Secondary envelope cycloid planet driving device

A secondary enveloping and planetary transmission technology, applied in transmission, gear transmission, belt/chain/gear, etc., can solve the problems of increasing the force of eccentric bearing, large accumulated error, large curvature of induced method, etc. The effect of improving lubricating properties, improving rolling performance, and reducing accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the drawings.

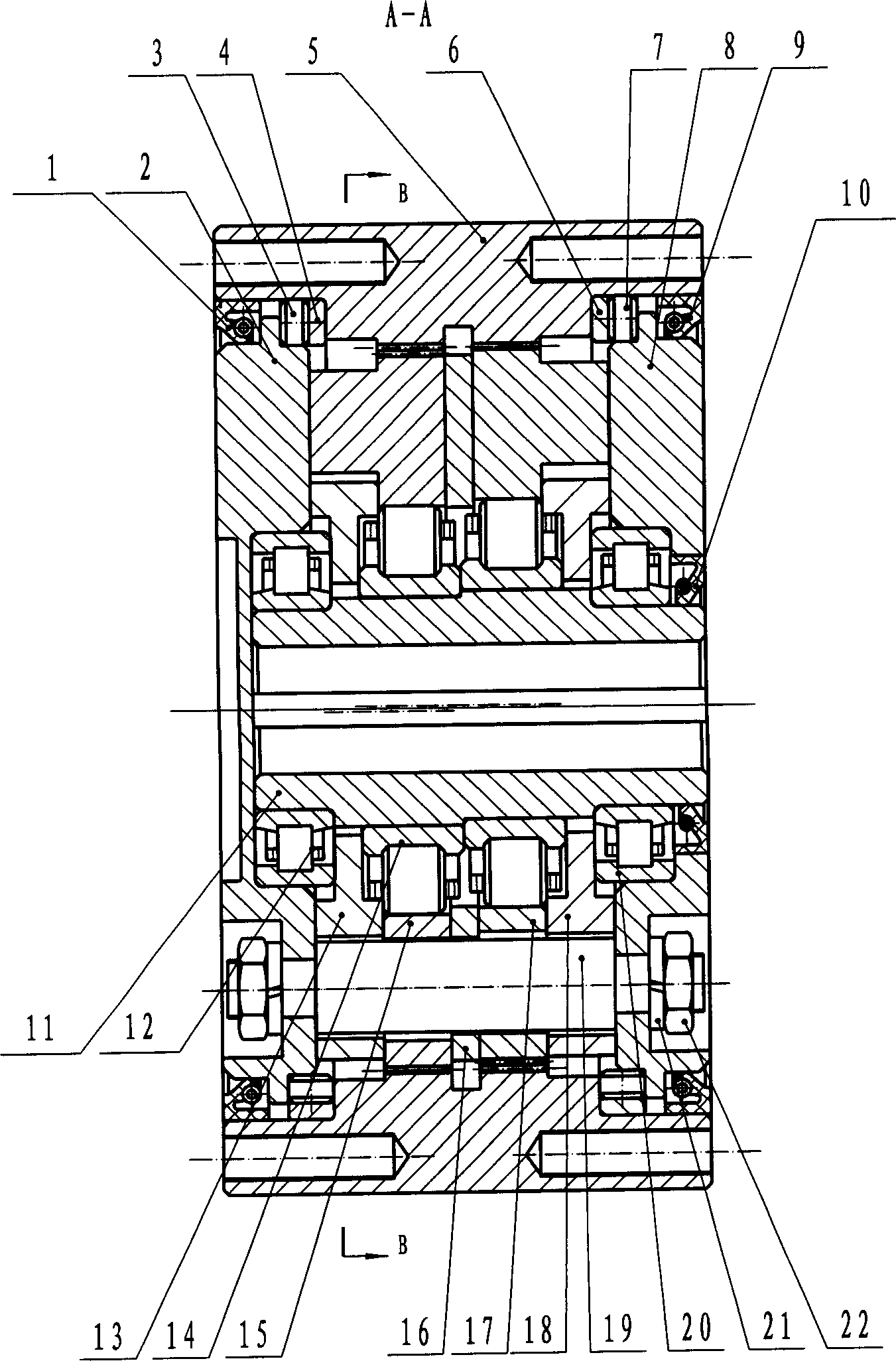

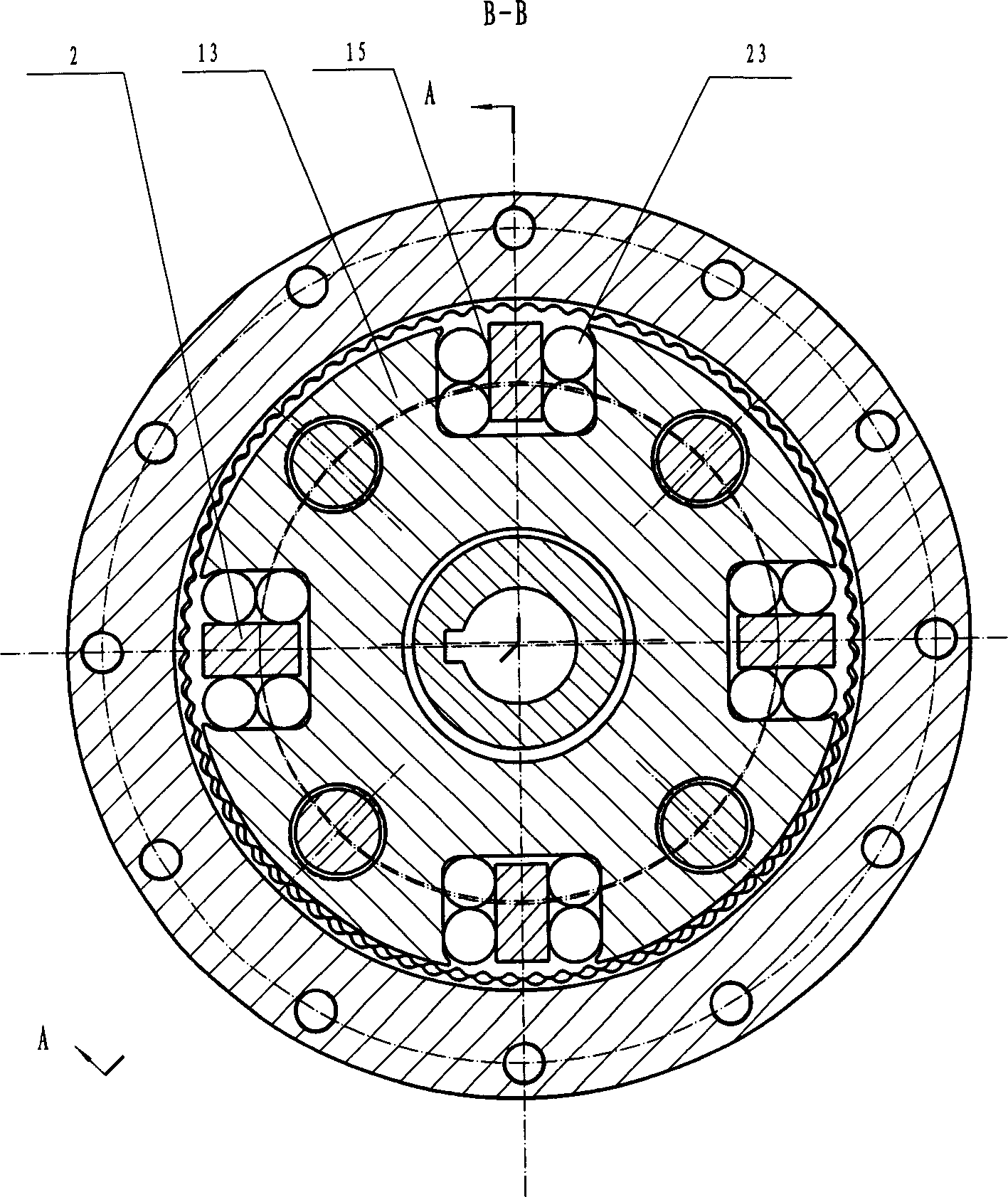

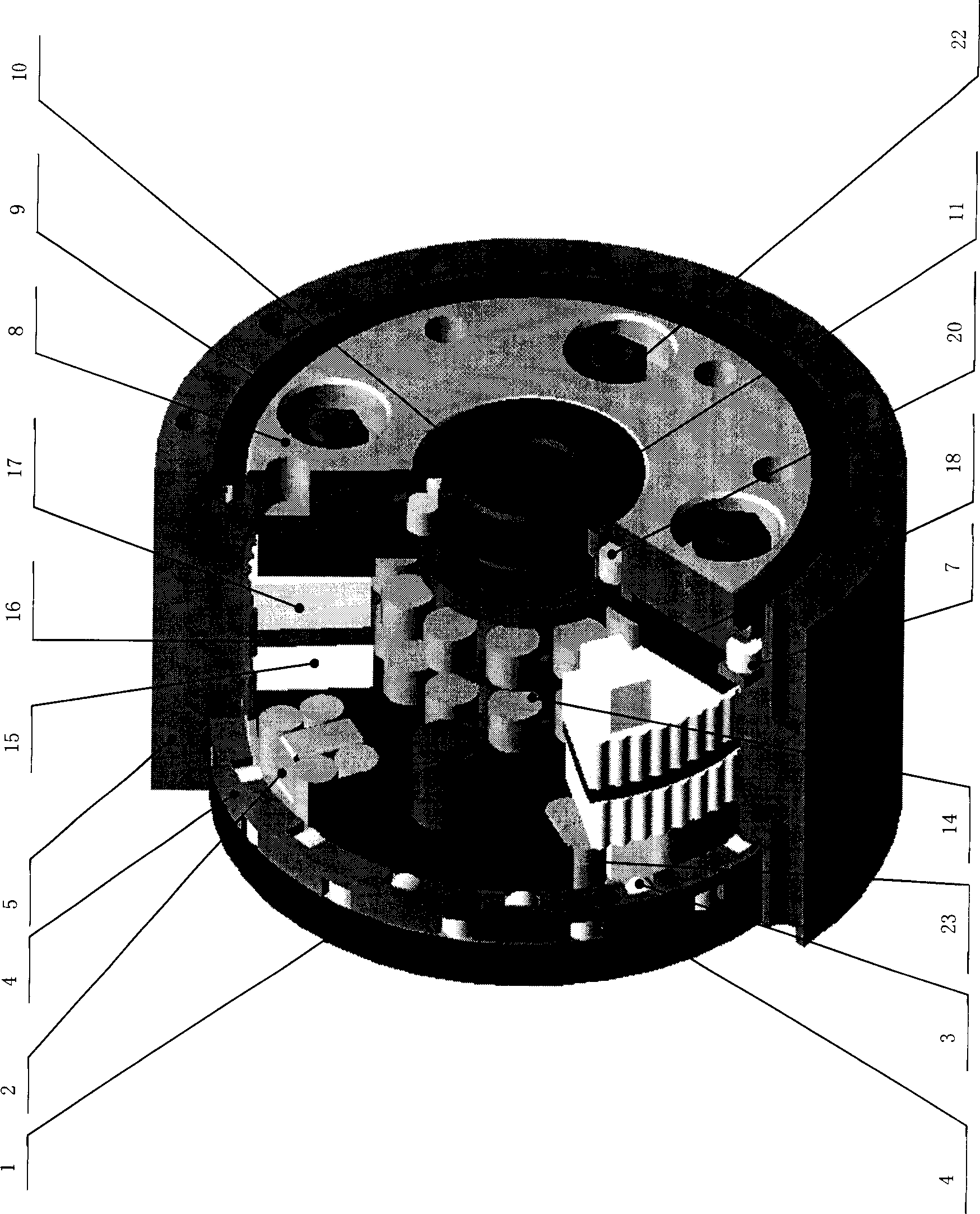

[0034] in figure 1 , 2 In 3, the tooth profile of the internal gear 5 is a secondary action tooth surface enveloped by the planetary motion of the cycloidal gear. The two cycloidal gears 15, 17 are mounted on the double eccentric bearing 14 in the middle of the input shaft 11. The tooth profile of the line wheels 15 and 17 and the tooth profile of the internal gear 5 form a conjugate meshing pair. In a certain area, the internal gear 5 and the pair of gear teeth of the cycloid wheel 15 and 17 produce two contact lines, and the second time The curvature of the enveloping point induction method tends to zero, which is conducive to improving the carrying capacity and improving the lubrication characteristics. At the same time, the number of contact points is greatly increased, which can give full play to the error equalization effect and improve the transmission accuracy; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com