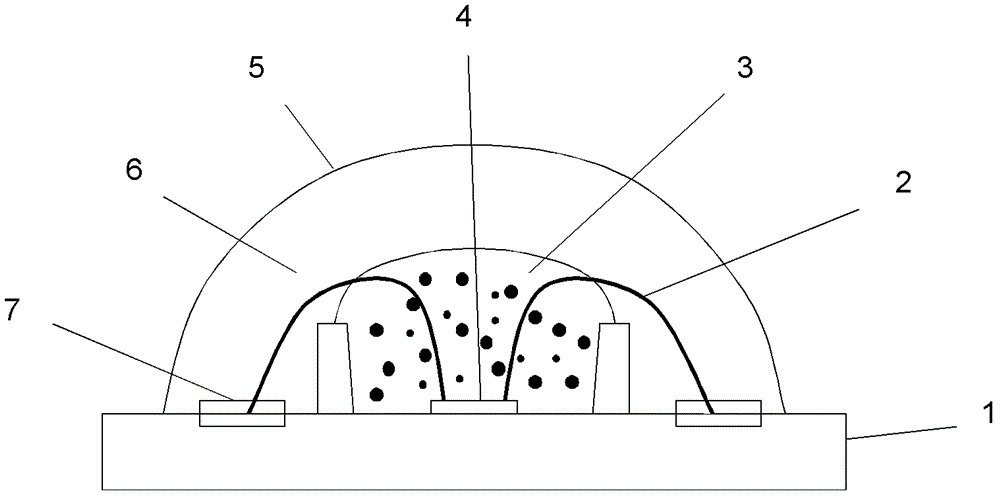

Method for manufacturing white light LED with wide color gamut

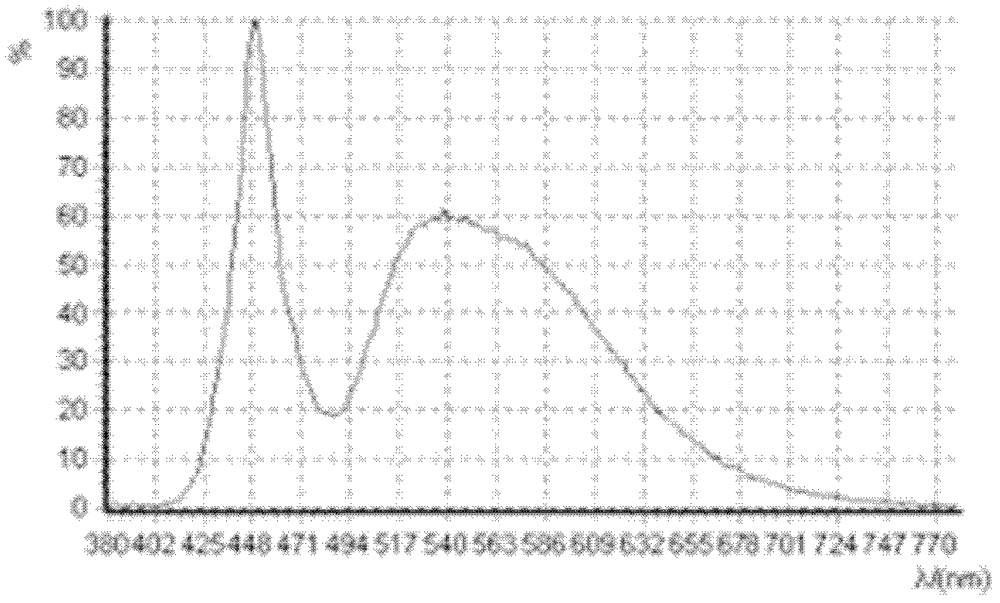

A wide color gamut, LED chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high color temperature, low color rendering index, narrow color gamut of white LEDs, etc., and achieve high emission light intensity and low operating temperature. , the effect of short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1). The preparation of macromonomer-modified core-shell quantum dots CdTe / CdS, the method is as follows:

[0033] a. Preparation of catalytic chain transfer agent CoBF

[0034] Add 3g of cobalt acetate and 2.5g of diacetyl to 250mL of diethyl ether pre-gassed with nitrogen for 2 hours to prepare a suspension, then add 15mL of boron trifluoride ether solution as a catalyst, and stir the reaction at room temperature to obtain a brown precipitate. The precipitate was filtered, washed with ice water, and dried at room temperature. The dried brown solid was recrystallized twice in methanol and dried to obtain CoBF as a brown powder.

[0035] b. Preparation of PMAA macromolecular ligands with double bonds at the end by catalytic chain transfer polymerization

[0036] Methacrylic acid and distilled water were pretreated to remove free oxygen from the solution. 0.3g of initiator VA-044 and 10mg of catalyst CoBF were dissolved in 2mL of acetone, then added to a three-necked fl...

Embodiment 2

[0044] (1). The preparation of macromer-modified core-shell quantum dots CdTe / CdS / CdS, the method is as follows:

[0045] Take by weighing 0.3127gPMAA macromonomer and be dissolved in the CdTe / CdS quantum dot solution prepared in 20g embodiment 1, and be placed in the 100mL four-necked flask, drop in the 5g aqueous solution that is dissolved in 0.1142g cadmium chloride wherein, Stir for 2 hours to adjust the pH value to about 8 with 2mol / L NaOH solution after the ligand and cadmium ion are fully coordinated, and pass N at room temperature 2 After deoxygenation for 30 minutes, place in a microwave reactor and heat to 95°C, inject 20 g of aqueous solution dissolved with 0.078 g of sodium sulfide, and stop the reaction after 130 min. The prepared CdTe / CdS / CdS core-shell quantum dot solution was then precipitated with a large amount of ethanol, and then dispersed after centrifugation at 6000 rpm for 15 min.

[0046] (2). Preparation of wide color gamut white LED

[0047] In the ...

Embodiment 3

[0049] (1). The preparation of macromonomer-modified core-shell quantum dots CdTe / ZnS, the method is as follows:

[0050] Take by weighing 0.3127gPMAA macromonomer and be dissolved in the CdTe quantum dot solution prepared in 20g embodiment 1, and be placed in the 100mL four-neck flask, drop in the 5g aqueous solution that is dissolved in 0.1142g zinc chloride wherein, stir 2h After the ligand is fully coordinated with the zinc ion, adjust the pH value to about 8 with 2mol / L NaOH solution, and pass N at room temperature. 2 After deoxygenation for 30 minutes, place in a microwave reactor and heat to 95°C, inject 20 g of aqueous solution dissolved with 0.078 g of sodium sulfide, and stop the reaction after 15 min. The prepared CdTe / ZnS quantum dot solution was then precipitated with a large amount of ethanol, and then dispersed after centrifugation at 6000 rpm for 15 min.

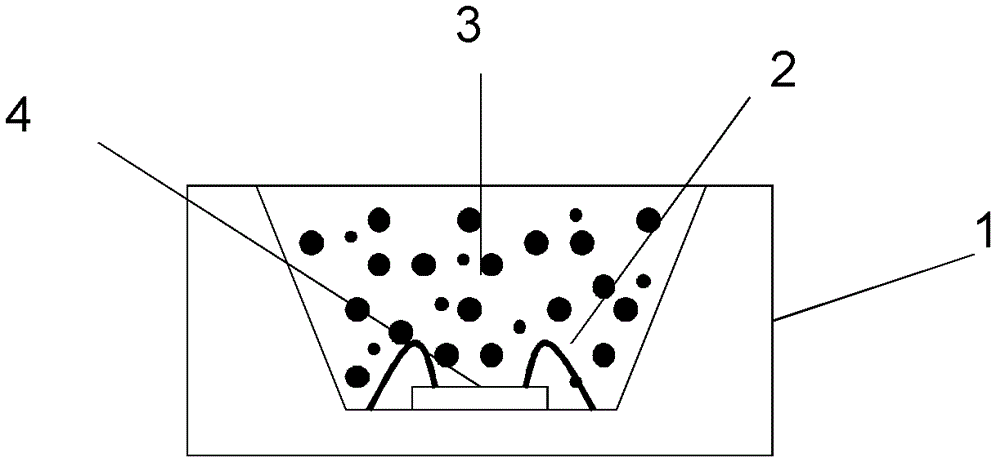

[0051] (2). Preparation of wide color gamut white LED

[0052] Such as figure 2 As shown, in the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com