Carbon fiber reinforced pantograph carbon sliding plate and manufacturing method thereof

A pantograph carbon slide plate and carbon fiber technology, which is applied in the field of electric locomotives, can solve the problems of unstable product performance, performance degradation, and low bonding strength, and achieve mass production, simple manufacturing methods, and excellent comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

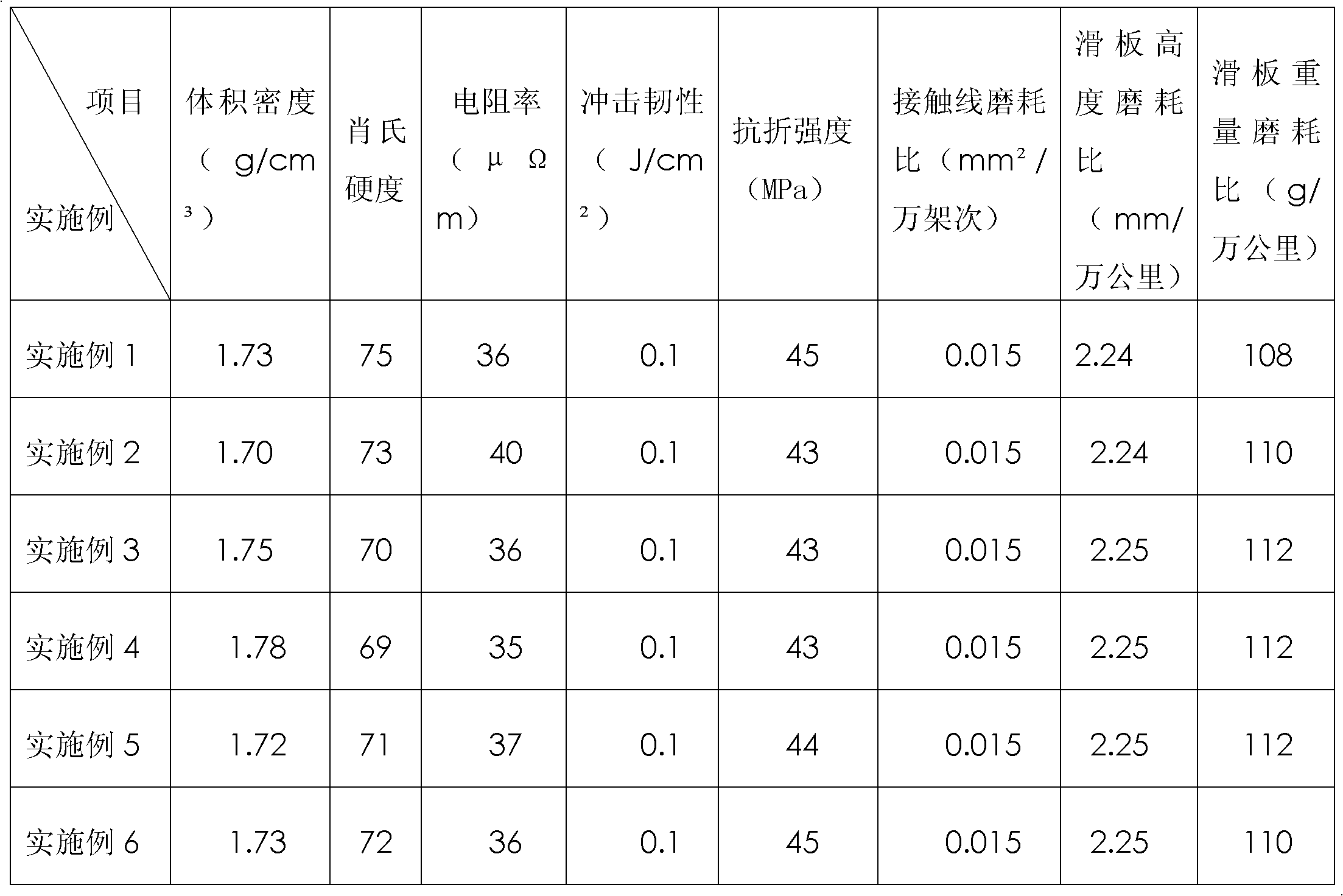

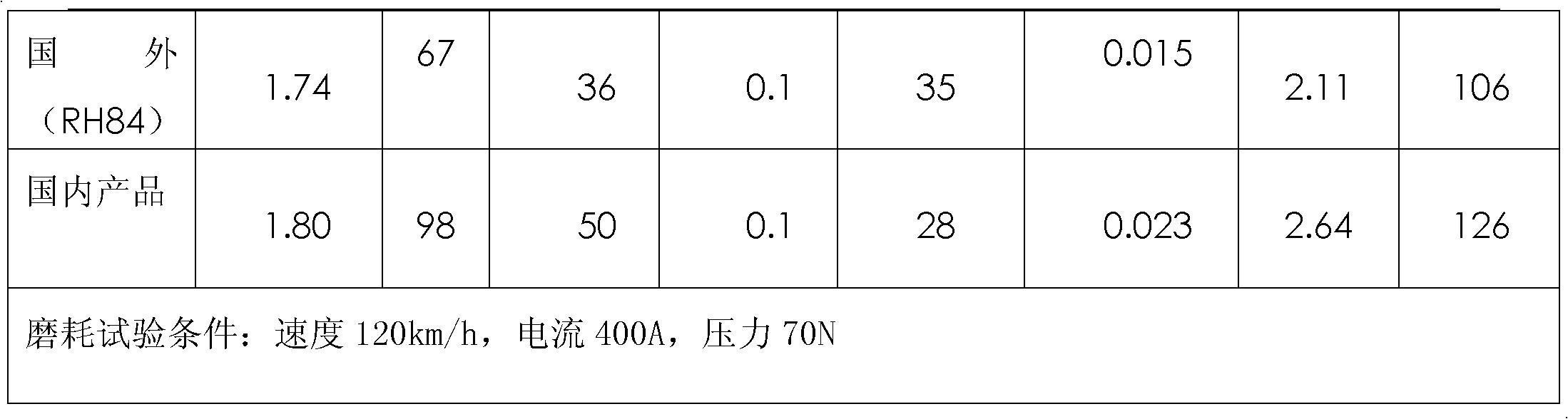

Examples

Embodiment 1

[0029] The intercalated graphite added to the carbon fiber reinforced pantograph carbon slide plate in this example is a copper-graphite intercalation compound.

[0030] The preparation of the copper-graphite intercalation compound includes the following steps:

[0031] 1. Mix the natural flake graphite and anhydrous copper chloride at a molar ratio of 2:3 and add them into a stainless steel pressure tank.

[0032] 2. Seal the stainless steel pressure tank and place it in a pit furnace, and heat it to 450-550°C at a heating rate of 2°C / min. After the heat preservation reaction for 72 hours, the temperature will be naturally cooled to room temperature to obtain copper chloride-graphite interlayer Compound.

[0033] 3. Spread the copper chloride-graphite interlayer compound in a stainless steel tray and place it in a hydrogen reduction furnace. After evacuating to 0.1MPa, add hydrogen at a flow rate of 1 to 2L / min, and at the same time press 1℃ / min The heating rate is heated to 450~500...

Embodiment 2

[0043] Others are the same as Example 1, except that intercalated graphite is 30% (weight ratio), petroleum coke is 40% (weight ratio), carbon fiber is 5% (weight ratio), and medium temperature pitch is 25% (weight ratio).

Embodiment 3

[0045] Others are the same as in Example 1, except that intercalated graphite is 50% (weight ratio), petroleum coke is 20% (weight ratio), carbon fiber is 2% (weight ratio), and medium temperature pitch is 28% (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com