Metal-based carbon fiber composite material and method for producing the same

A composite material and manufacturing method technology, applied in nanotechnology for materials and surface science, thin material processing, nanotechnology for information processing, etc., can solve the problems of reducing the strength and thermal conductivity of composite materials, and achieve Cheap and easy method, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 6g of aluminum powder (manufactured by Kishida Chemical Co., Ltd.) with an average particle diameter of 30 μm and 3 g of pitch-based carbon fibers with a fiber length of 20 cm and a diameter of 10 μm (manufactured by Japan Graphite Faiba One, YS) were placed in a rod mill with an inner diameter of 13 mm. -95A), and a glass rod with a diameter of 5 mm x a length of 20 mm. Mixing was carried out by rotating the rod mill along the axis of the rod mill to obtain a metal fiber mixture.

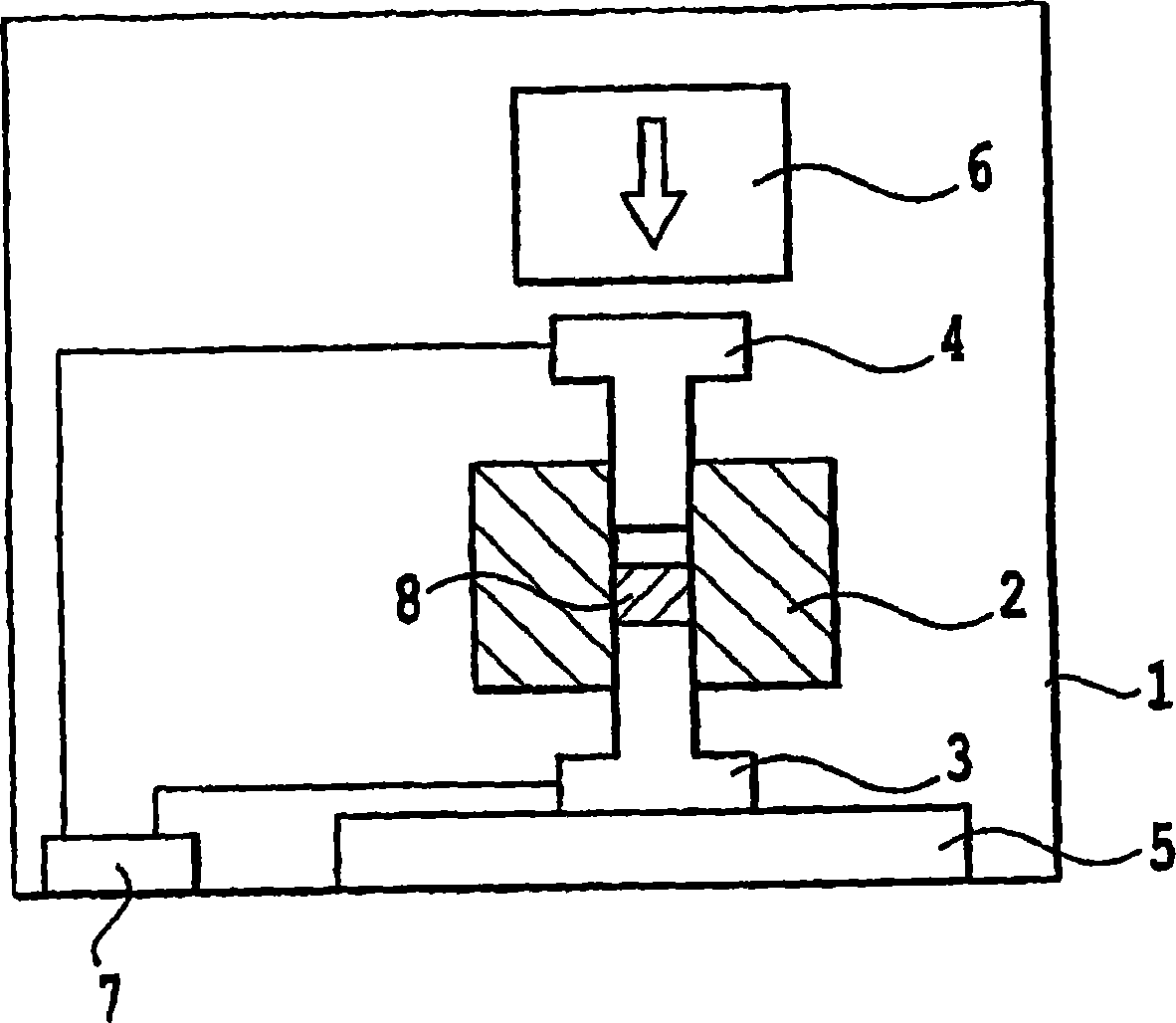

[0061] Next, at figure 1 The device shown is filled with a metal fiber mixture and the pressure inside the device is set at 8Pa. In this example, a mold having through holes of 20×20 cm was used. The mold and the lower punch are fitted together, and the metal fiber mixture is filled in the concave part formed by this, and the carbon fiber is aligned in one direction. Next, an upper punch was placed above the filled metal fiber mixture, and a pressure of 25 MPa was applied by a plunger.

...

Embodiment 2

[0065] The procedure of Example 1 was repeated except that the amount of carbon fiber was changed to 4 g and the amount of aluminum powder was changed to 4 g. The resulting metal-matrix carbon fiber composite contains 60% carbon fibers based on the total weight of the composite and has a mass of 1.75 g / cm 3 Density. The ideal density of this material is 2.38g / cm 3 , the relative density is 73%. The thermal conductivity of the obtained composite material was measured, and a value of 300 W / mK was obtained in the direction in which the carbon fibers were arranged.

Embodiment 3

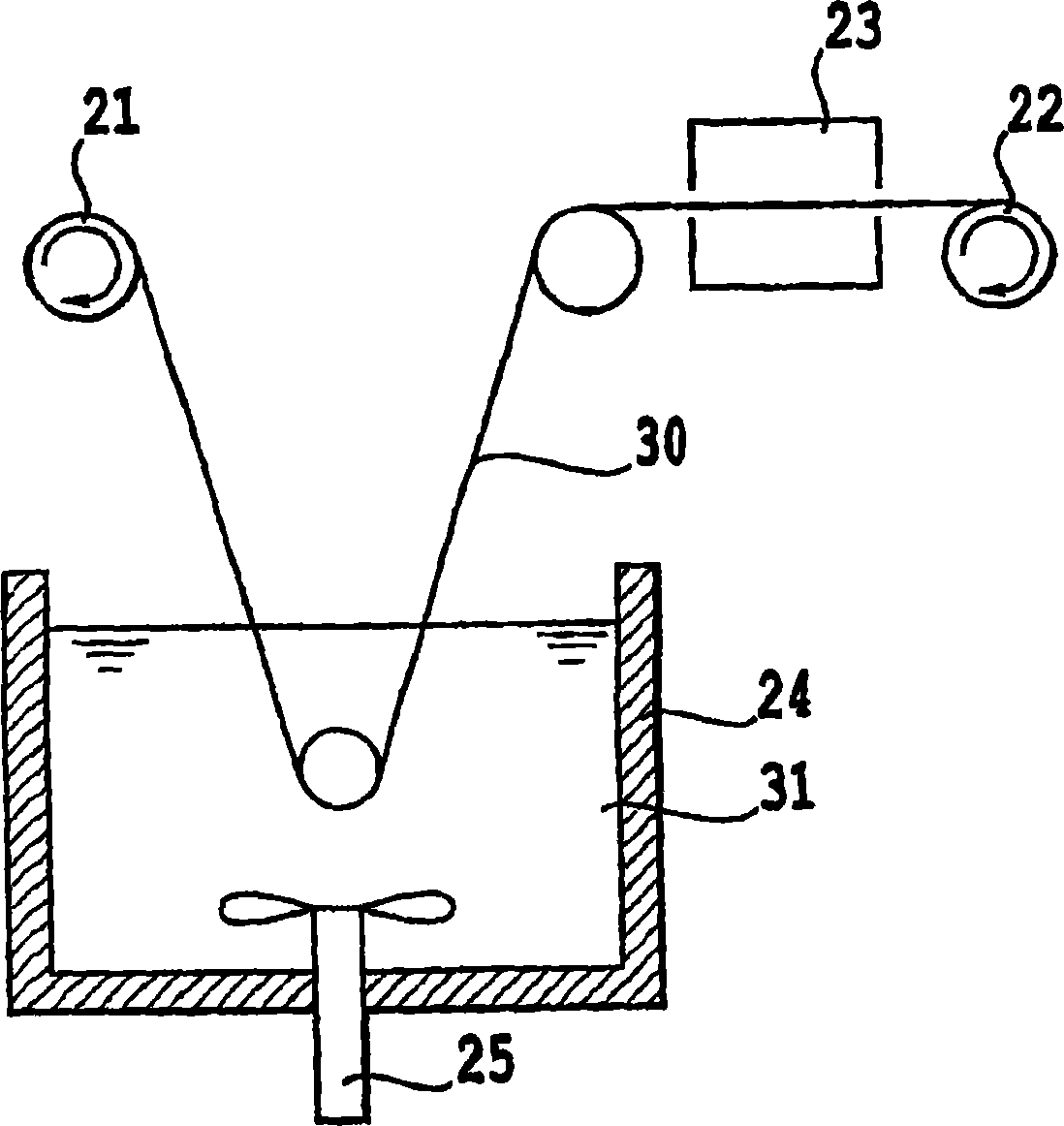

[0067] This embodiment provides the following metal-based carbon fiber composite material: for carbon fibers that can be treated as continuous fibers, a metal fiber mixture is prepared by using a suspension impregnation method using an aluminum powder suspension, and the prepared metal fiber mixture is sintered by a pulse energization sintering method. Sintering to obtain metal matrix carbon fiber composites.

[0068] As the carbon fibers, pitch-based carbon fibers having a diameter of 10 μm having a thermal conductivity of 1000 W / mK were used, and a bundle of 6000 of these fibers was wound on the pay-off reel 2 . As the aluminum powder, a flaky powder having a thickness of 1 μm or less and an average representative length in the planar direction of 30 μm was used. In ethanol containing 2% by weight (based on the weight of ethanol) of a dispersion binder (Pluronic (registered trademark) F68), aluminum powder was mixed to form a metal powder suspension. The content of aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com