Flat plate heat pipe and manufacturing method thereof

A flat plate heat pipe and a manufacturing method technology, which are applied in the field of heat transfer and heat dissipation, can solve problems such as affecting the internal overall gas-liquid circulation efficiency, the overall performance of the flat plate heat pipe, and the inability to meet heat dissipation, so as to avoid slowing down the condensation speed and avoid working fluids. The effect of poor reflow and avoiding the increase of heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The present application preferably carries out the preparation of hydrophobic thin layer, and the preparation process of described hydrophobic thin layer is specifically:

[0076] Place the copper powder on the position of the condensing cover except the boss, heat and oxidize, add silver nitrate solution to the oxidized copper powder, add n-dodecyl mercaptan to the condensing cover, and then clean the condensing cover After the surface of the board is heated, dried and pressed, a condensation cover board with a thin hydrophobic layer of copper-based microstructure is obtained.

[0077] In the present application, it is preferred to prepare the liquid filling pipe at the end. The preparation of the liquid filling pipe is a technical means well known to those skilled in the art, and there is no special limitation here. The liquid filling tube is arranged in the through hole. The manufacturing process of the through holes is not particularly limited in the present applic...

Embodiment 2

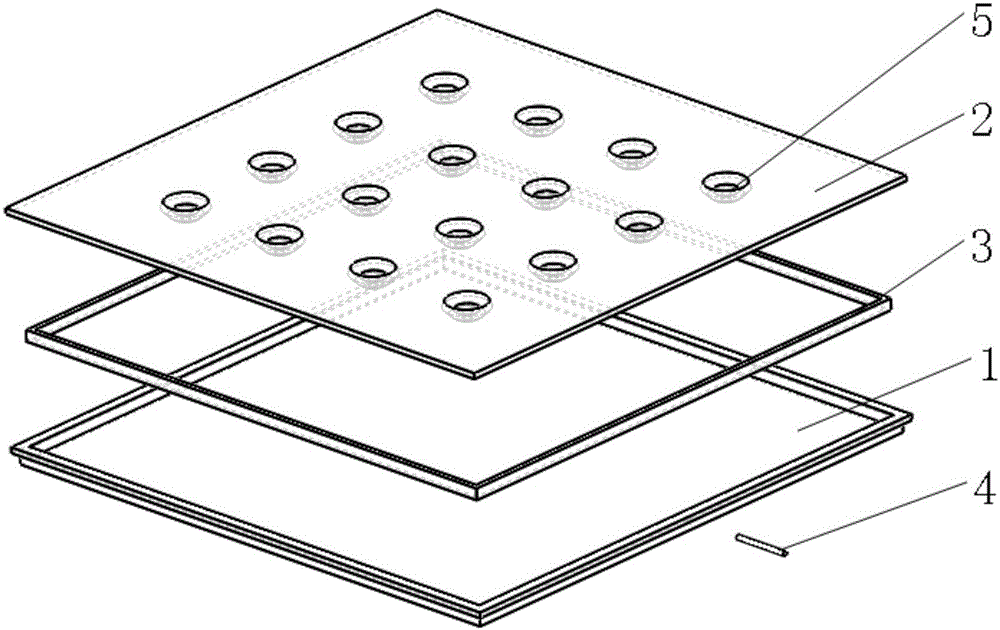

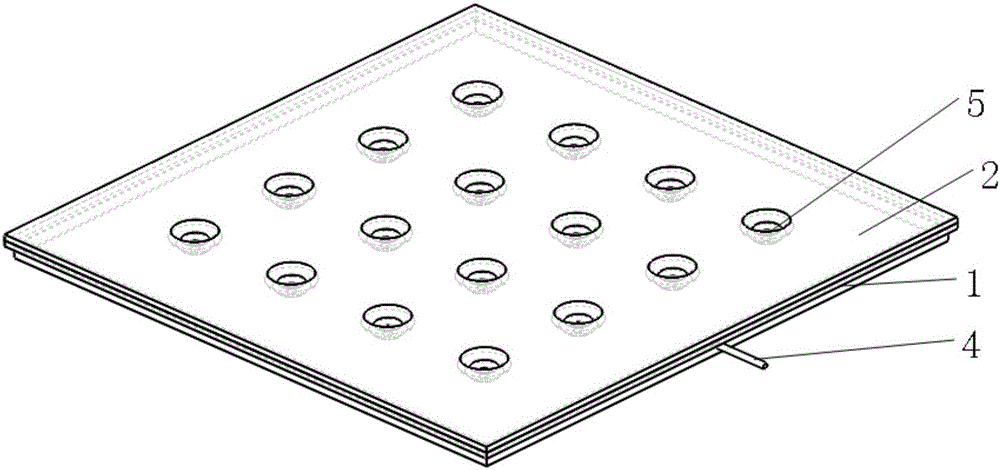

[0083] The structure of the flat heat pipe of this embodiment is the same as that of Embodiment 1. As a preferred solution, this embodiment has been improved as follows:

[0084] The evaporation cover plate 1 is used as the evaporation surface of the flat heat pipe, and its inner bottom surface is covered with a thin layer of hydrophilic copper hydroxide microstructure, and the hydrophilic copper hydroxide microstructure thin layer is put into the surface by the evaporation cover plate 1 Potassium hydroxide solution is used as an anode for electrochemical dissolution, and the hydrophilic copper hydroxide microstructure thin layer has a hydrophilicity with a contact angle of less than 10°; the inner bottom surface of the condensation cover plate 2 is covered with a hydrophobic copper base The microstructure thin layer, the hydrophobic copper-based microstructure thin layer is synthesized by reacting oxidized copper powder, silver nitrate solution and n-dodecyl mercaptan on the con...

Embodiment 3

[0086] The structure of the flat heat pipe of this embodiment is the same as that of Embodiment 1. As a preferred solution, this embodiment has been improved as follows:

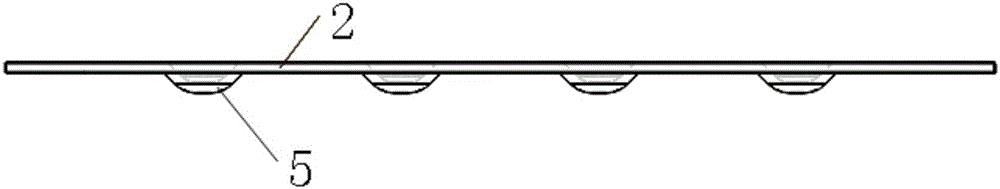

[0087] The structural parameters, quantity and position of the support bosses are optimized and designed by thermal analysis and structural analysis simulation software, and the taper bosses with non-through-hole structure are processed on the condensation cover plate by point pressing processing. The center of the upper end surface of the supporting bosses is distributed uniformly in a square lattice. Starting from the central layer of bosses, each time a layer of bosses is added, the diameter of the upper end surface of the bosses of this layer is smaller than that of the upper end surface of the bosses of the previous layer. The diameter is reduced by 1mm, and the horizontal and vertical distances of the center of the upper end surface of each layer of bosses are equal. The contact with the condensing cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com