Machining method for cross-scale staggered embedded type self-lubricating gear surface

A processing method and self-lubricating technology, used in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve problems such as failure to achieve self-lubricating purposes, reduced self-lubricating properties, and failure to achieve lubrication purposes, and achieve production efficiency. High, improved surface strength, reliable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A method for processing the surface of a cross-scale staggered embedded self-lubricating gear of the present invention will be further described below in conjunction with the accompanying drawings:

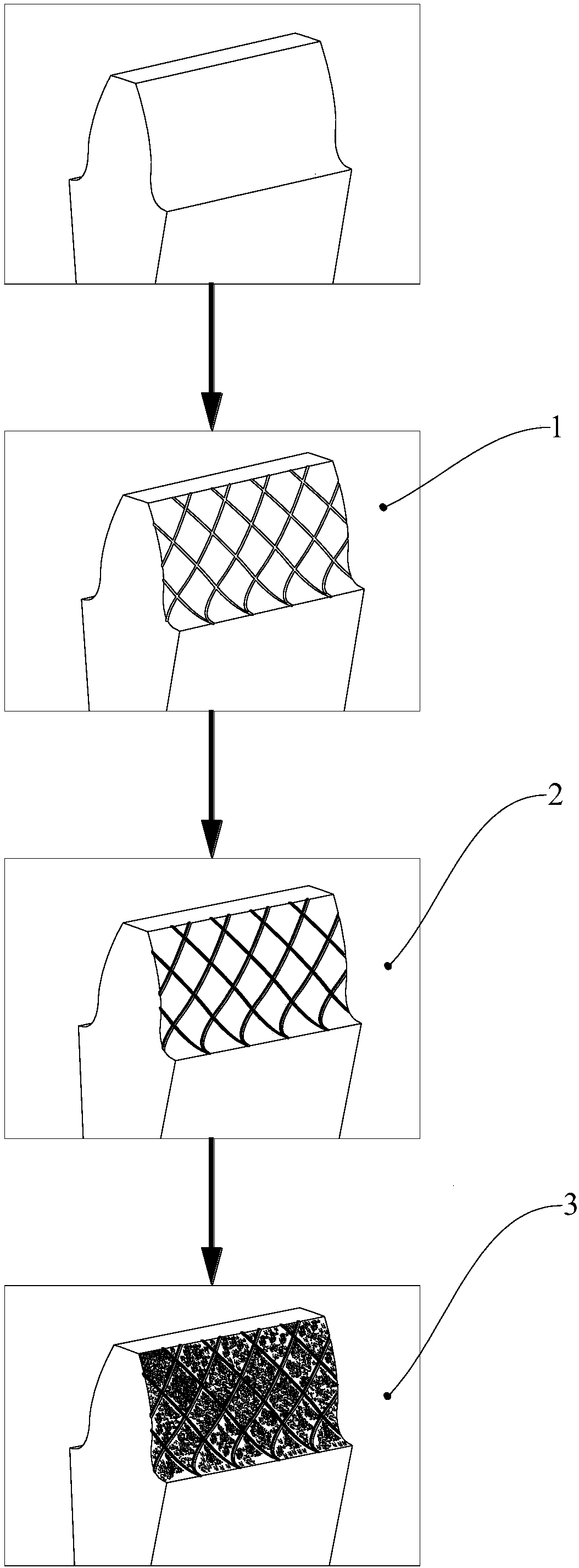

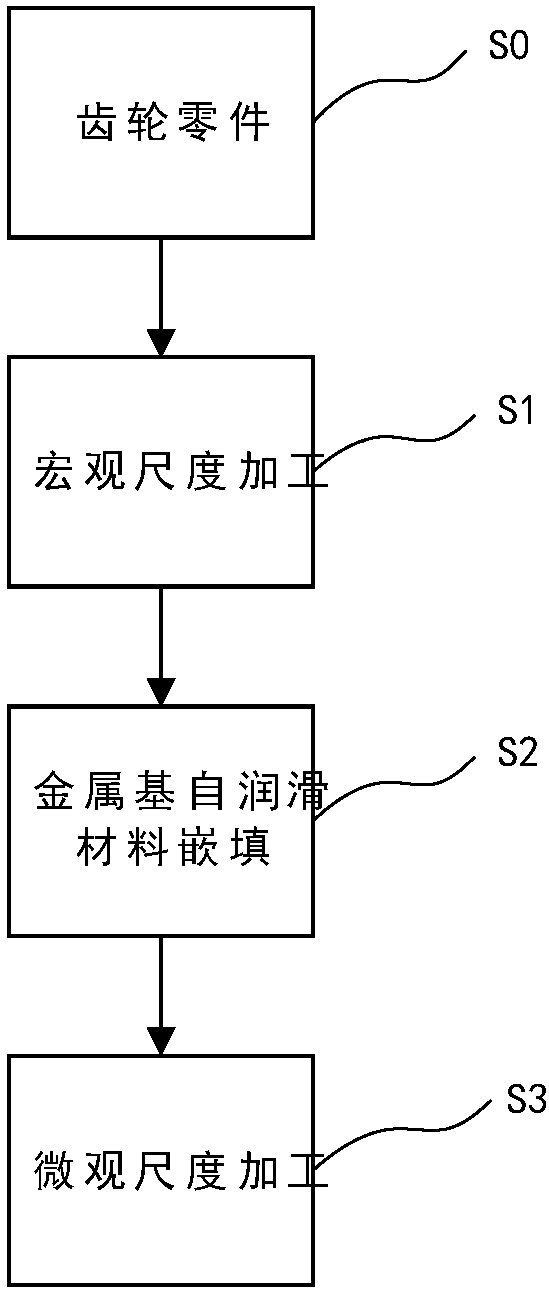

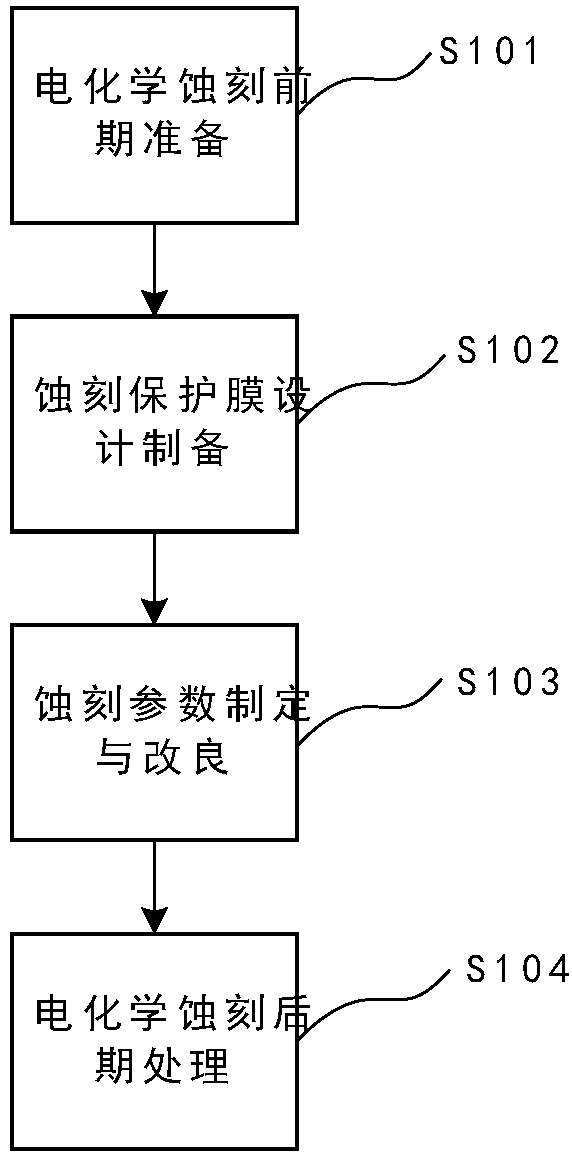

[0026] Such as figure 1 , figure 2 and image 3 As shown, step S0 is to introduce the processed 20Cr gear parts, and step S1 is the macro-scale processing 1 of the gear surface in this embodiment; in this embodiment, the macro-scale processing 1 of the gear surface uses an electrochemical machining method, and the process is as follows: Perform step S101 preparation for electrochemical etching, including cleaning the surface of the gear part and removing burrs on the gear surface, recording the necessary parameters of the gear part, and setting electrochemical related parameters; performing step S102 according to the parameters of the gear part to design and prepare the etching protective film, Prepare the protective film required for etching the surface of the gear part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com