Spool for embedding cable and construction method for embedding cable

A cable and wire tube technology, which is applied in the field of cable construction, can solve the problems that the cable cannot move in the pipeline, the traction force is too large or too small, and the cable sheath is easy to be pulled and damaged, etc., so that the cable burying construction is convenient, simple and fast , Improving construction efficiency and embedding is simple, convenient and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

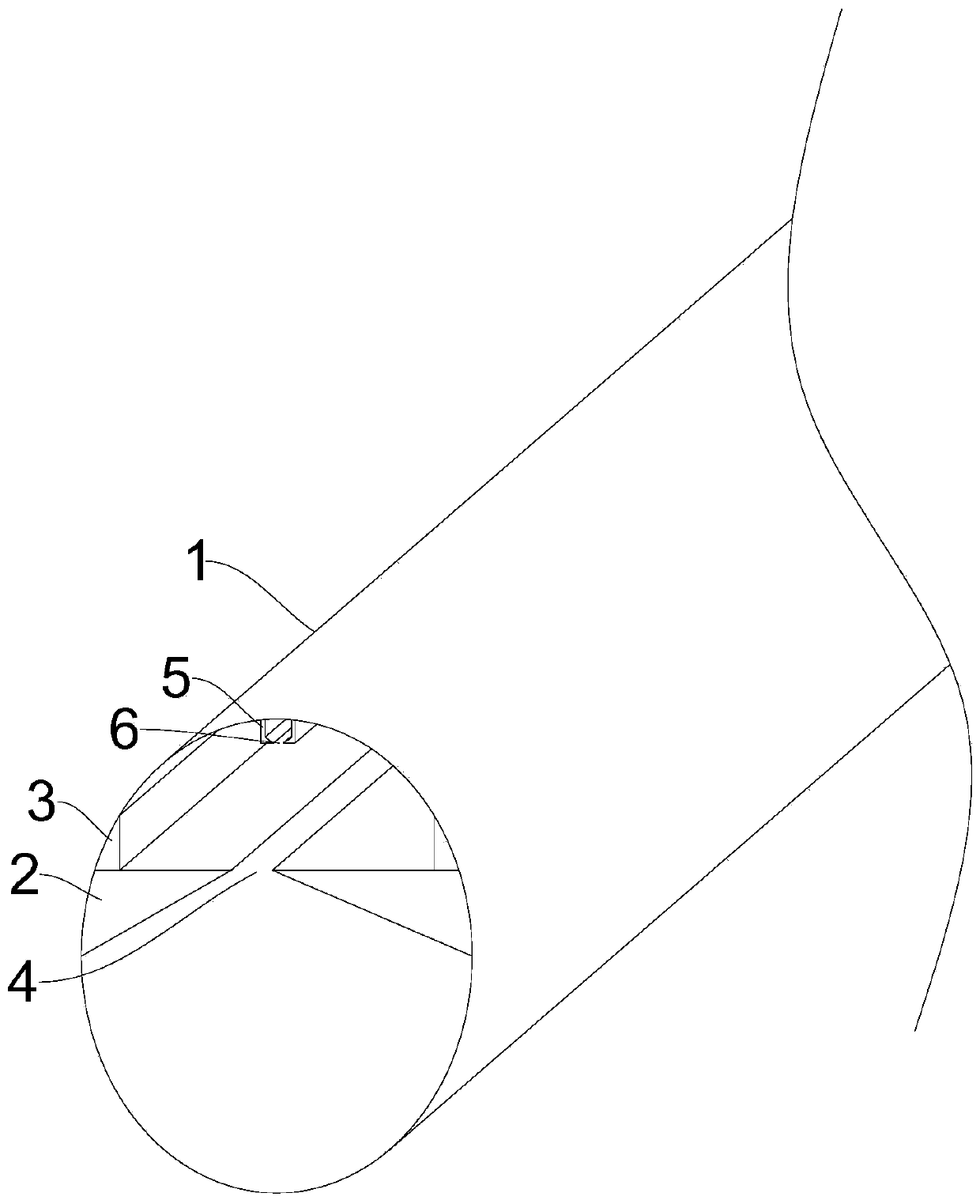

[0037] Such as Figure 1-4 As shown, a line pipe for laying cables includes a pipe 1, the pipe 1 is circular, and the pipe 1 is provided with two oppositely arranged track platforms 2 extending along the length direction of the pipeline 1, the track platform 2 is triangular, and the two Two track platforms 2 are fixedly connected to the inner wall of the pipeline 1 respectively, and a cable lowering gap 4 is provided between the two track platforms 2, and the cable lowering gap 4 can accommodate cables to pass through;

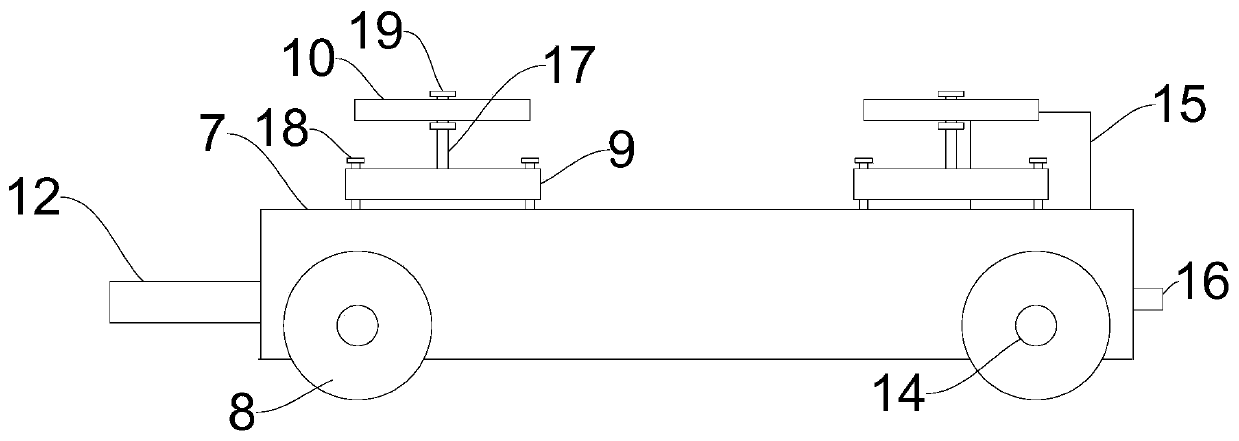

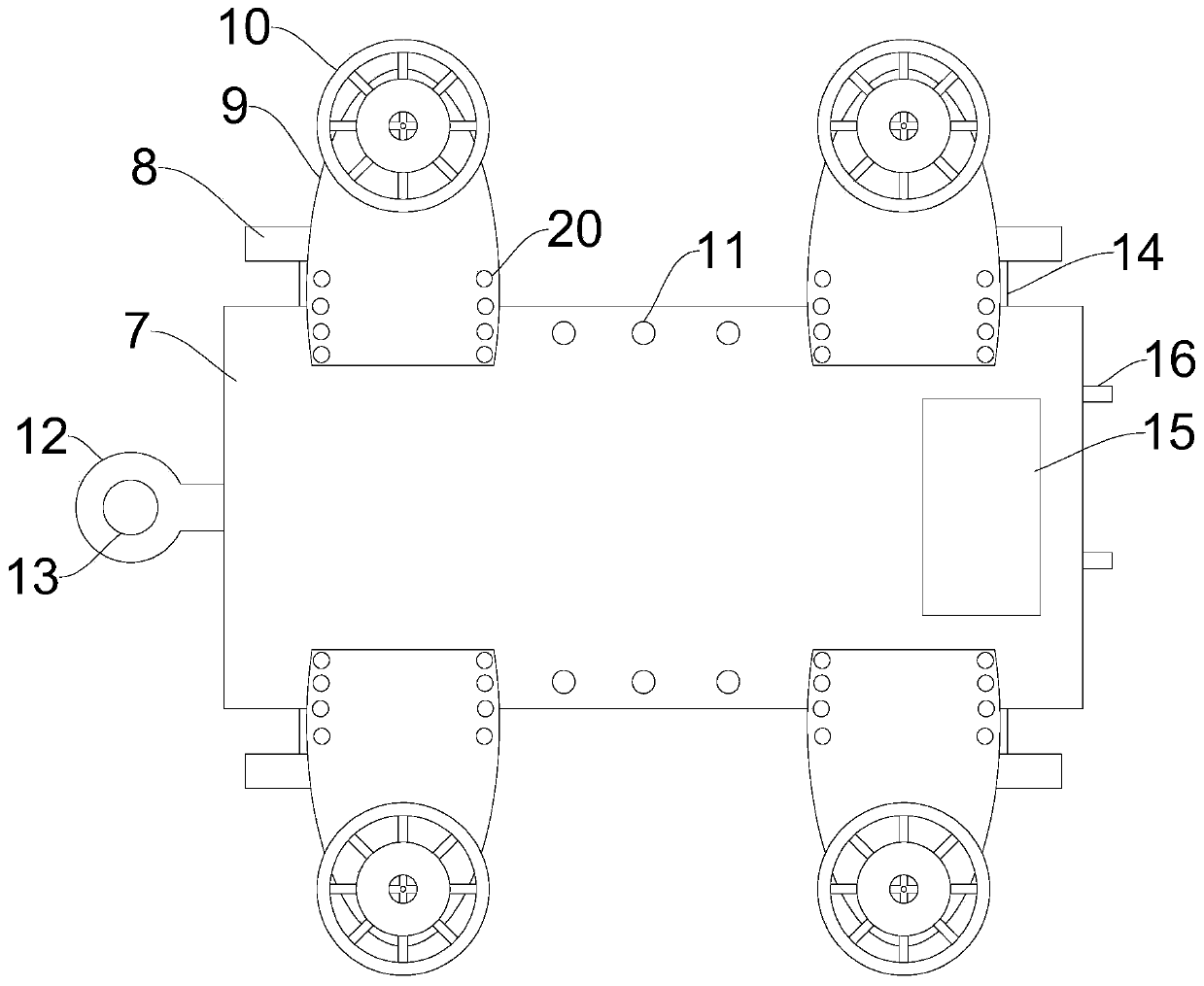

[0038] Also includes a traction trolley, the traction trolley is placed on two track platforms 2, and one side of the traction trolley is fixedly connected with a cable traction hook 12, and the cable traction hook 12 is arranged on the vertical top of the cable lowering gap 4, and the cable traction The cable is fixed on the cable traction hook 12. As the traction trolley travels forward on the track platform 2, the traction trolley drives the cable into the ...

Embodiment 2

[0053] The difference between this embodiment and the above embodiments is that the pipeline 1 is square, specifically as Figure 5 As shown, the track platform 2 is also triangular in shape, and the track platform 2 is arranged at the middle and upper position of the pipeline 1. The limiting platform 3 is a cuboid, and the two sides of the limiting platform 3 are fixedly connected with the inner wall of the pipeline 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com