FDM 3D printer with heating thermal insulation property

A technology of heating, heat preservation and printing, which is applied in the direction of additive processing, etc., can solve the problems of low heating temperature and constant temperature, and achieve the effect of beautiful structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

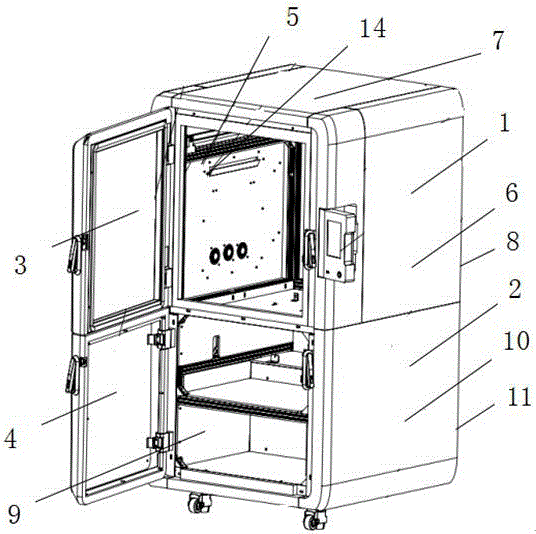

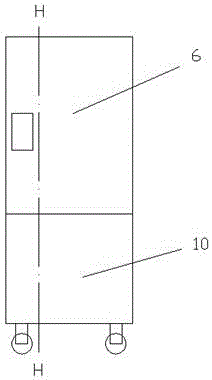

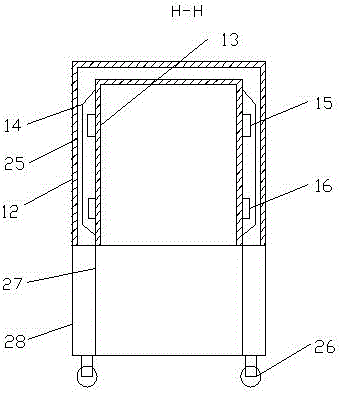

[0029] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a FDM3D printer with heating and heat preservation performance includes a housing and a printing mechanism. The printing mechanism includes a head body, a discharge channel and a nozzle. The housing includes a lower housing 1 and is fixedly connected above the lower housing 1. The upper casing 2; the upper front door 3 is installed directly in front of the upper casing 2, and the lower front door 4 is installed directly in front of the lower casing 1;

[0030] The upper casing 2 is set to a cuboid cavity structure without a front end; the upper left side 5, the upper right side 6, the upper top end 7 and the upper rear end 8 of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com