Vehicle engine oil additive and engine oil

A technology for the preparation of additives and additives, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor dispersion stability, unable to meet the requirements of long-term use of the engine, block the oil circuit, etc., and achieve high surface activity, excellent dispersion stability, etc. performance, excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) The preparation of the steam engine oil lubricating additive of the present invention

[0023] Nano WS 2 20% powder, 20% polyisobutylene succinimide, base oil (40°C kinematic viscosity: 88.75mm 2 / s, 100℃ kinematic viscosity: 13.9mm 2 / s) 69%, antioxidant (2,4,6 tri-tert-butyl p-cresol) 0.5%, metal deactivator (benzotriazole derivative) 1%, mixing and stirring for 15-20 minutes, ultrasonic treatment for 30 minutes .

[0024] 2) preparation of steam engine oil of the present invention

[0025] Add 10% of the prepared additive to 90% of the engine oil (40°C kinematic viscosity: 89.52mm 2 / s, 100℃ kinematic viscosity: 14.2mm 2 / s), mixed and stirred for 20-30 minutes, and ultrasonically treated for 30 minutes, the finished product engine oil of the present invention was obtained.

[0026] 3) Add the prepared finished engine oil into the crankcase of the engine, and then normal driving can be carried out.

[0027] The engine oil prepared by the present invention h...

Embodiment 2

[0031] 1) The preparation of the steam engine oil lubricating additive of the present invention

[0032] Nano WS 2 Powder 15%, Nano MoS 2 5% powder, 20% polyisobutylene succinimide, base oil (40°C kinematic viscosity: 88.75mm 2 / s, 100℃ kinematic viscosity: 13.9mm 2 / s) 59.5%, metal deactivator (benzotriazole derivatives) 0.5%, mixed and stirred for 15-20 minutes, and ultrasonically treated for 30 minutes.

[0033] 2) preparation of steam engine oil of the present invention

[0034] Add 10% of the prepared additive to 90% of the engine oil (40°C kinematic viscosity: 89.52mm 2 / s, 100℃ kinematic viscosity: 14.2mm 2 / s), mixing and stirring for 20-30 minutes, ultrasonic treatment for 30 minutes, that is, a finished engine oil.

[0035] 3) Add the prepared finished engine oil into the crankcase of the engine, and then normal driving can be carried out.

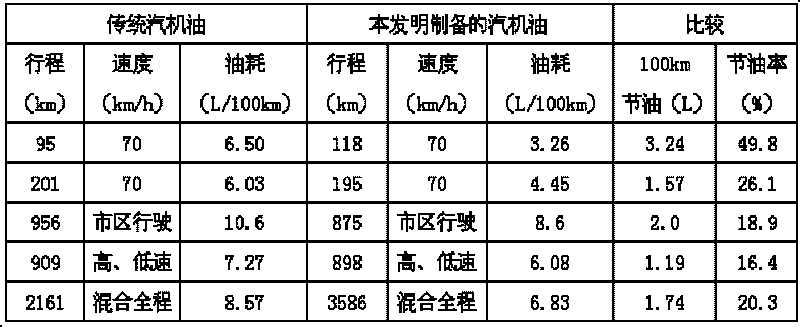

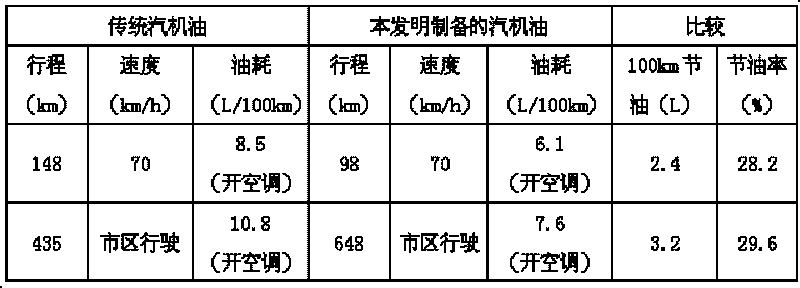

[0036] The gasoline engine oil prepared by the present invention is used in a driving test on a Buick Excelle car (displ...

Embodiment 3

[0040] 1) Diesel engine oil additive preparation of the present invention

[0041] Nano WS 2 Powder 10%, Nano MoS 2 10% powder, 20% polyisobutylene succinimide, base oil (40°C kinematic viscosity: 165.15mm 2 / s, 100℃ kinematic viscosity: 17.1mm 2 / s) 59.5%, metal deactivator (benzotriazole derivatives) 0.5%, mixed and stirred for 15-20 minutes, and ultrasonically treated for 30 minutes.

[0042] 2) Diesel engine oil preparation of the present invention

[0043] Add 20% of the prepared additive to 80% diesel engine oil (40°C kinematic viscosity: 170.02mm 2 / s, 100℃ kinematic viscosity: 18.8mm 2 / s), mix and stir for 20-30 minutes, and ultrasonically treat for 30 minutes to become a finished diesel engine oil.

[0044] 3) Add the prepared finished diesel engine oil into the crankcase of the engine, and then normal driving can be carried out.

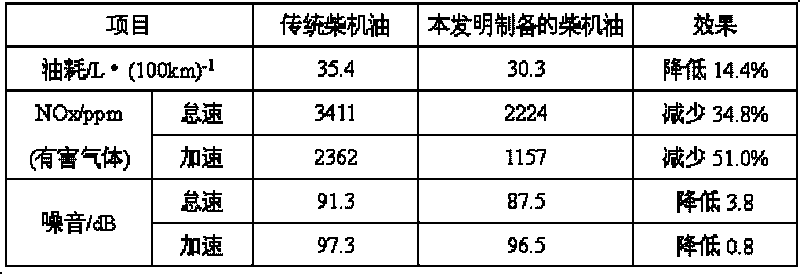

[0045] Diesel engine oil prepared by the present invention is tried out on No. 04 car (Xiang A 09495) of No. 142 bus fleet in Chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com