Splicing pair and splicing box body

A technology of box body and socket slot, which is applied to the connection between sub-assemblies of the upper structure, the upper structure, and vehicles including people's living utensils, etc., which can solve the problems of high assembly time and inappropriateness, and achieve easy assembly Good production, tightness and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

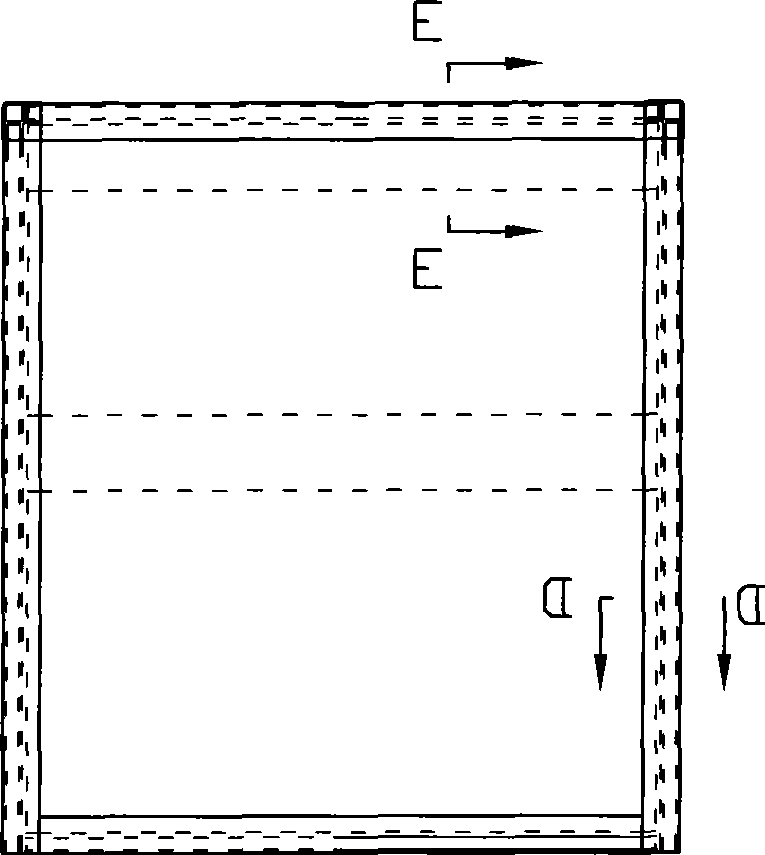

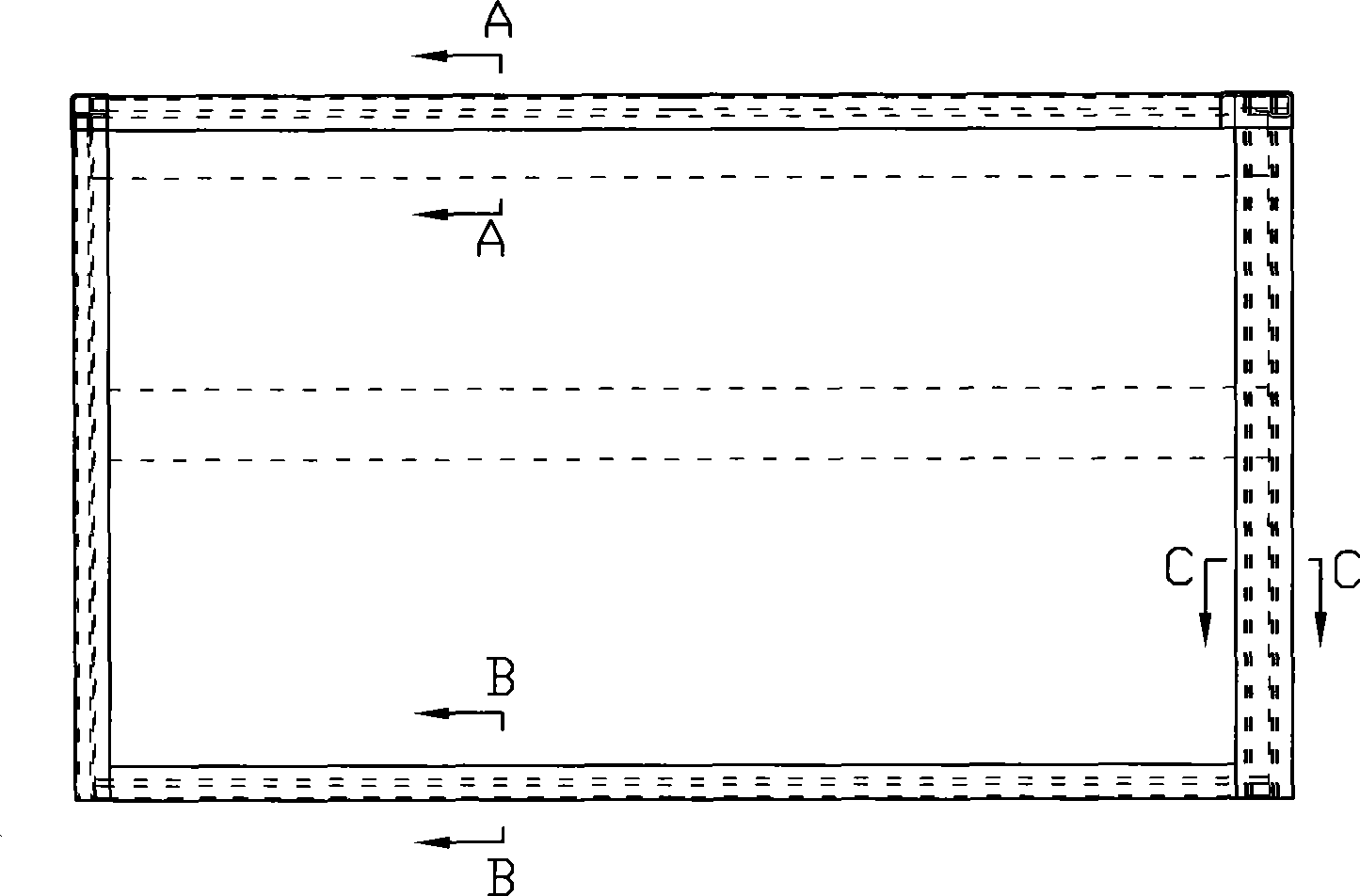

[0027] Such as Figure 1-Figure 7 The shown plug box includes two side panel assemblies 3 , a top panel assembly 6 , a bottom panel assembly 10 , a door frame assembly 11 and a front panel assembly 12 . Bottom plate assembly 10 and side plate assembly 3, top plate assembly 6 and side plate assembly 3, front plate assembly 12 and side plate assembly 3, front plate assembly 12 and top plate assembly 6 are all provided A plug-in secondary connection. The door frame assembly 11 is connected to the rear ends of the top plate assembly 6 and the two side plate assemblies 3 .

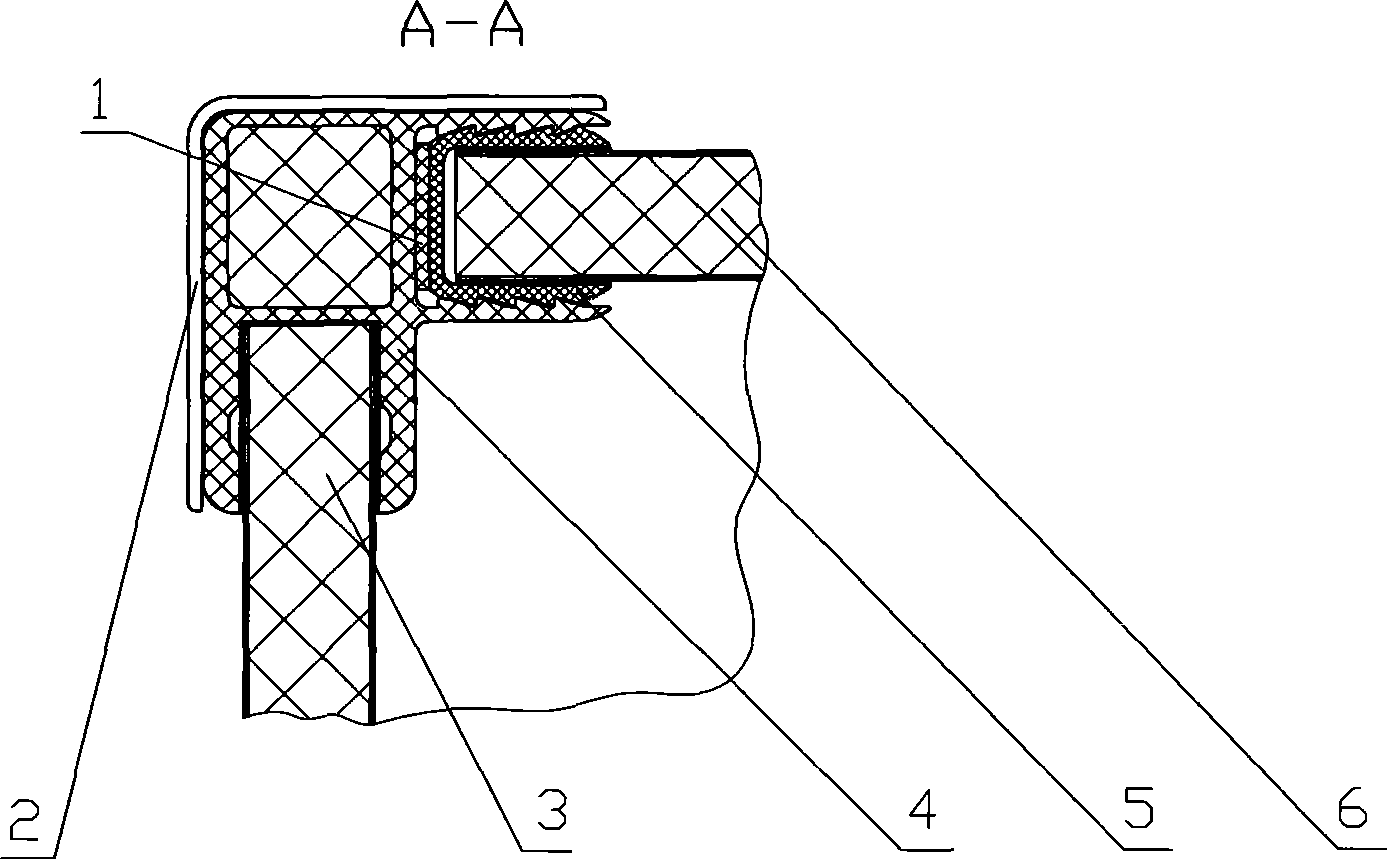

[0028] Such as image 3 and Figure 4 As shown, the aforementioned plug-in pair includes a gasket 1, a connecting corner piece 4 and a plug-in groove 5, and the connecting corner piece 4 has two vertical grooves, and teeth 8 are provided on the two inner walls of one of the grooves, and the connecting angle The middle part of the inner wall of the other groove of the part 4 is provided with a glue storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com