Box type freight unmanned aerial vehicle, matching system thereof and application

A drone and box-type technology, applied in the field of air transportation, can solve the problems of high cost, high flight delay rate, high empty load rate, etc., and achieve the effects of saving time and cost, simplifying the packaging structure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

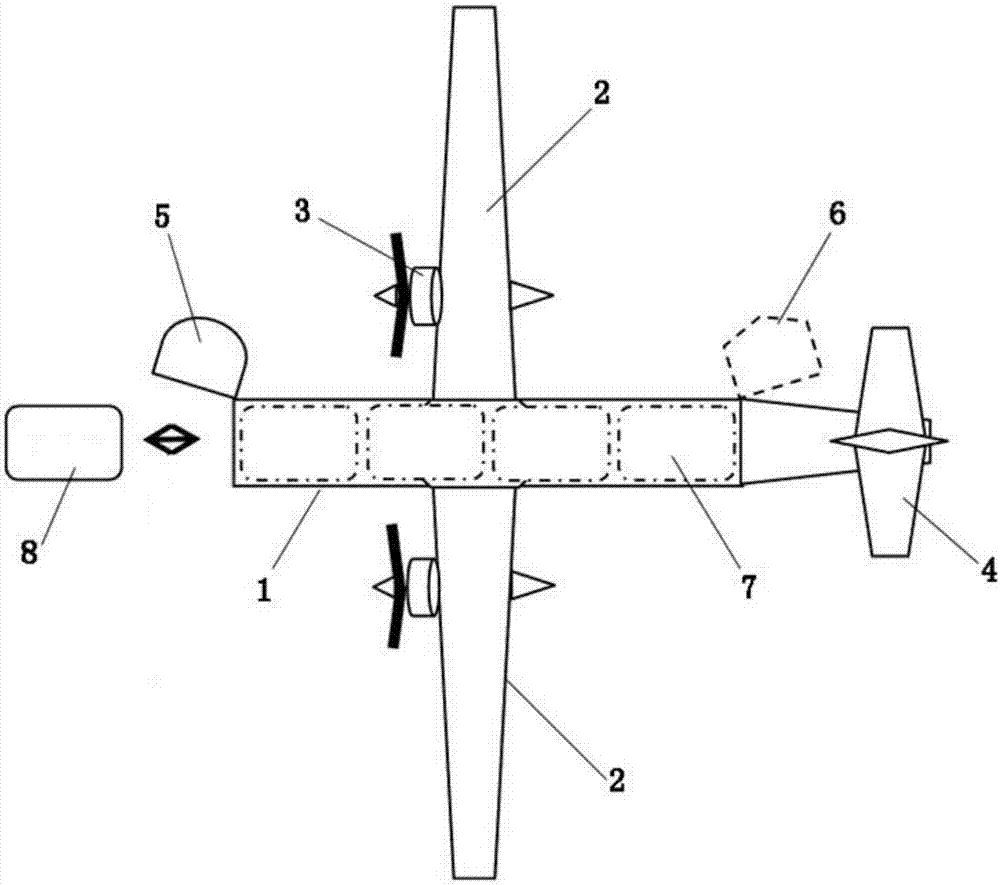

[0023] A box-type cargo unmanned aerial vehicle system adopts a single wing and a fuselage 1 with a rectangular section. The tail 4 can be optionally equipped with a T-shaped or double tail brace. Two engines 3 are installed under the wing 2. The front three-point landing gear The main landing gear is mounted aft of the nacelle. The overall length is 11m, the wingspan is 18m, and the height is 1.75m. Fuselage cargo compartment 7 has a length of 6m (4 air box type cargo boxes 8 and express carriages can be loaded in series along the course), height 1.25m, width 1.15m, fuselage 1 belly is 0.5m from the ground, fuselage 1 cargo compartment 7 The first hatch 5 is opened at the nose and can make the rear hatch and the second hatch 6 at the tail simultaneously according to user needs, which is convenient for the entry and exit of superlong cargo. See figure 1 .

[0024] Technical indicators: maximum takeoff weight 2500kg, loading weight 700kg, average cruising speed 160km / h, maxi...

Embodiment 2

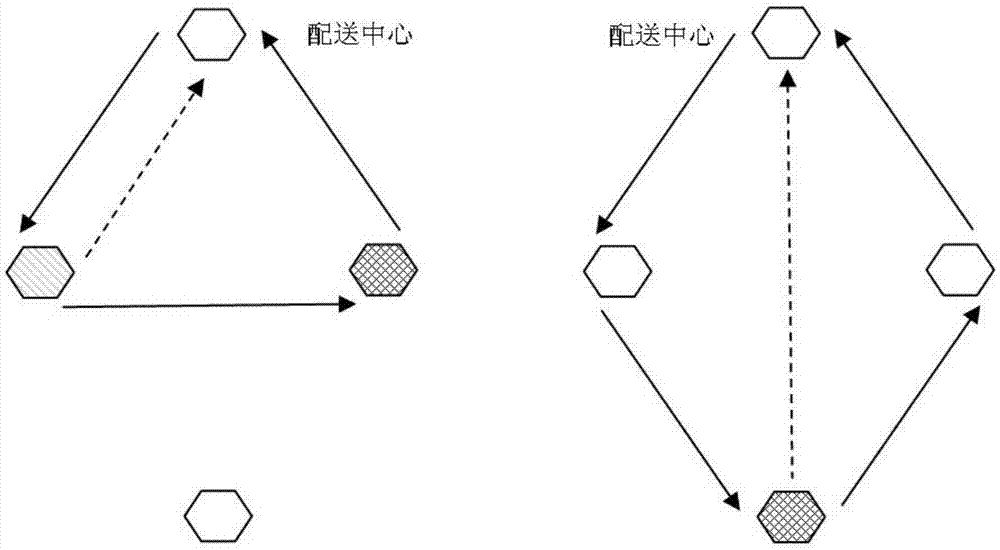

[0034] The implementation case of take-off and landing at different airports. The cargo drone takes off from the urban airport where the distribution center is located, and lands at the delivery urban airport along the scheduled route, which is a landing at an airport in a different place. Then take off from here, it belongs to a different airport to take off. The landing and takeoff of cargo drones at remote airports is a regular takeoff and landing state. The lowest domestic airport construction standard is a general aviation category III airport. According to the minimum airport operation standard announced by the National Civil Aviation Administration, there is no limit to the performance and operation level of specific manned models, and the take-off and landing of UAV systems can be compared with manned Aircraft precision approach and landing operation classification, industrial-grade and system-complete UAV system, meeting the most stringent CAT IIIC operation of early...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com