Light-emitting device and illuminating device

A technology for light-emitting devices and light-emitting elements, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of low on-axis luminosity, large emission angle, increased light loss, etc., and achieves improved emission light intensity and light extraction efficiency. High, the effect of suppressing color variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

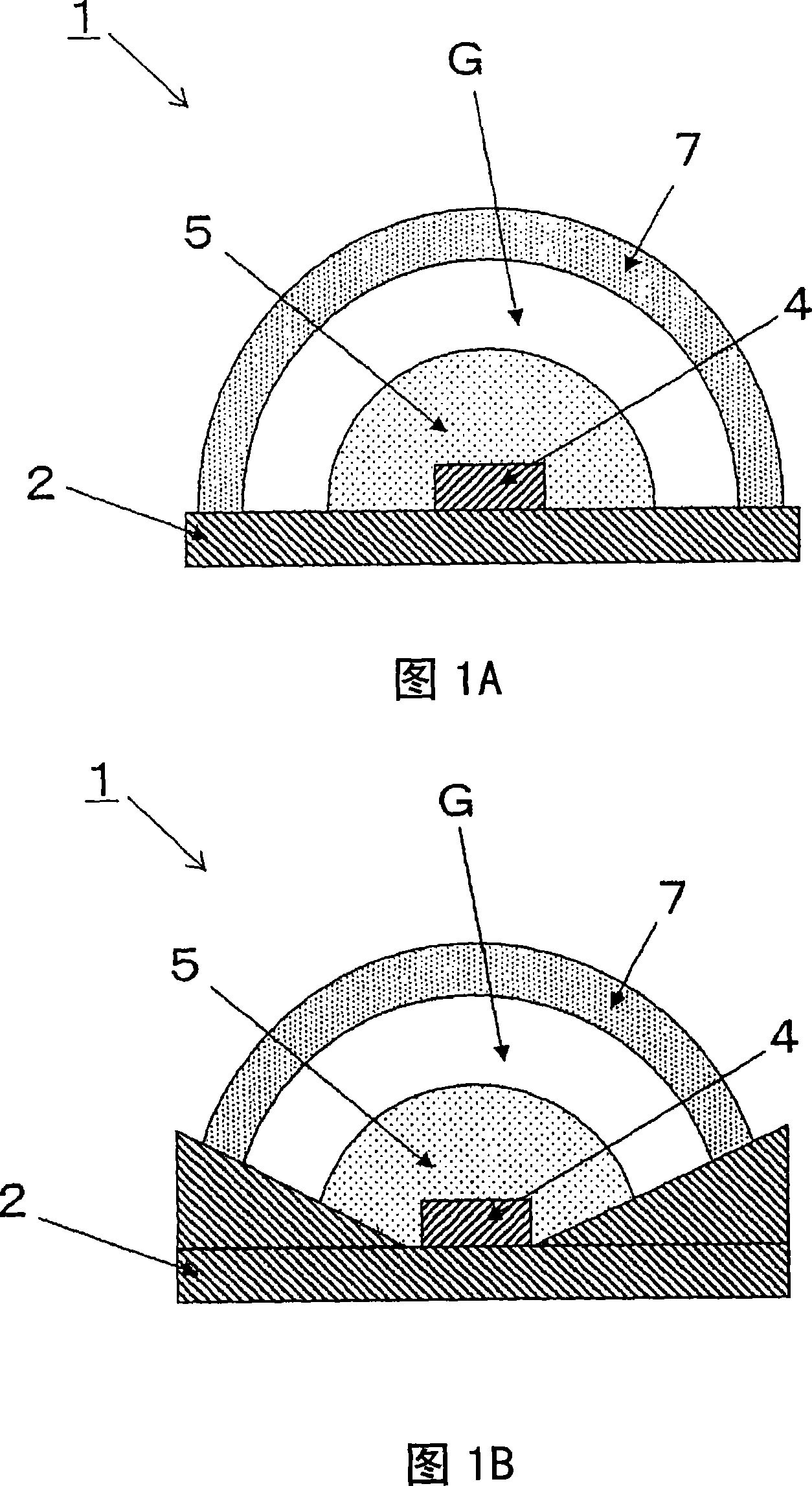

[0069] 1A and 1B are cross-sectional views showing the first embodiment of the present invention. First, as shown in FIG. 1A, the light-emitting device 1 is composed of a base 2, a light-emitting element 4, a first light-transmitting portion 5, a second light-transmitting portion 7, a third light-transmitting portion G, and the like.

[0070] On the base 2, a wiring conductor for supplying current to the light-emitting element 4 is formed extending from the upper surface to the lower surface or the side surface.

[0071] The light emitting element 4 is mounted on the upper surface of the base 2 so as to be electrically connected to the wiring conductor of the base 2.

[0072] The first light-transmitting portion 5 is formed of a light-transmitting material, and covers the light-emitting element 4.

[0073] The second translucent portion 7 is formed of a translucent material containing a phosphor that converts the wavelength of light emitted by the light-emitting element 4, and is ...

no. 2 Embodiment approach

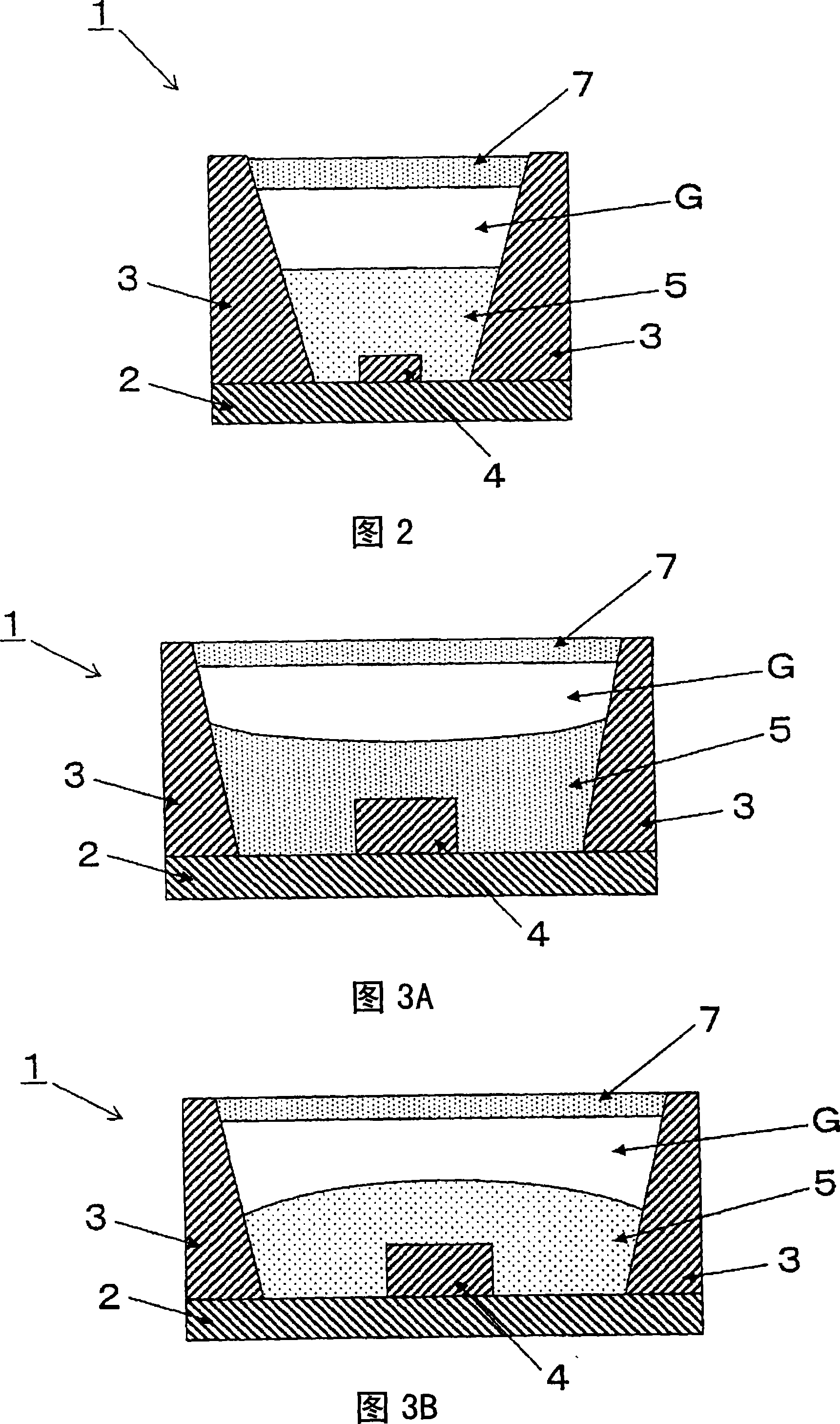

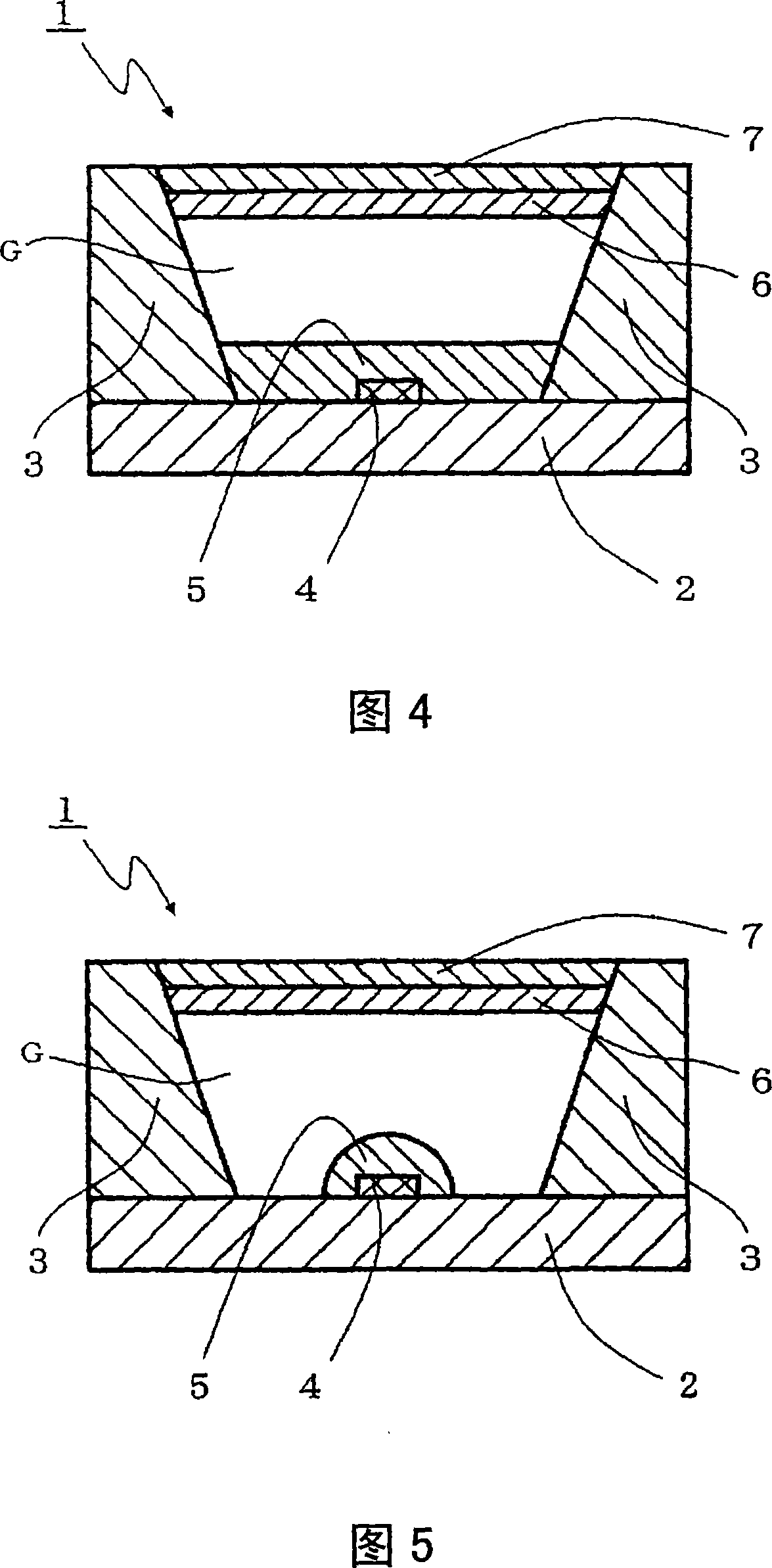

[0089]Fig. 2 is a cross-sectional view showing a second embodiment of the present invention. The light-emitting device 1 is composed of a base 2, a housing 3, a light-emitting element 4, a first light-transmitting portion 5, a second light-transmitting portion 7, a third light-transmitting portion G, and the like.

[0090] On the base 2, a wiring conductor for supplying current to the light emitting element 4 is arranged from the upper surface to the lower surface or to the side surface.

[0091] The light emitting element 4 is mounted on the upper surface of the base 2 so as to be electrically connected to the wiring conductor of the base 2.

[0092] The casing 3 is fixed on the base 2 and has an inner surface inclined upward in a manner of surrounding the light emitting element 4. It is preferable that the inner surface of the housing 3 has light reflectivity from the viewpoint of light use efficiency.

[0093] The first light-transmitting portion 5 is formed of a light-transmit...

no. 3 Embodiment approach

[0106] 3A and 3B are cross-sectional views showing a third embodiment of the present invention. First, as shown in FIG. 3A, the light-emitting device 1 is composed of a base 2, a housing 3, a light-emitting element 4, a first light-transmitting portion 5, a second light-transmitting portion 7, a third light-transmitting portion G, and the like.

[0107] On the base 2, a wiring conductor for supplying current to the light emitting element is formed extending from the upper surface to the lower surface.

[0108] The light emitting element 4 is mounted on the upper surface of the base 2 so as to be electrically connected to the wiring conductor of the base 2.

[0109] The housing 3 is fixed on the base 2 and has an inner surface inclined upward so as to surround the light emitting element 4. It is preferable that the inner surface of the housing 3 has light reflectivity from the viewpoint of light use efficiency.

[0110] The first light-transmitting portion 5 is formed of a light-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com