SiC-coated hexagonal boron nitride composite powder modified self-lubricating ceramic cutter material and preparation method thereof

A hexagonal boron nitride and composite powder technology, which is applied in the field of ceramic tool materials, can solve the problems of unsuitable self-lubricating ceramic tool materials, etc., and achieve the effects of slowing down adverse effects, excellent mechanical properties, and good lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

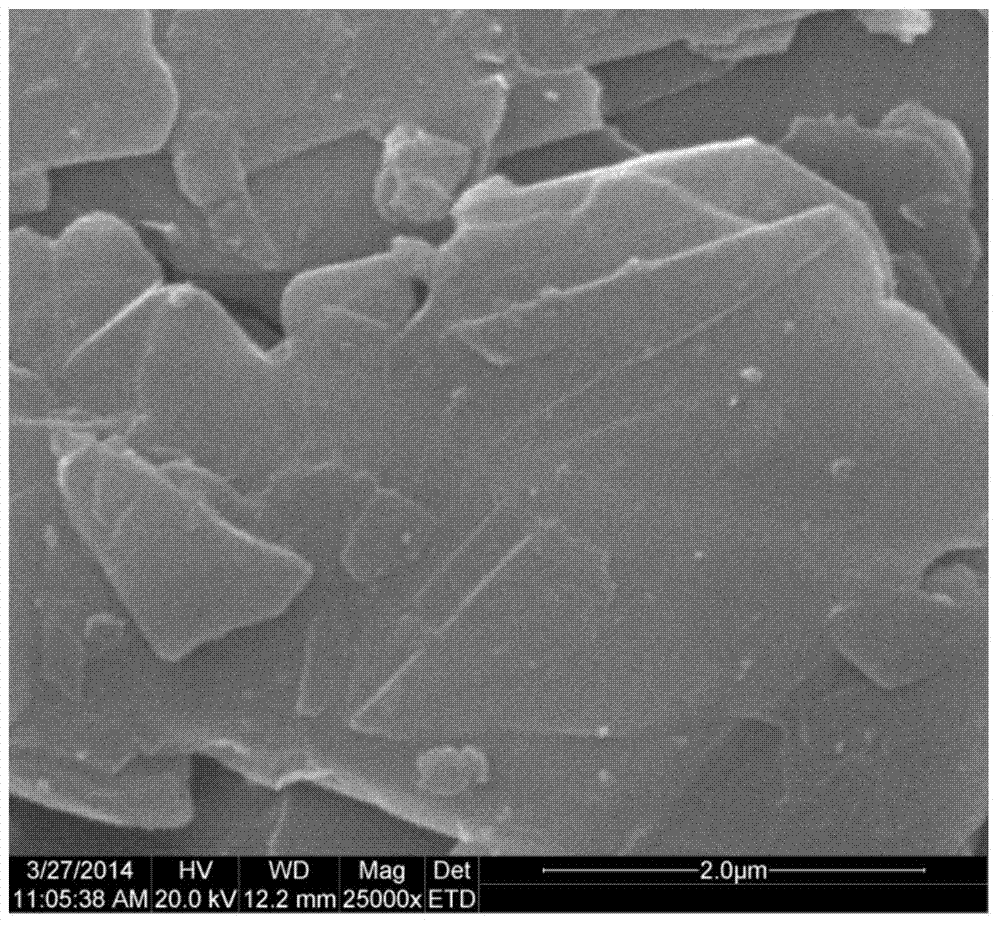

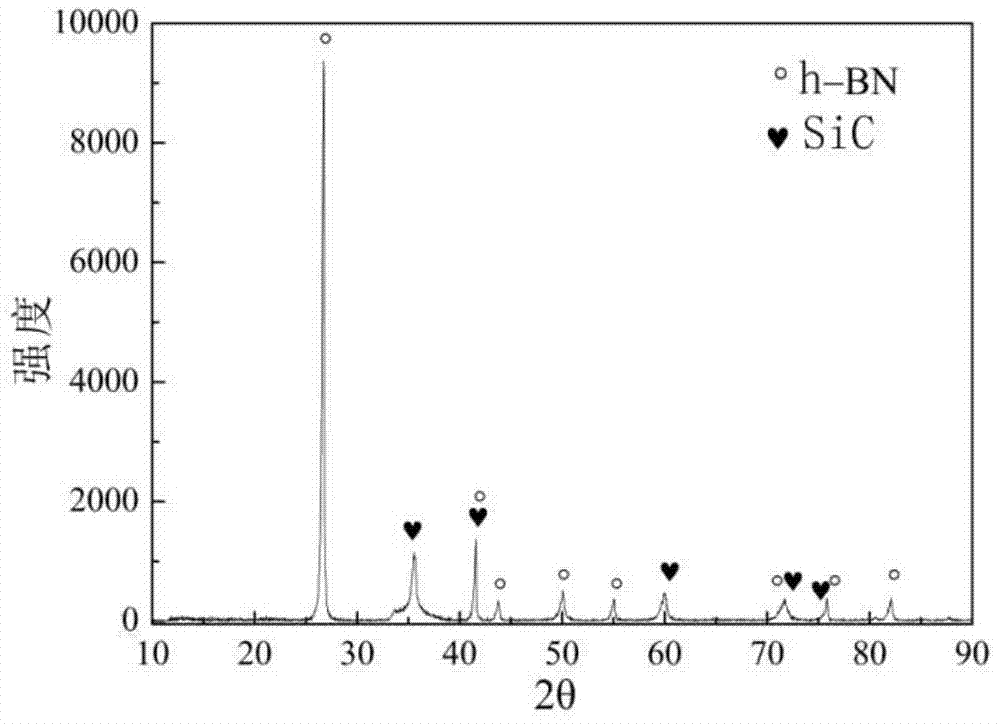

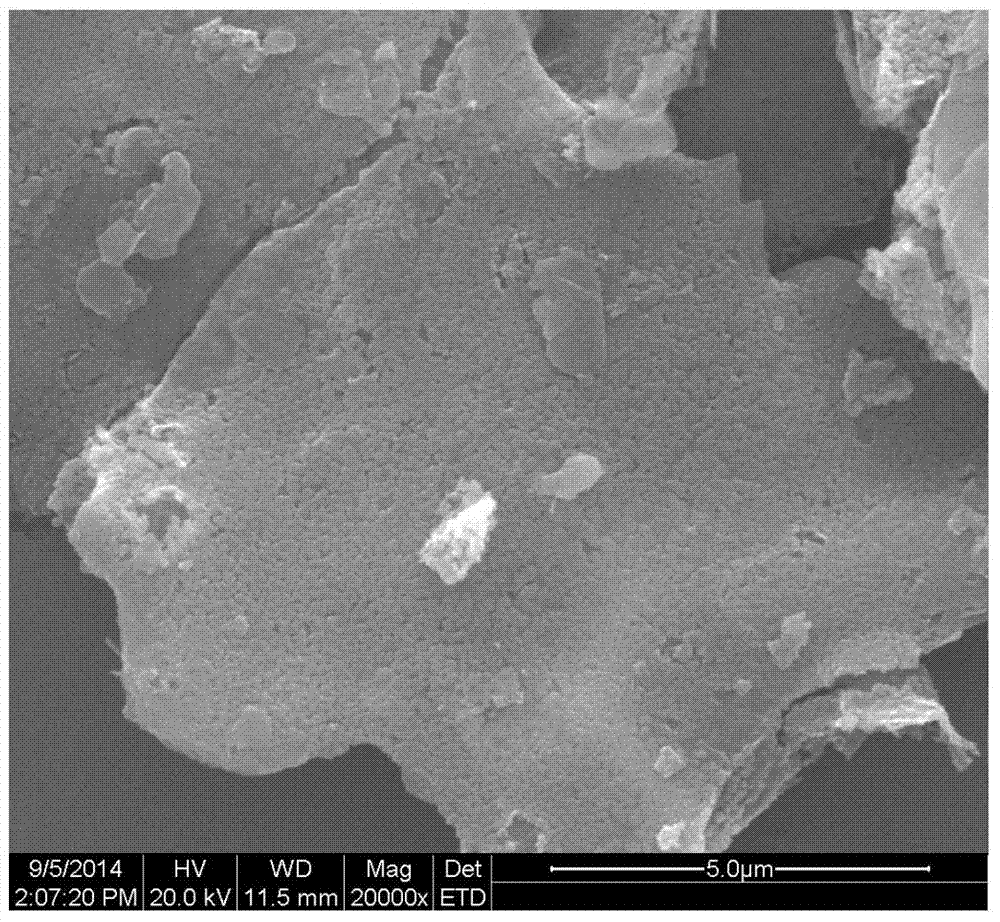

Method used

Image

Examples

Embodiment 1

[0041] The self-lubricating ceramic tool material modified by adding silicon carbide-coated hexagonal boron nitride composite powder, the volume percentage of each component material is: Al 2 o 3 66.15%, TiC 28.35%, h-BNSiC 5% (based on h-BN contained therein), MgO 0.5%. The preparation method is as follows:

[0042] (1) Take Al in proportion 2 o 3 and TiC were respectively dispersed in absolute ethanol, ultrasonically dispersed and mechanically stirred for 25 minutes, the resulting suspension was mixed, MgO was added in proportion, and then ultrasonically dispersed and mechanically stirred for 25 minutes to obtain a uniformly mixed multi-phase suspension;

[0043] (2) Pour the above-mentioned multi-phase suspension into the ball mill pot, add cemented carbide balls to ensure that the weight ratio of balls to materials is 10:1, fill in nitrogen as a protective atmosphere and continue ball milling for 48 hours;

[0044] (3) Add h-BNSiC composite powder in proportion, ball ...

Embodiment 2

[0048] The self-lubricating ceramic tool material modified by adding silicon carbide-coated hexagonal boron nitride composite powder, the volume percentage of each component is: Al 2 o 3 62.65%, TiC 26.85%, h-BNSiC 10% (based on h-BN contained therein), MgO 0.5%. The preparation method is as follows:

[0049] (1) Weigh an appropriate amount of Al in proportion 2 o 3 and TiC, respectively, dispersed in absolute ethanol, ultrasonically dispersed and mechanically stirred for 20 minutes, the obtained suspension was mixed, an appropriate amount of MgO was added, and then ultrasonically dispersed and mechanically stirred for 20 minutes to obtain a uniformly mixed multi-phase suspension;

[0050] (2) Pour the above-mentioned multi-phase suspension into the ball mill pot, add cemented carbide balls to ensure that the weight ratio of balls to materials is 12:1, fill in nitrogen as a protective atmosphere and continue ball milling for 48 hours;

[0051] (3) Add h-BNSiC composite po...

Embodiment 3

[0055] The self-lubricating ceramic tool material modified by adding silicon carbide-coated hexagonal boron nitride composite powder, the volume percentage of each component is: Al 2 o 3 47%, TiC 47%, h-BNSiC 5% (based on h-BN contained therein), MgO 1%. The preparation method is as follows:

[0056] (1) Take Al in proportion 2 o 3 and TiC, respectively, dispersed in absolute ethanol, ultrasonically dispersed and mechanically stirred for 15 minutes, the obtained suspension was mixed, MgO was added in proportion, and ultrasonically dispersed again and mechanically stirred for 15 minutes to obtain a uniformly mixed multi-phase suspension;

[0057] (2) Pour the above-mentioned multi-phase suspension into the ball mill tank, add cemented carbide balls to ensure that the weight ratio of balls to materials is 10:1, fill in nitrogen as a protective atmosphere and continue ball milling for 36 hours;

[0058] (3) Add h-BNSiC composite powder in proportion and ball mill again for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com