Electric spark punching rapid penetrating machining method and punching machine

A processing method and electric spark technology, applied in electric processing equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problem of inability to flush workpiece hole waste, electrode wire and workpiece unable to continue to discharge, and failure to meet processing requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

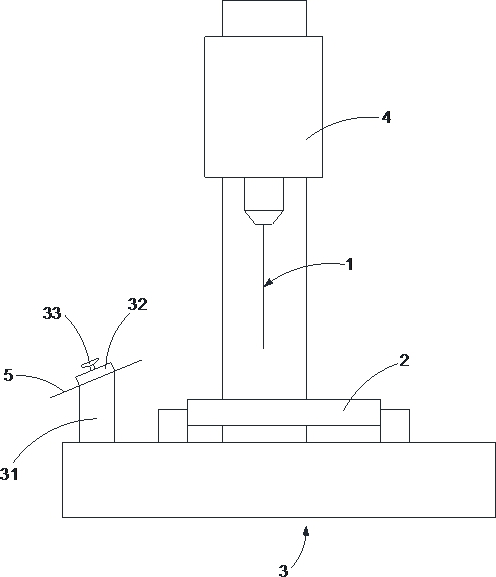

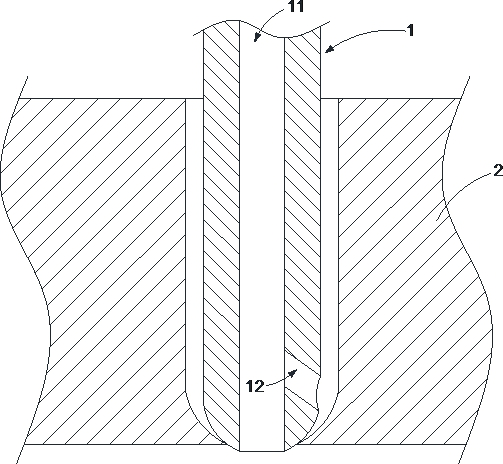

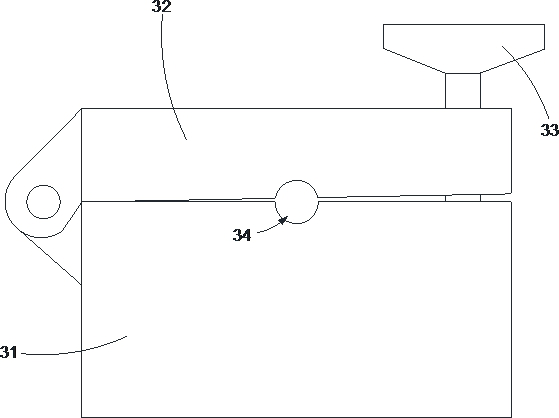

[0030] Such as Figure 1-Figure 3 As shown, the present invention provides a rapid penetration processing method for electric discharge drilling, which uses a punching machine to punch holes. The punching machine can be a common electric spark punching machine. The wire electrode 1 is installed in a punching machine, and the position of the wire electrode 1 is adjusted by the punching machine to punch a workpiece 2 . The electrode wire 1 is in the shape of a tube, and a flow hole 11 is arranged inside it along its length direction. The outer wall of the front end of the electrode wire 1 is provided with a guide hole 12 communicating with the flow hole 11 . The setting timing of the guide hole 12 is before the workpiece hole penetrates the workpiece 2 . Specifically, when the wire electrode 1 starts drilling and the hole reaches a certain depth, the wire electrode 1 is withdrawn from the workpiece hole and the diversion hole 12 is processed, and then the wire electrode 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com