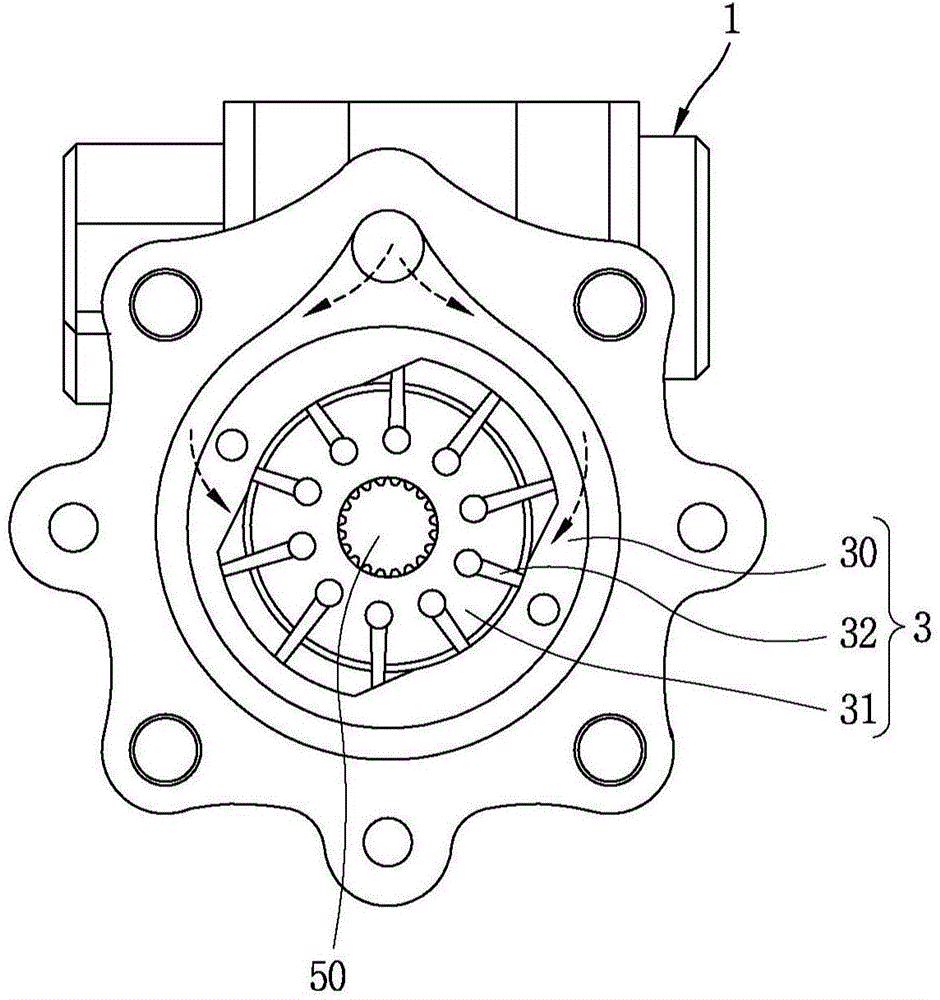

Vane Pump

A vane pump and vane technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of high vane friction coefficient, long heat treatment time, large wear damage, etc., and achieve low friction coefficient and improved wear resistance. , The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the vane pump according to the present invention will be described in detail with reference to the drawings. Here, the present invention does not relate to the form of the components constituting the vane pump, but relates to the materials of the rotor, vane, and stator, so it is applicable to a vane pump having any form of the rotor, vane, and stator. In the following description, based on the above figure 1 The above-described vane pump will be described.

[0034] First, the manufacturing process of the rotor in the above-mentioned embodiment will be described.

[0035] (1) Melting

[0036] Contains C: 3.5-3.9%, Si: 2.2-3.0%, Mn: 0.1-0.5%, S≤0.02%, P≤0.04%, Cu: 0.1-0.5%, Mo: 0.1-0.3%, Mg by weight : 0.02 to 0.05% and Re: 0.01 to 0.04%, the elements are mixed in an appropriate proportion, heated by an electric furnace, etc., and then smelted.

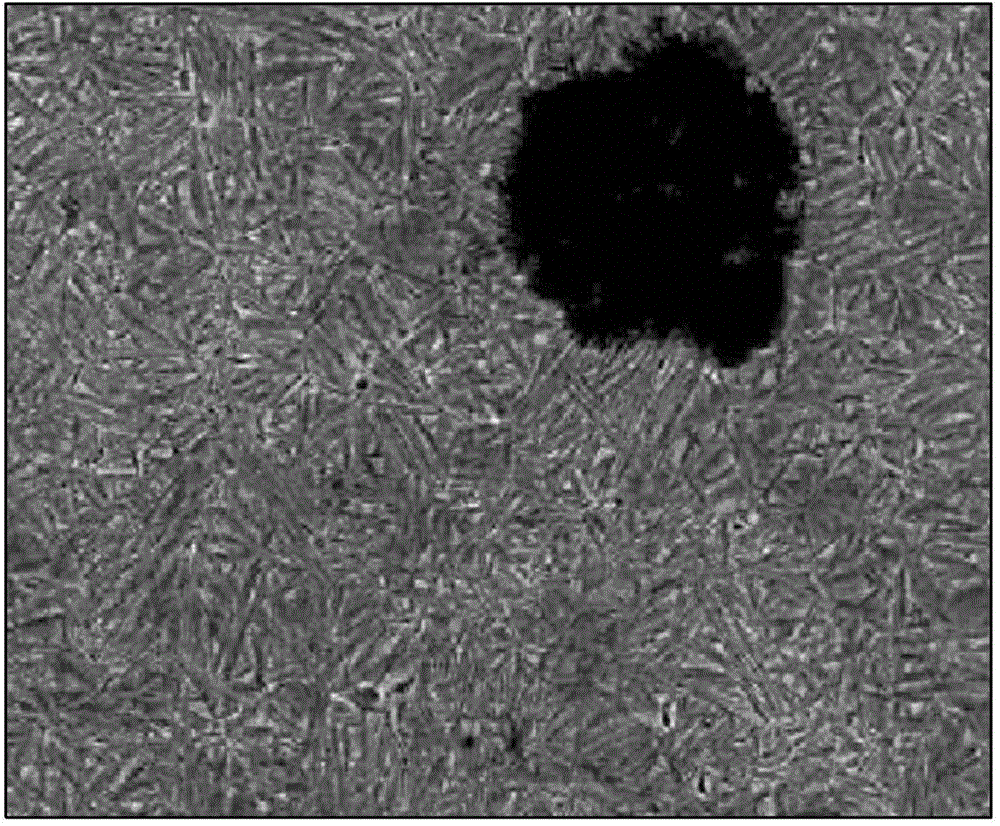

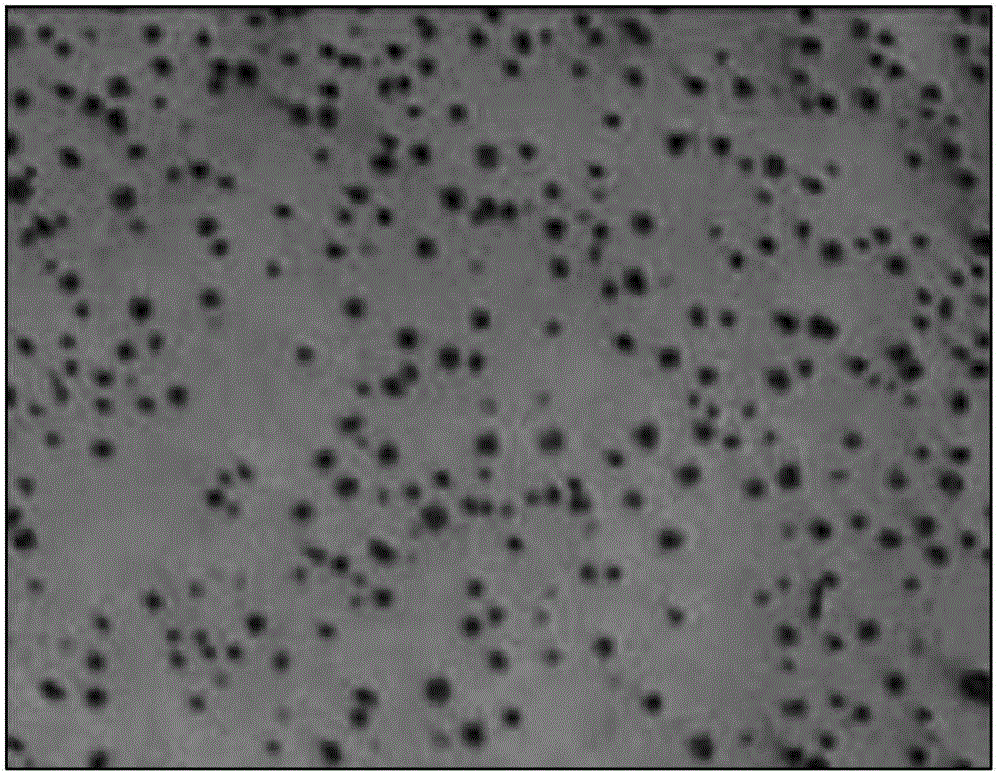

[0037] (2) Spheroidization treatment and inoculation

[0038] Inoculate the nodulizer and ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com