Automatic frame-type penicillin bottle preparation feeding and discharging device of freeze dryer

A technology of freeze dryer and vial, which is used in drying solid materials, drying, lighting and heating equipment, etc., and can solve problems such as product pollution and product scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

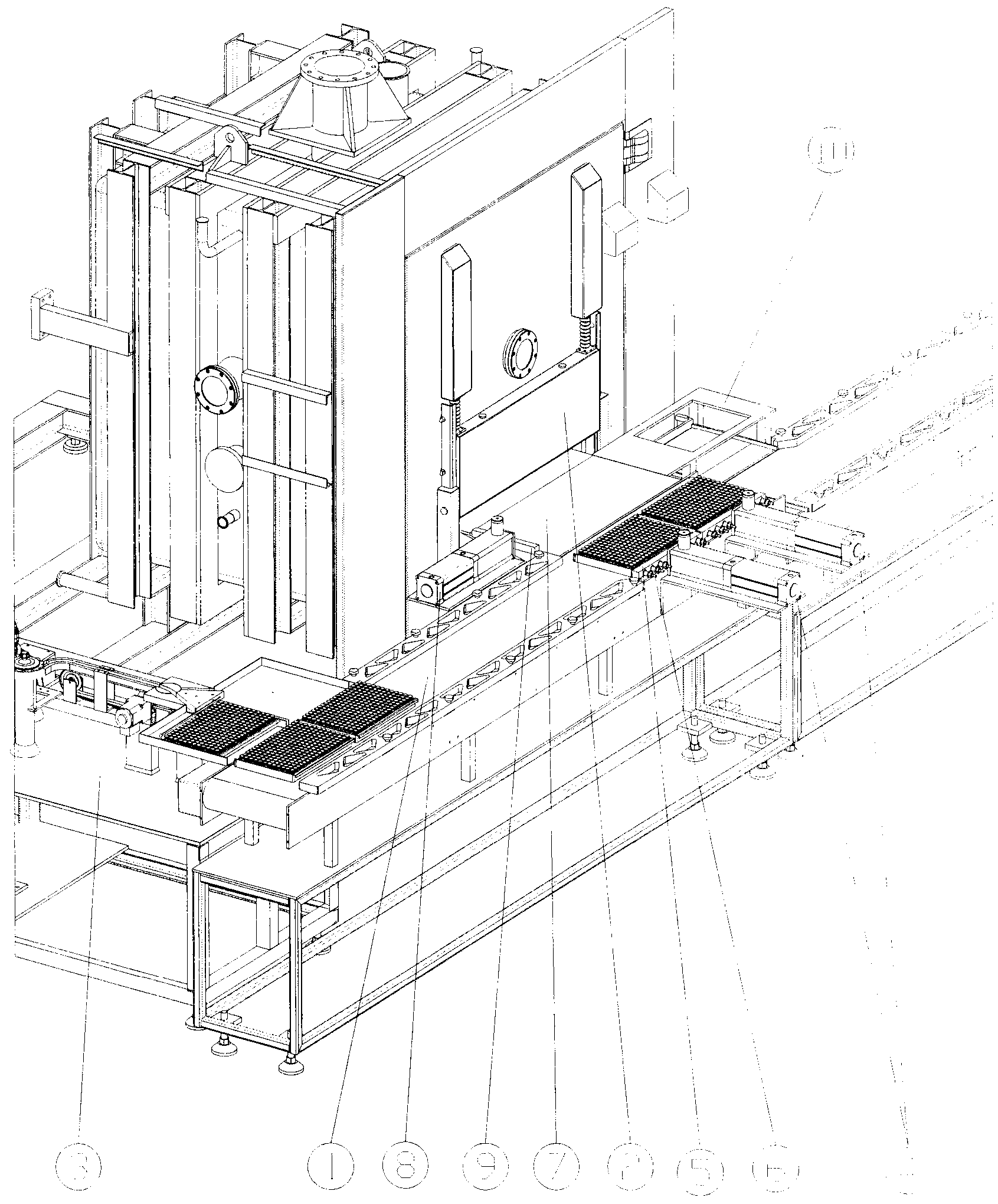

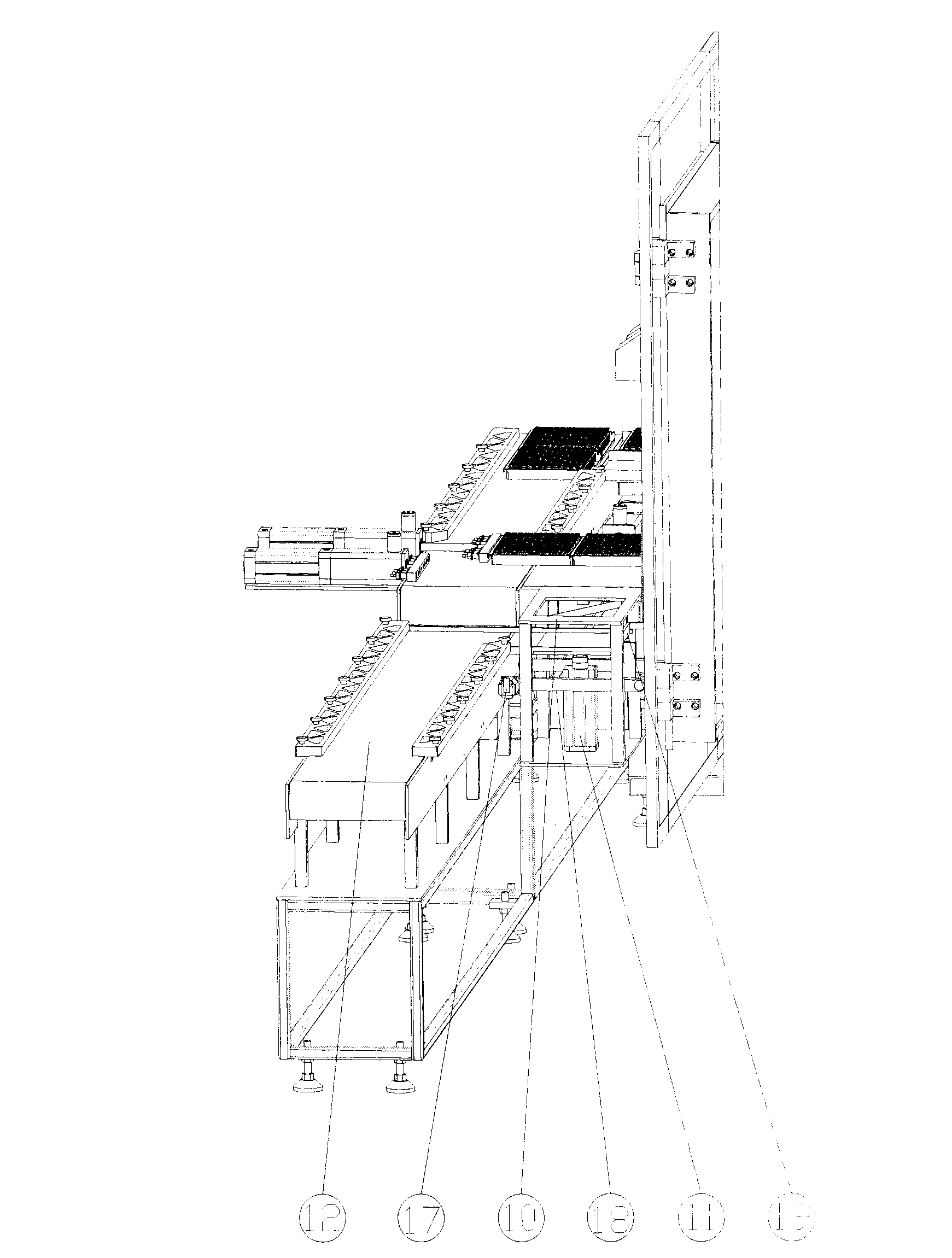

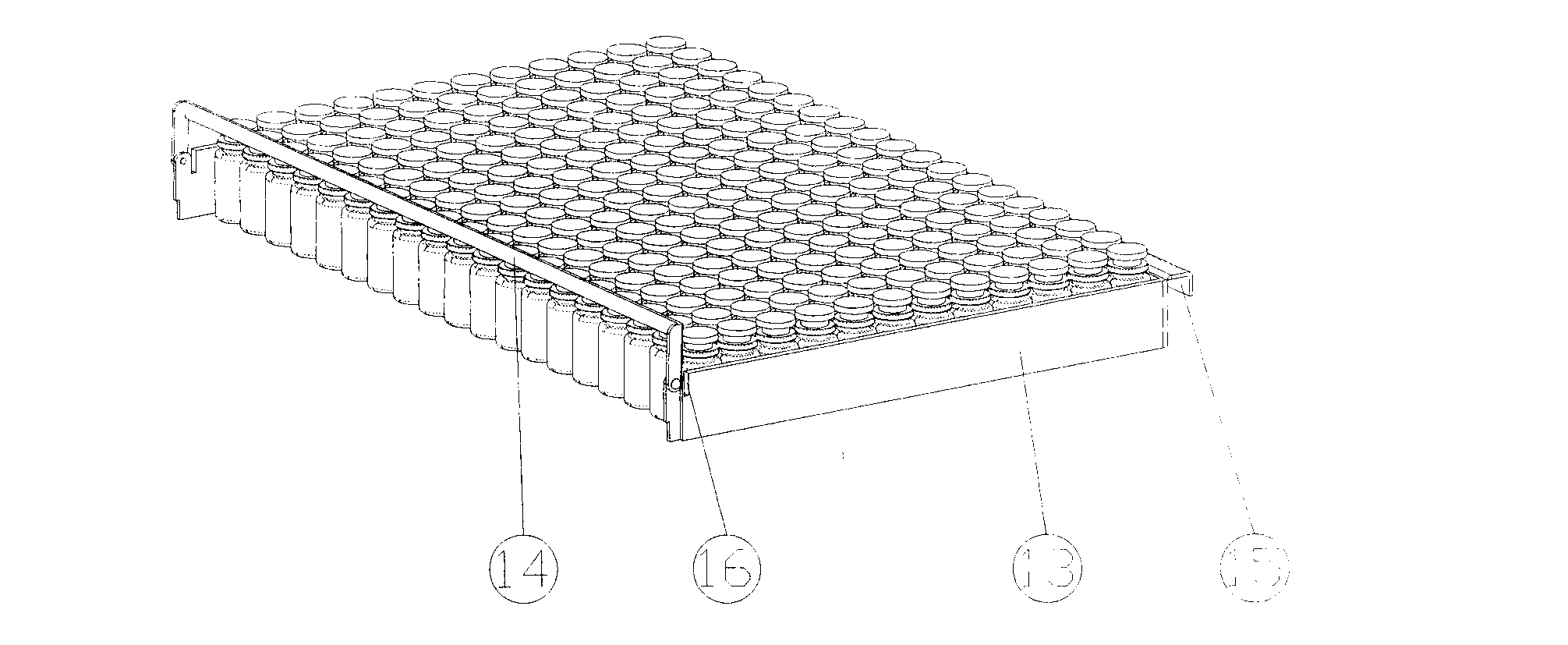

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] See attached figure 1 , 2 , 3, 4, the whole device is fixed on the front of the freeze dryer through the frame. The feeding conveyor belt 1 is installed in front of the small feeding door 2 of the freeze dryer, the feeding end of the feeding conveyor belt 1 is connected to the discharge port of the filling machine 3, and the feeding conveyor belt 1 is facing the small feeding door of the freeze dryer Two feeding linear guide rails 4 are installed on the outer side of 2, feeding push rod 5 is installed at the front of feeding linear guide rail 4, 30 vacuum suction cups 6 are housed inside feeding push rod 5, feeding small door 2 and feeding A bridging platform 7 is installed between the material conveyor belts 1, and the left side of the bridging platform 7 is equipped with a discharge linear guide rail 8, and the front part of the discharge linear guide rail 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com