Device and method for testing explosion properties of flammable gases at ultralow temperature

A gas explosion and characteristic testing technology, which is applied in the direction of material explosion, can solve the problems of physical explosion hazards, large amount of liquid nitrogen, container failure, etc., to avoid risks and excessive thermal stress, high refrigeration efficiency, and easy temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

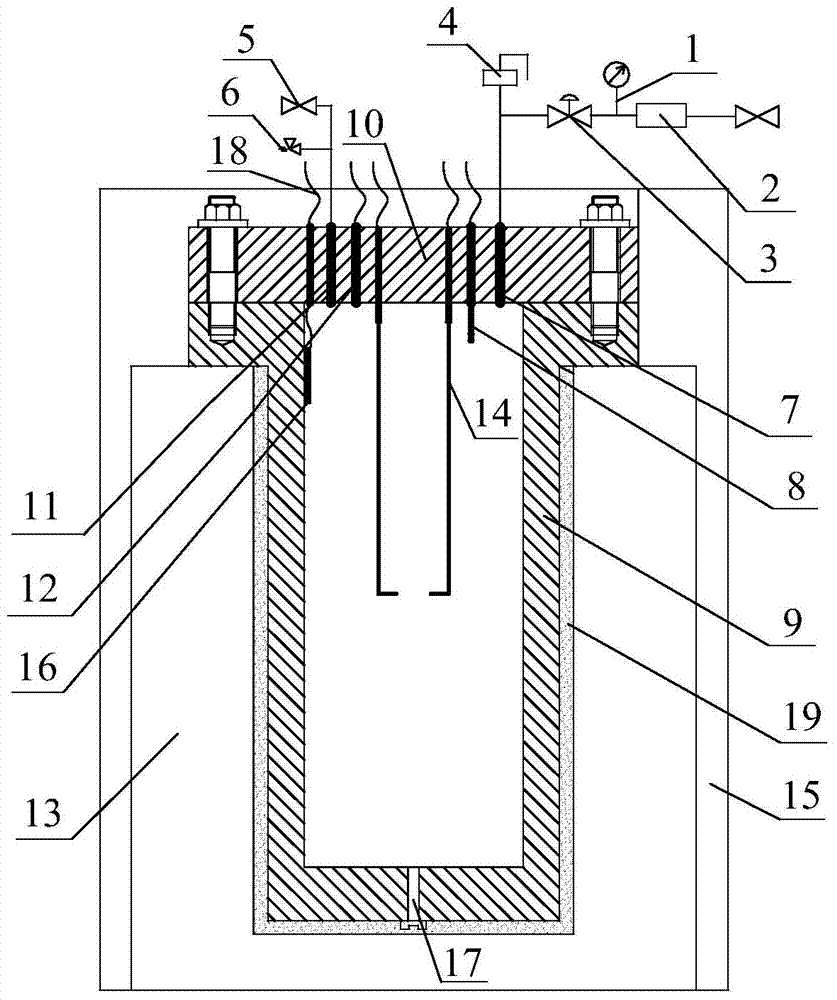

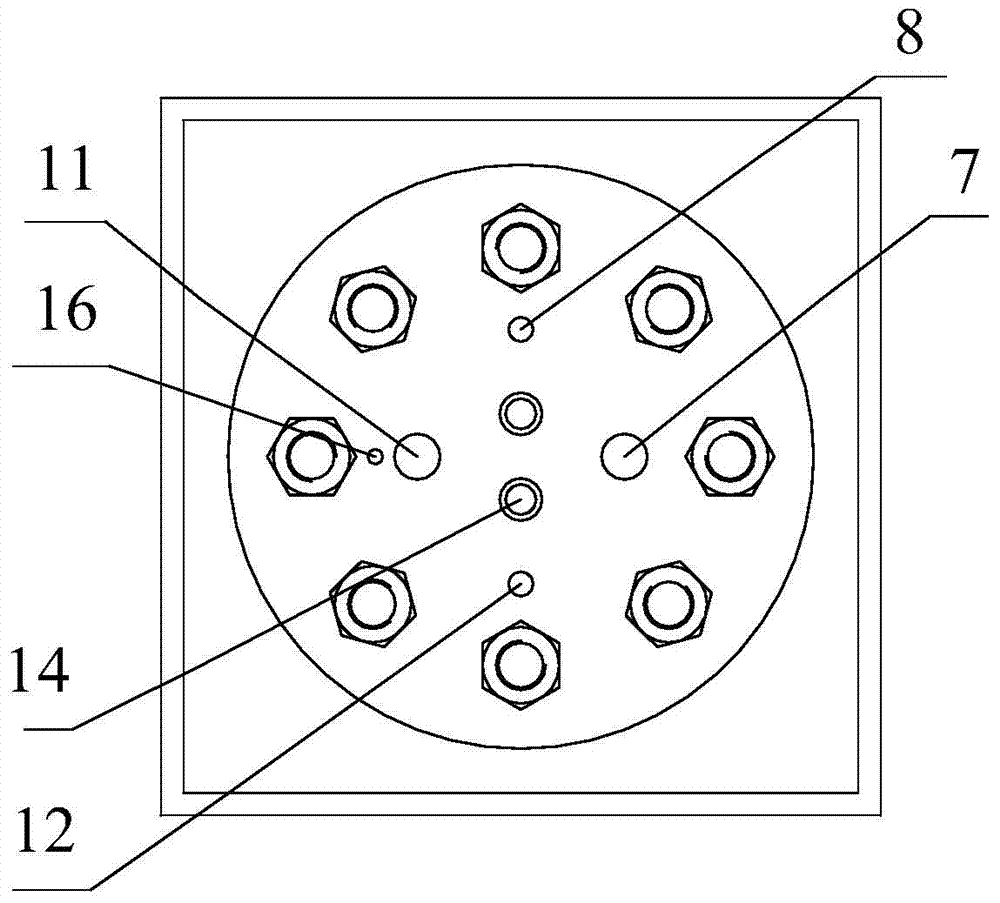

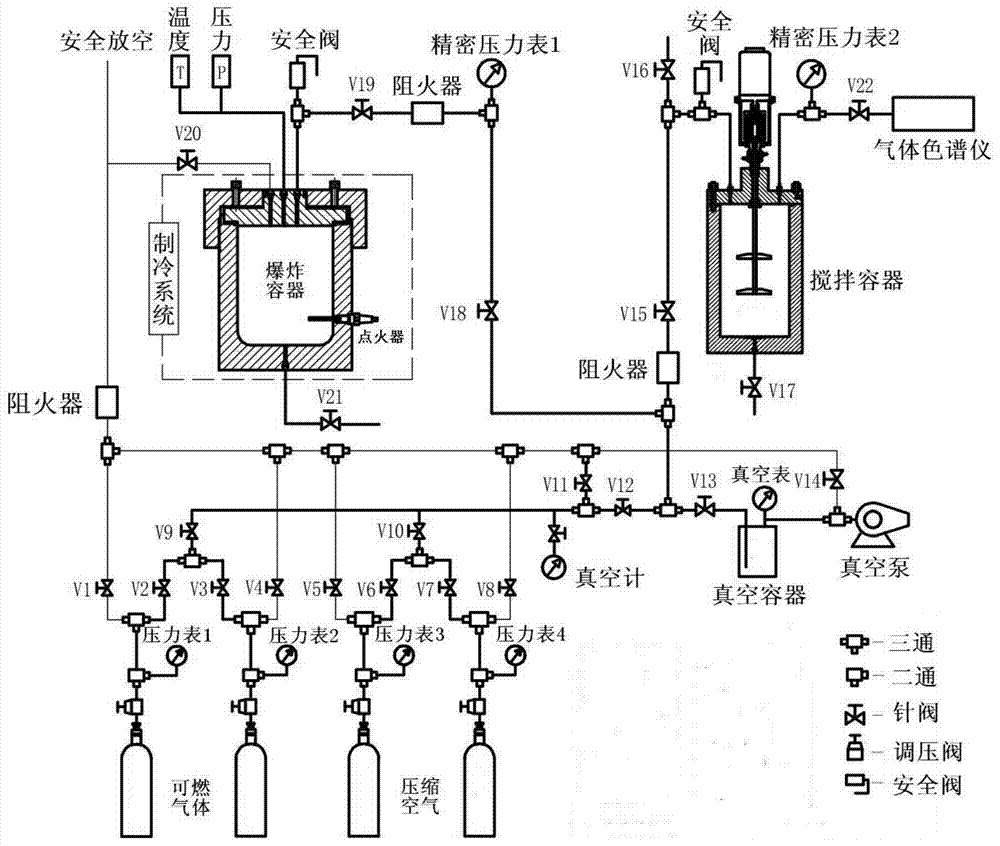

[0035] Such as figure 1 Shown, a kind of combustible gas explosion characteristic testing device under the ultra-low temperature, comprises a refrigeration unit, is placed an explosion vessel 9 that length-to-diameter ratio is 3:1 in the inner chamber of described refrigeration unit, and described explosion vessel 9 and described refrigeration A gap is formed between the inner chambers of the device, and the gap is added with heat-conducting aluminum powder 19 that makes the explosion vessel 9 and the gas in the explosion vessel 9 drop to the experimental temperature; the top of the explosion vessel 9 is sealed by a flange cover 10 , the interior of the explosion vessel is provided with two ignition electrodes 14 connected to the ignition energy console, the bottom of the explosion vessel 9 is provided with a liquid discharge port 17 for cleaning carbon deposits in the expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com