Flexible force or pressure sensor array using semiconductor strain gauge, fabrication method thereof and measurement method thereof

a technology of flexible force or pressure sensor array and strain gauge, which is applied in the direction of force measurement, measurement devices, instruments, etc., can solve the problems of reducing sensitivity, limiting quantitatively measuring the distribution of force or pressure, and limited application of flexible and bendable force or pressure sensing arrays, etc., to achieve increased strain, sensor structure is physically robust, and sensor structure. robust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

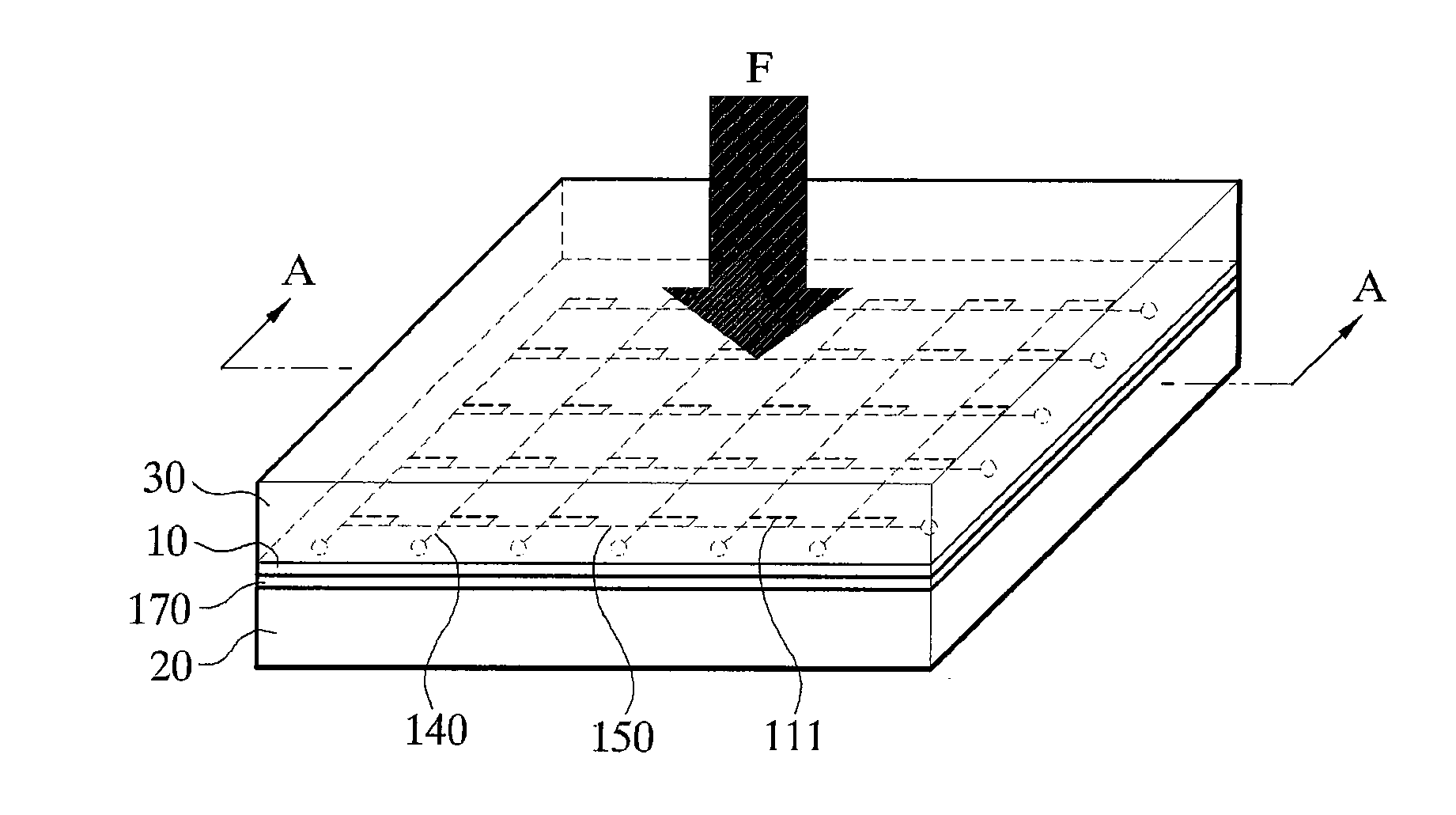

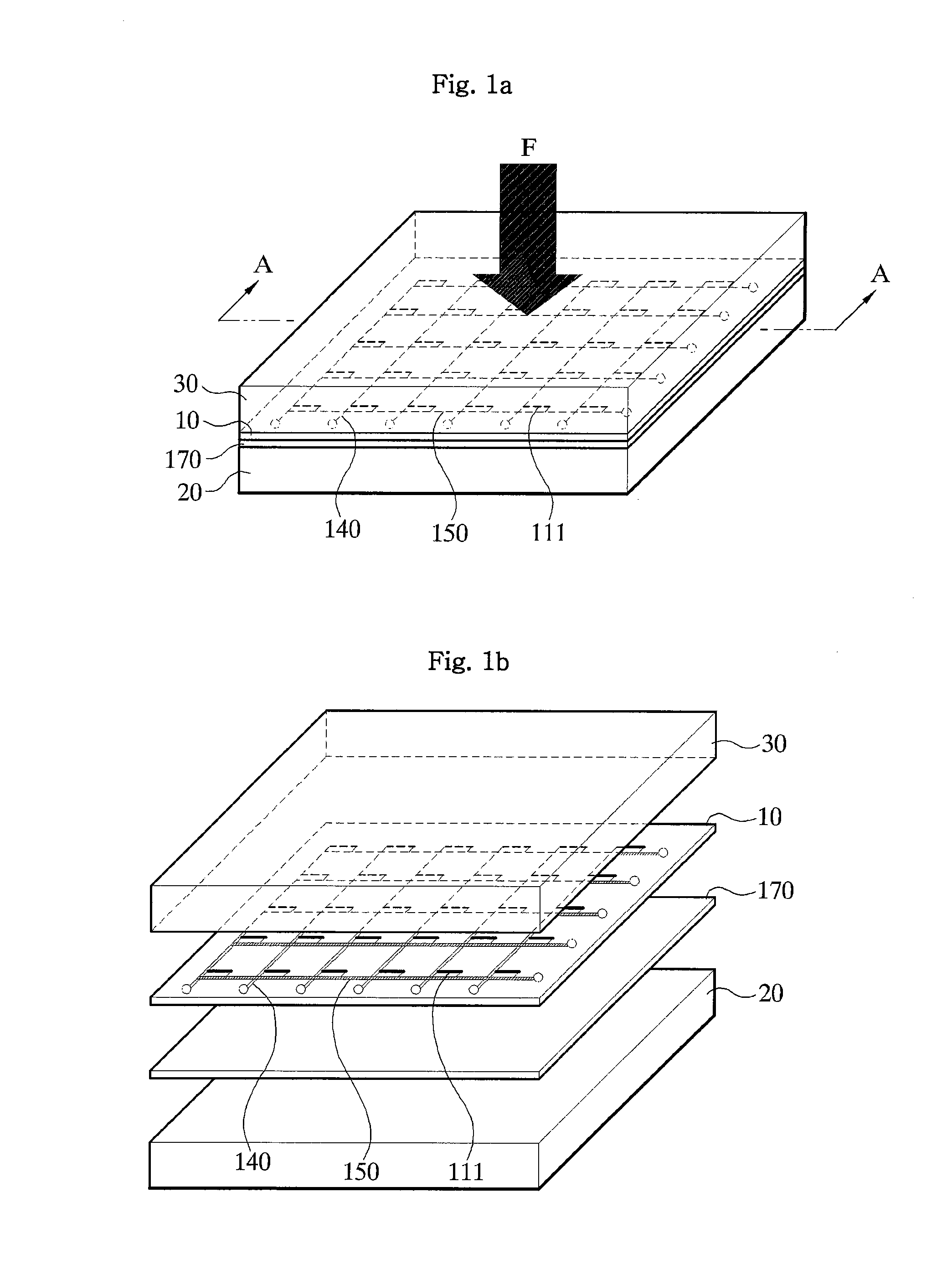

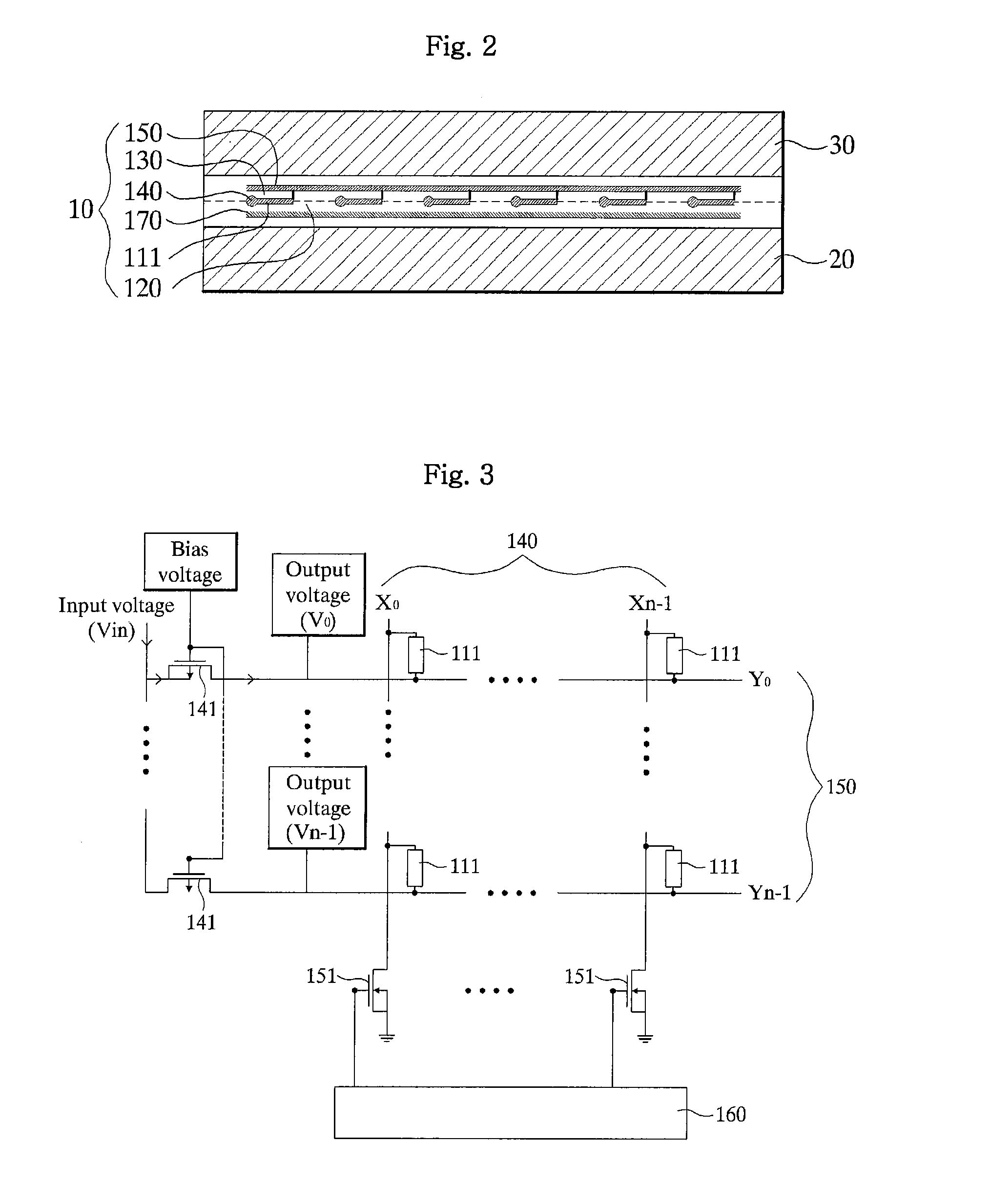

[0028]FIG. 1a is a perspective view showing a force or pressure sensor array using semiconductor strain gauges 100 according to an embodiment of the present invention, and FIG. 1b is an exploded perspective view showing the force or pressure sensor array in FIG. 1 decomposed into a layer structure. As shown in FIGS. 1a and 1b, the force or pressure sensor array according to an embodiment of the present invention comprises a substrate 10 and a pair of elastomer layers 20 and 30 bonded to both sides of the substrate. Here, a polymer film layer and semiconductor strain gauges 110 containing a plurality of elements 111 arranged in a specific array pattern are placed in the substrate 10, and a plurality of first and second signal lines respectively forming an electrode is provided in the substrate. In addition, the substrate 10 further includes a CMOS circuit layer 170 at the lower part of the substrate, where current sources 141 for flowing a constant current to the first signal l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com