Cold-chain logistics storage supervisory system and method

A technology of supervision system and cold chain logistics, applied in logistics, data processing applications, instruments, etc., can solve the problems of loss in product circulation, low logistics efficiency, lack of equipment, etc., and achieve the effect of reducing inventory occupancy and large benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

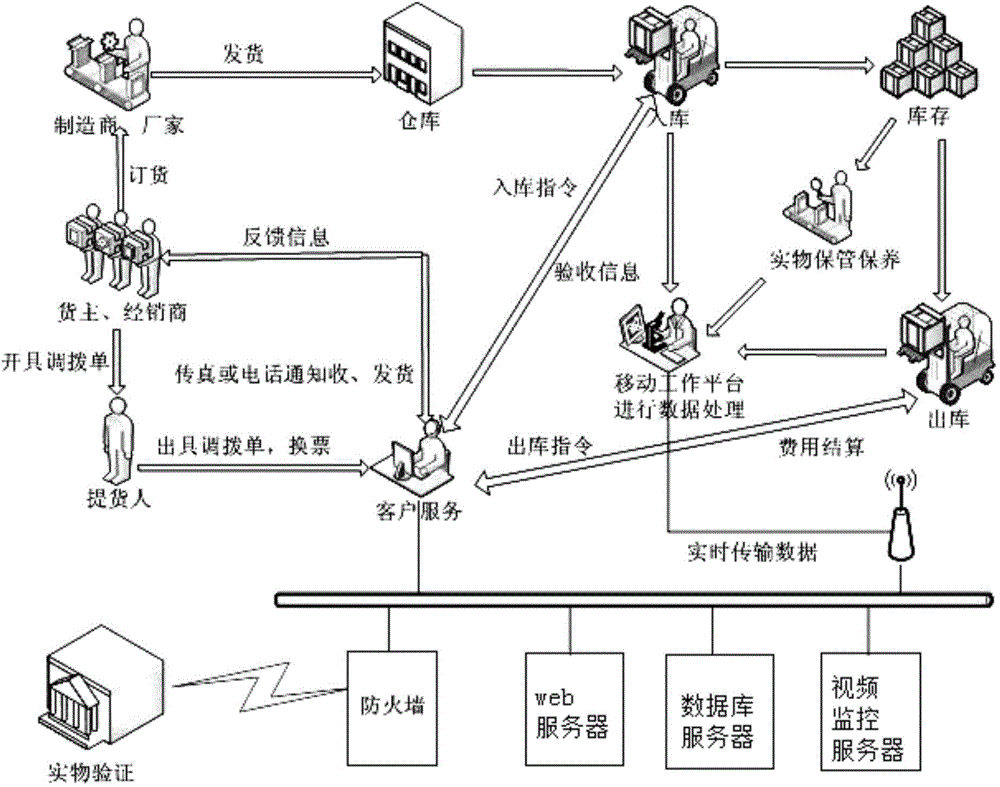

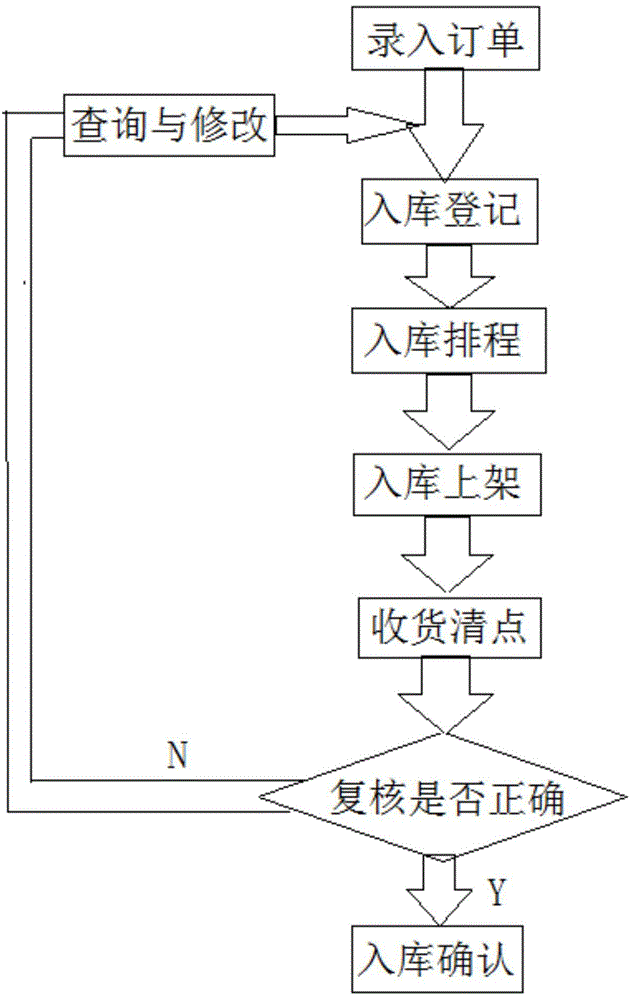

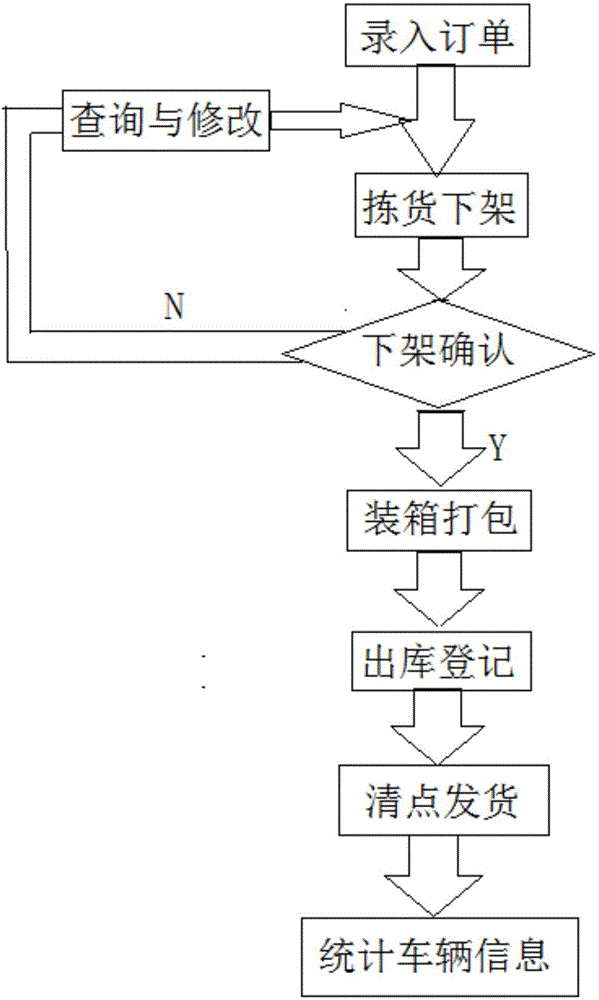

[0051]WMS is a management system based on a full understanding of the warehouse management process and optimization of the warehouse process. It changes the original warehouse software bookkeeping management into warehouse accounting management process control management and warehouse physical management process control management. It combines modern barcode technology to greatly improve the controllability and traceability of the physical management process. The warehouse management system came into being, and its advantages such as rapid retrieval, convenient search, high reliability, large storage capacity, good confidentiality, long life, and low cost greatly improve the efficiency of personnel and labor management; it can effectively organize personnel, Space and equipment for receiving, storing, picking and transporting, organizing the delivery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com