Latent heat absorbing apparatus for gas boiler

A gas-fired boiler and latent heat technology, applied in air heaters, water heaters, fluid heaters, etc., can solve problems such as difficult assembly and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Some preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

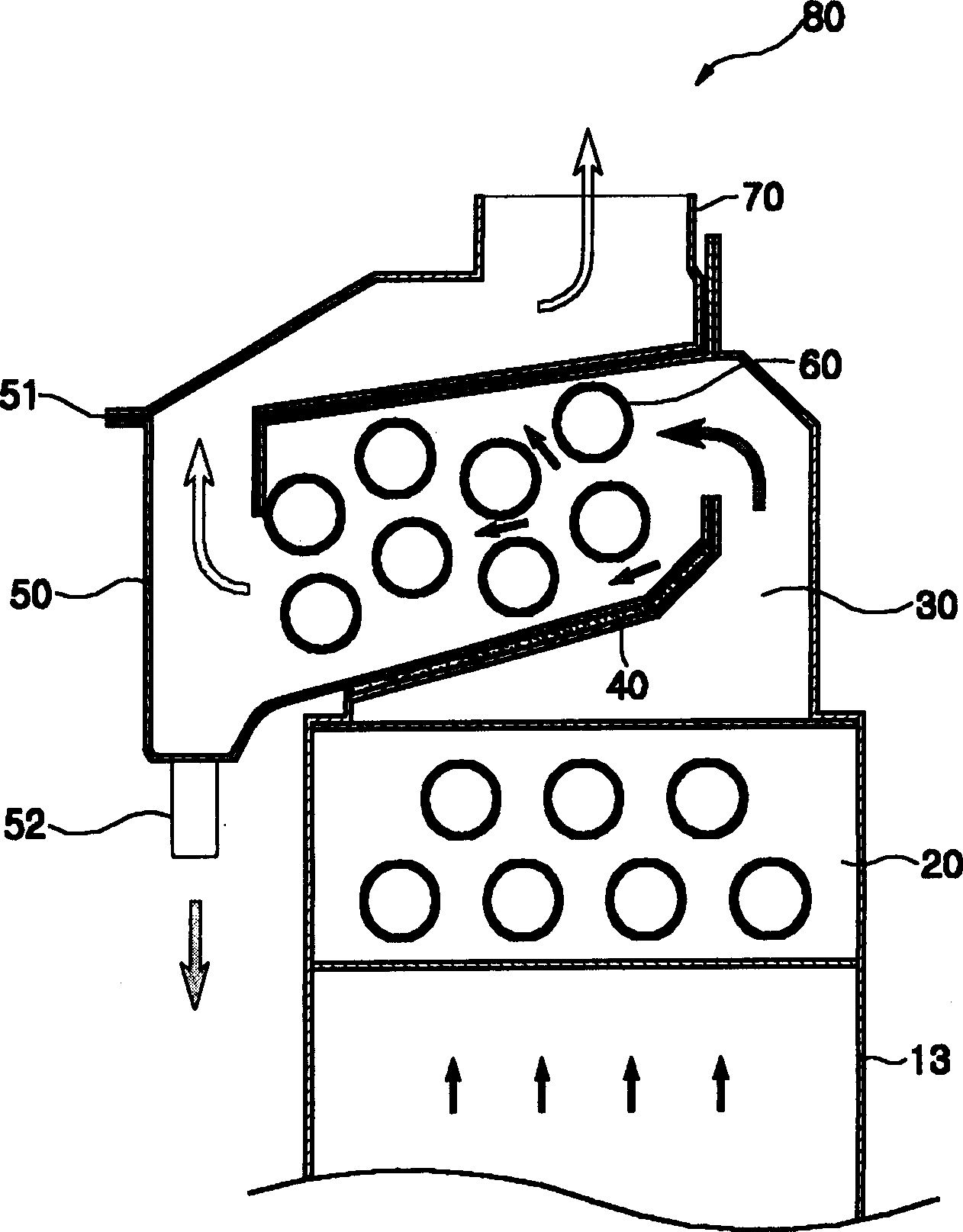

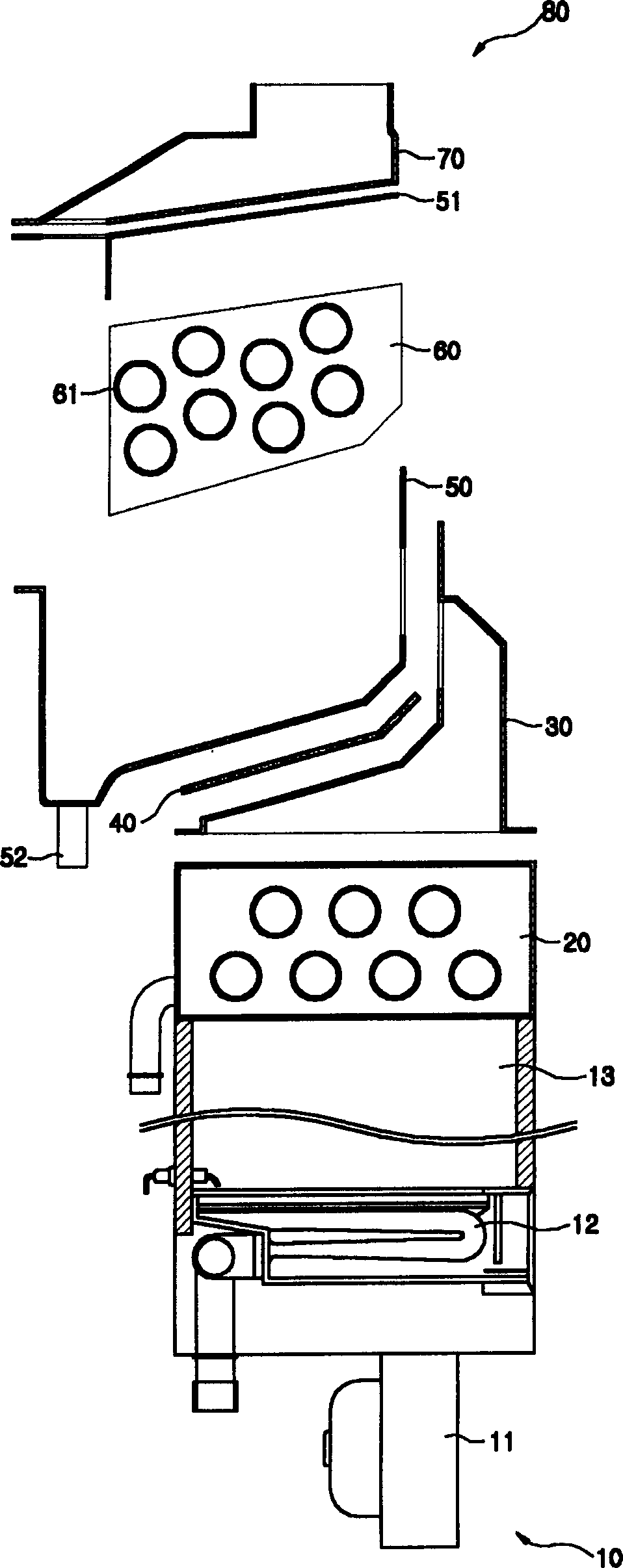

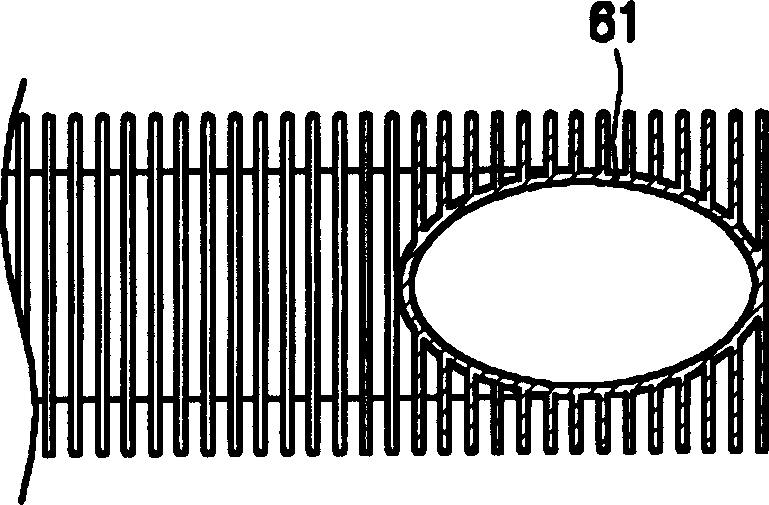

[0020] figure 1 shows a latent heat absorber 80 according to the invention, figure 2 Shown is a gas boiler 10 provided with a latent heat absorber 80 of the present invention. image 3 and Figure 4 Conduits 61 and 62 of latent heat absorber 80 of the present invention are shown.

[0021] According to the present invention, the latent heat absorbing device 80 is installed above the combustion chamber 13 of the gas boiler 10 .

[0022] In addition to the combustion chamber 13 , the gas boiler 10 also includes a blower 11 , a burner 12 , a sensible heat exchanger 20 and a first passage 30 .

[0023] The blower 11 is installed below the lowermost portion of the gas boiler 10 . The blower 11 includes a motor and a blower fan. The motor is rotated by supplying electric power to the motor from the outside. Under the action of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com