugar, starch and dextrin.

[0112] b. Put the mixed powder in the coating granulator to start the coating granulator host speed r / min50. Air pressure of blower: 0.02Kpa. The 30% syrup solution passes through the peristaltic pump at r / min: 75. The spray gun is atomized and sprayed onto the rotating mixed powder to form sugar pellets. Place the sugar pellets in a fluidized bed to boil and dry, control the inlet air temperature at 90-110 degrees, dry for 35-45 minutes, set the temperature in the fluidized bed to 100°C, moisture content ≤5%, and sieving to make it the target pellet The diameter is 0.2-0.4mm sugar pill.

[0113] Step 2: Making the main medicine layer:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com