A kind of oilfield polymer flooding whole sewage compounding treatment process

A polymer and sewage technology, which is applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of clean water waste, pollution, and high cost of desalination, and achieve reduction Desalination treatment steps, broad application prospects, and the effect of expanding the treatment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

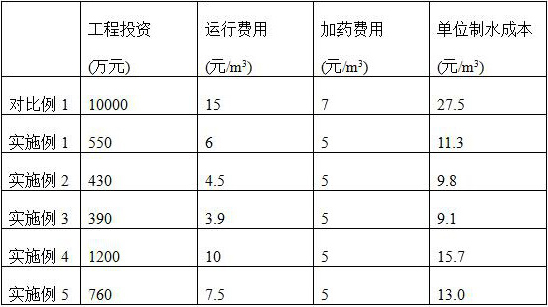

[0027] Example 1 uses air as the oxidant, and adopts the "pressure type micro-nano aeration sewage oxidation treatment device" (ZL201320644303.8) in the prior art for oxidation treatment. The treated sewage is added with a composite stabilizer that can inhibit corrosion and inhibit the reproduction of sulfate-reducing bacteria. The stabilizer is mainly composed of nitrite corrosion inhibitor, anthraquinone, imidazoline and thiourea. See the attached manual for the process flow figure 1 .

[0028]After being boosted by the air compressor 1-1, the air and the sewage to be treated simultaneously enter the pressure type micro-nano aeration sewage oxidation treatment device 1-2 for oxidation treatment. After treatment, the sewage is added with a compound stabilizer through the dosing device 1-3, and then enters the stabilization tank 1-4 for stabilization to remove the remaining air, and fully mixes and reacts with the stabilizer. The stabilization time is generally 2-4 hours. ...

Embodiment 2

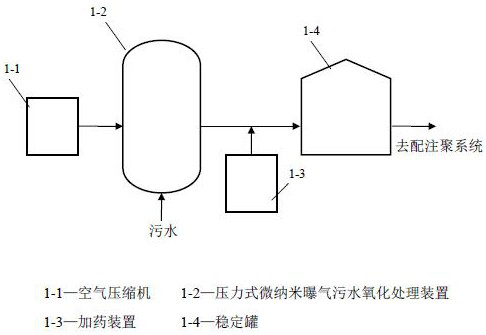

[0030] Example 2 uses air as the oxidant, and uses a high-rate industrial sewage aeration oxidation treatment device (ZL201310669010.X) for oxidation treatment. The treated sewage is added with a composite stabilizer that can inhibit corrosion and inhibit the reproduction of sulfate-reducing bacteria. The stabilizer is mainly composed of nitrite corrosion inhibitor, anthraquinone, imidazoline and thiourea. See the attached manual for the process flow figure 2 .

[0031] After being boosted by the fan 2-1, the air enters the high-rate industrial sewage aeration and oxidation treatment device 2-2 simultaneously with the sewage to be treated for oxidation treatment. After treatment, the sewage is added with a compound stabilizer through the dosing device 2-3, and then enters the stabilization tank 2-4 for stabilization to remove the remaining air, and fully mixes and reacts with the stabilizer. The stabilization time is generally 2-4 hours. After stabilization, the sewage ca...

Embodiment 3

[0033] Example 3 uses air as the oxidant, and uses a solid-state catalytic aeration oxidation tower for oxidation treatment. The treated sewage is added with a composite stabilizer that can inhibit corrosion and inhibit the reproduction of sulfate-reducing bacteria. The stabilizer is mainly composed of nitrite corrosion inhibitor, anthraquinone, imidazoline and thiourea. The solid-state catalytic aeration oxidation tower is a tower-shaped device filled with a solid-state oxidation catalyst. See the attached manual for the process flow image 3 .

[0034] After being boosted by the fan 3-1, the air enters the solid-state catalytic aeration oxidation tower 3-2 simultaneously with the sewage to be treated for oxidation treatment. After treatment, the sewage is added with a compound stabilizer through the dosing device 3-3, and then enters the stabilization tank 3-4 for stabilization to remove the remaining air, and fully mixes and reacts with the stabilizer. The stabilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com