Vacuum insulation pipe filled with inert gas

A technology of inert gas and vacuum insulation, applied in the direction of pipeline protection through heat insulation, heat preservation, pipeline protection, etc., can solve the problems of large heat loss of heat insulation pipelines, high vacuum requirements, complex construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

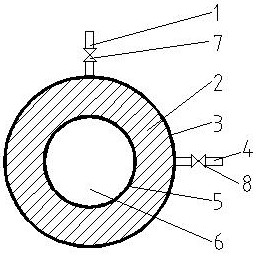

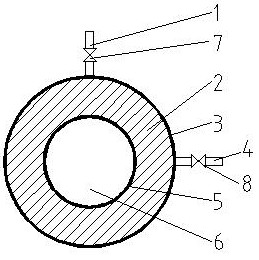

[0012] Such as figure 1 As shown, the inert gas-filled vacuum insulation pipeline of the present invention includes a vacuum tube 1, an outer tube 3, an inert gas inflation tube 4, an inner tube 5, a vacuum valve a7, and a vacuum valve b8.

[0013] Inside the inner tube 5 there is a working medium 6 .

[0014] Between the inner tube 5 and the outer tube 3, superfine particle (fiber) insulation material 2 is filled, and the air in the insulation material space is replaced by inert gas with low thermal conductivity such as argon, krypton, xenon, etc., and the inert gas argon, krypton, xenon, etc. The vacuum state is maintained, and the absolute pressure is 10-15000 Pa. The lower the pressure, the better the heat preservation effect. The heat dissipation loss of the present invention is only 2.5%-25% of that of conventional heat preservation pipes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com