Substrate holding mechanism and substrate assembling apparatus provided with the same

A substrate holding and assembling device technology, which is applied to identification devices, transportation and packaging, conveyors, etc., can solve the problems of substrate deformation, complex peeling mechanism of adhesive tape and upper substrate, and powder occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

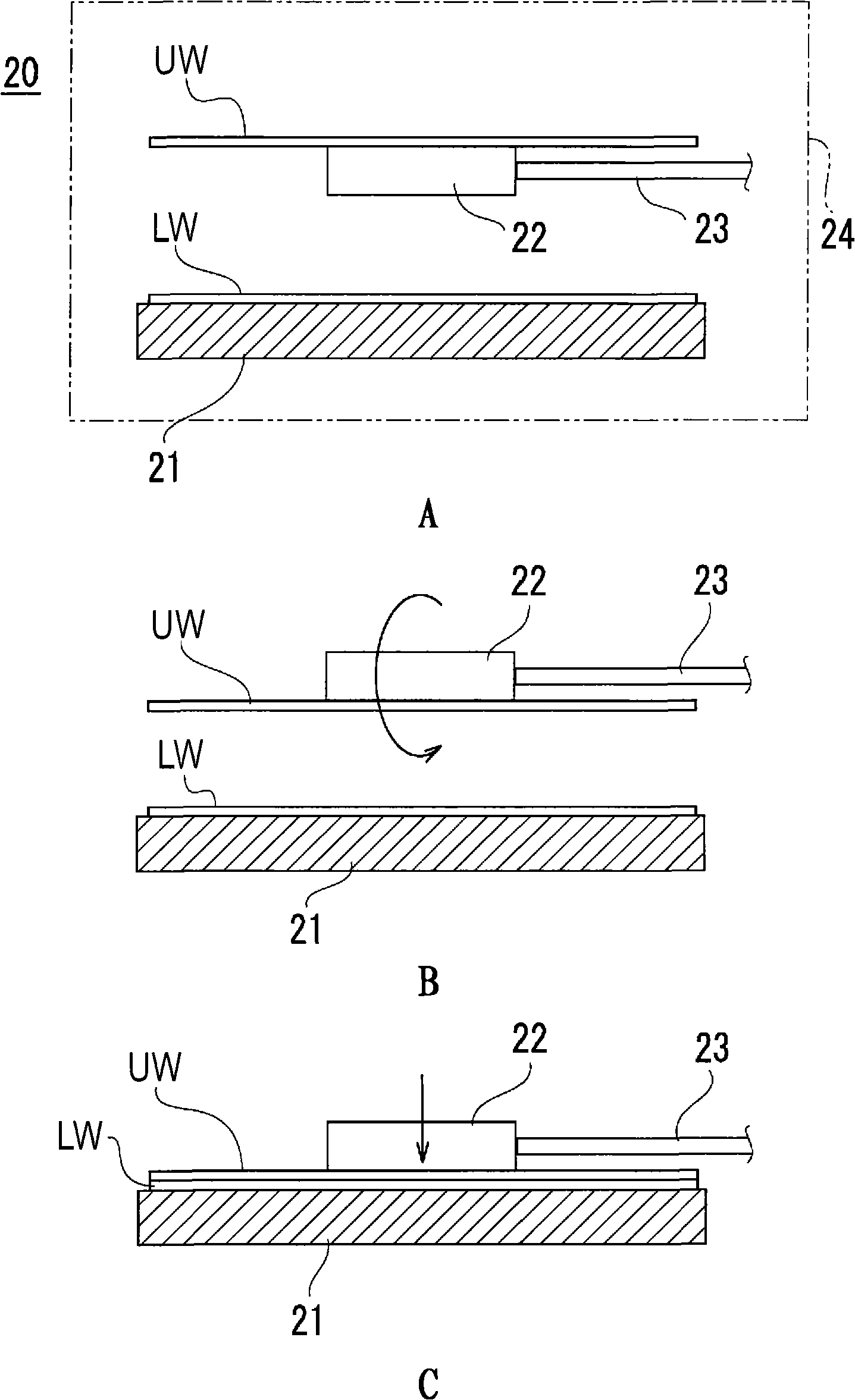

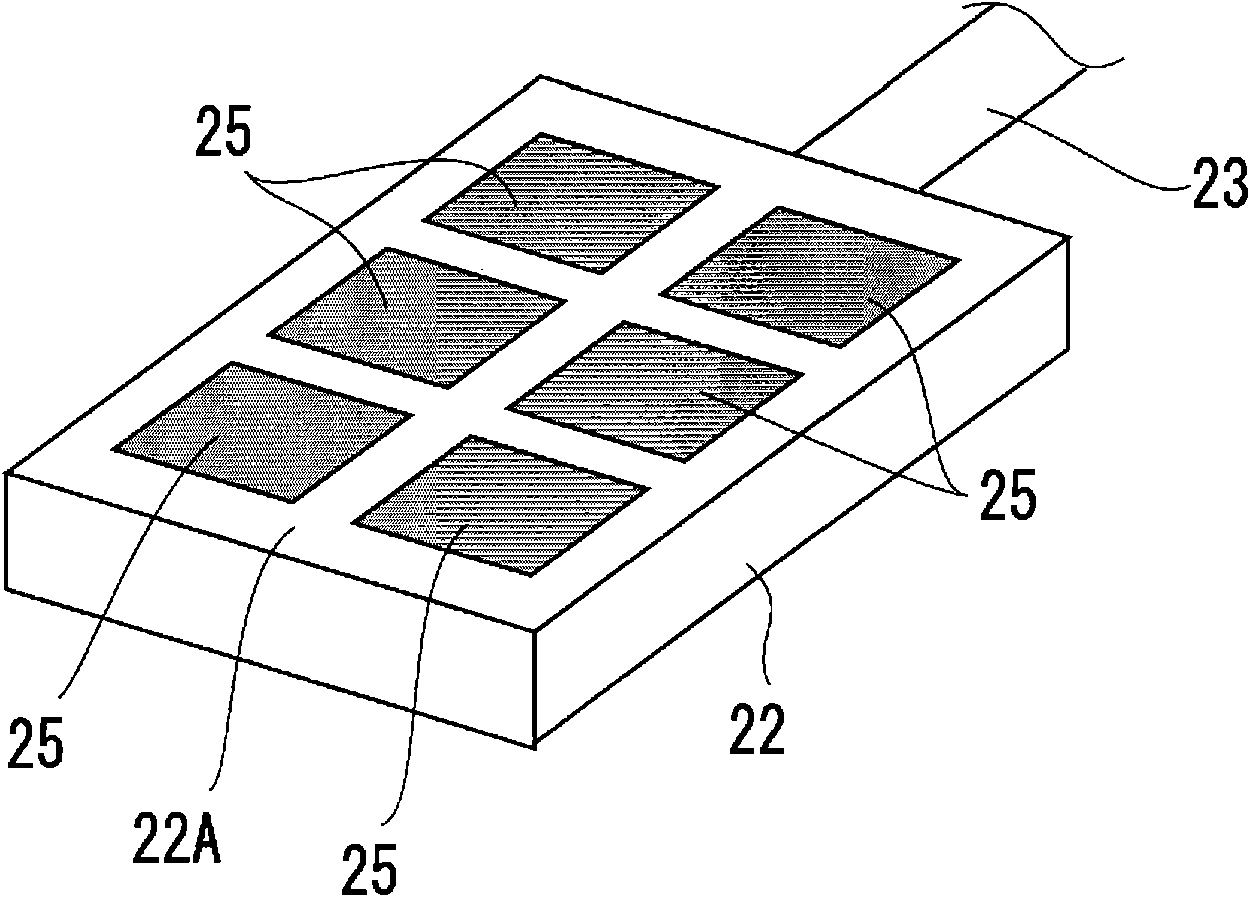

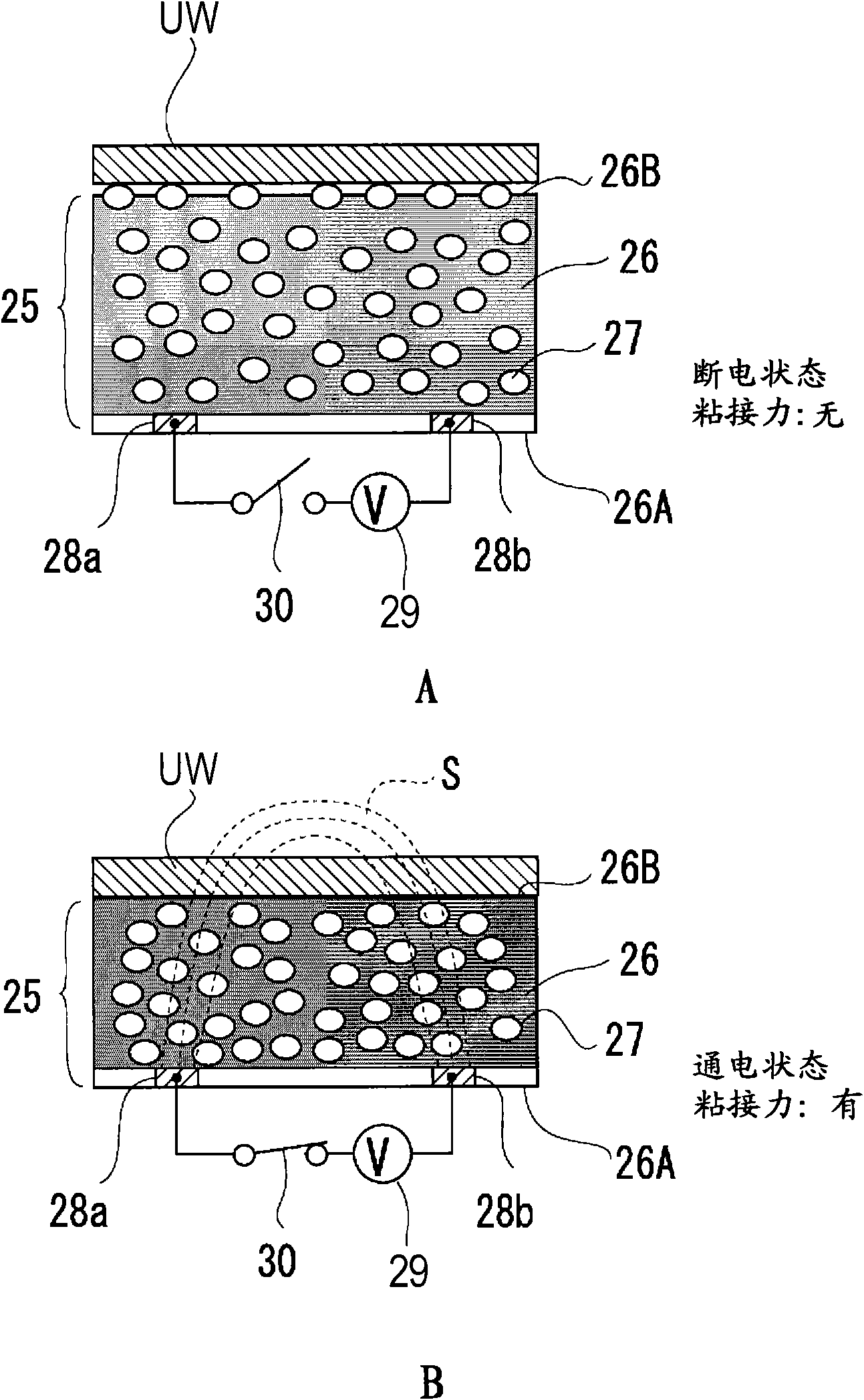

[0027] A substrate holding mechanism in a first embodiment of the present invention includes a holding body and a functional element. The above-mentioned holding body has a holding surface for holding the substrate, the above-mentioned functional element is arranged on the above-mentioned holding surface, and the holding force generated by it can be changed according to the magnitude of the received voltage.

[0028] When the above-mentioned substrate holding mechanism is used, the holding force acting on the substrate can be electrically controlled by the above-mentioned functional elements arranged on the above-mentioned holding surface. Therefore, the present invention can simplify the structure of the holding mechanism. In addition, since the holding force applied to the substrate can be changed smoothly, it is always possible to normally hold or release a thin substrate.

[0029] The above-mentioned functional element may also be a functional adhesive element whose adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com