Method for preparing focal plane of quantum trap infrared detecter

A technology of infrared detectors and quantum wells, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as indium column solder joint drop-off, lattice mismatch, thermal expansion coefficient mismatch, etc., to reduce Signal delay, no cross contamination, and reduced inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will now be described in detail in conjunction with the accompanying drawings and embodiments. The embodiment is operated completely according to the above-mentioned operation steps.

[0040] Embodiment Preparation of Quantum Well Infrared Detector Focal Plane

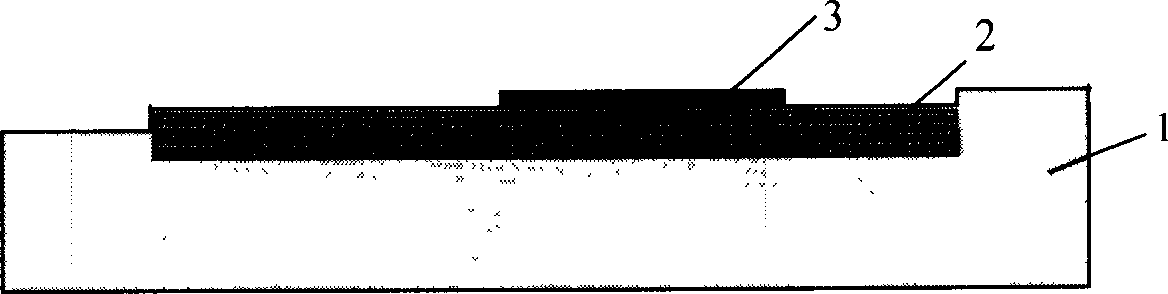

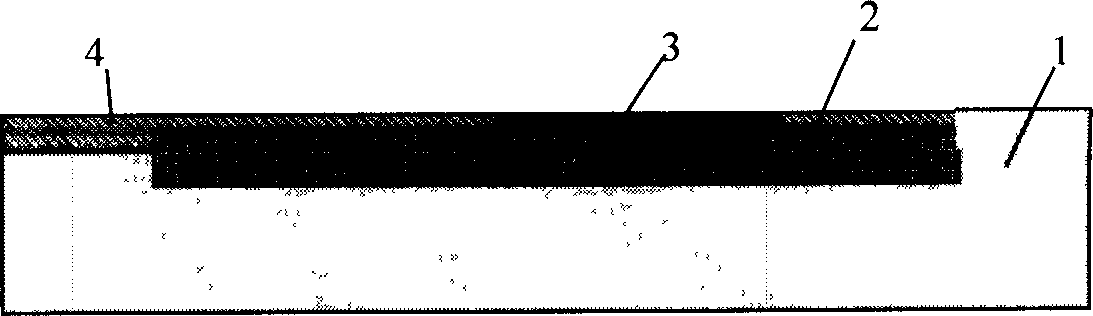

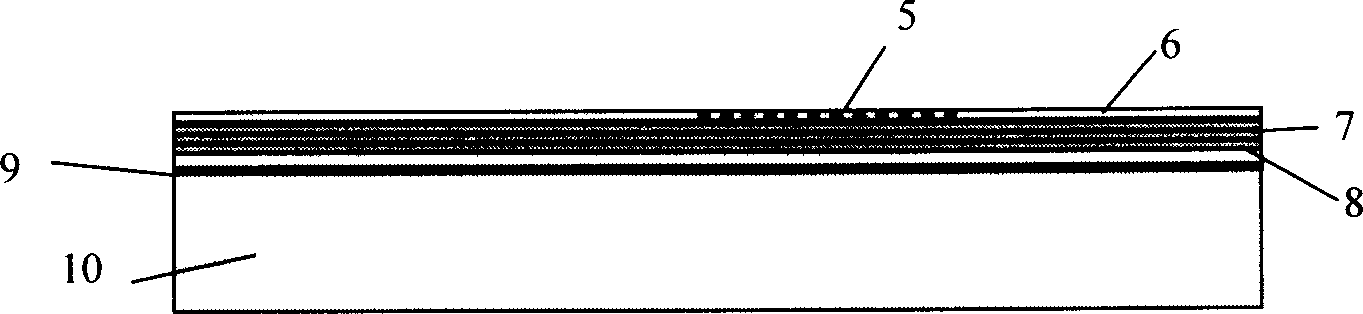

[0041] The preparation begins with two heterogeneous wafers. The diameter of the two heterogeneous wafers is 1 to 8 inches. The two heterogeneous wafers are respectively a silicon wafer 1 and a GaAs wafer 10, and a silicon-based readout integrated circuit 2 is formed on the silicon wafer 1. , GaAs wafer 10 is made with termination layer 9, lower electrode layer 8, quantum well layer 7, upper electrode layer 6 and two-dimensional grating 5, operation steps:

[0042] The first step is metal electrode processing of silicon-based readout integrated circuit 2

[0043] Evaporate CrAu or TiAu thin film 3 on silicon-based readout integrated circuit 2 by electron beam eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com