Patents

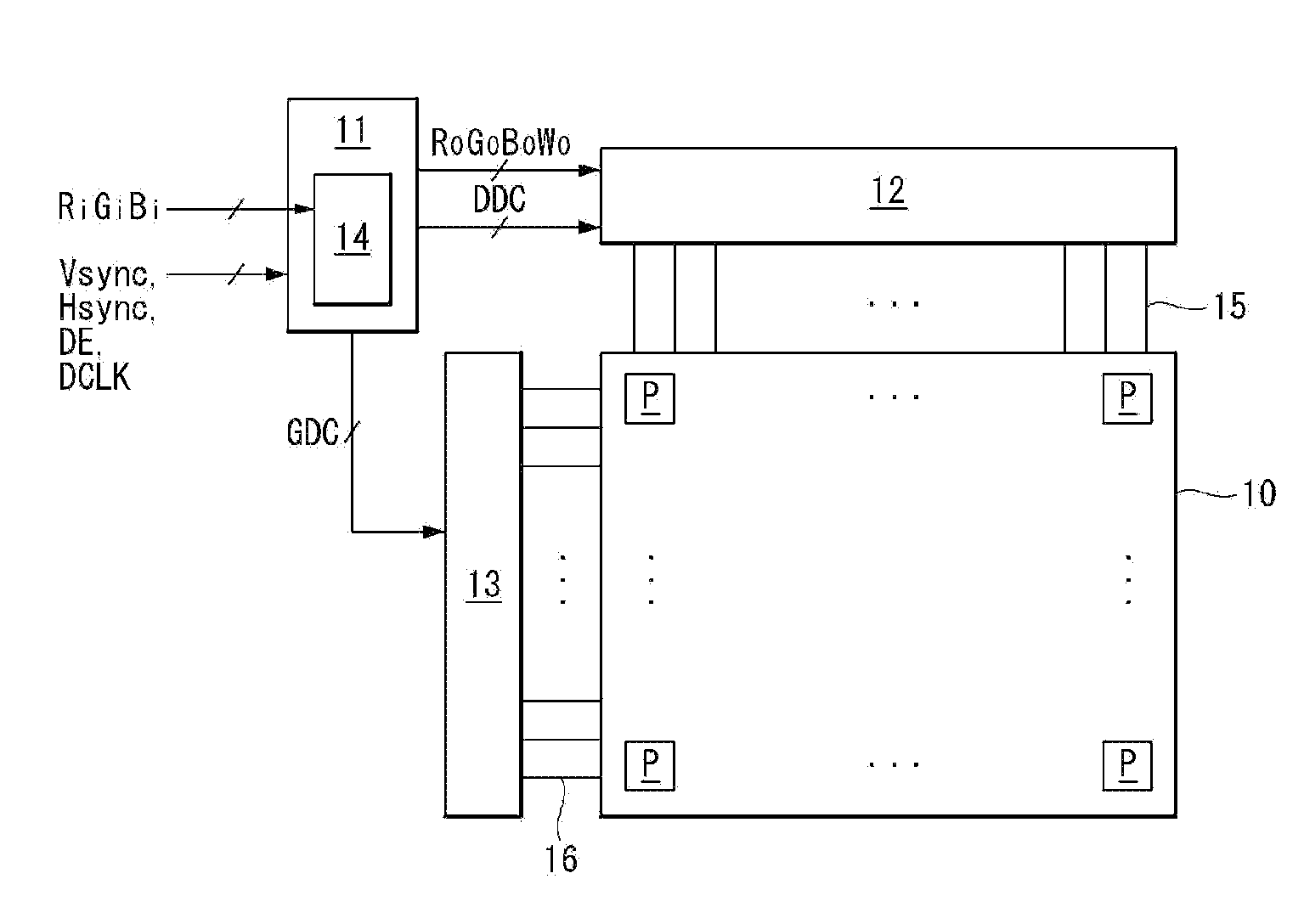

Literature

74results about How to "Increase gain value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

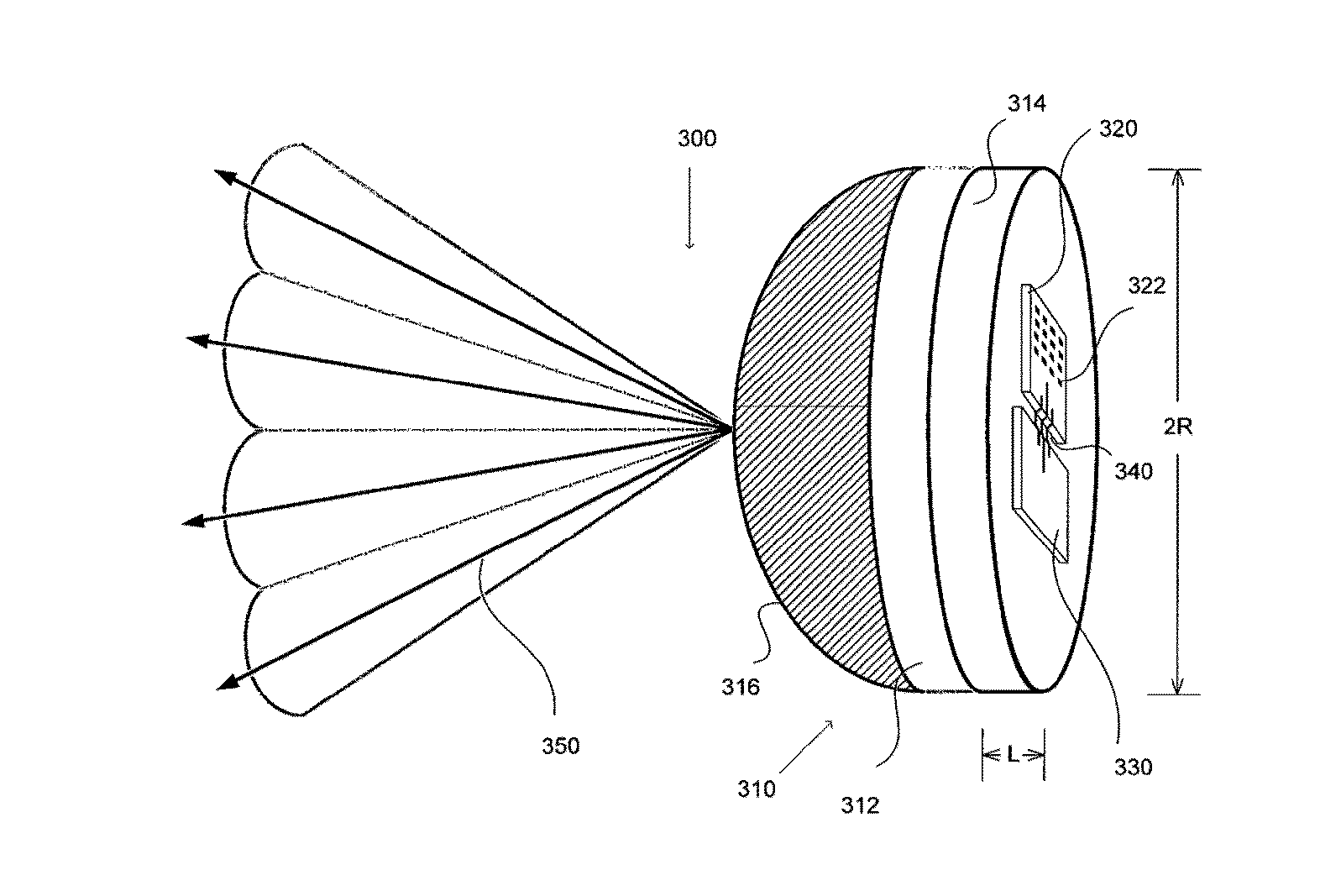

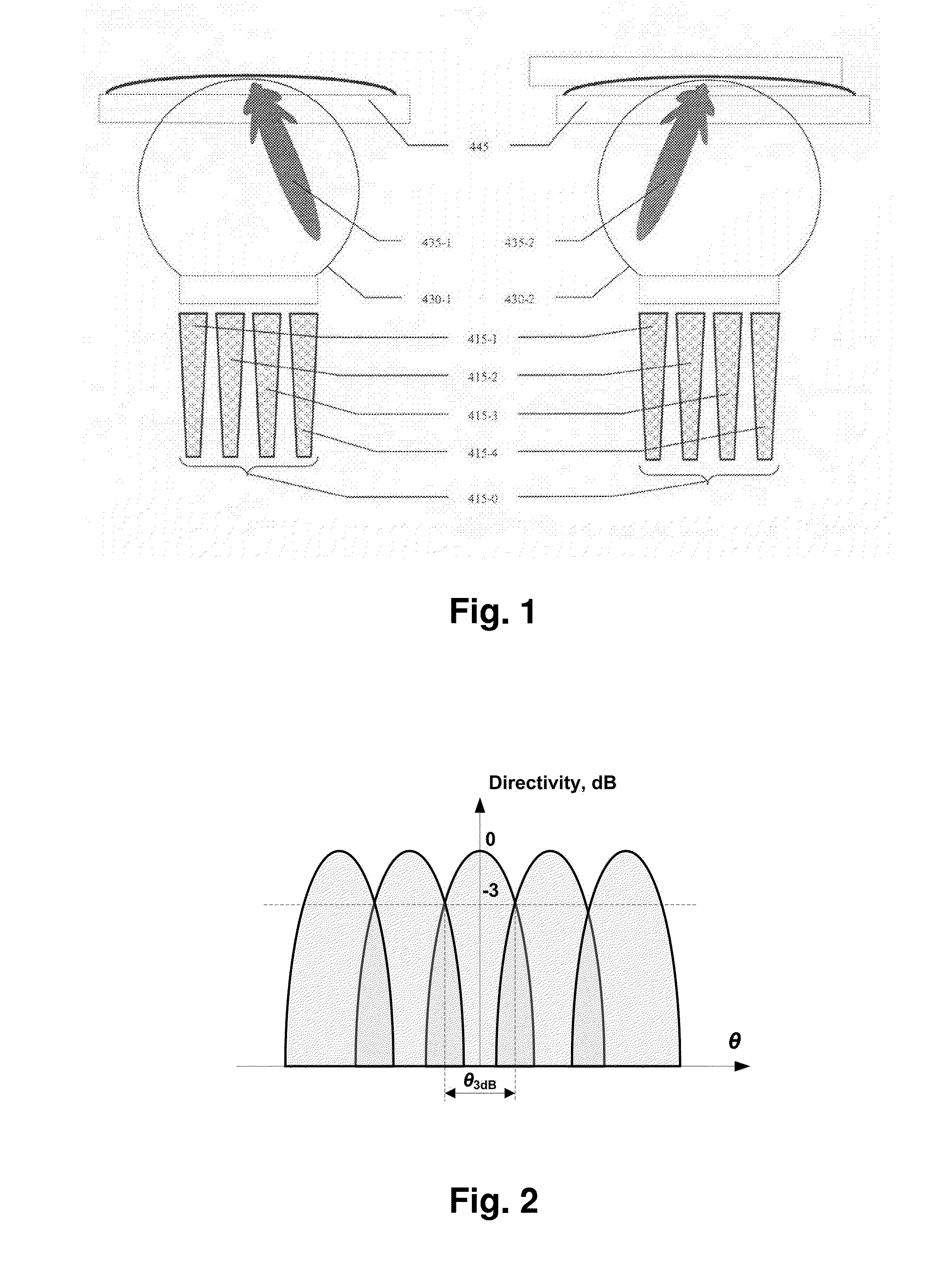

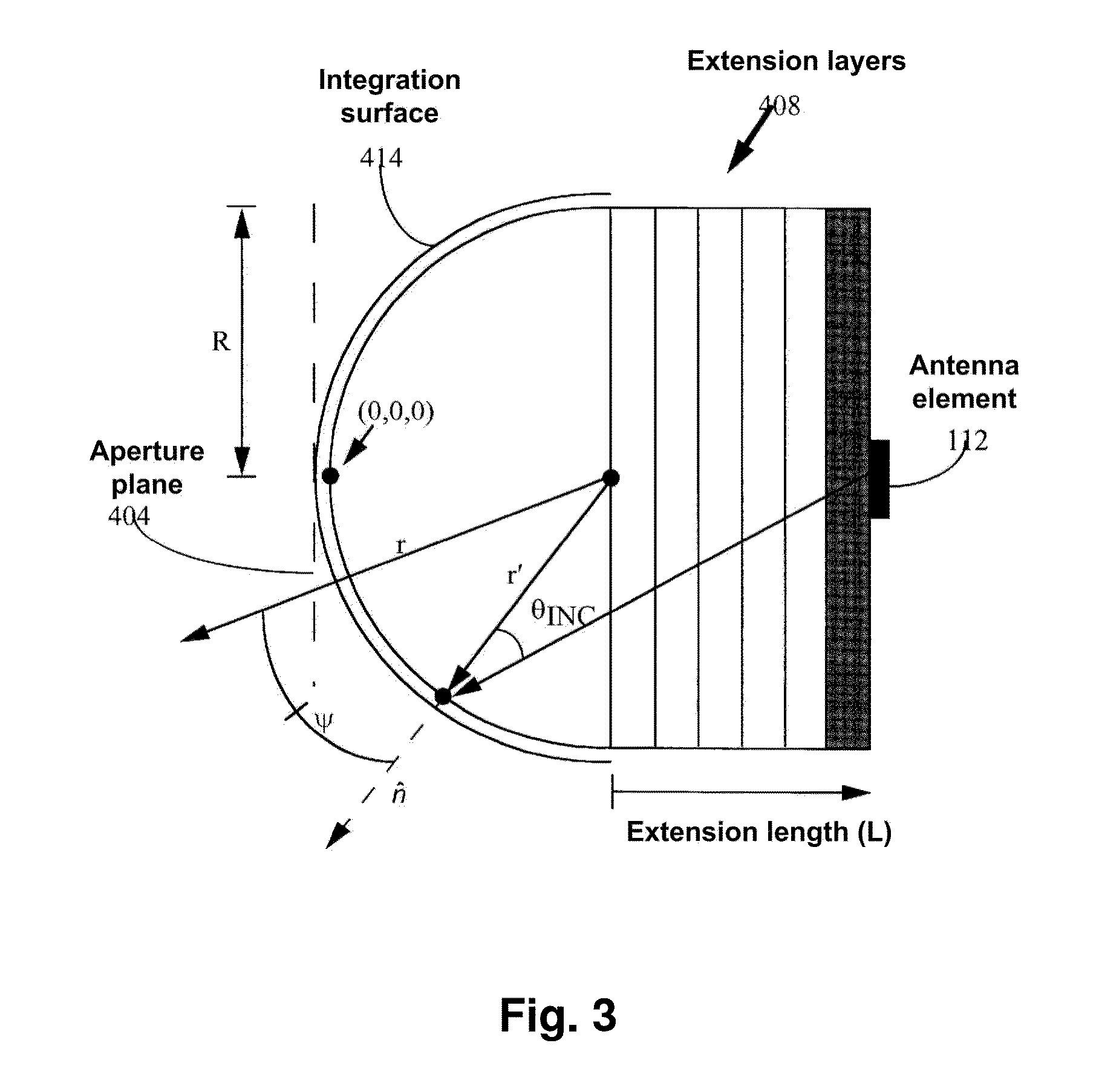

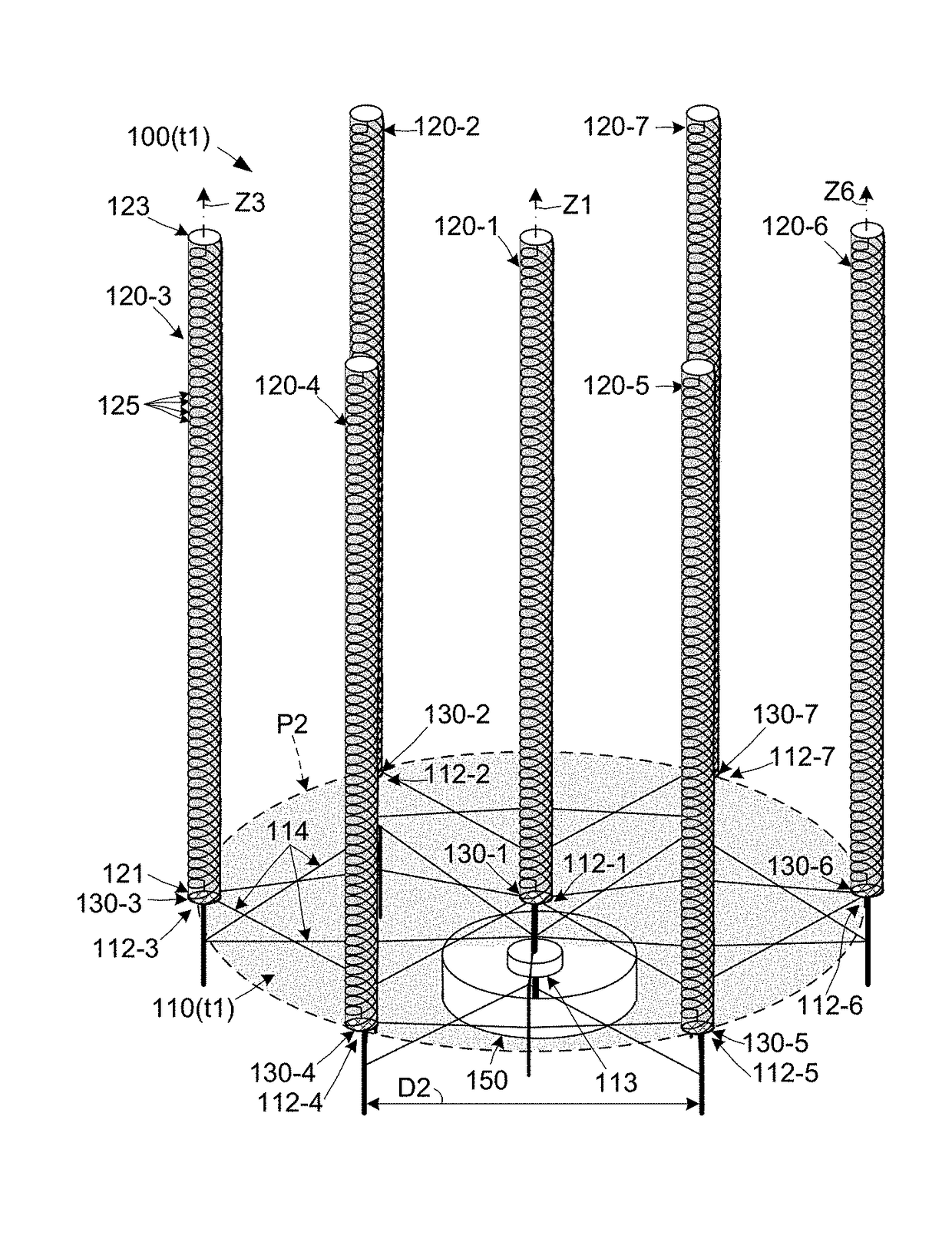

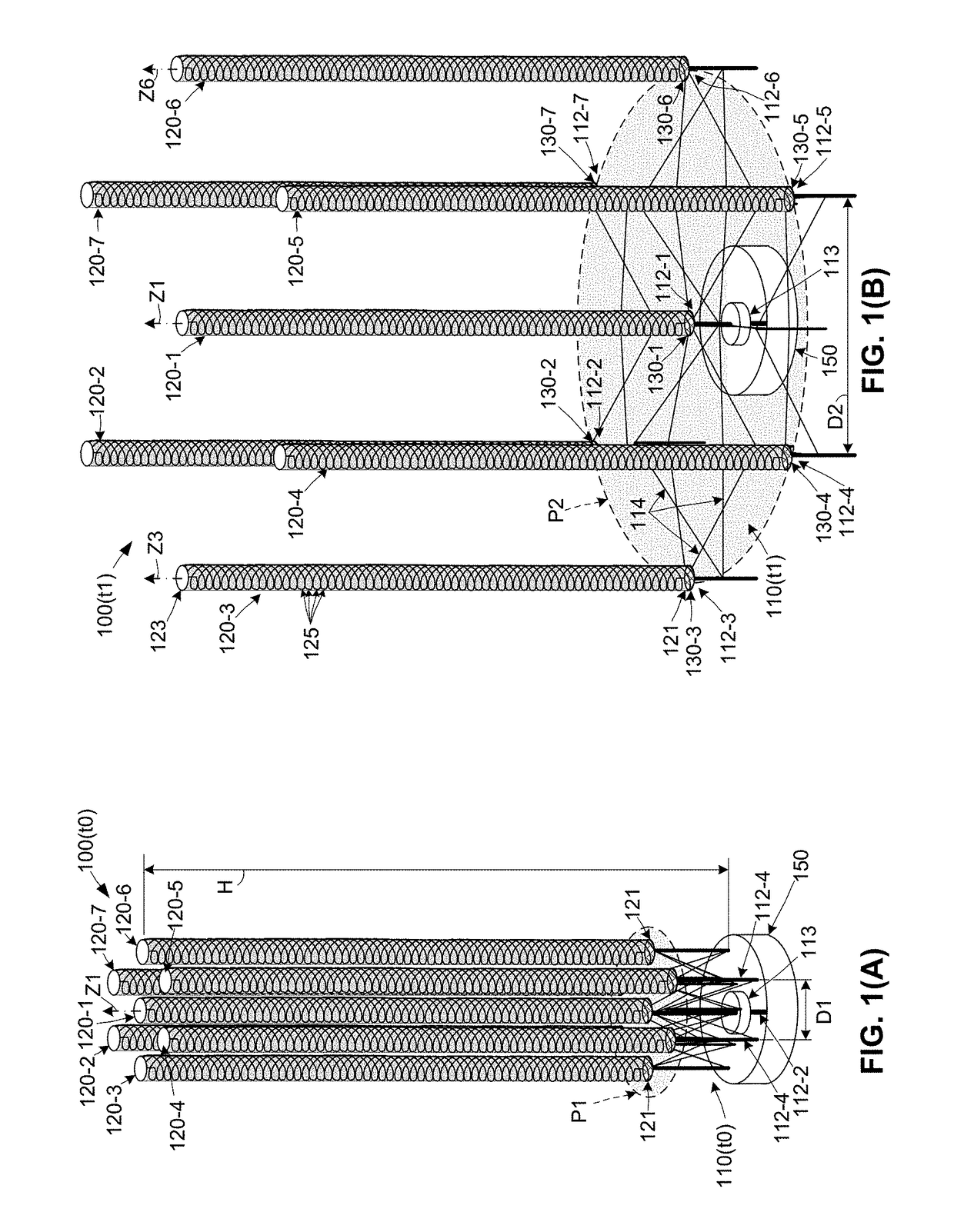

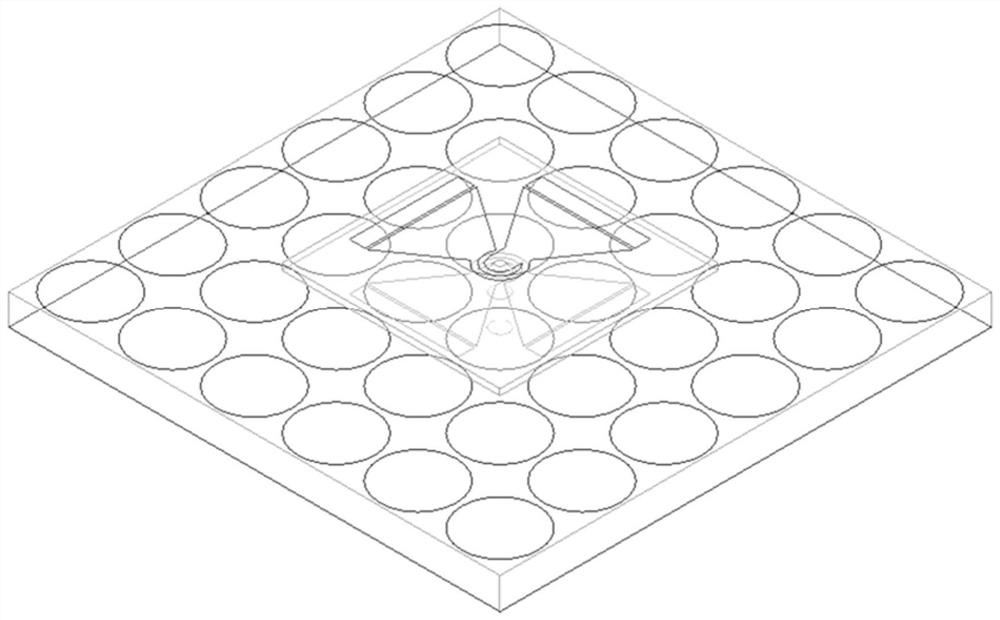

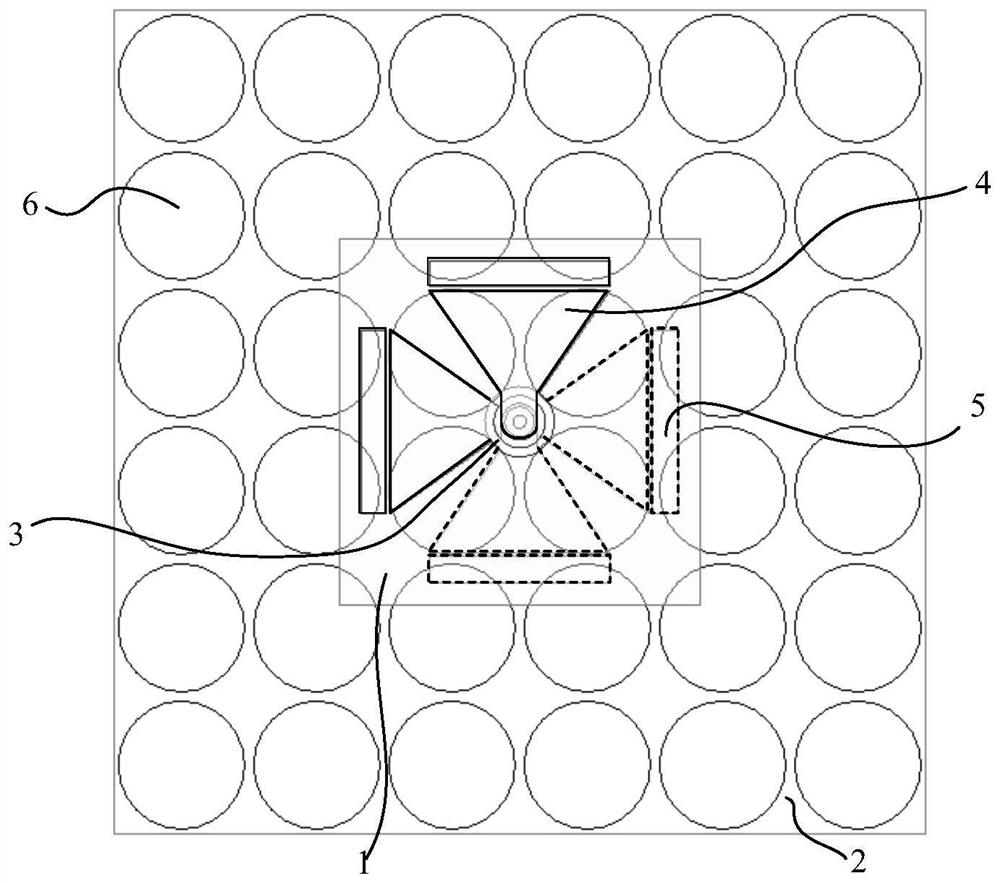

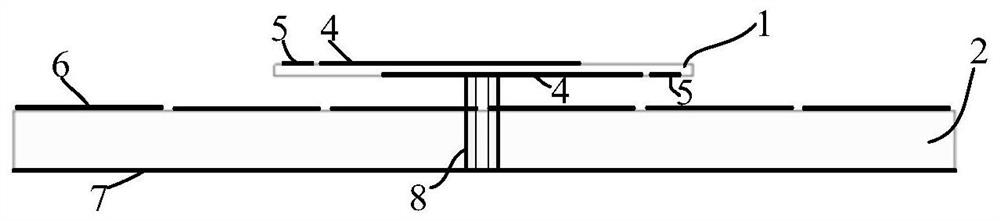

Lens antenna with electronic beam steering capabilities

InactiveUS20150116154A1Improve directivityImprove radiation efficiencyWaveguide hornsAntenna gainRadio relay

The invention discloses a lens antenna with high directivity intended for use in radio-relay communication systems, said antenna providing the capability of electronic steering of the main radiation pattern beam by switching between horn antenna elements placed on a plane focal surface of the lens. Electronic beam steering allows antenna to automatically adjust the beam direction during initial alignment of transmitting and receiving antennas and in case of small antenna orientation changes observed due to the influence of different reasons (wind, vibrations, compression and / or extension of portions of the supporting structures with the temperature changes, etc.). The technical result of the invention is the increase of the antenna directivity with simultaneously provided capability of scanning the beam in a continuous angle range and also the increase of the antenna radiation efficiency and, consequently, the increase of the lens antenna gain. This result is achieved by the implementation of horn antenna elements with optimized geometry.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETSTVENNOSTYU RADIO GIGABIT

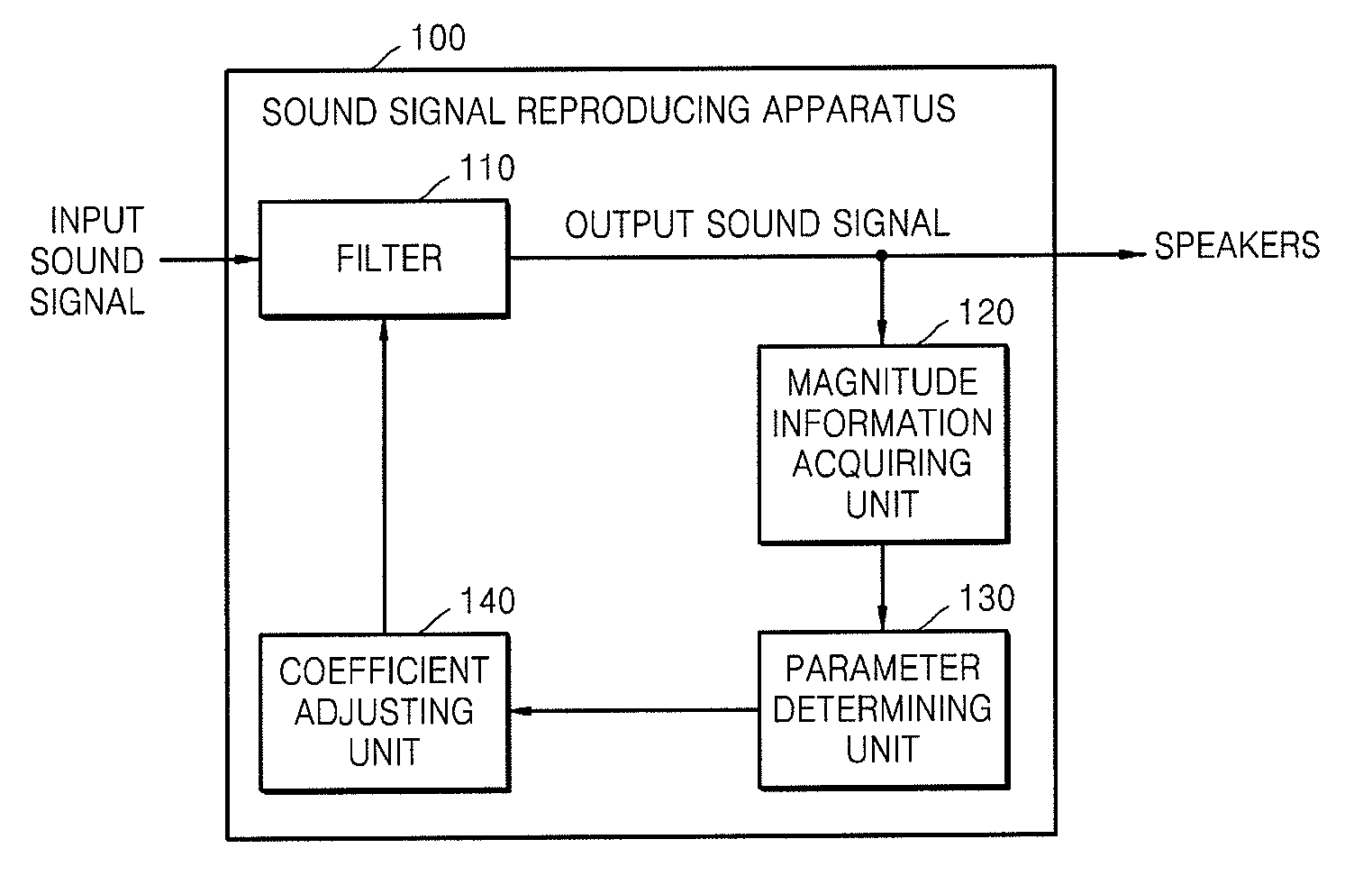

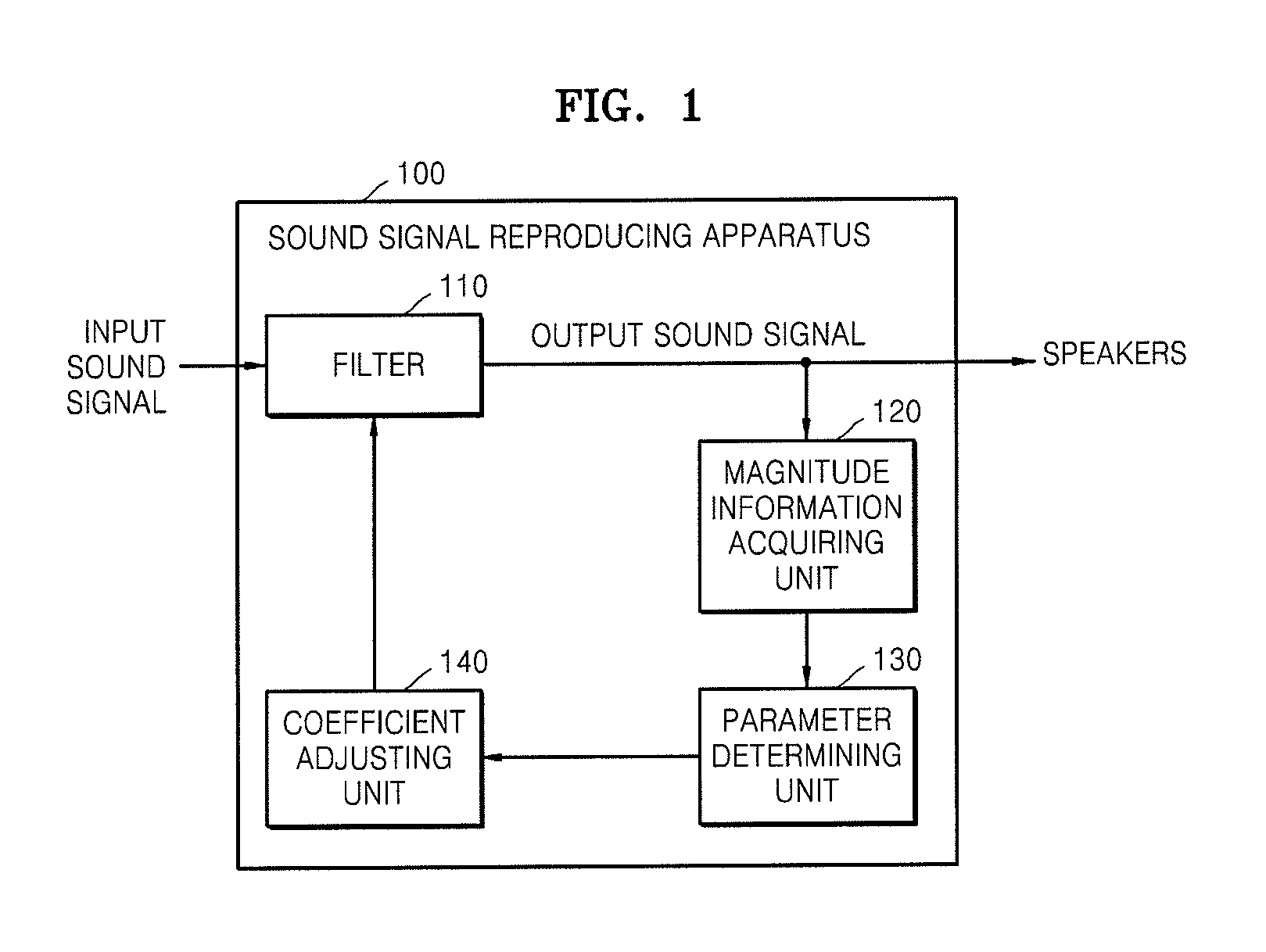

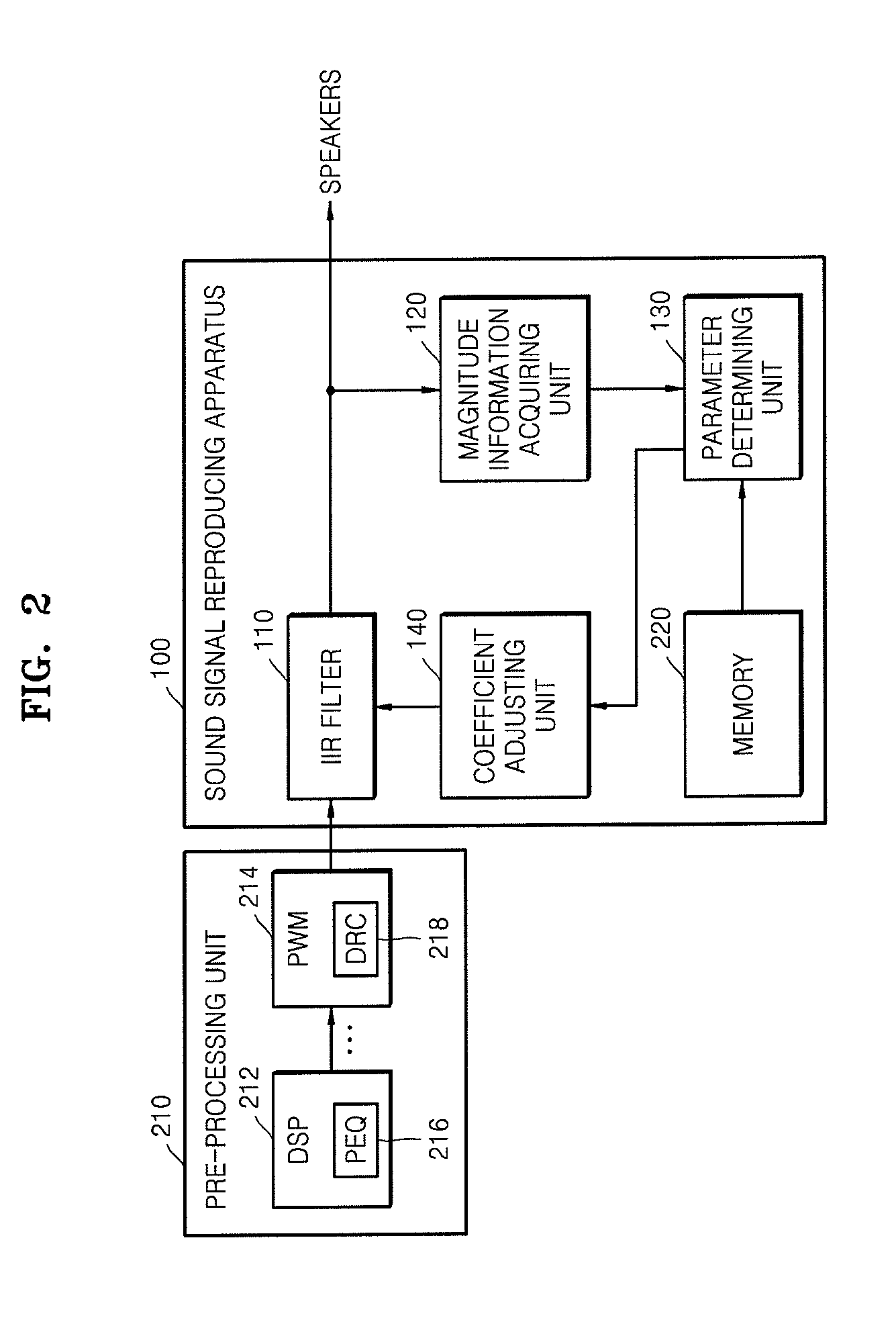

Method and apparatus for reproducing audio signal by adaptively controlling filter coefficient

InactiveUS20120051558A1Increase gain valueDigital/coded signal combination controlTransducer casings/cabinets/supportsAudio signal flowLoudspeaker

A method and an apparatus for reproducing a sound signal are provided. The method includes generating an output sound signal to be transmitted to speakers by transmitting a first input sound signal through a filter; acquiring magnitude information of the output sound signal; determining frequency response parameters related to frequency responses of the filter based on the magnitude information; and adaptively adjusting coefficients of the filter based on the determined frequency response parameters.

Owner:SAMSUNG ELECTRONICS CO LTD

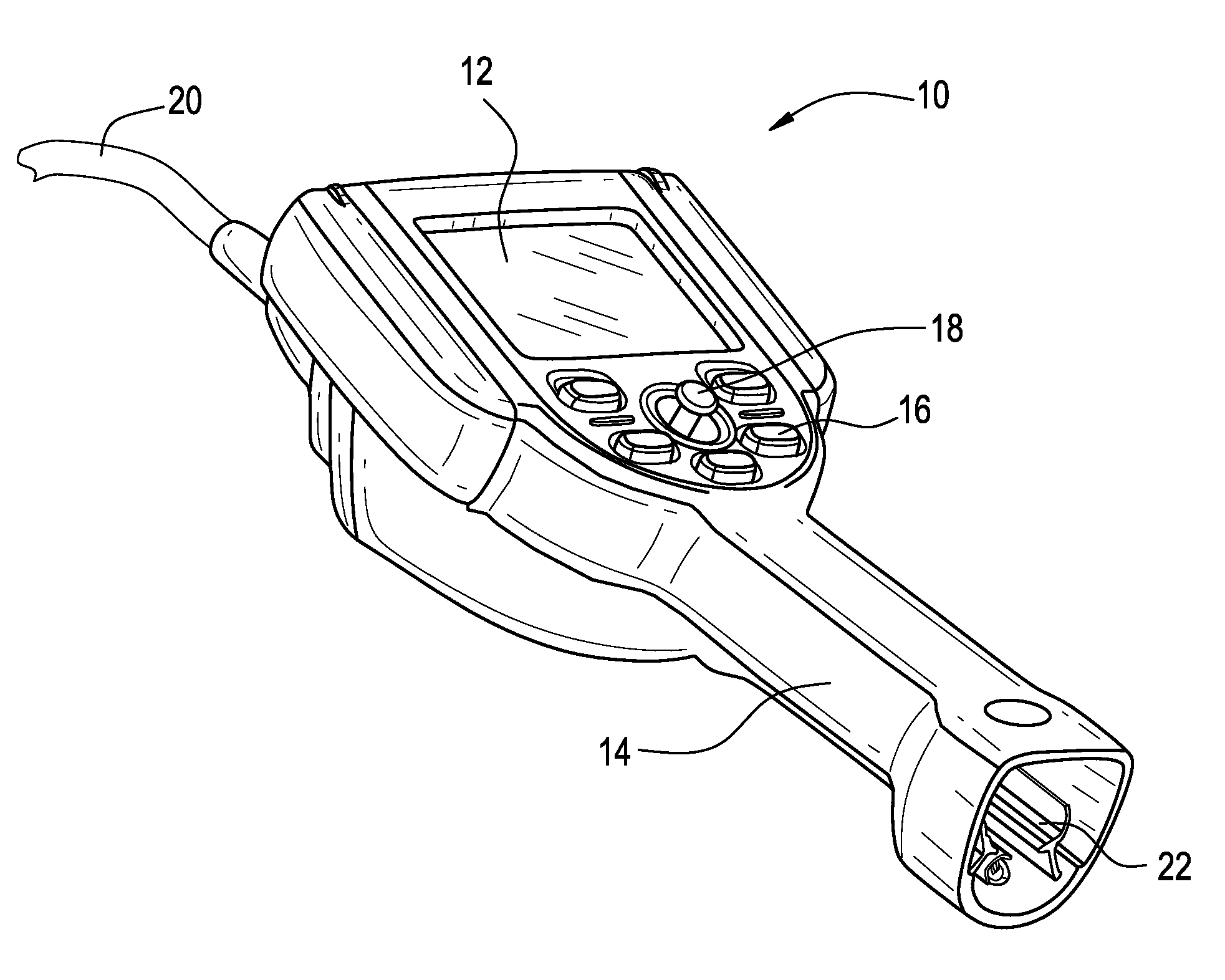

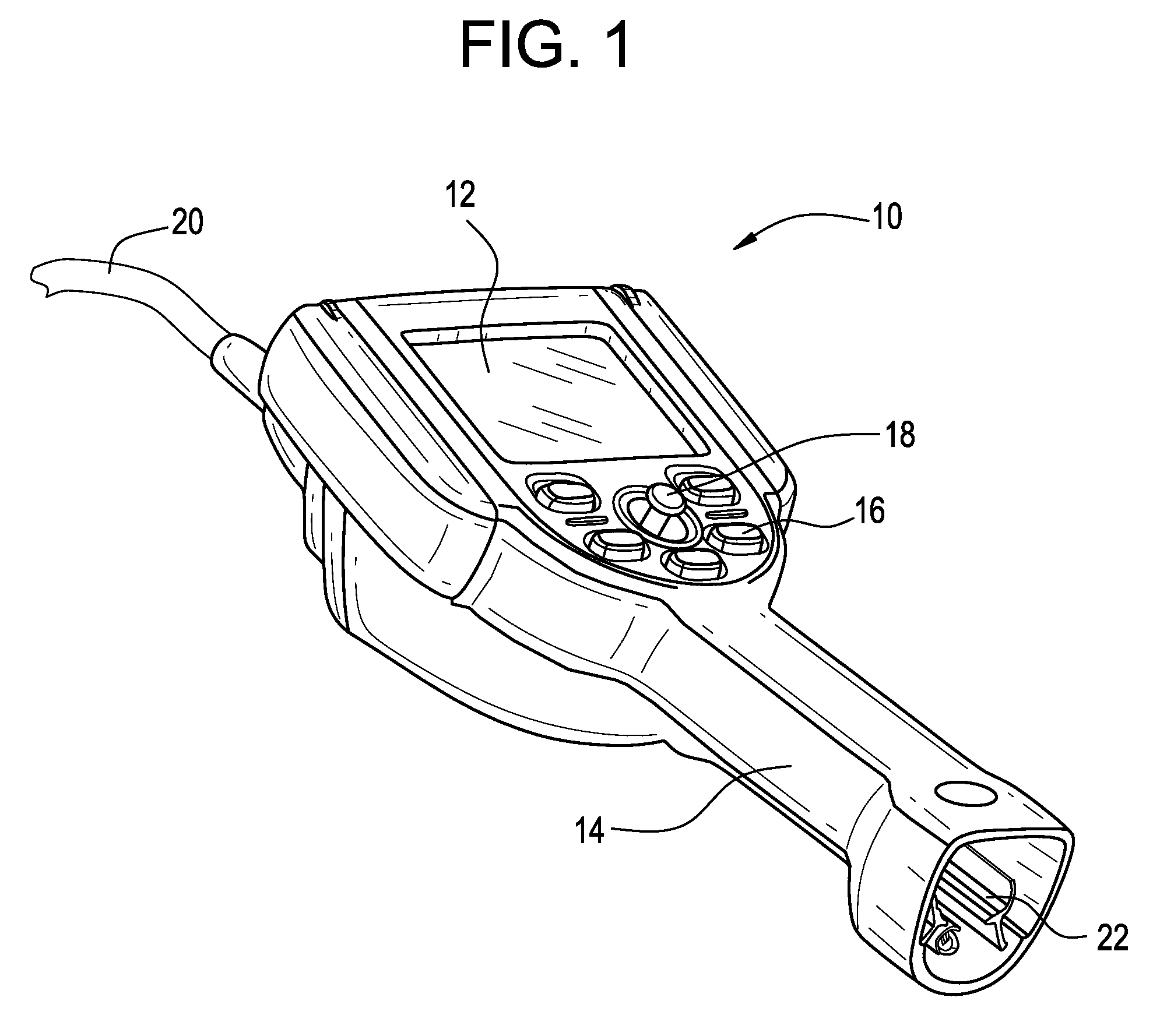

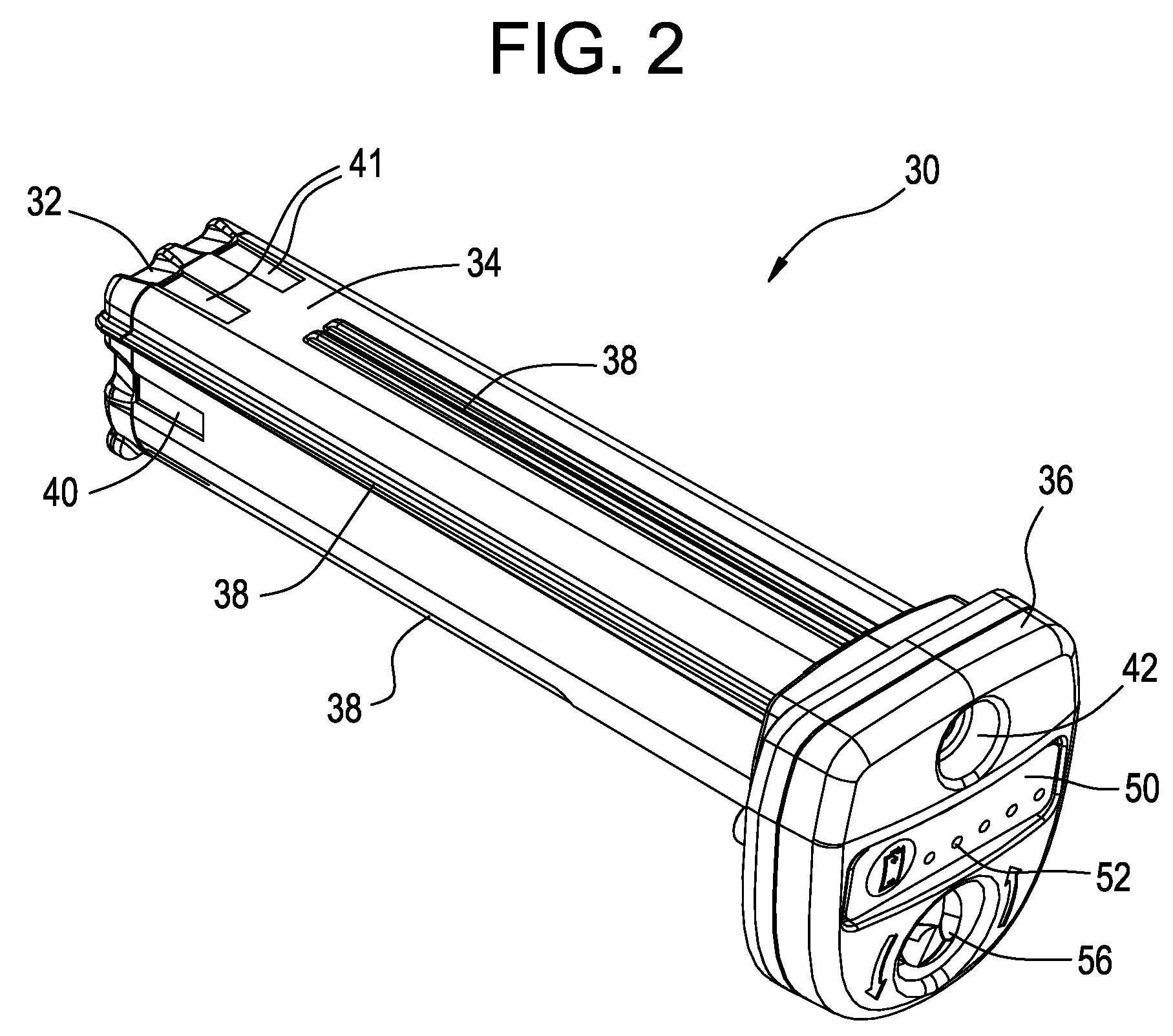

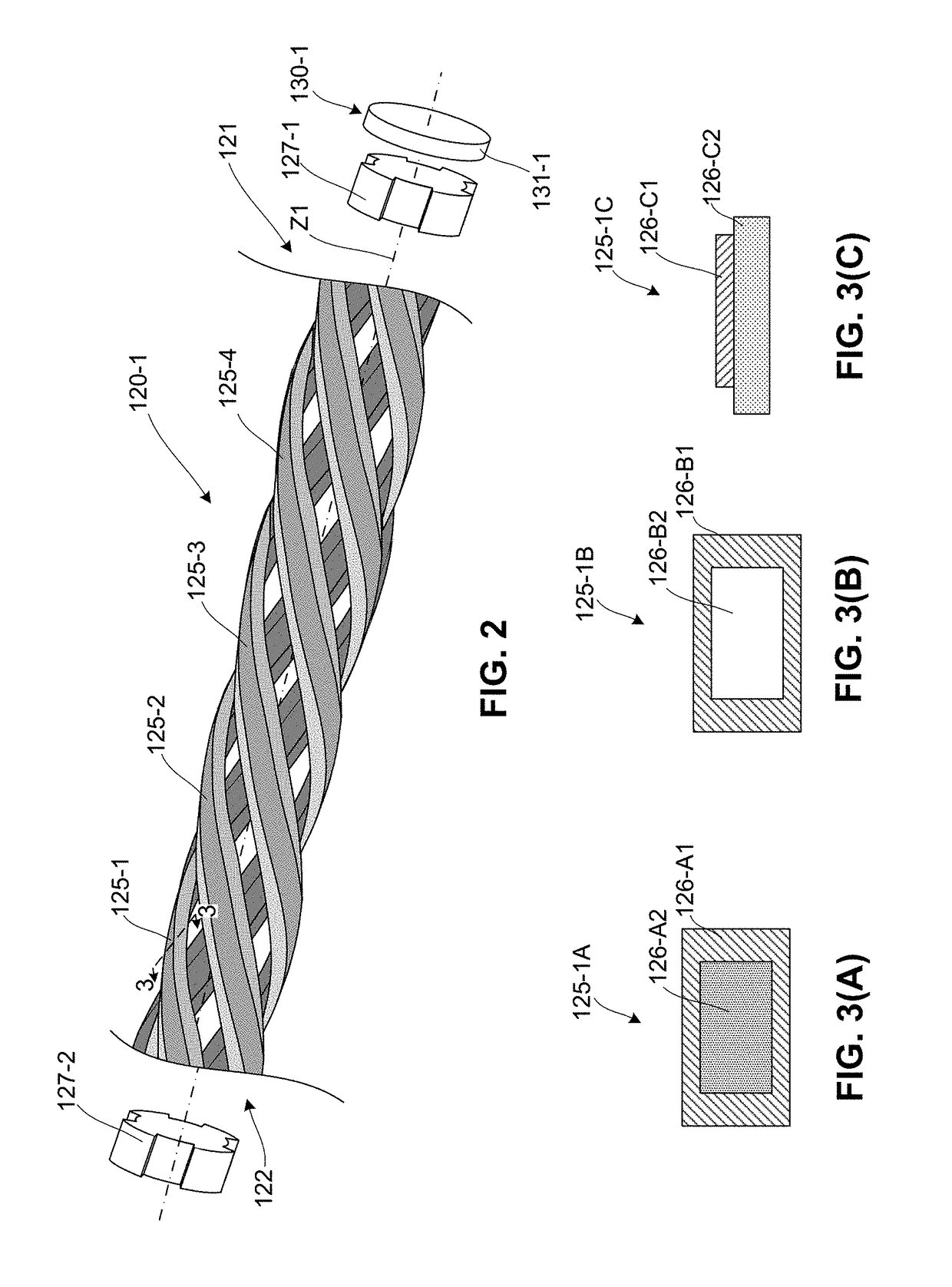

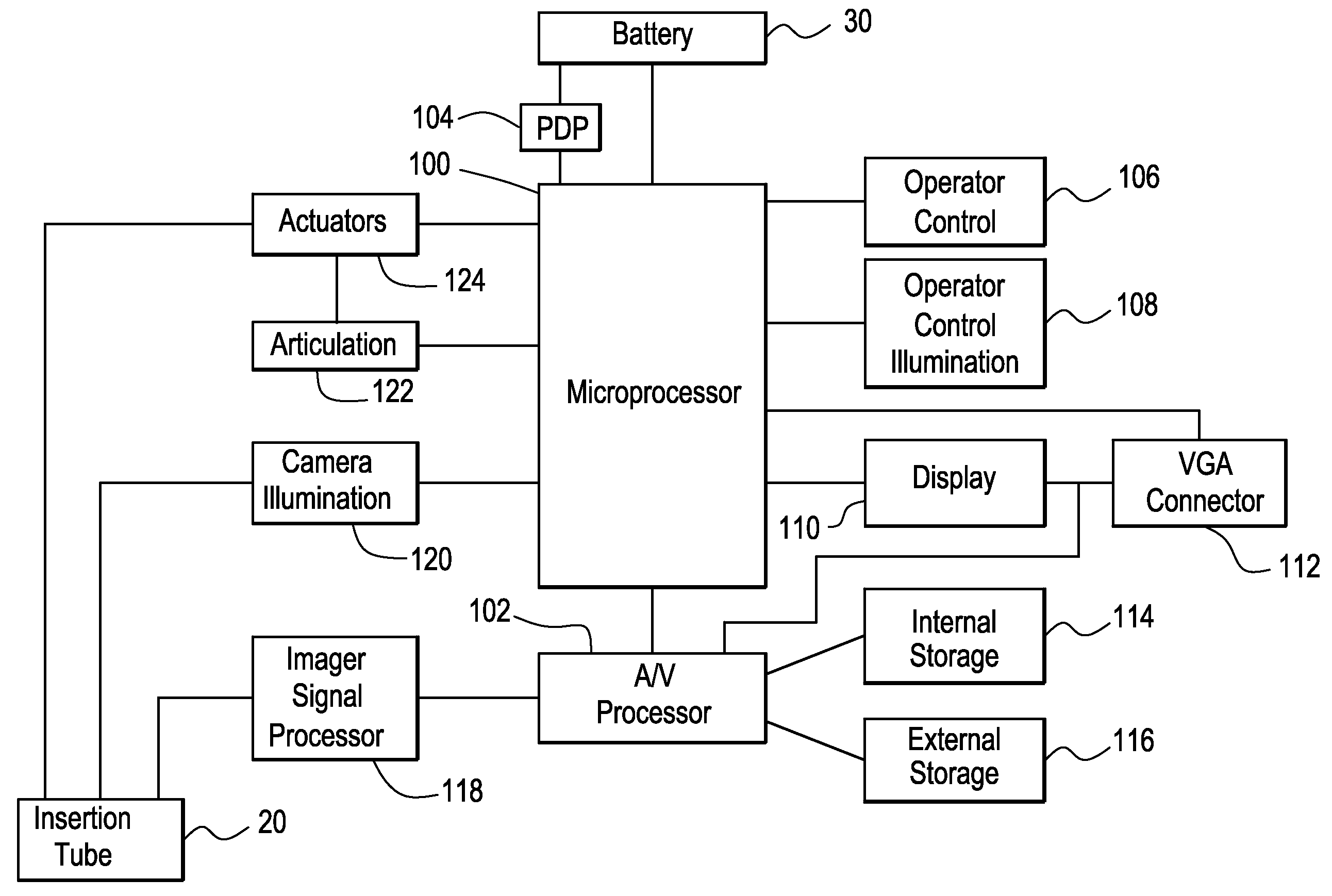

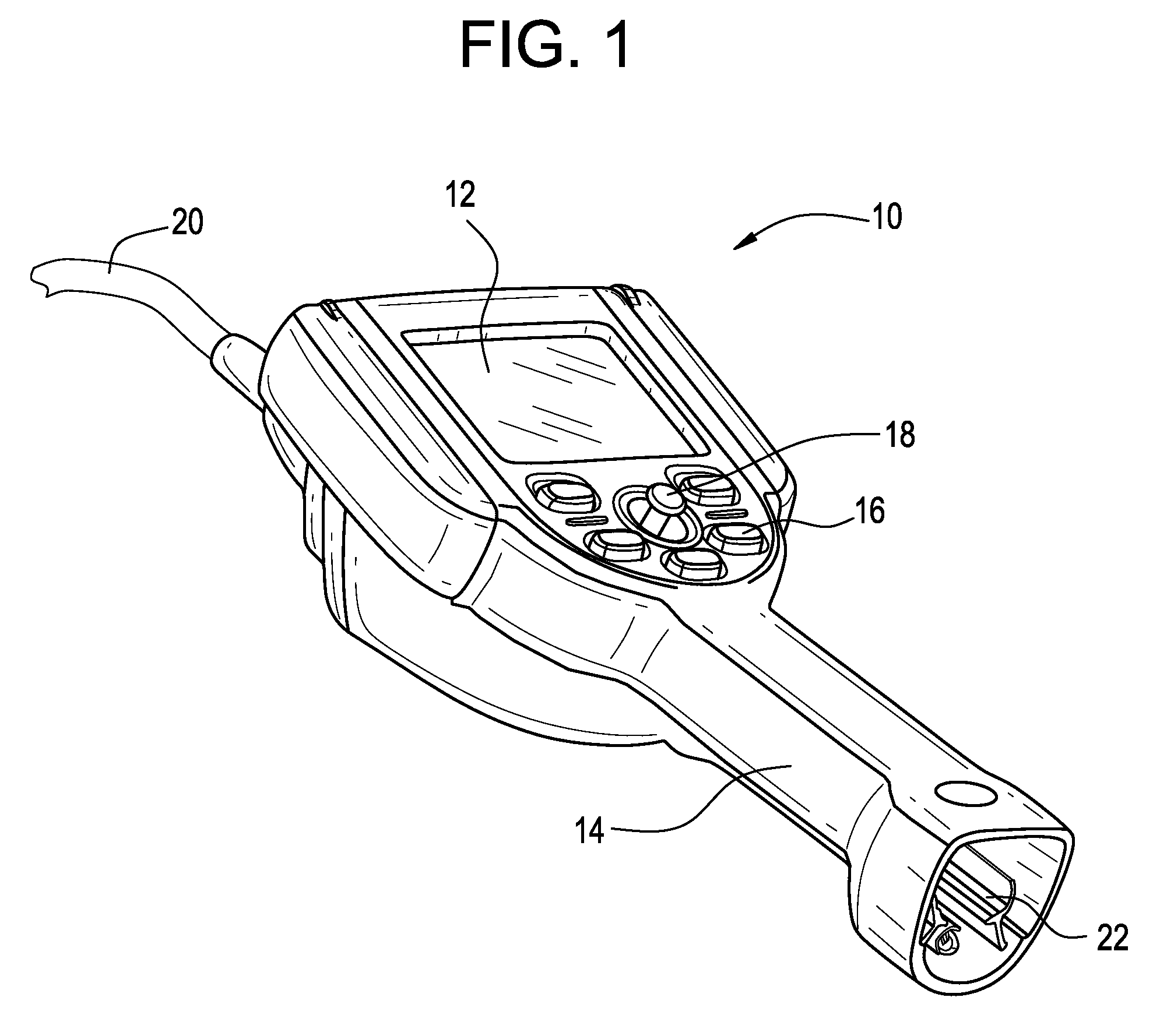

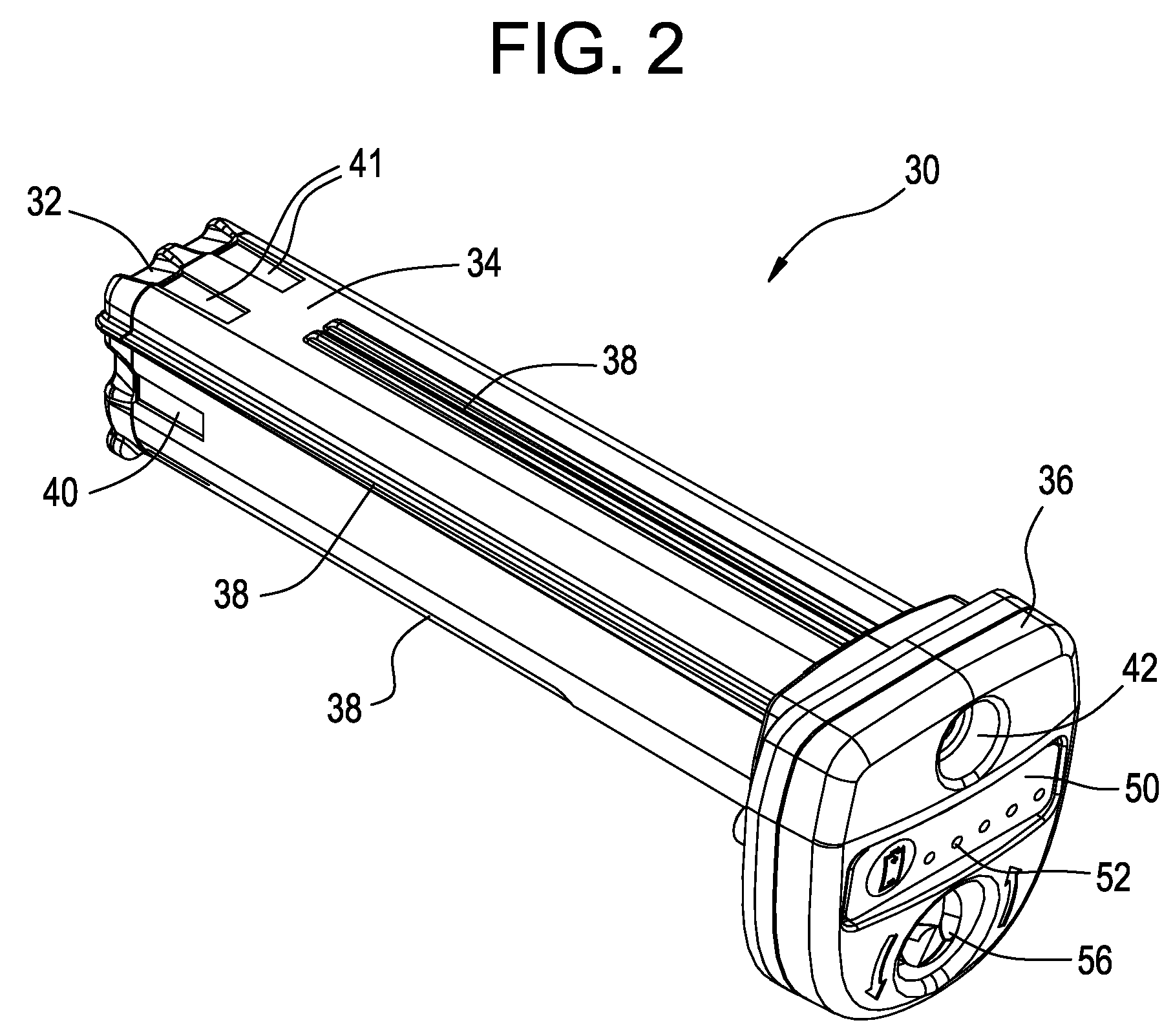

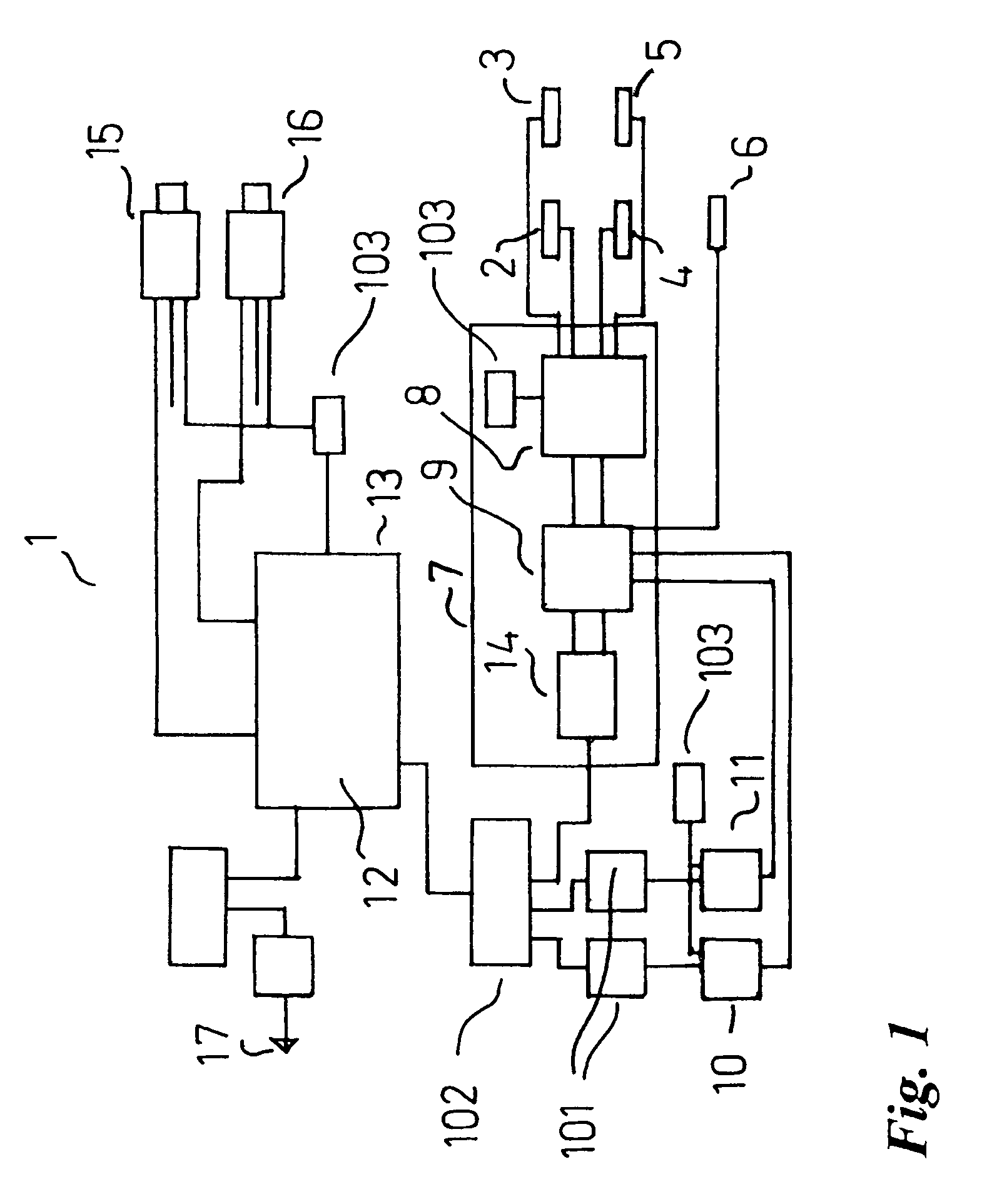

Battery and power management for industrial inspection handset

ActiveUS7902990B2Increase gain valueTelevision system detailsCircuit monitoring/indicationElectrical batteryEngineering

An industrial inspection handset is disclosed, comprising a battery assembly for providing power to the handset, wherein the battery assembly comprises a connector for connecting a battery charger, a battery circuit for communicating with a processor in the handset, and a battery charge indicator on the surface of the battery assembly connected to the battery circuit for providing a visual indication of the charge remaining in the battery assembly. A method of power management for an industrial inspection handset is also disclosed comprising the steps of setting a first maximum power output value for the camera illumination for the insertion, monitoring an imager signal processor, to determine that the gain value of the image signal processor is less than a predetermined gain value, and setting a lower second maximum power output value for the camera illumination in order to increase the gain value. Additional methods of power management for an industrial inspection handset are disclosed, comprising the steps of setting a first maximum power output value for the articulation of the insertion tube attached to the handset, monitoring the operator controls to determine that there has been no articulation for a first predetermined amount of time, monitoring the position of the insertion tube to determine whether the insertion tube position is inside or outside of a predetermined zone of coordinates, and reducing or turning off the articulation power to hold the position of the insertion tube.

Owner:GE INSPECTION TECH LP

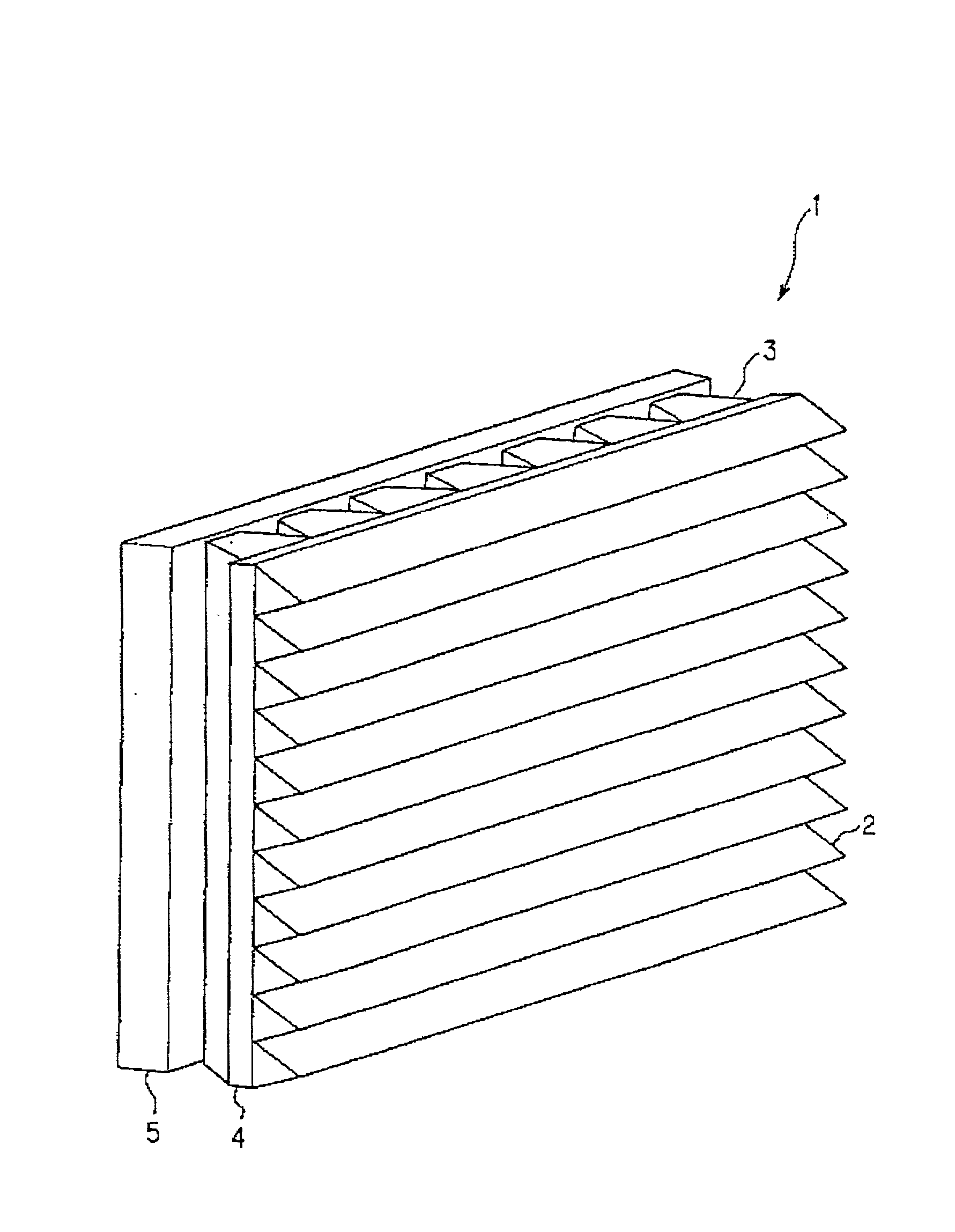

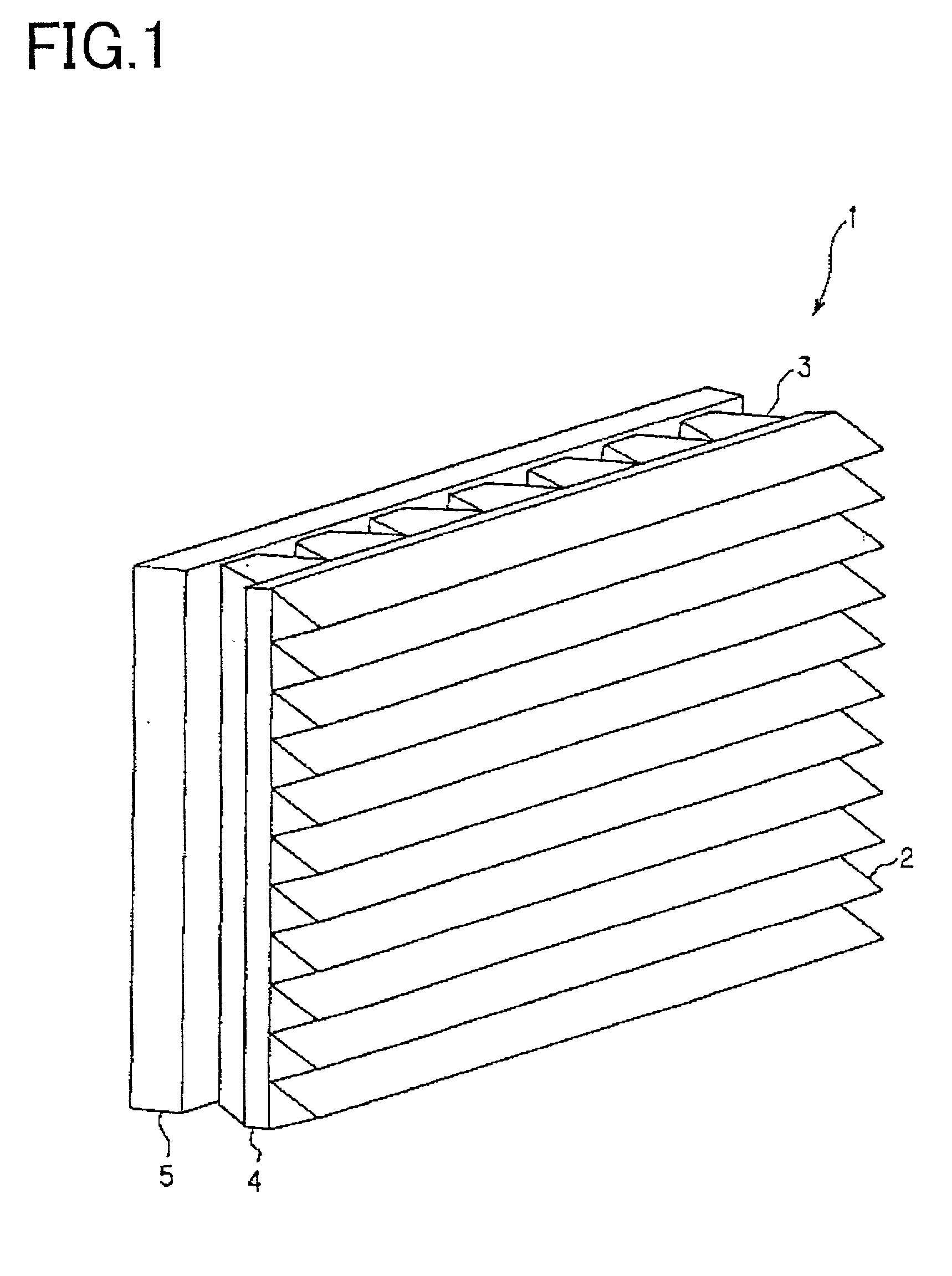

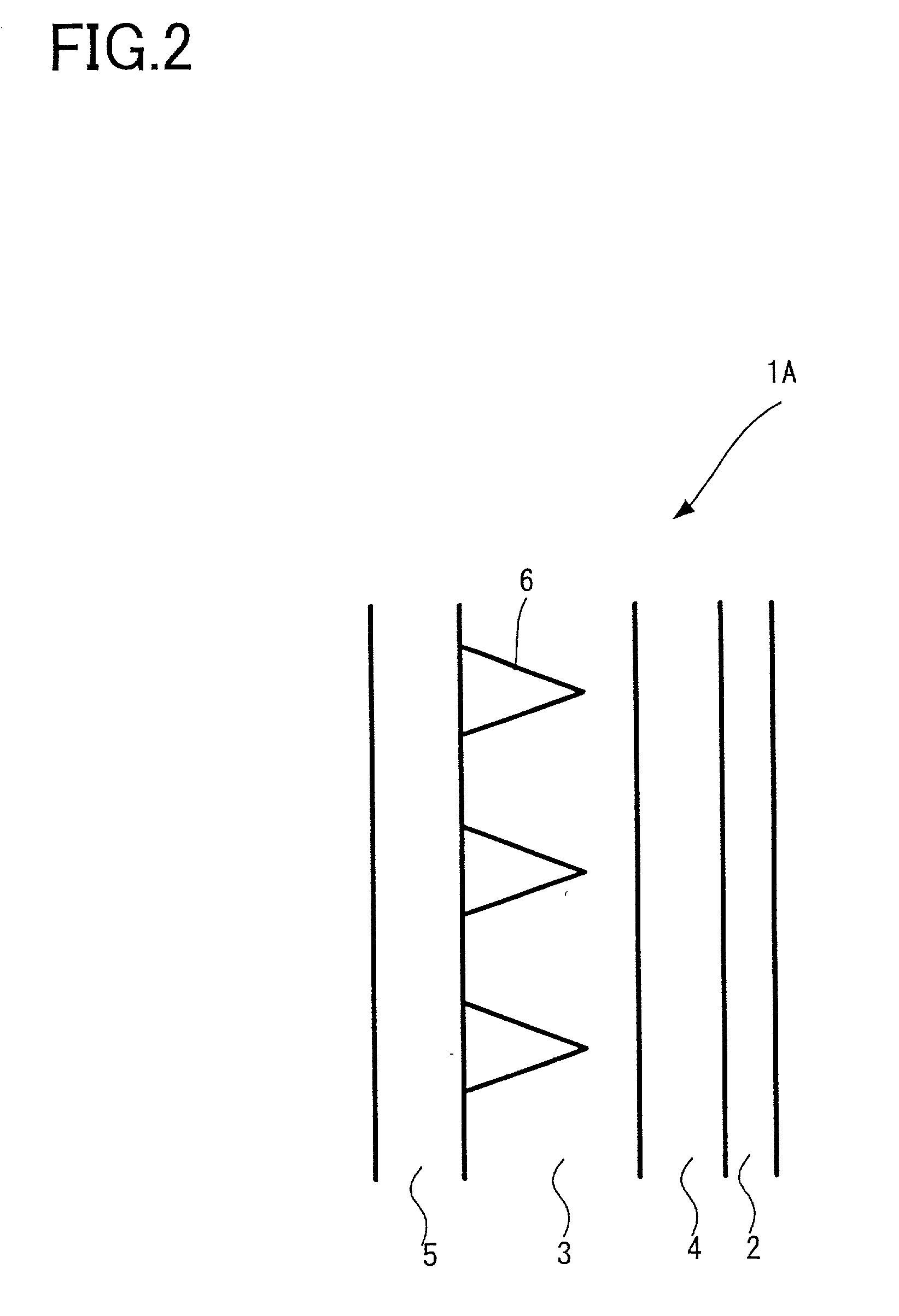

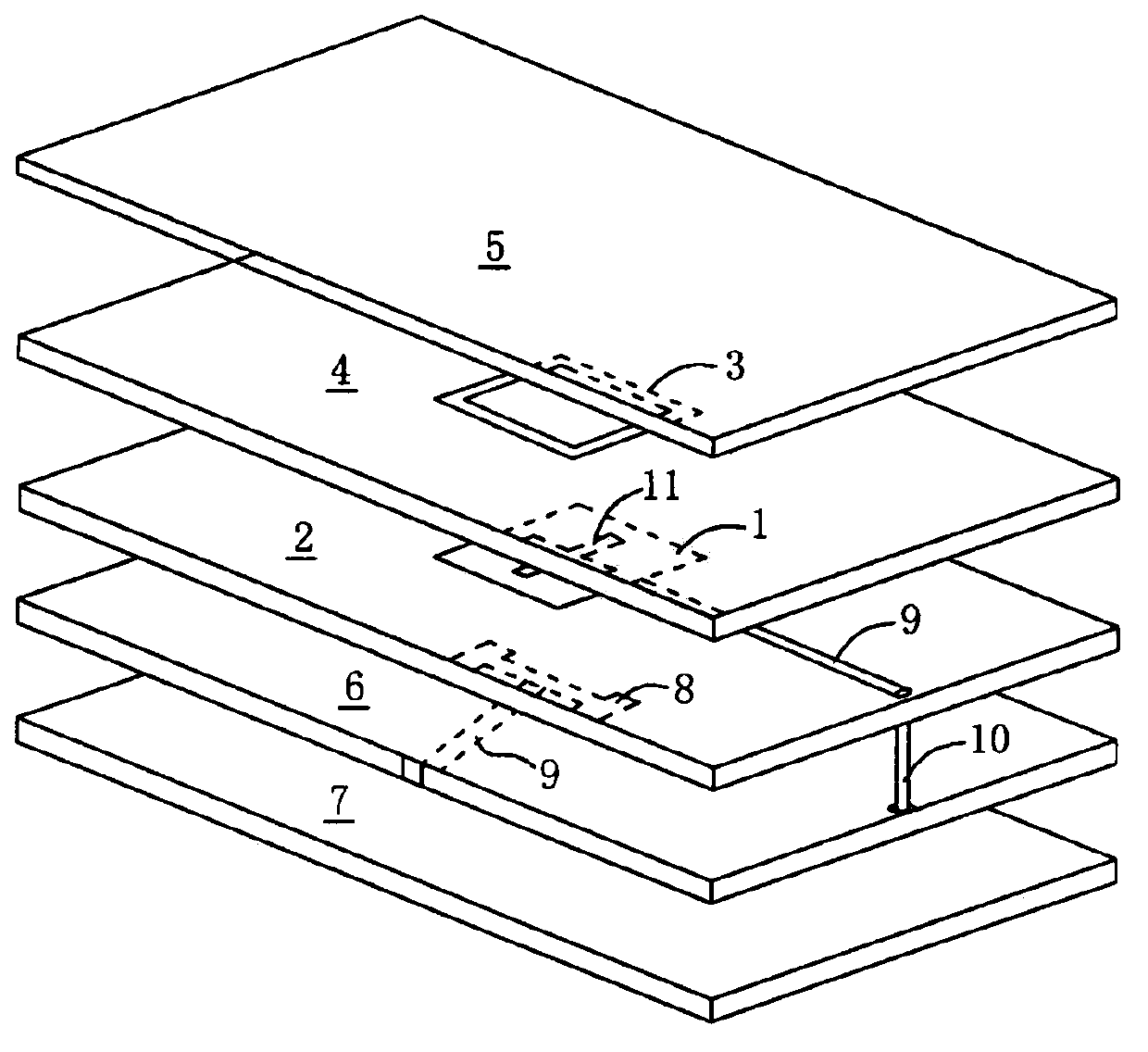

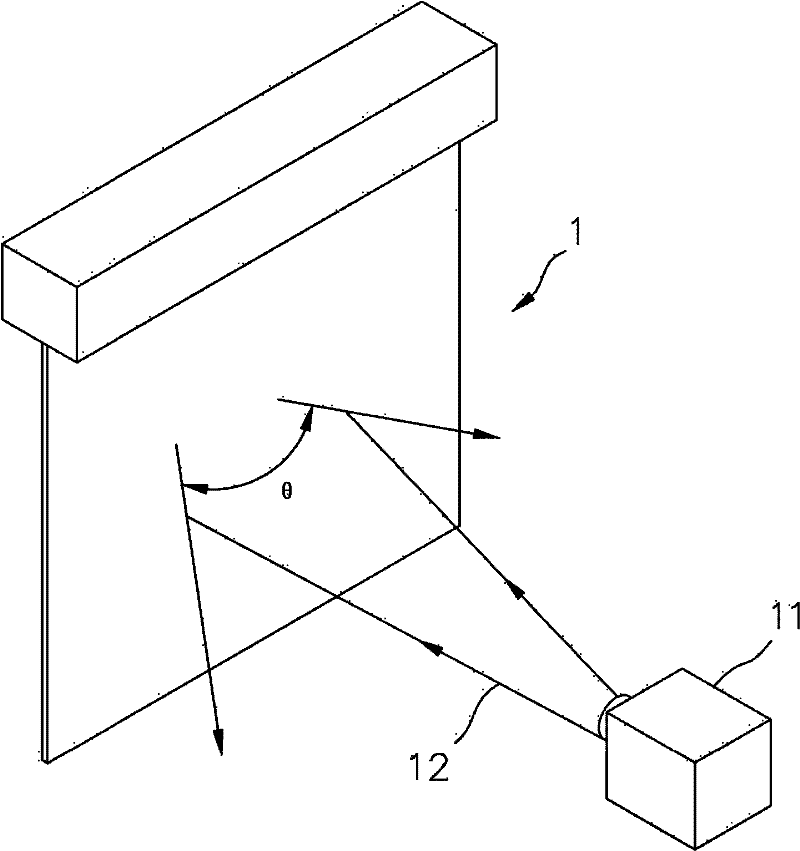

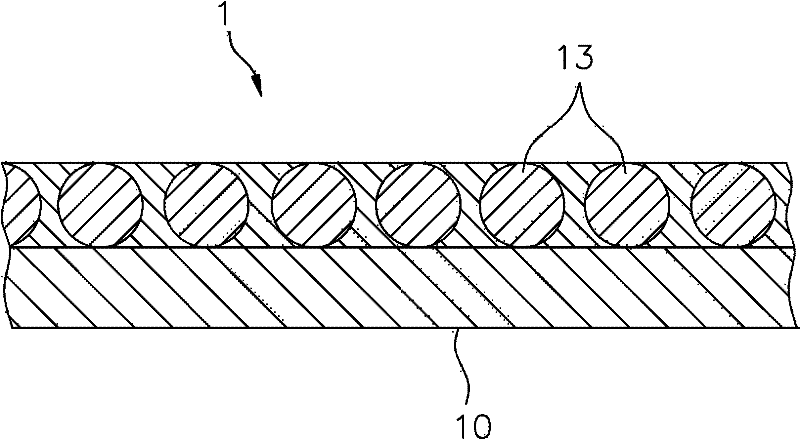

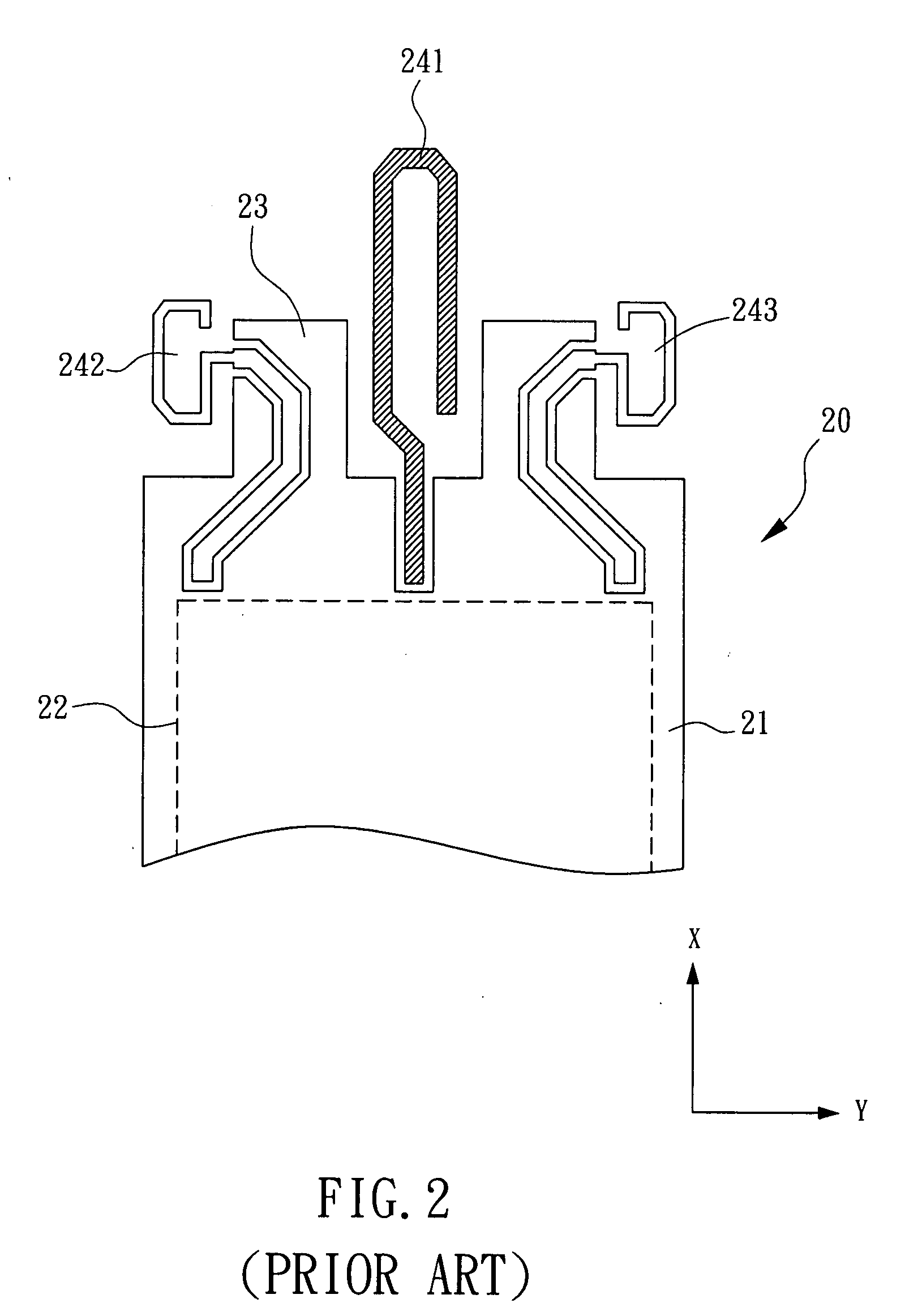

Sheet for use for projection screen, light diffusion sheet and projection screen

InactiveUS20020167725A1Improve the level ofImprove visual effectsProjectorsOptical elementsDiffusionProjection screen

Provided is a light diffusion sheet capable of preventing the reflection of an external light that has entered from the light emission surface and of obtaining a high gain, and a projection screen using the light diffusion sheet. In the light diffusion sheet or film, the light diffusion sheet or film having formed thereon a plurality of unit lenses one-dimensionally or two-dimensionally, the unit lens is substantially trapezoidal in cross section; the lower bottom of the trapezoid is made to be a light incidence portion and the upper bottom thereof is made to be a light emission portion; and the unit lens is formed using a material having a prescribed refractive index of N1; a portion, the cross section of that is triangular, and that is located between adjacent two of the unit lenses, is formed using a material having a refractive index N2 lower than the N1 and having added thereto light absorption particles; and when it is assumed that T represents the length of the upper bottom of the trapezoid; H represents the height of the upper bottom thereof; and theta represents the angle defined by the slant of the trapezoid with respect to a normal line to the light emission portion, the relationship holds true that is expressed as: <paragraph lvl="0"><in-line-formula>sin (90°-theta)>N2 / N1 < / in-line-formula><paragraph lvl="0"><in-line-formula>N1<1 / sin 2theta< / in-line-formula><paragraph lvl="0"><in-line-formula>0<H<T / (tan (2theta+10°)-tantheta) < / in-line-formula>and the surface of the light incidence portion has performed thereon embossing processing.

Owner:DAI NIPPON PRINTING CO LTD

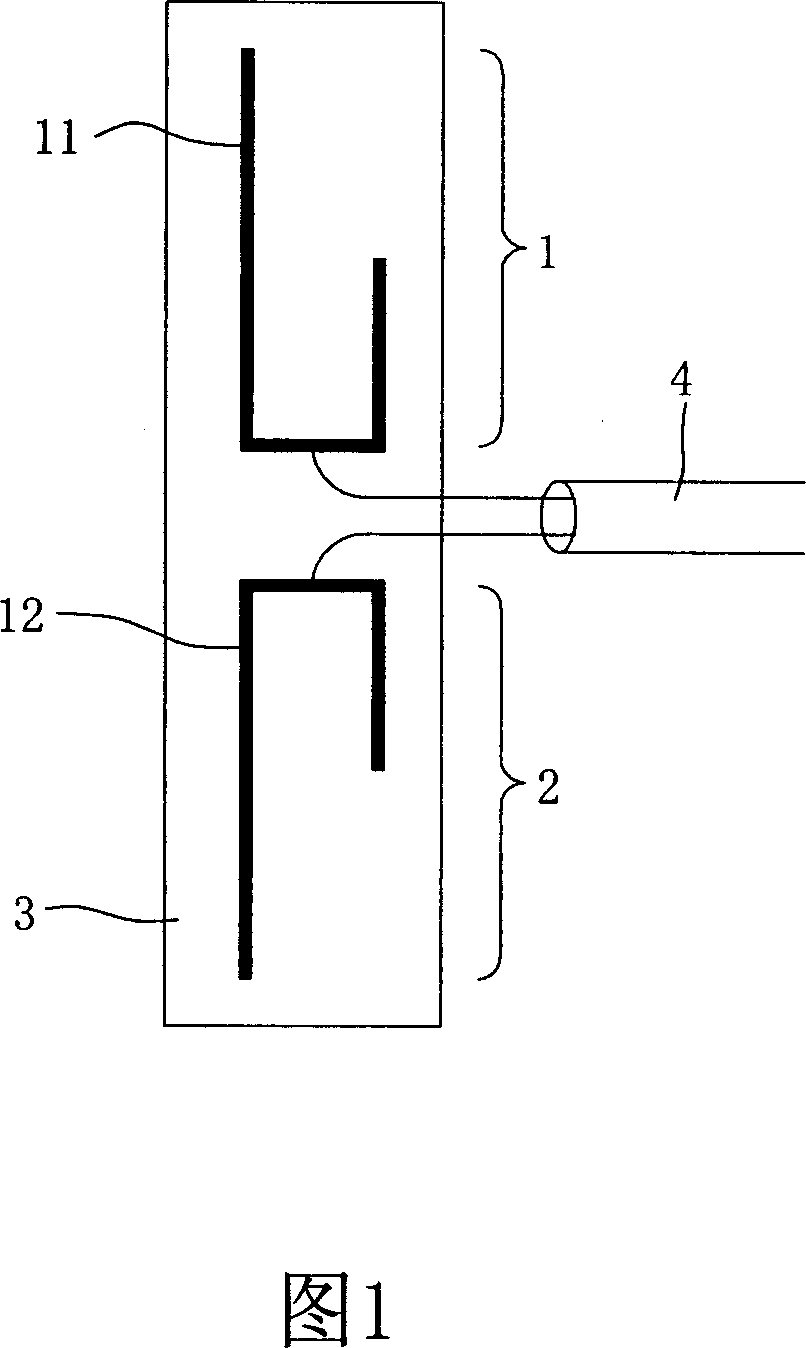

Flat plate antenna of high gain wide band

ActiveCN101005156AIncrease gain valueImproving Impedance BandwidthRadiating elements structural formsAntenna feed intermediatesMicrowaveOptoelectronics

The disclosed flat antenna is in use for solving issue that traditional antenna structure is unable to apply to broadband in high gain. The flat antenna includes following parts: microwave base plate with first surface and second surface; being collocated at the first surface, the first symmetrical type radiation element possesses a first radiation portion, and a second radiation portion; being collocated at the second surface, the second symmetrical type radiation element possesses a third radiation portion, and a fourth radiation portion; at least a connection unit in use for connecting the microwave base plate and reflecting plate. Design method of steps structure is adopted for tail ends of the first radiation portion, the second radiation portion, the third radiation portion, and the fourth radiation portion. The disclosed flat antenna can realize broadband in high gain.

Owner:UNIVERSAL GLOBAL TECH KUNSHAN

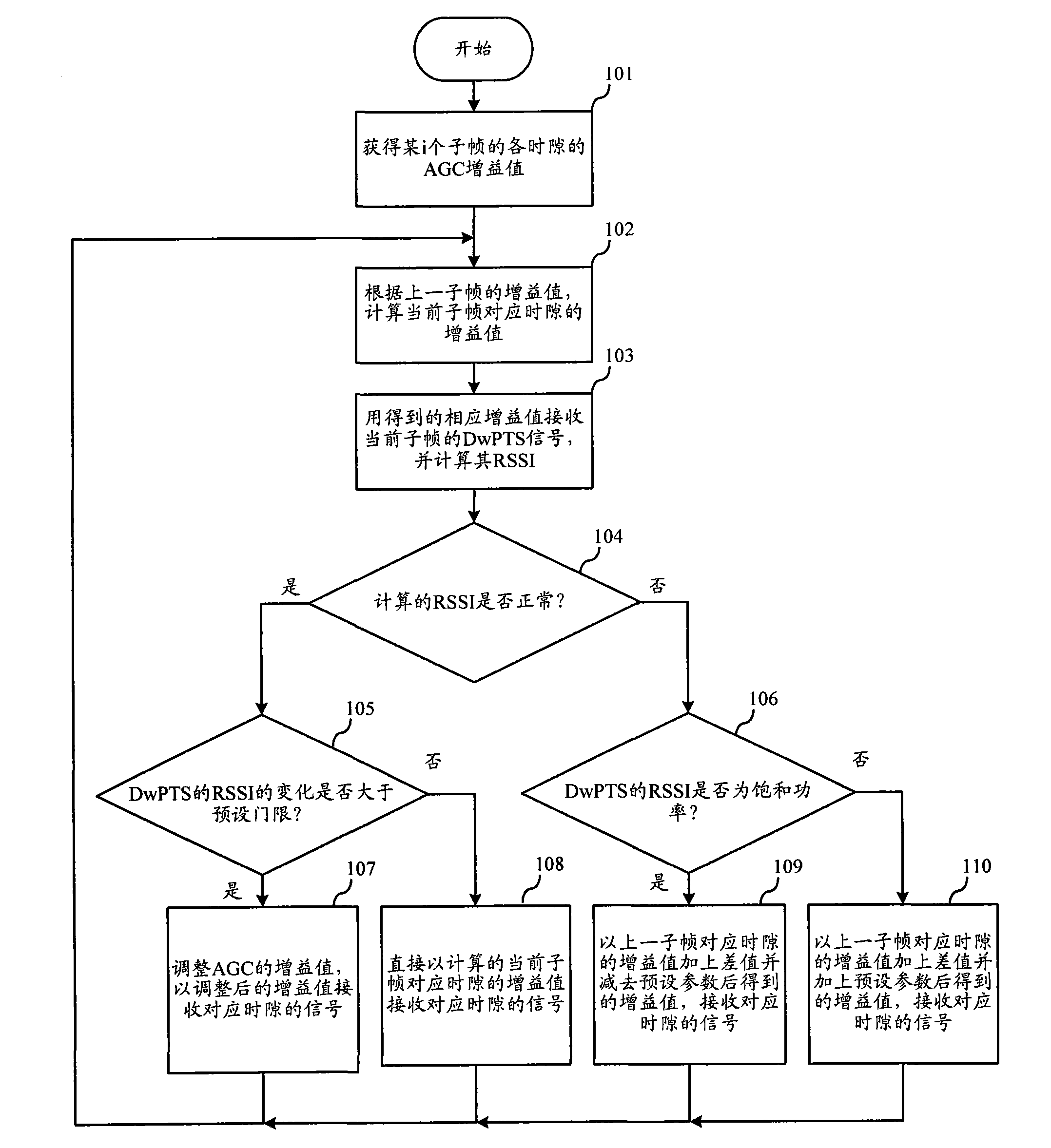

Automatic gain control regulating method for received signals and signal receiving equipment

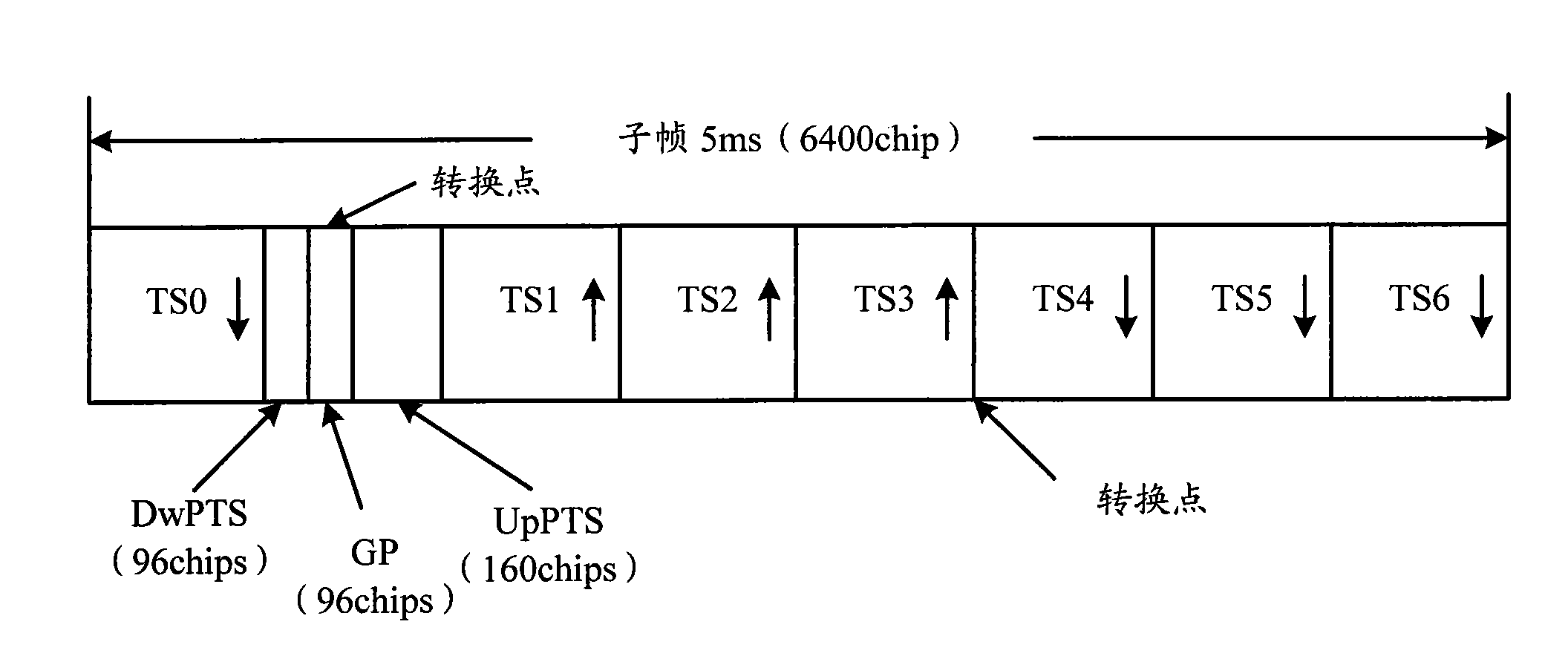

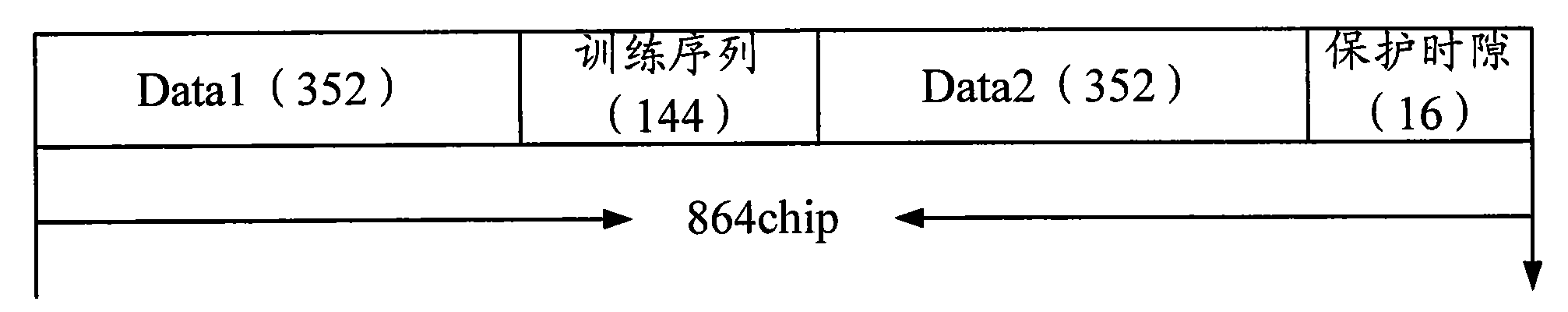

ActiveCN101959288AMeet the needs of signal mutationImprove accuracyPower managementTransmission control/equalisingSignal processingAutomatic gain control

The invention relates to a signal receiving technology, and discloses an automatic gain control regulating method for received signals and signal receiving equipment. In the method, DwPTS is used as guidance, if the RSSI change of the DwPTS is more than a threshold, the AGC gain value of the corresponding time slot of a current sub-frame is regulated according to the RSSI change value of the DwPTS, a signal of the corresponding time slot in the current sub-frame is received by the regulated AGC gain value; and if the RSSI change of the DwPTS is less than or equal to the threshold, the signal of the corresponding time slot is received directly by the AGC gain value of the corresponding time slot the time slot in the current sub-frame which is calculated by the AGC gain value of the last sub-frame. Therefore, the method can deal with the situation of great signal change, meet the requirement of signal mutation, and improve the accuracy of subsequent signal processing.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

Deployable Phased Array Antenna Assembly

ActiveUS20170263997A1High gain valueHigh efficiencyCollapsable antennas meansElectrically long antennasThin walledStowage

Owner:PALO ALTO RES CENT INC

Battery and power management for industrial inspection handset

ActiveUS20090109045A1Increase gain valueTelevision system detailsCircuit monitoring/indicationElectrical batteryEngineering

An industrial inspection handset is disclosed, comprising a battery assembly for providing power to the handset, wherein the battery assembly comprises a connector for connecting a battery charger, a battery circuit for communicating with a processor in the handset, and a battery charge indicator on the surface of the battery assembly connected to the battery circuit for providing a visual indication of the charge remaining in the battery assembly. A method of power management for an industrial inspection handset is also disclosed comprising the steps of setting a first maximum power output value for the camera illumination for the insertion, monitoring an imager signal processor, to determine that the gain value of the image signal processor is less than a predetermined gain value, and setting a lower second maximum power output value for the camera illumination in order to increase the gain value. Additional methods of power management for an industrial inspection handset are disclosed, comprising the steps of setting a first maximum power output value for the articulation of the insertion tube attached to the handset, monitoring the operator controls to determine that there has been no articulation for a first predetermined amount of time, monitoring the position of the insertion tube to determine whether the insertion tube position is inside or outside of a predetermined zone of coordinates, and reducing or turning off the articulation power to hold the position of the insertion tube.

Owner:GE INSPECTION TECH LP

Organic light emitting diode display and method for compensating chromaticity coordinates thereof

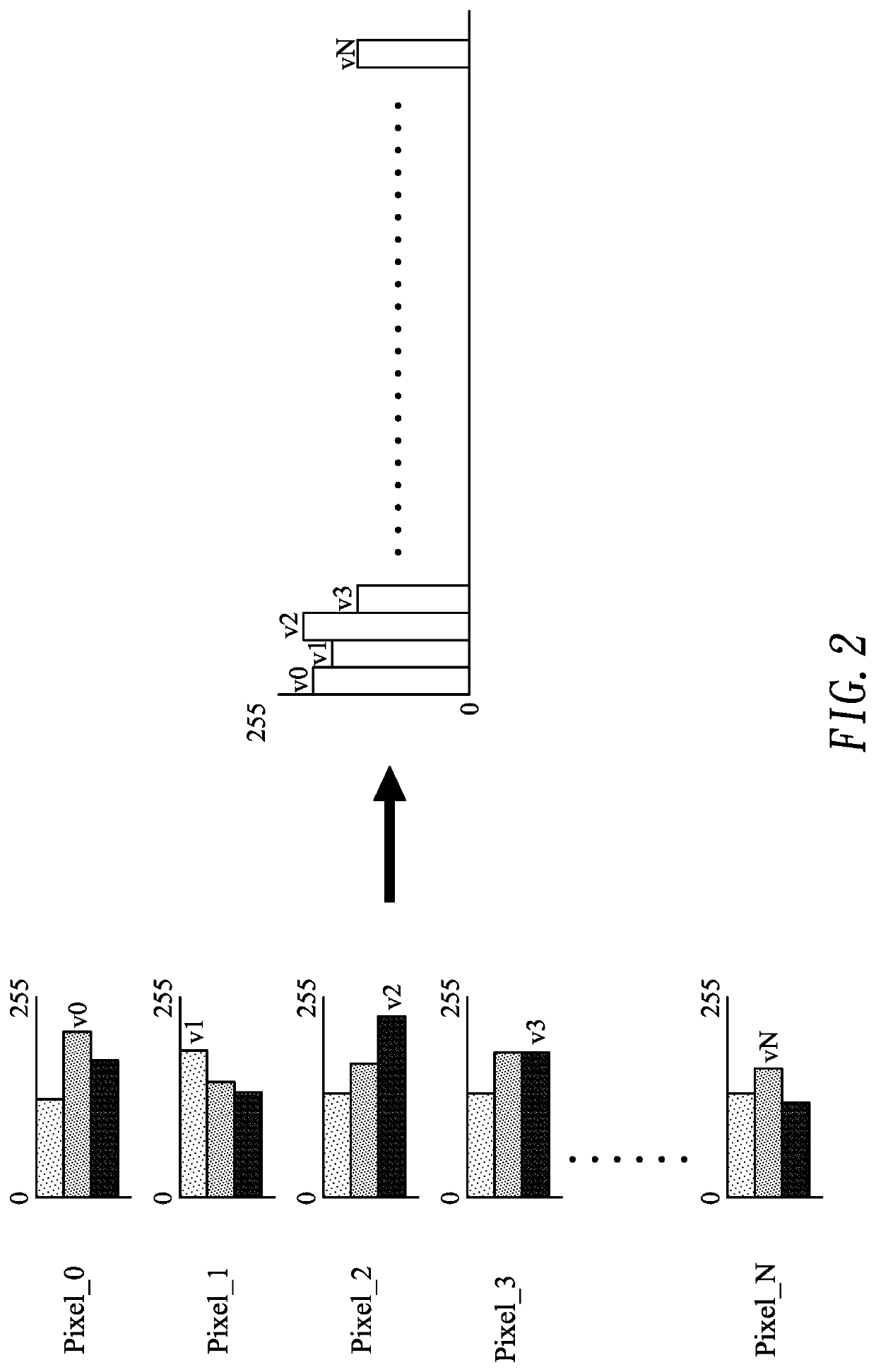

ActiveUS20110292087A1Compensation deviationIncrease gain valueCathode-ray tube indicatorsInput/output processes for data processingData conversionColor compensation

An organic light emitting diode display, comprising: a display panel on which a plurality of pixels are arranged, each of the pixels comprising an R sub-pixel for generating red light through a white OLED and an R color filter, a G sub-pixel for generating green light through a white OLED and a G color filter, a B sub-pixel for generating blue light through a white OLED and a B color filter, and a W sub-pixel for generating white light through a white OLED; a data operation unit for generating a data operation value by extracting a representative value for each pixel based on three primary color data, determining white data of the corresponding pixel as the representative value, and then subtracting the white data from the three primary color data for each pixel; a gain adjusting unit for generating a gain adjusting value of the three primary color data by multiplying a preset gain value of the three primary color data by the corresponding white data; and a data conversion unit for generating four color compensation data, whose white chromaticity coordinates are compensated for each pixel, by adding the gain adjusting value to the data operation value and matching the corresponding white data to the three primary color data converted by the adding.

Owner:LG DISPLAY CO LTD

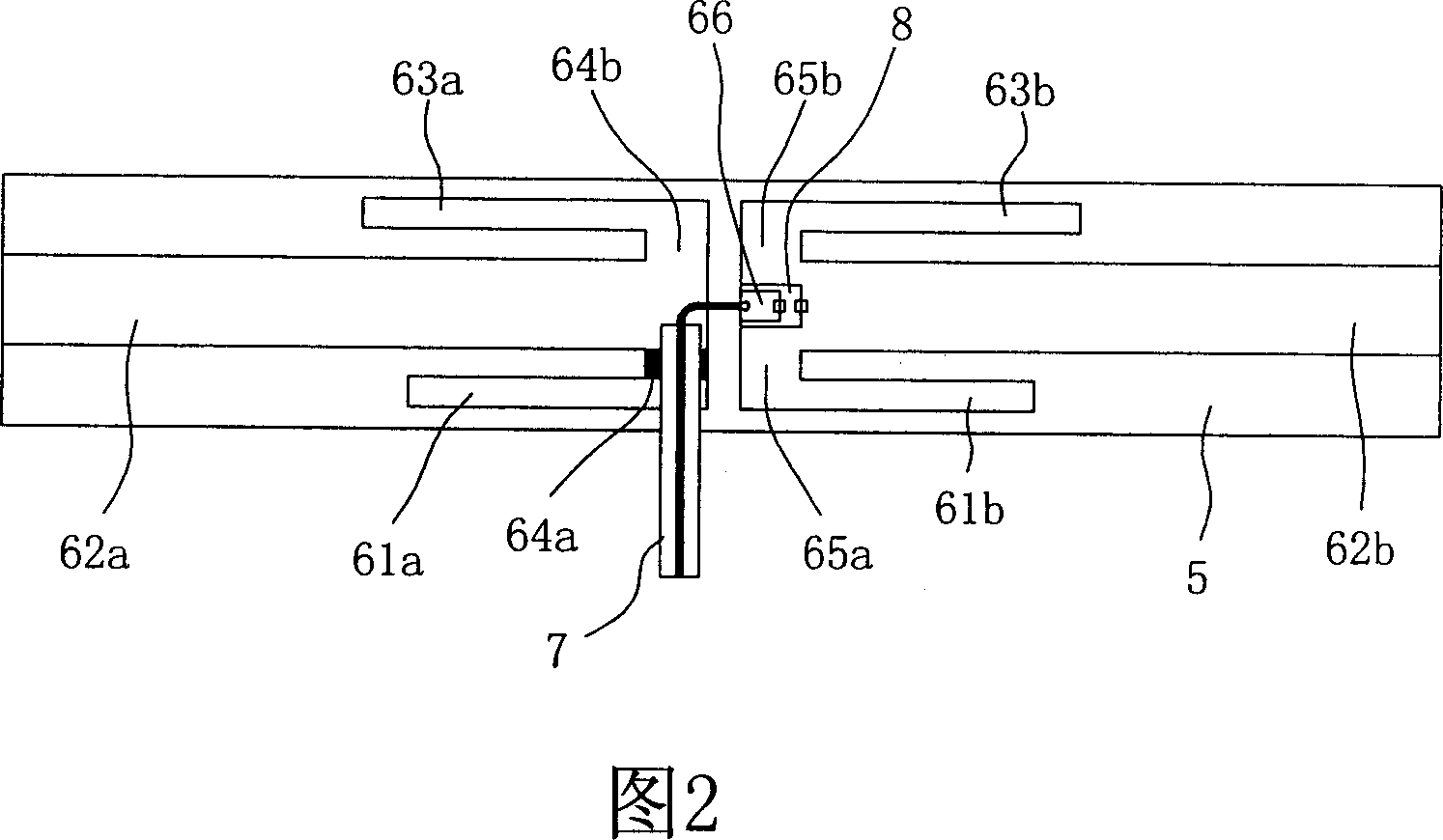

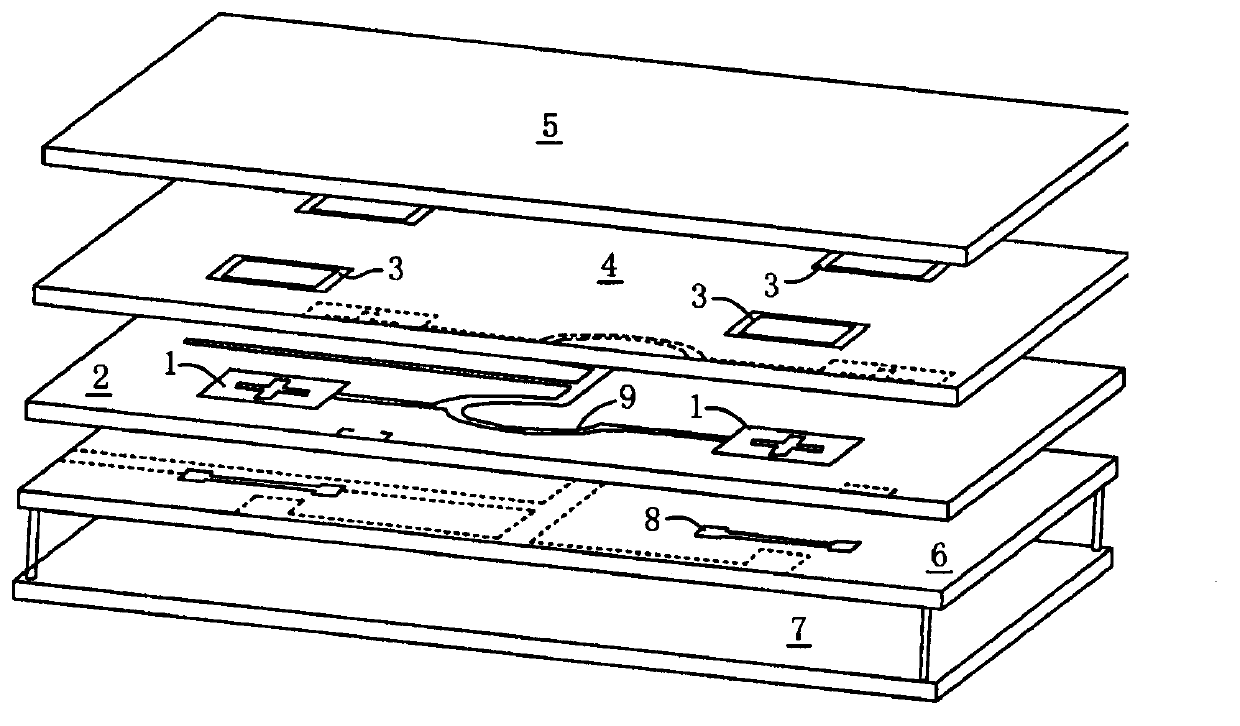

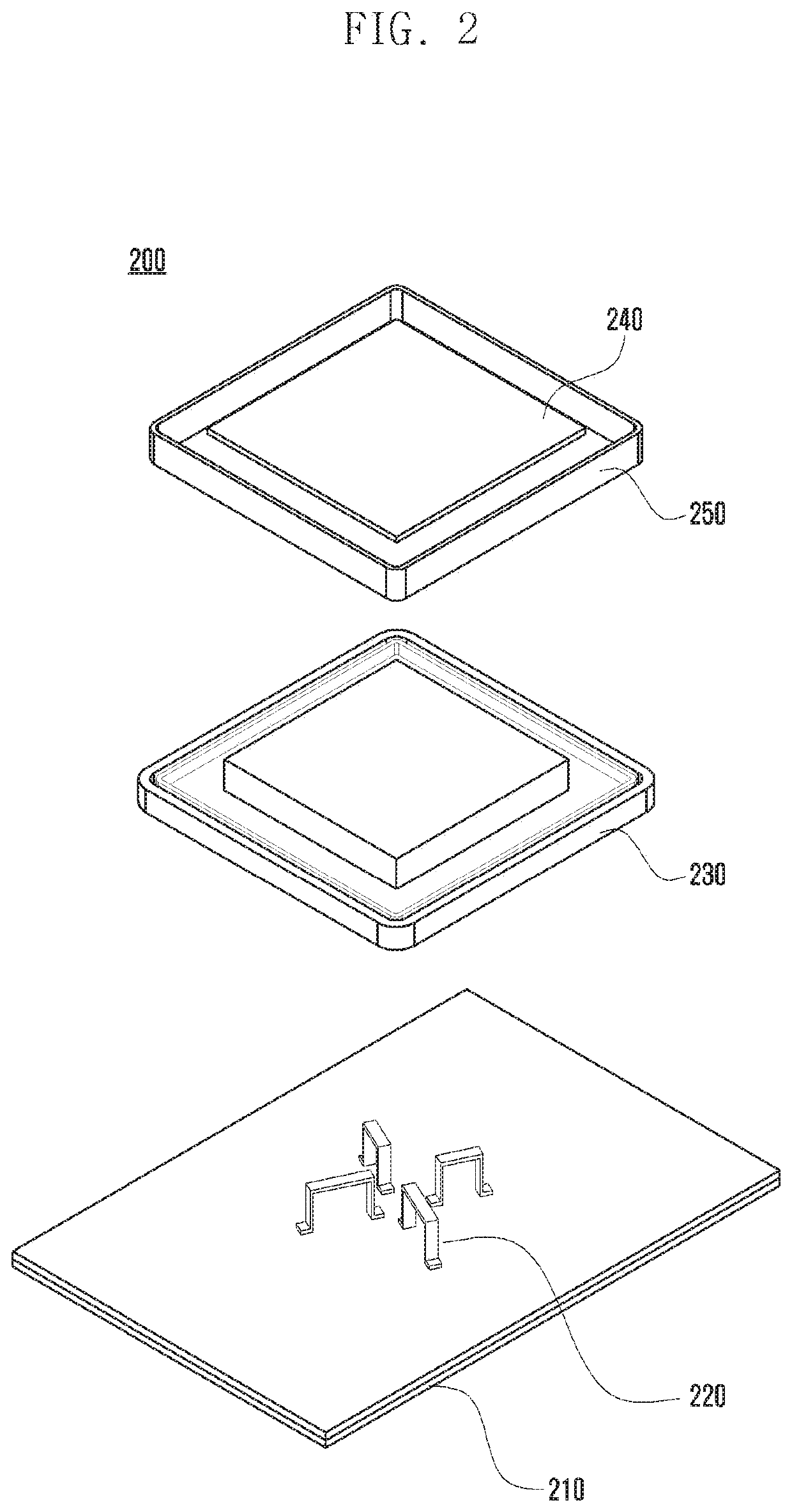

Micro-strip antenna unit and array thereof

InactiveCN103000994AIncrease gain valueReduce the chance of mutual interferenceAntenna arraysRadiating elements structural formsPhysicsDielectric substrate

The invention discloses a micro-strip antenna unit and an array thereof and belongs to antennas. The antenna unit comprises a first dielectric substrate and a second dielectric substrate positioned over the first dielectric substrate, wherein a primary radiation patch is arranged over the first dielectric substrate, a parasitic patch and a covering dielectric slab are arranged over the second dielectric substrate, an earth plate is arranged under the first dielectric substrate, and a baffle board is arranged under the earth plate. Through arrangement of the parasitic patch in the micro-strip antenna unit, under the assistance of the covering dielectric slab, resonance gain is achieved, the grain value of the micro-strip antenna is improved effectively; aperture-coupled feed of an H-shaped groove and direct feed of the primary irradiation patch are not performed in the same layer of the antenna unit, therefore the isolation is effectively improved, a micro-strip feed network is simple after array combination of the antenna unit, and the using loss is low; and simultaneously, the micro-strip antenna unit and the array can be widely applied to aviation airborne computer systems, and are simple in structure, suitable for industrial production and easy to popularize.

Owner:何小祥

optical projection screen

InactiveCN102262343ABig angleAvoid interferenceDiffusing elementsProjectorsProjection screenReflective layer

An optical projection screen comprises a basal film, a lens layer, a reflecting layer, a surface film and a diffusion layer; wherein the lens layer is formed on the basal film and provided with a plurality of micro lens structures; the reflecting layer is formed on the lens layer; the surface film is arranged on the reflecting layer; and the diffusion layer is formed on the surface film and provided with a plurality of nano-scale black particles, a surface of the diffusion layer is in an uneven shape, thus the diffusion layer has a glare-resistant function and a scratch-resistant function. The reflecting layer reflects an incident light coming from a projector into an emergent light, a gain value of the emergent light can be raised and a reflection angle of the emergent light can be increased via the reflecting layer, then the uneven surface of the diffusion layer is utilized to diffuse the emergent light and avoid interferences of external lights, thus the optical projection screen may have a good light resistance and a high gain, and a half gain visual angle of the optical projection screen can reach more than 175 degrees.

Owner:ZHEJIANG MINGPIN PHOTOELECTRIC NEW MATERIAL

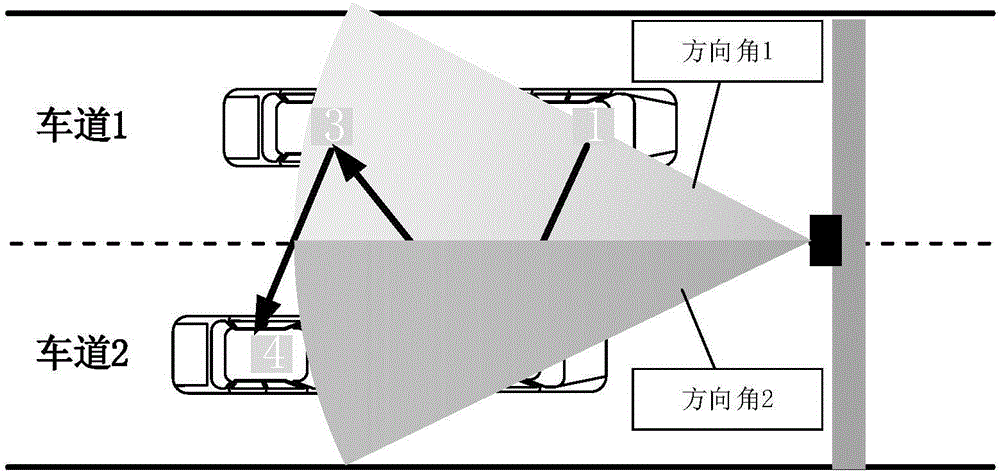

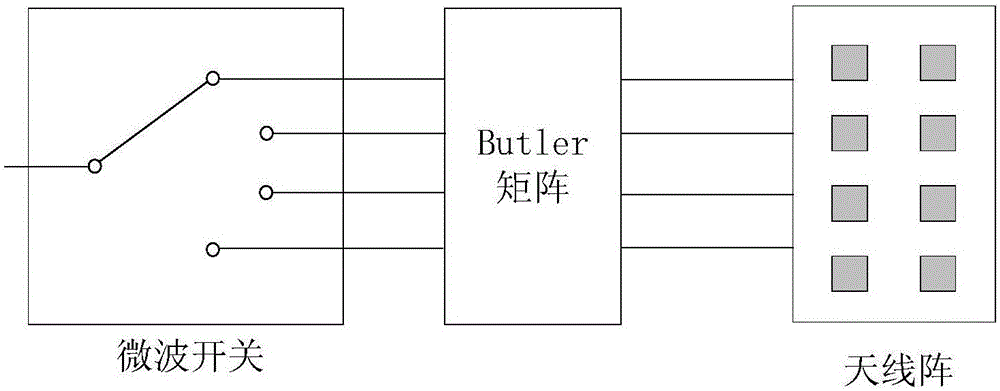

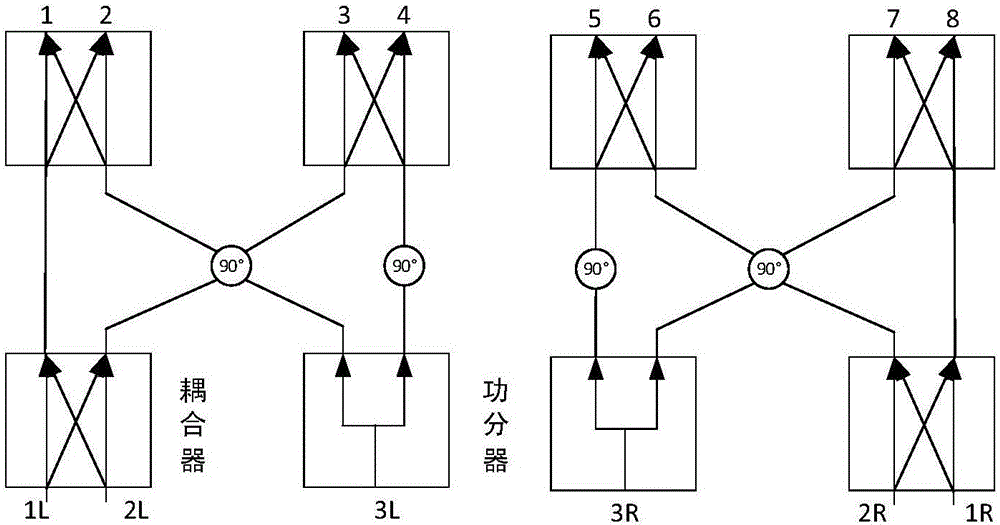

Microstrip phased array antenna applied on ETC terminal information acquisition system

InactiveCN106532273AComprehensive detection functionImprove recognition distanceIndividually energised antenna arraysPhase differenceBeam scanning

The invention discloses a microstrip phased array antenna applied on an ETC terminal information acquisition system. The microstrip phased array antenna comprises the following three parts: a feeding network which is composed of an RF switch, a crossover and a power divider and is used for distributing signals with different powers and different phases to different ports of a Butler matrix and inputting the signal to a preset port in switching; a wave beam forming network which is composed of improved Butler matrixes and is used for generating the signal with the required phase and inputting to a preset antenna unit; an antenna array, wherein each antenna unit is composed of double radiation sheets with a 90-DEG phase difference. The antenna is mounted right above the middle line of a middle lane. The projection of the antenna in the normal line direction is in the middle line of the middle lane. The microstrip phased array antenna can settle technical problems of wave beam scanning, lane identification, identification distance increase, identification success rate increase, etc.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

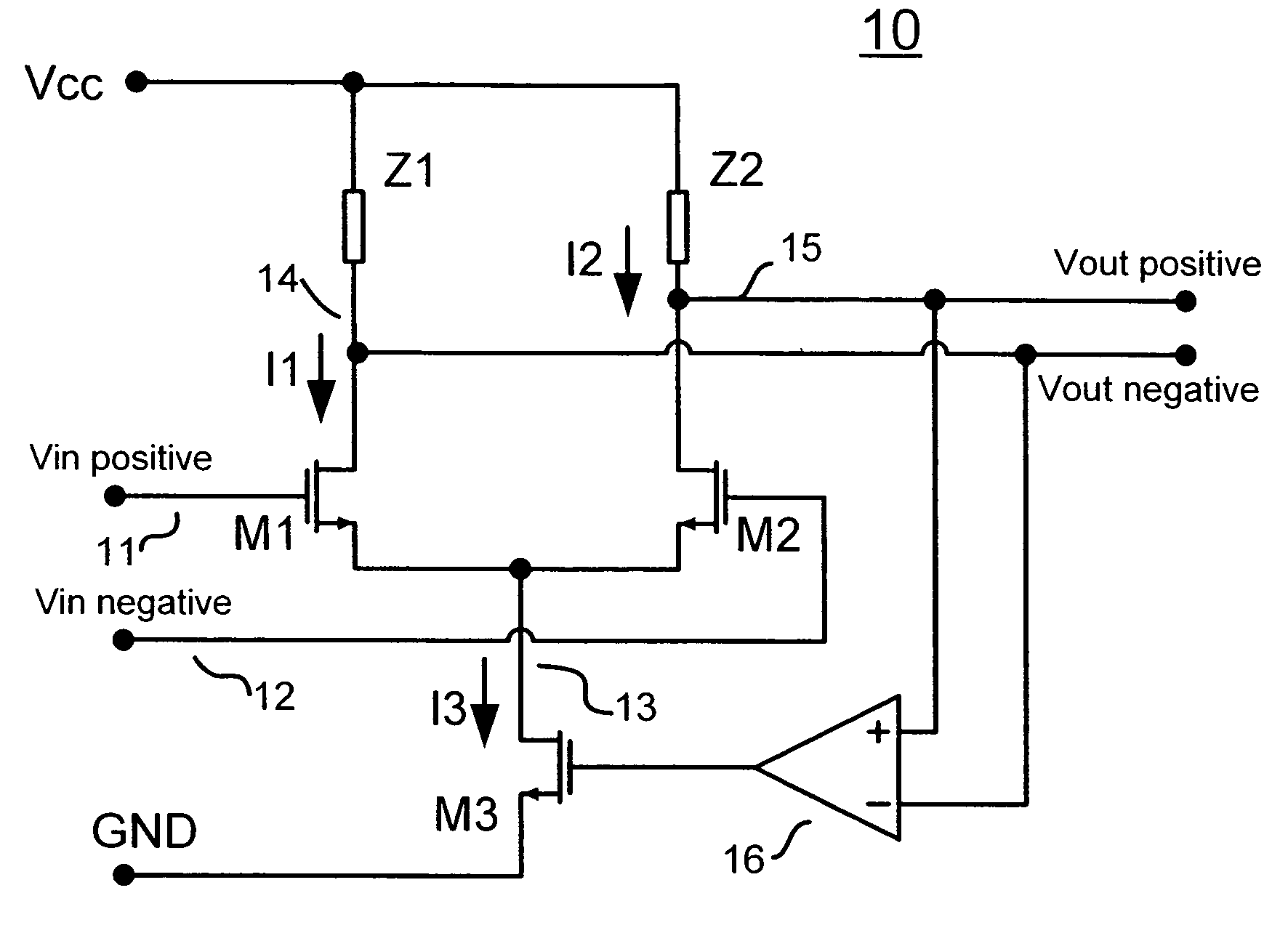

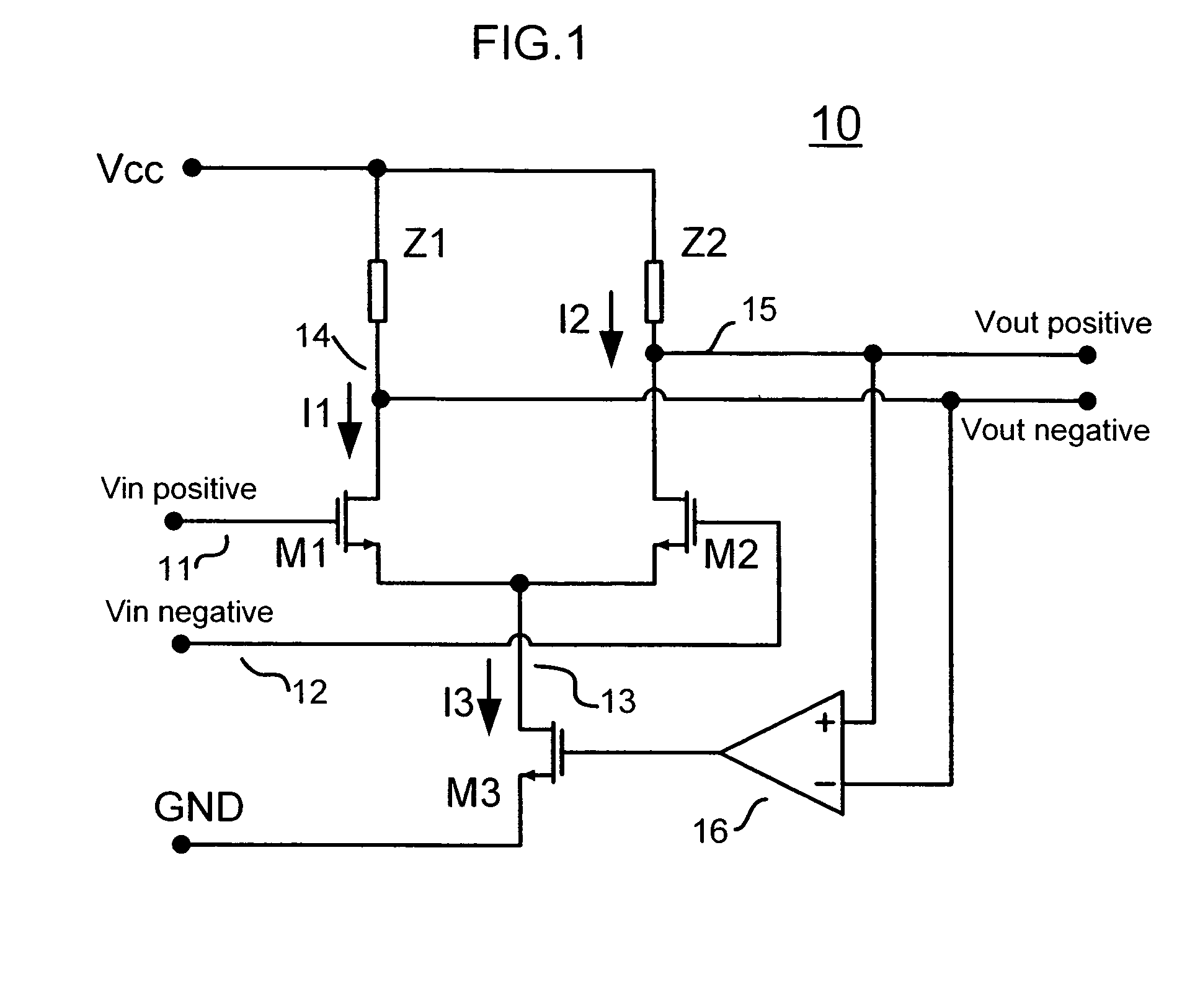

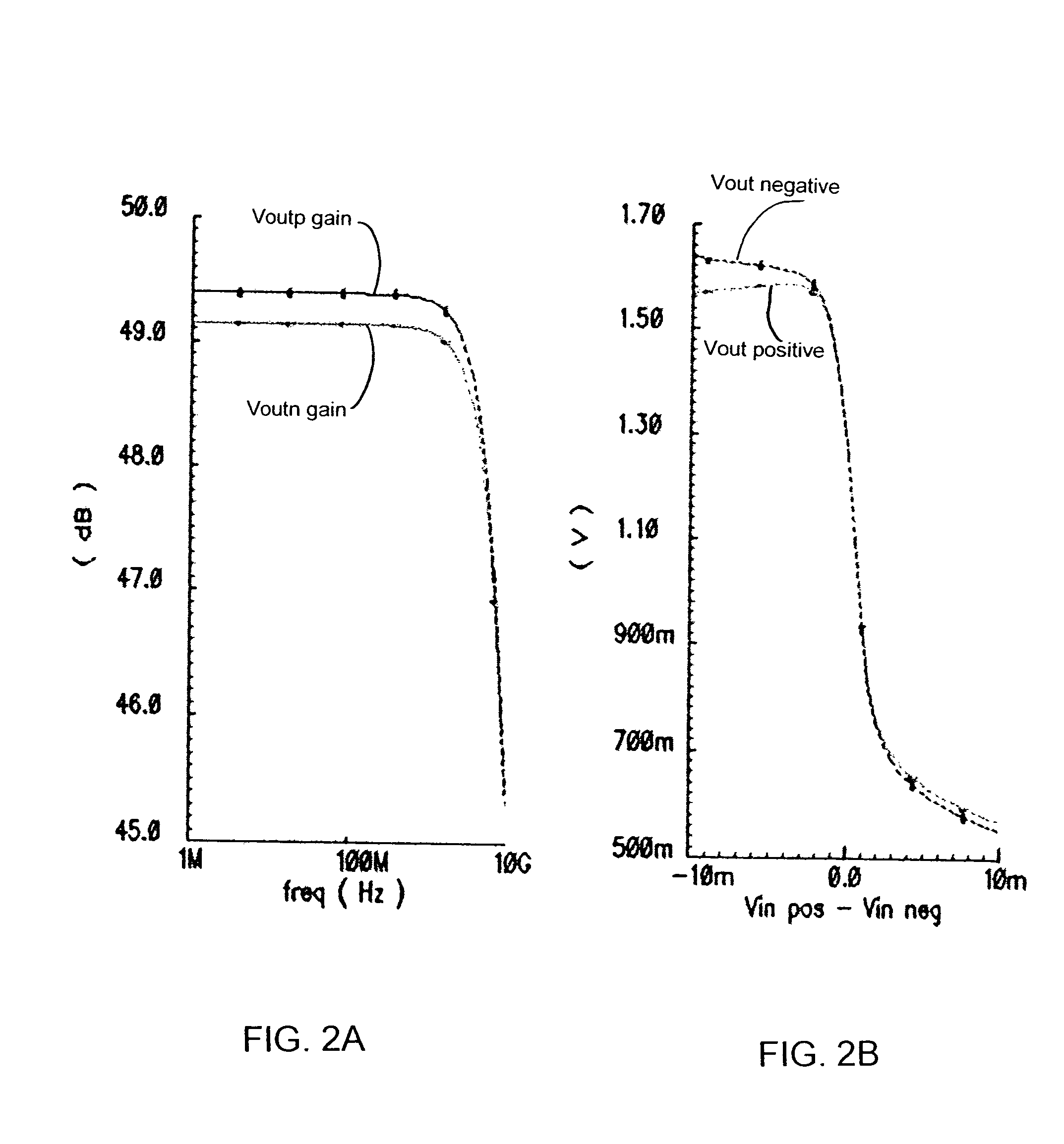

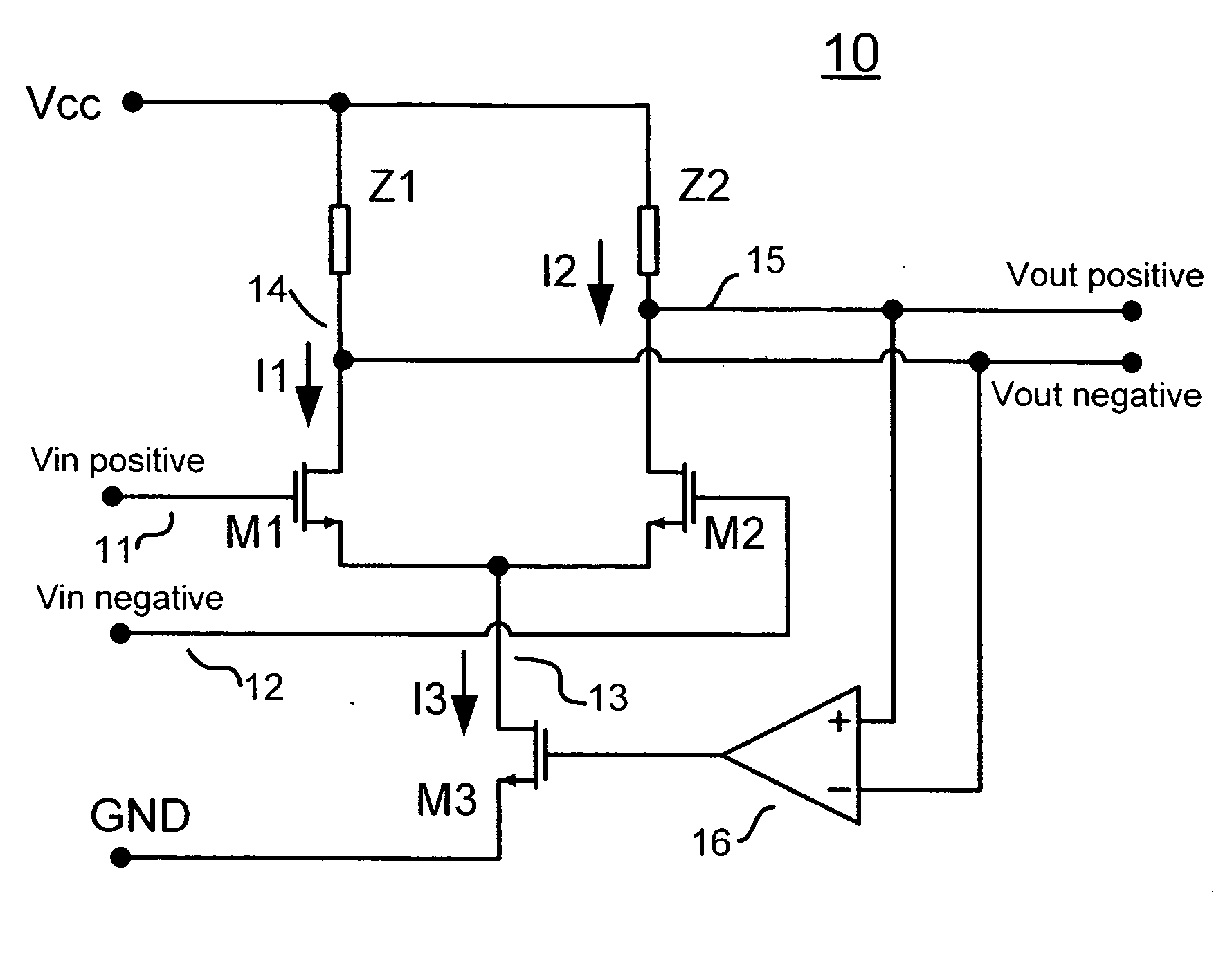

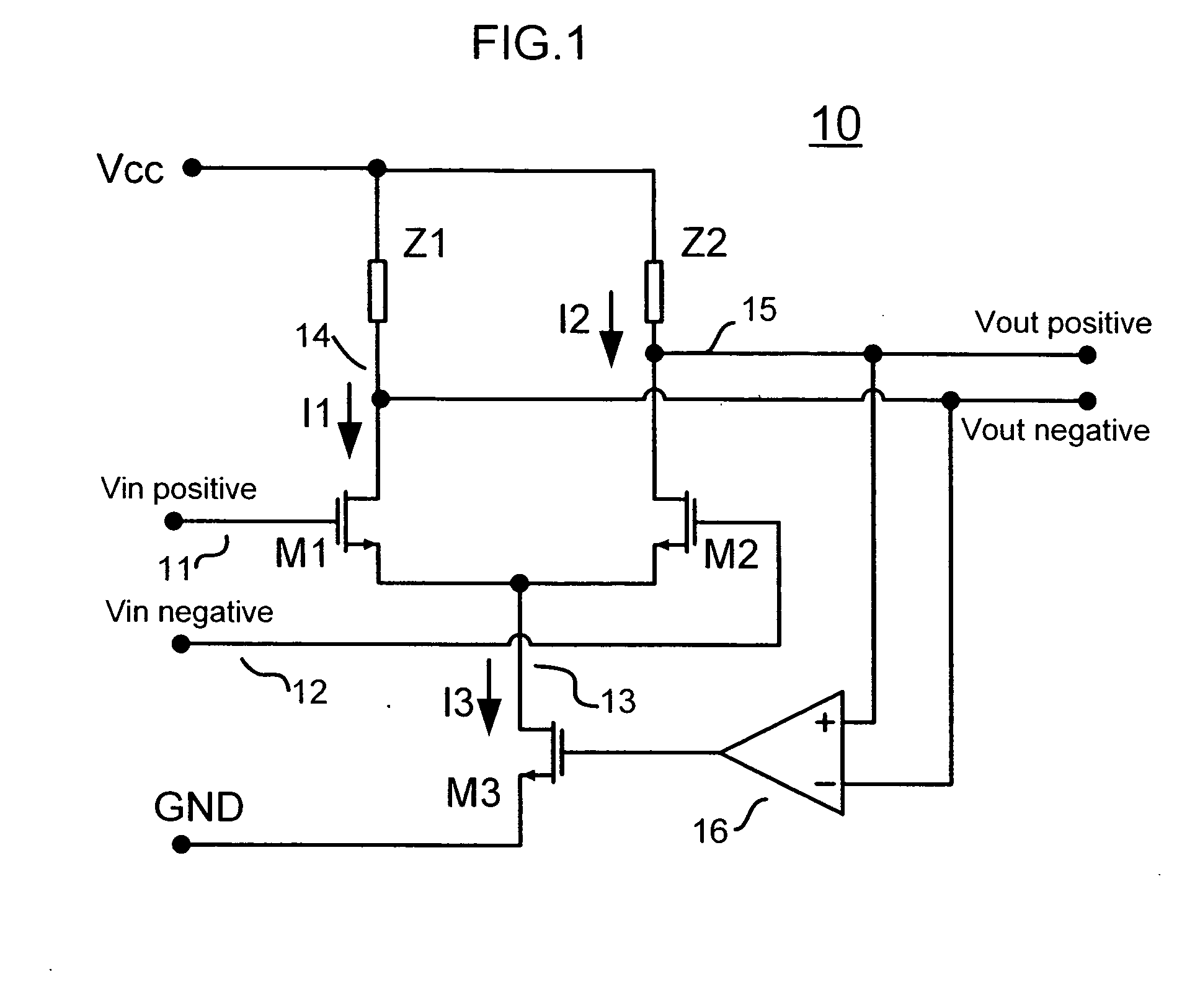

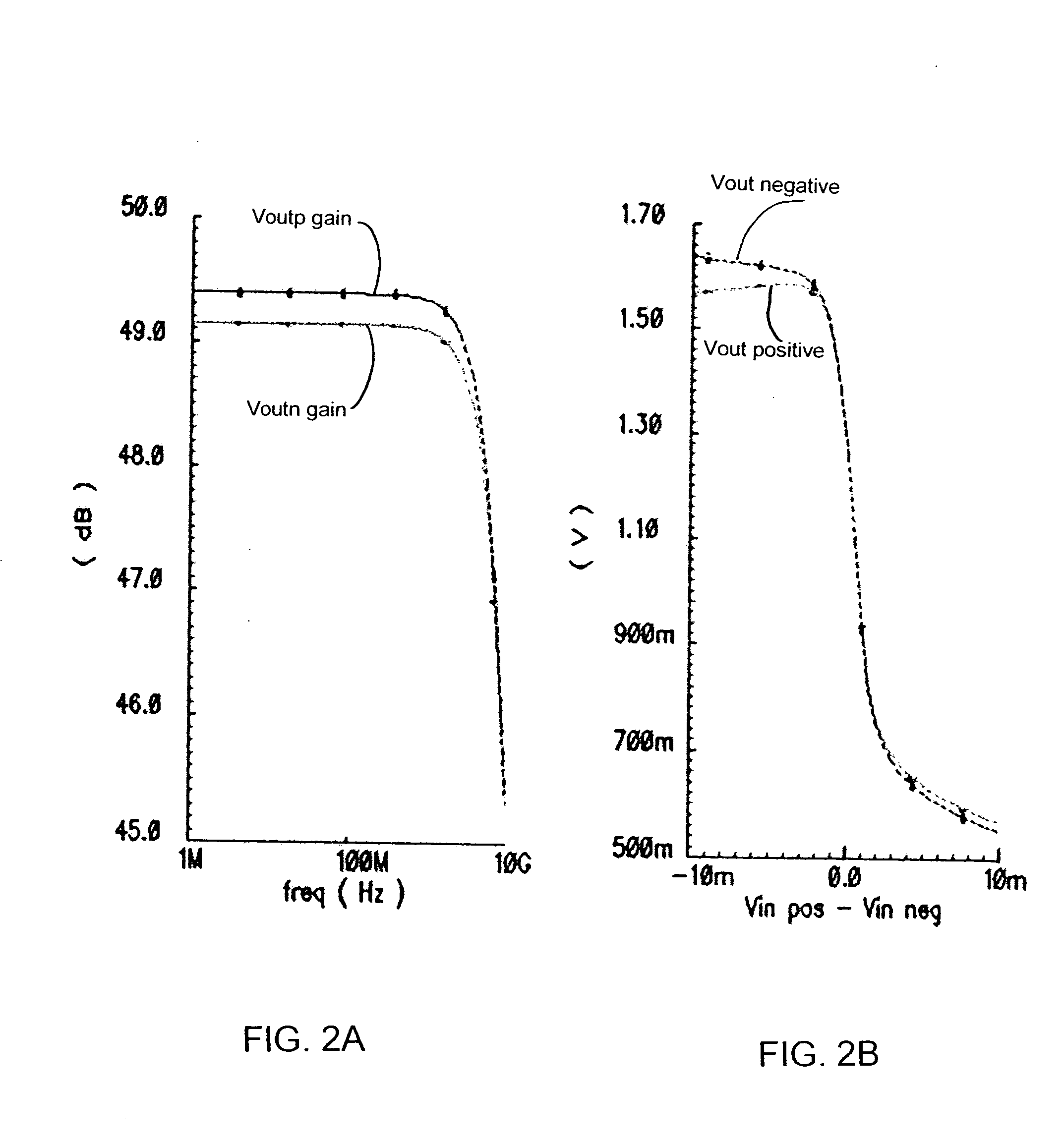

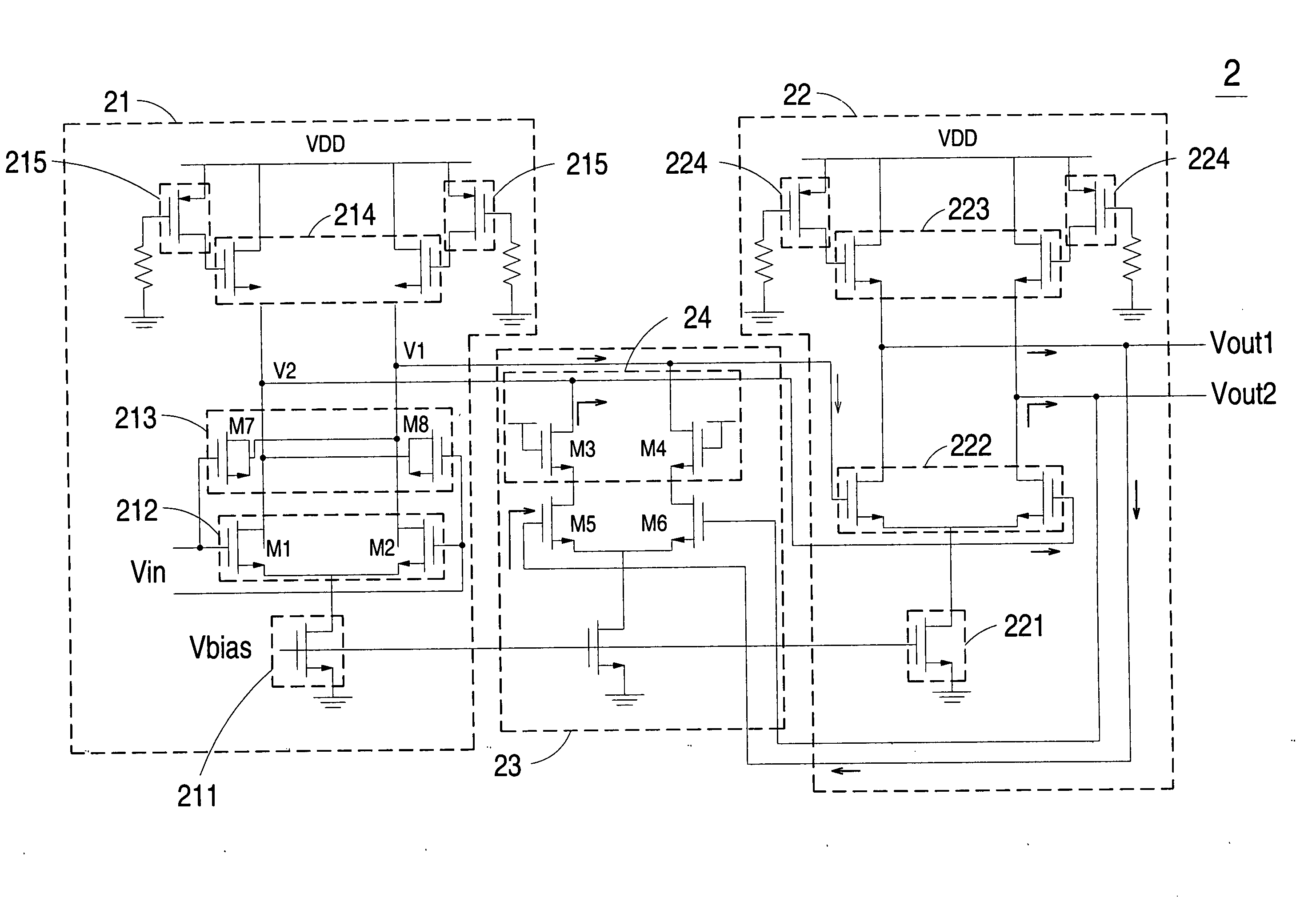

Differential amplifier with current source controlled through differential feedback

ActiveUS7719361B2Increase gain valueDifferential amplifiersDc-amplifiers with dc-coupled stagesAudio power amplifierDirect coupling

A differential amplifier includes a first electrical path formed between a first transistor and a first load impedance; a second electrical path formed between a second transistor and a second load impedance; a tail-current transistor coupled to the first and second transistors; an input end of a feedback amplifier coupled directly to the first and second electrical paths for receiving a differential voltage output signal; and an output end of the feedback amplifier coupled directly to the tail-current transistor for adjusting the current provided through each of the first and second electrical paths. The feedback amplifier includes a non-inverting input node and an inverting input node, each node coupled directly to one or the other of the first and second electrical paths.

Owner:HARRIS GLOBAL COMM INC

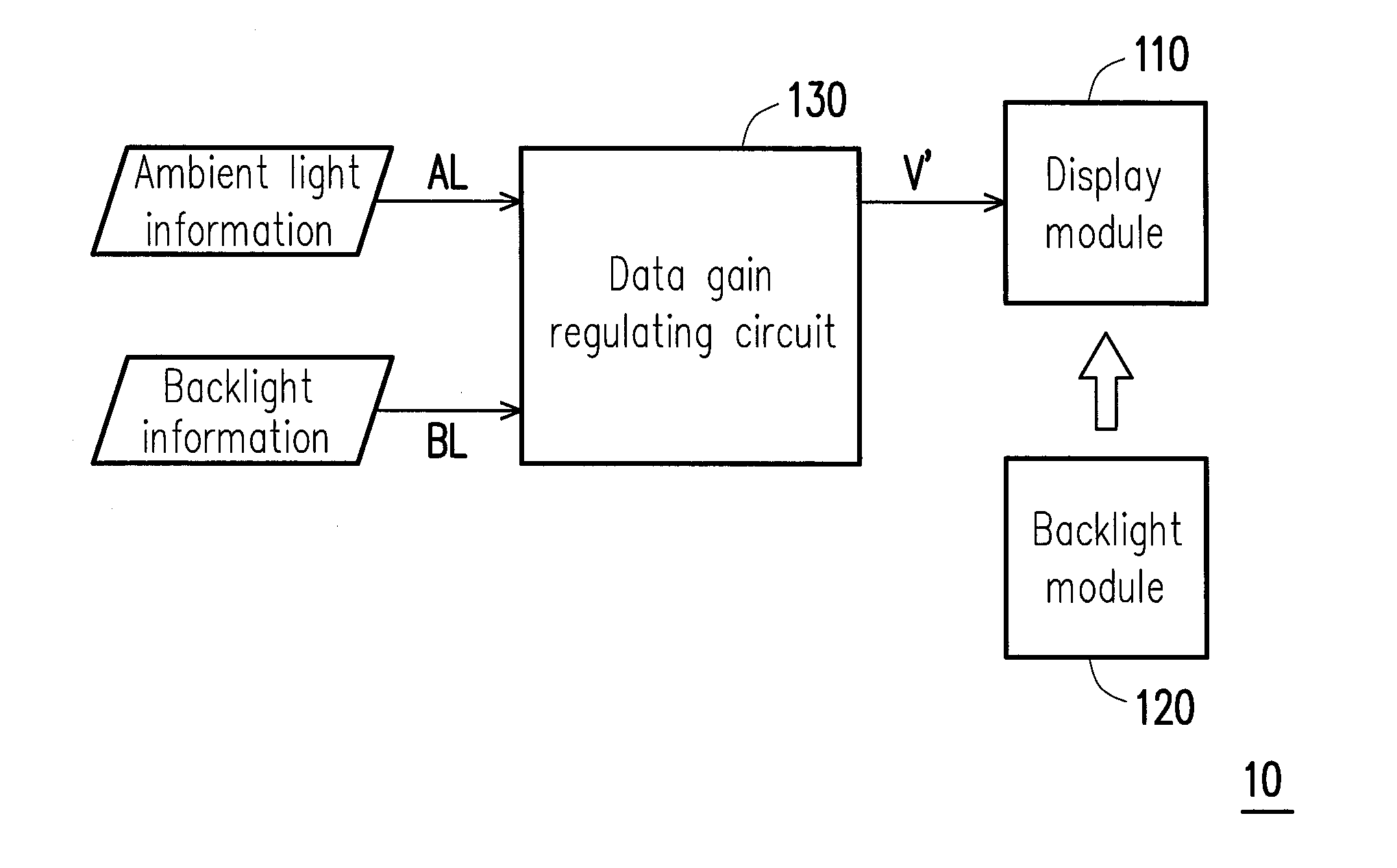

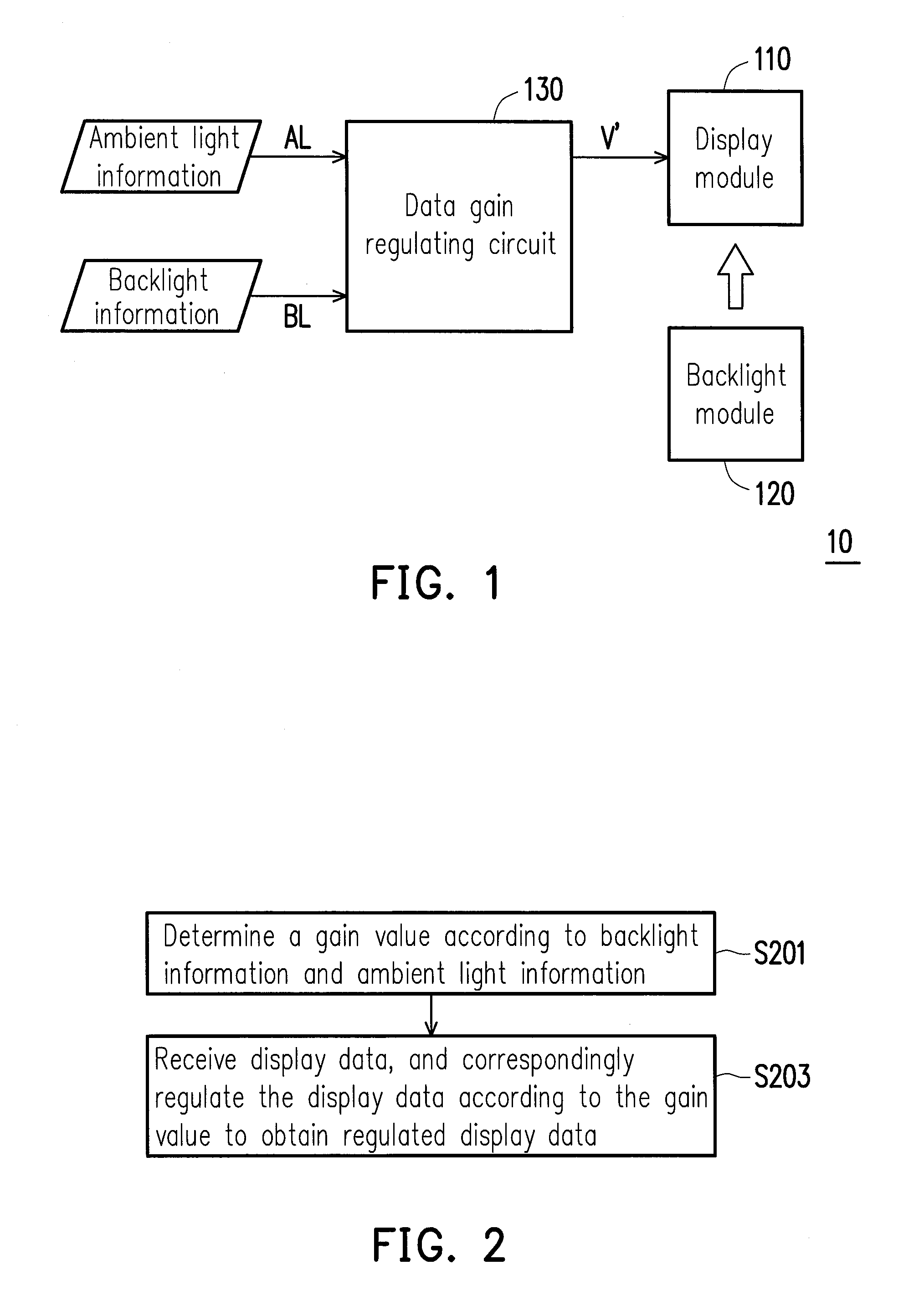

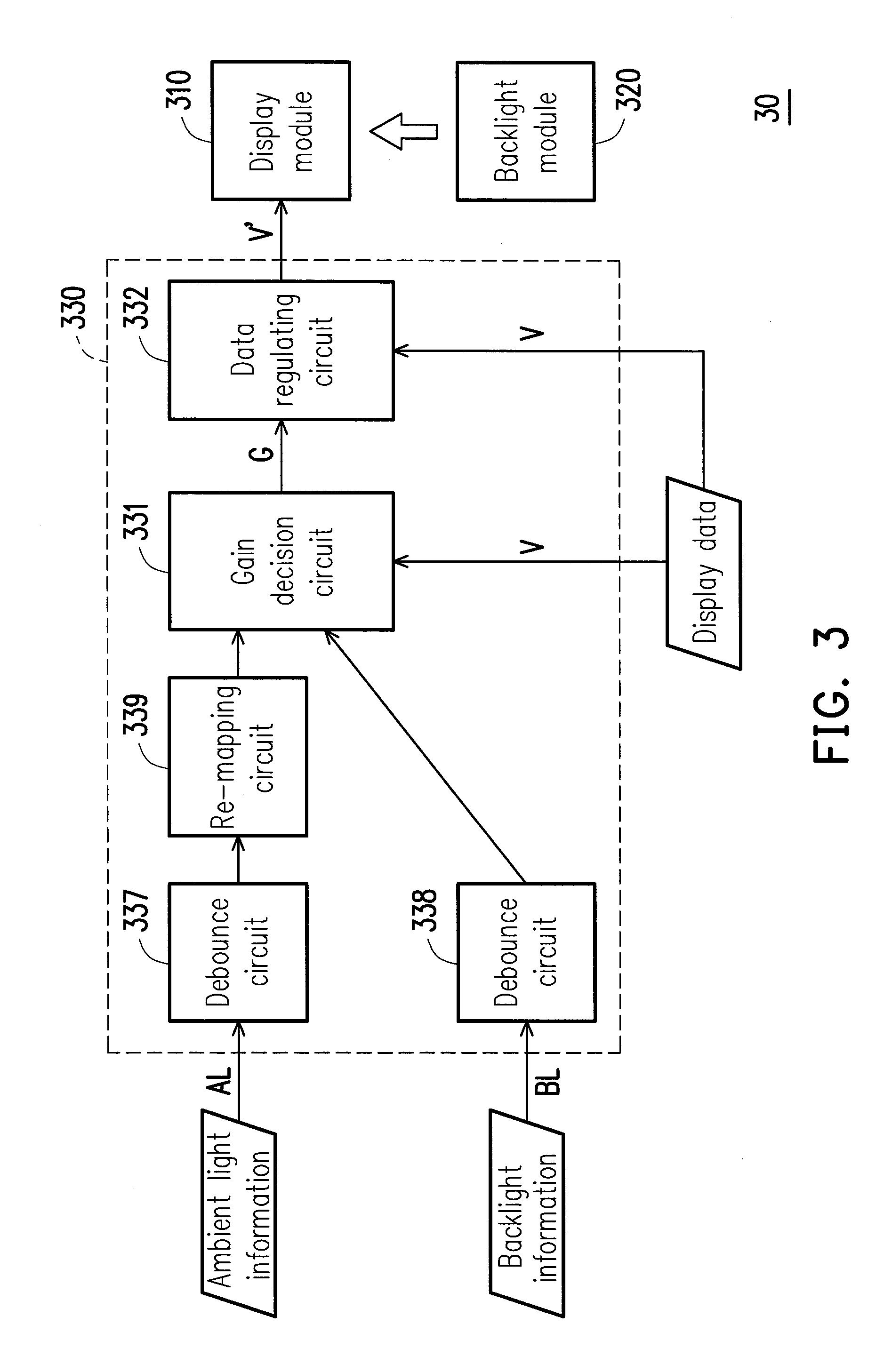

Display apparatus, data gain regulating circuit and data gain regulating method

InactiveUS20140292632A1Improve image display qualityIncrease gain valueStatic indicating devicesEngineeringElectrical and Electronics engineering

A display apparatus, a data gain regulating circuit and a data gain regulating method are provided. The display apparatus includes a display module, a backlight module and the data gain regulating circuit. The backlight module provides backlight to the display module. The data gain regulating circuit is coupled to the display module and determines a gain value according to ambient light information and backlight information. The data gain regulating circuit regulates display data according to the gain value to obtain regulated display data and transmits the regulated display data to the display module.

Owner:NOVATEK MICROELECTRONICS CORP

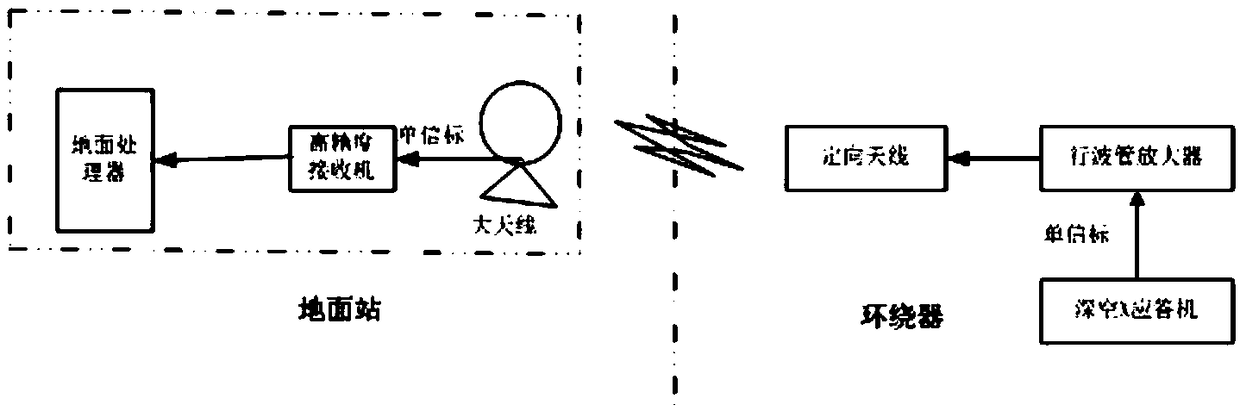

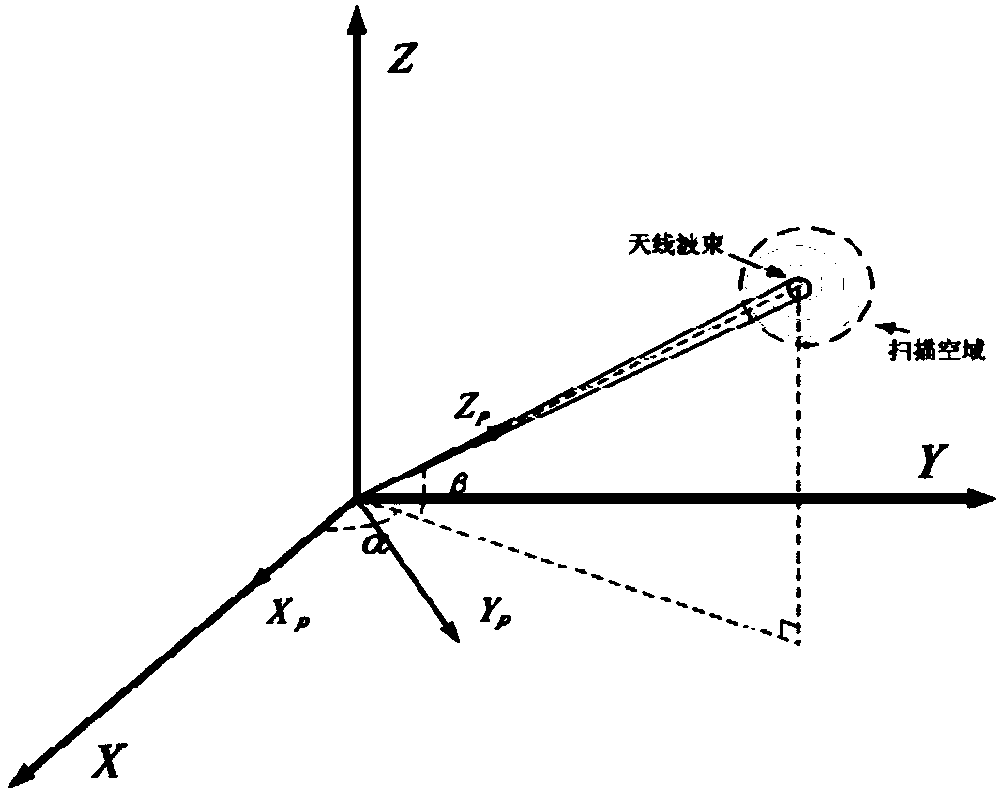

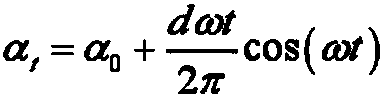

Deep-space exploration high-gain antenna in-orbit calibration system and method

ActiveCN109039422AEliminate ground pointing errorsIncrease gain valueReceivers monitoringTime-division multiplexTelecommunications linkCarrier signal

A system and method for on-orbit calibration of high-gain antenna for deep space exploration are provided. A high-gain antenna in-orbit calibration system for deep space exploration adopts a ground station and a ground station receiving detector, the ground station mainly gives a highly sensitive receiver and a large antenna. The ground station receives the single beacon or the residual carrier radio frequency signal transmitted by the detector, finds out the strongest time of the received signal, and inverts the position of the pointing space through the ground station's receiving detector. The invention carries out antenna on-orbit calibration, eliminates high-gain antenna pointing error to ground in long-term flight of the detector on orbit, and improves the gain value of the communication link.

Owner:SHANGHAI SATELLITE ENG INST

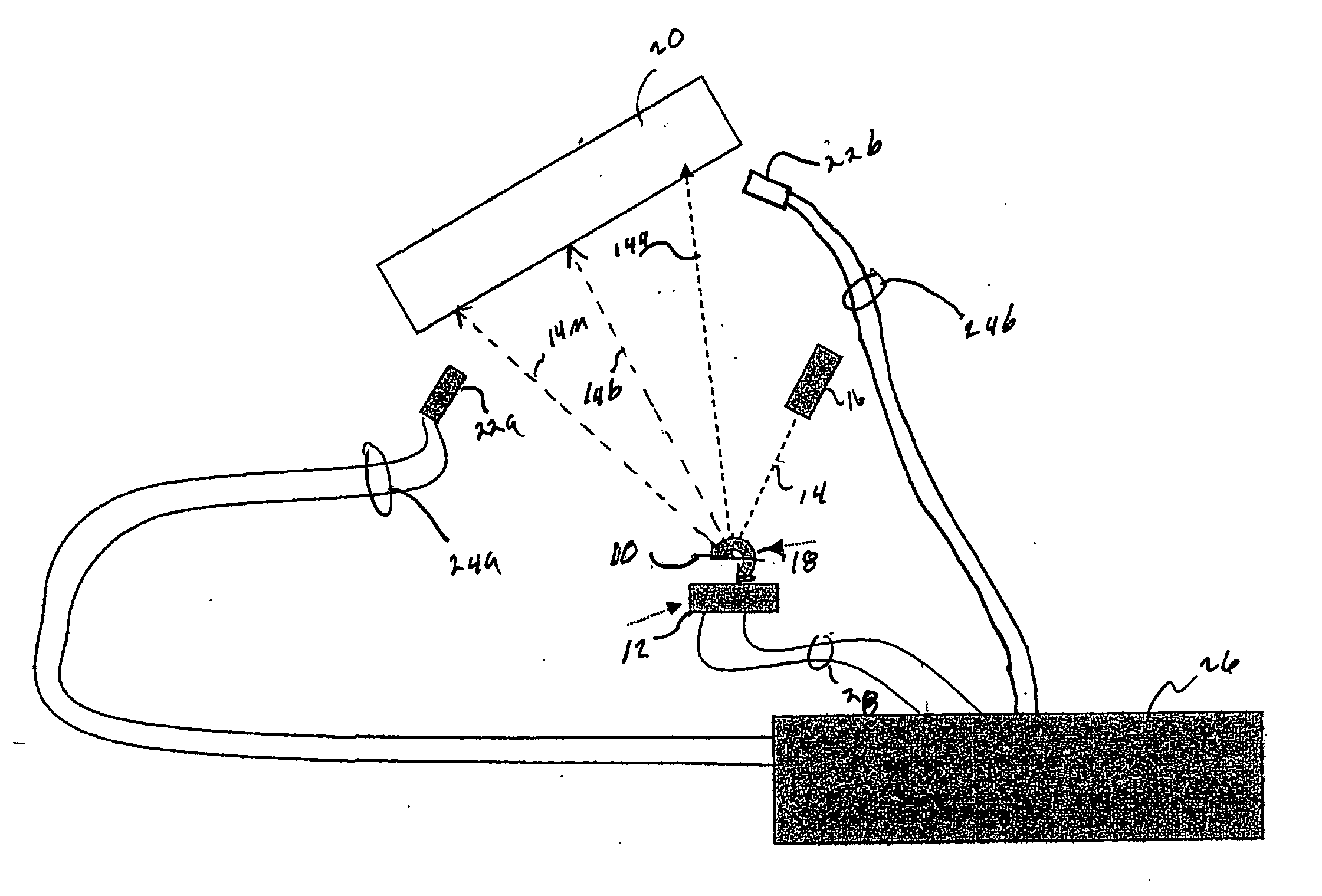

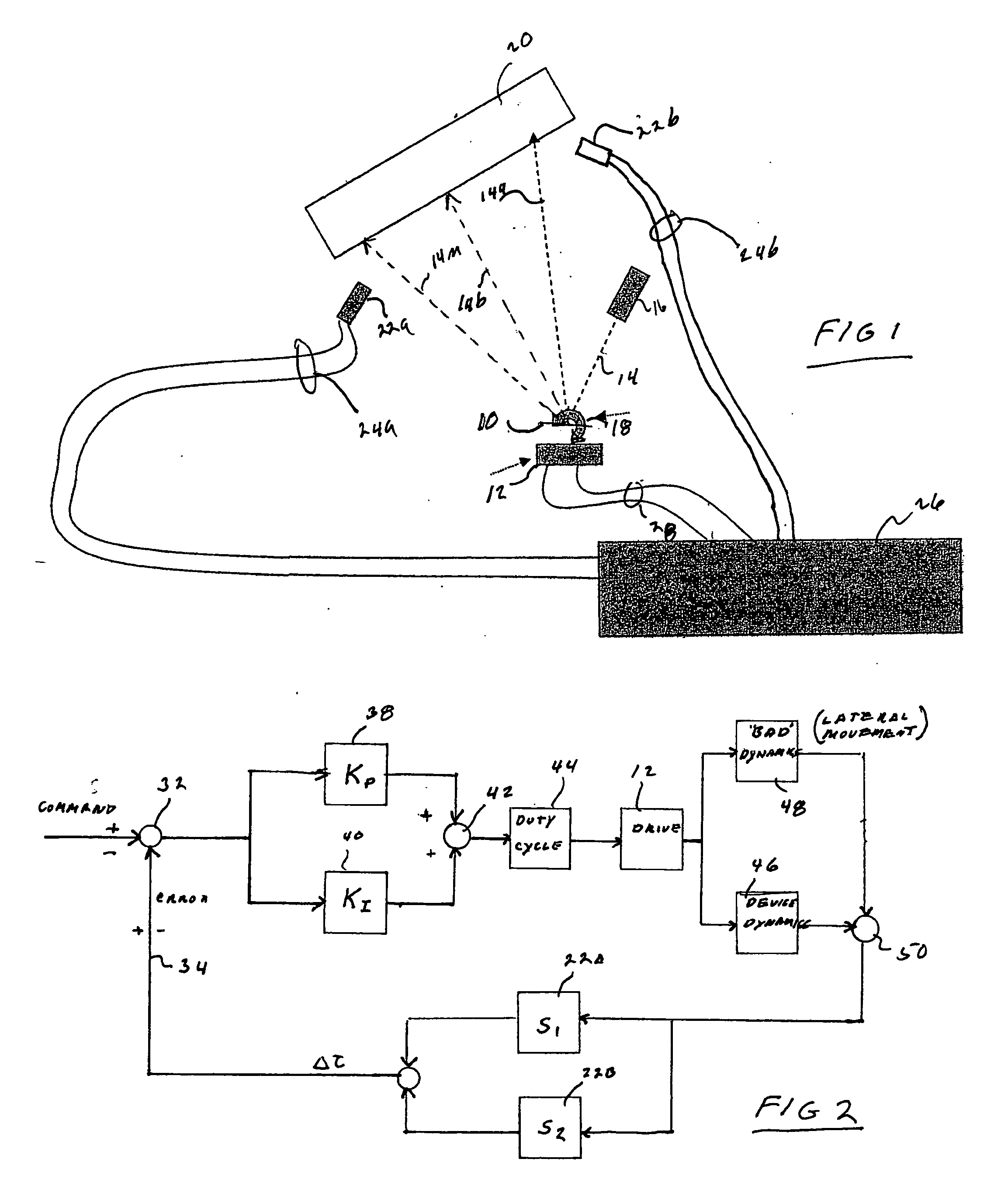

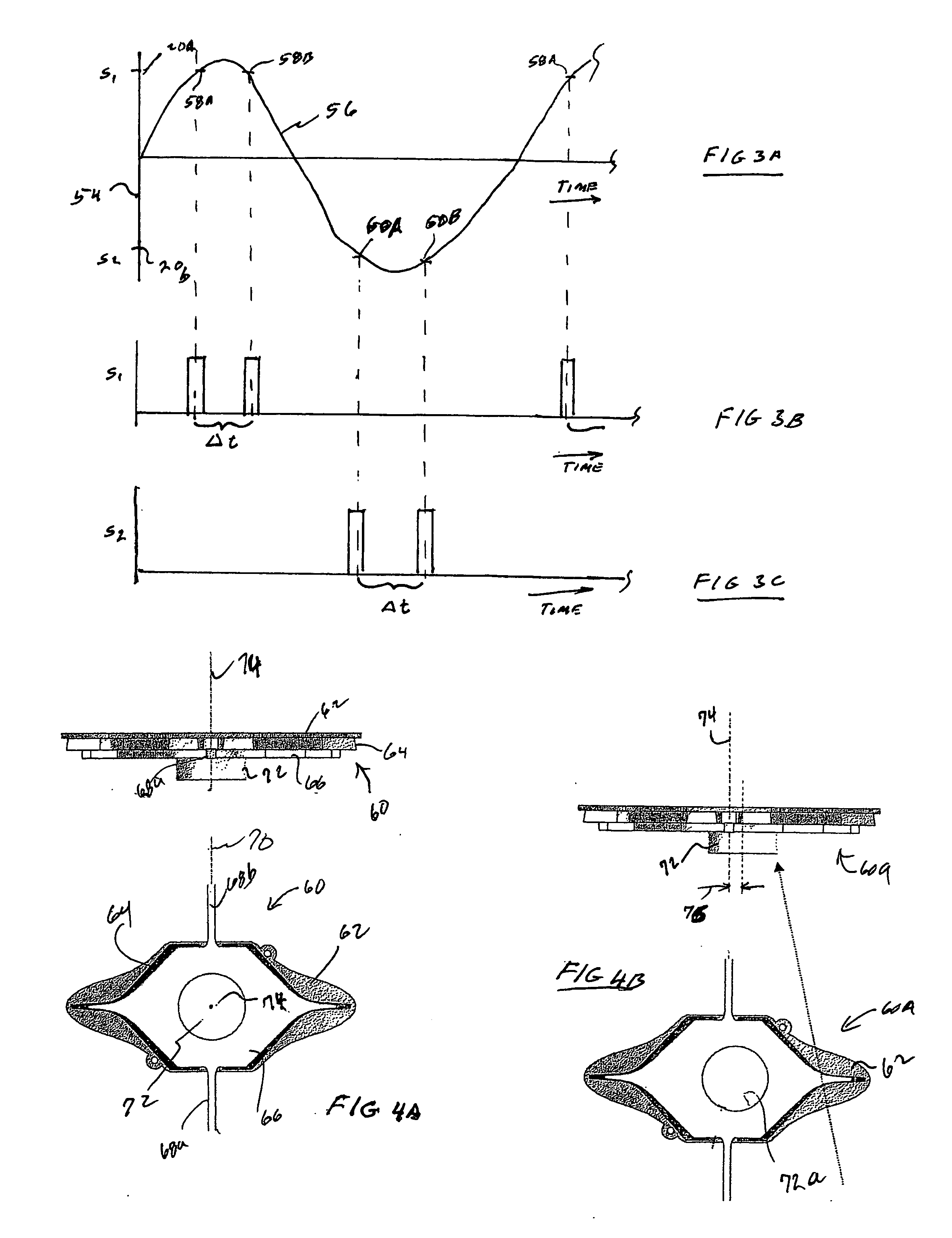

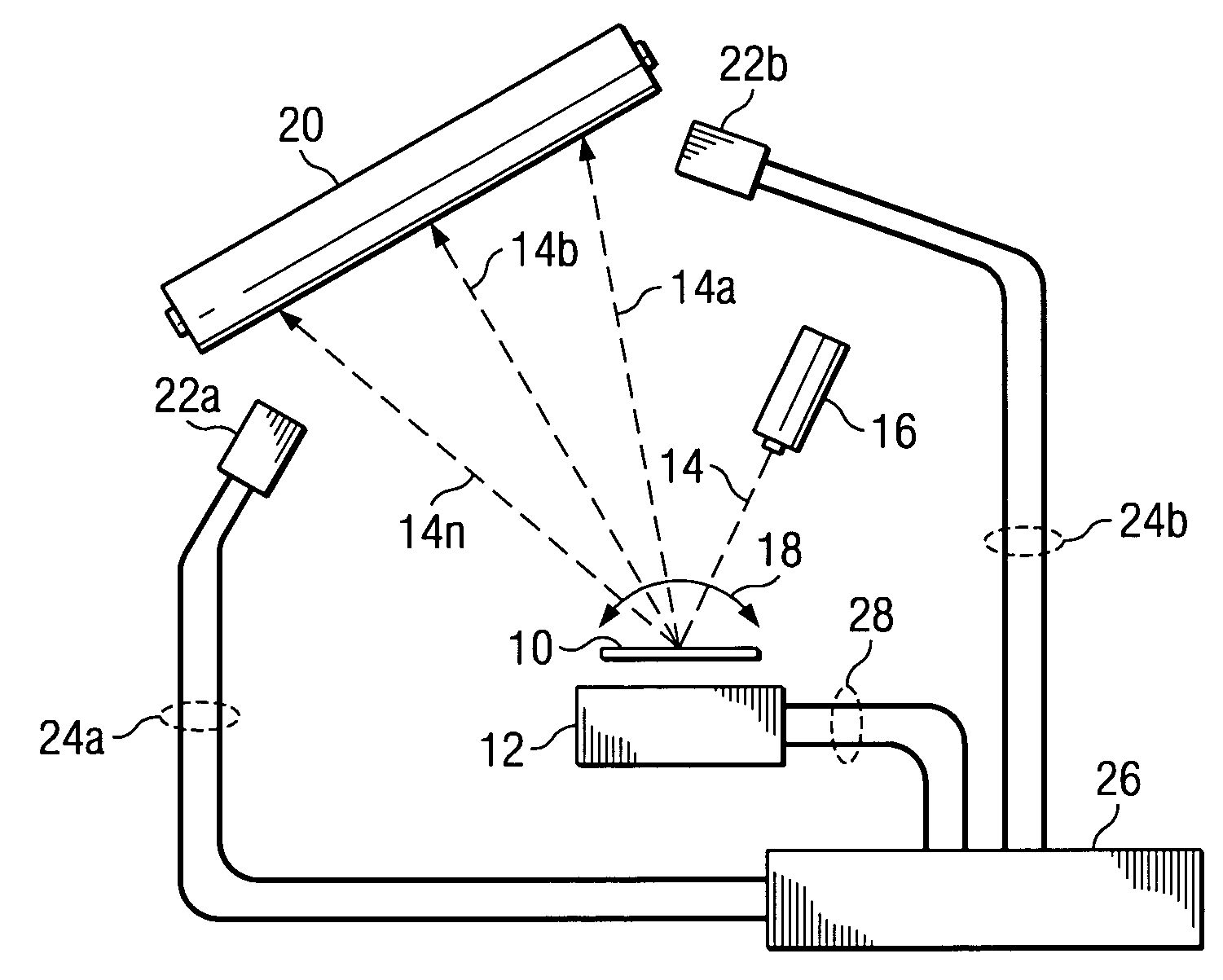

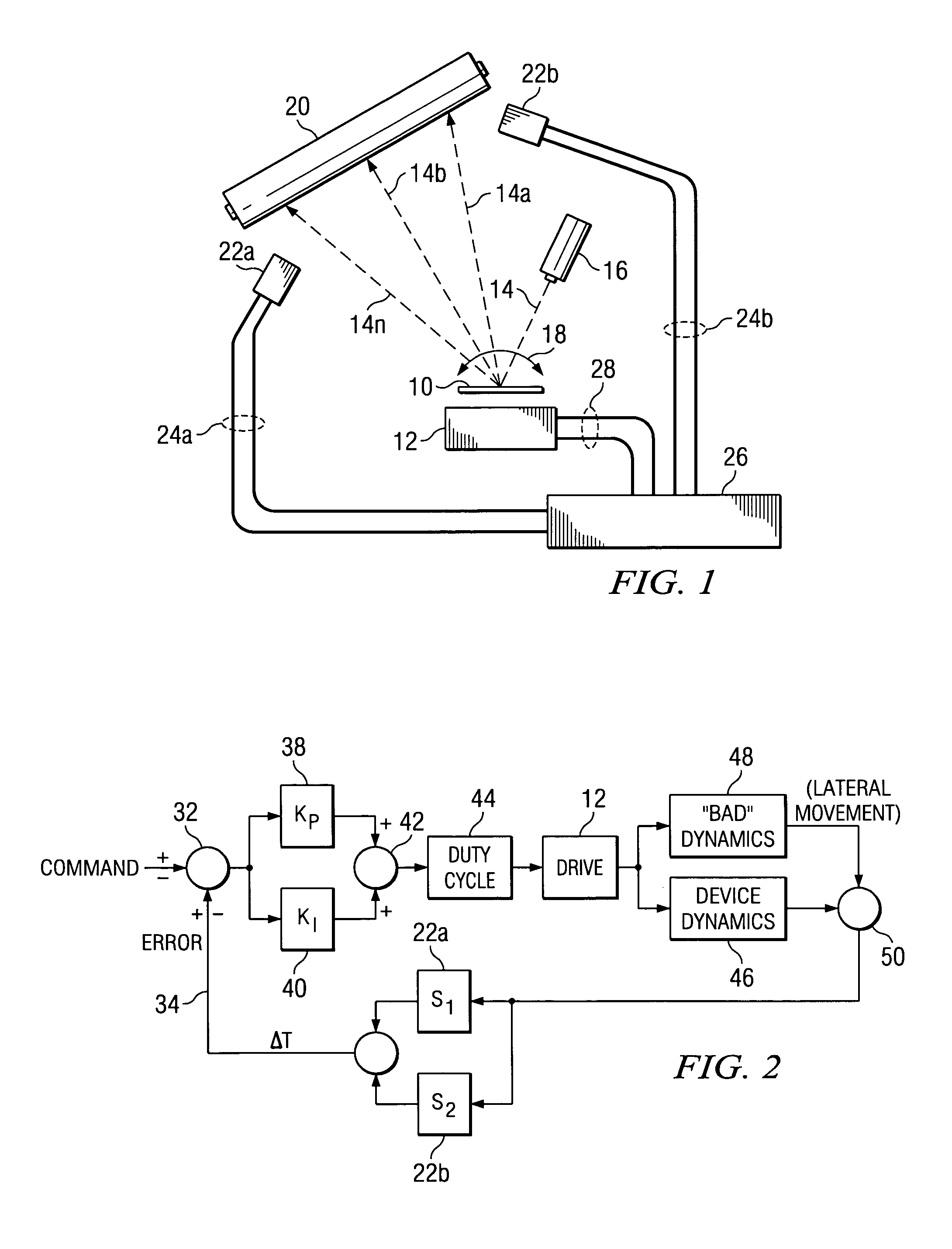

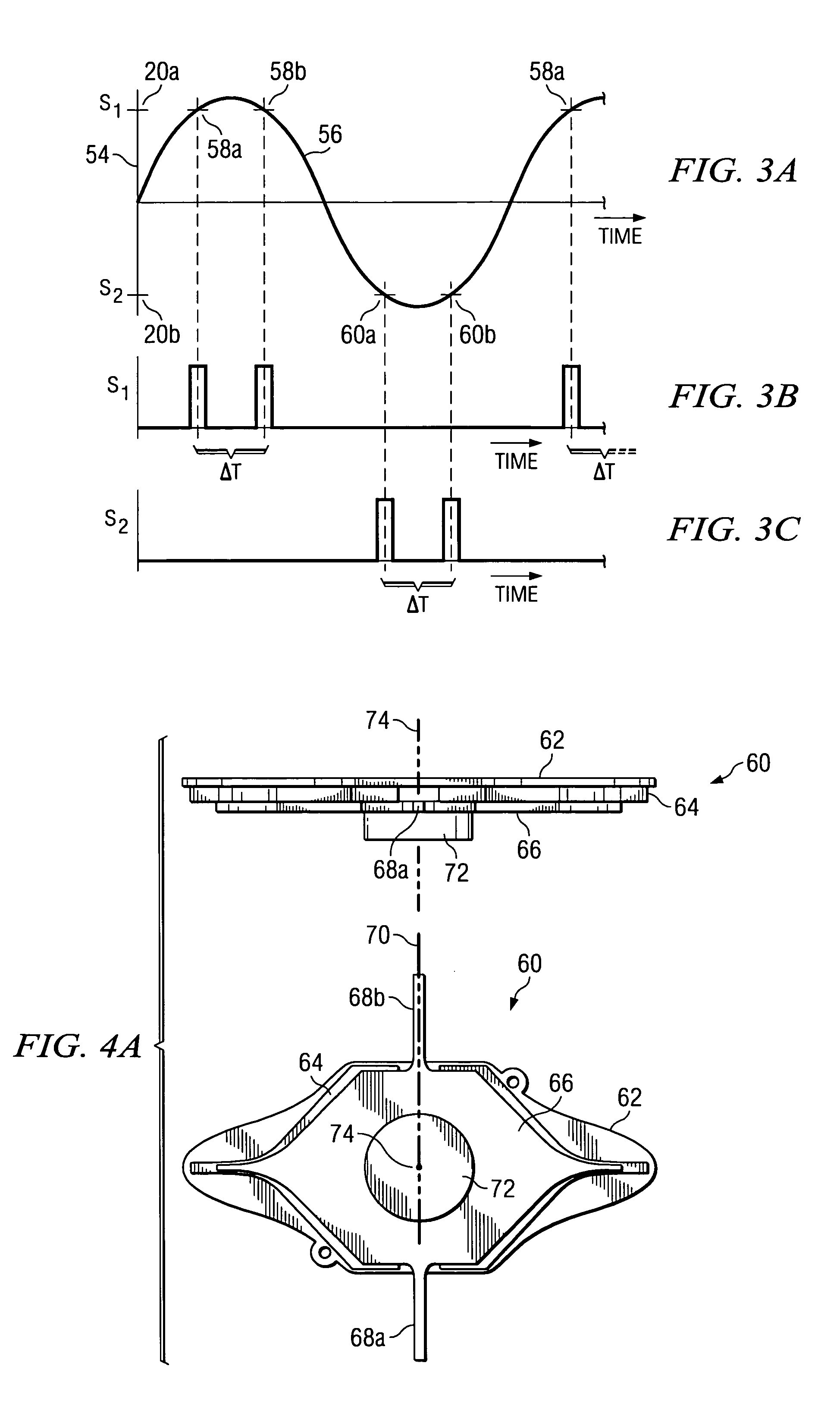

Stabilization of closed loop operation of a torsional hinged device

ActiveUS20060001940A1High proportional gain valueReduced amplificationStatic indicating devicesMountingsClosed loopAsymmetry

Apparatus and methods for removing jitter and stabilizing the feed back system of a torsional hinged device with minimal changes to the system. The stabilization is accomplished by introducing a selected amount of lateral motion (in addition to the rotational motion) by creating asymmetry in the oscillating device or the drive torque applied to the device.

Owner:TEXAS INSTR INC

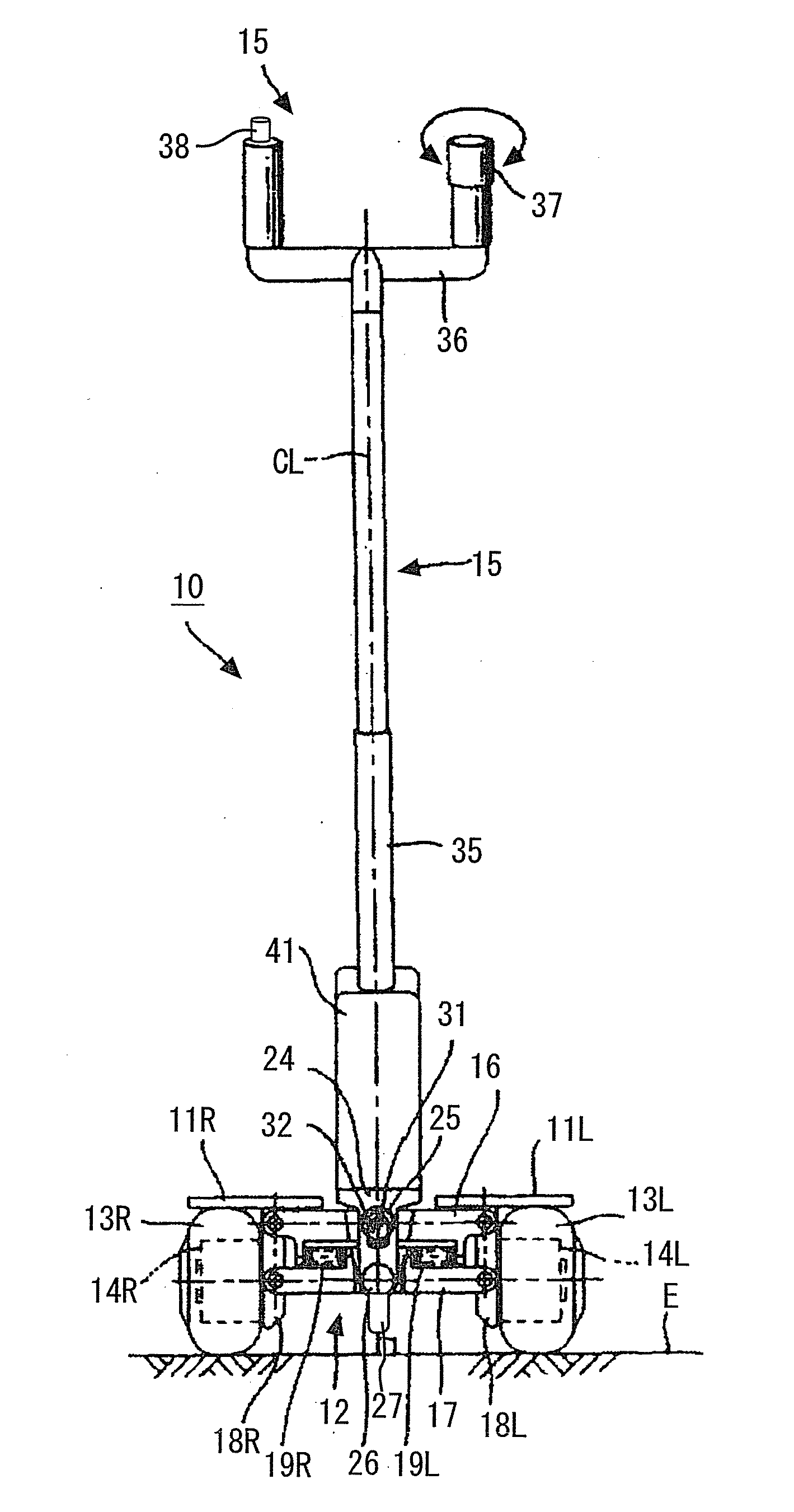

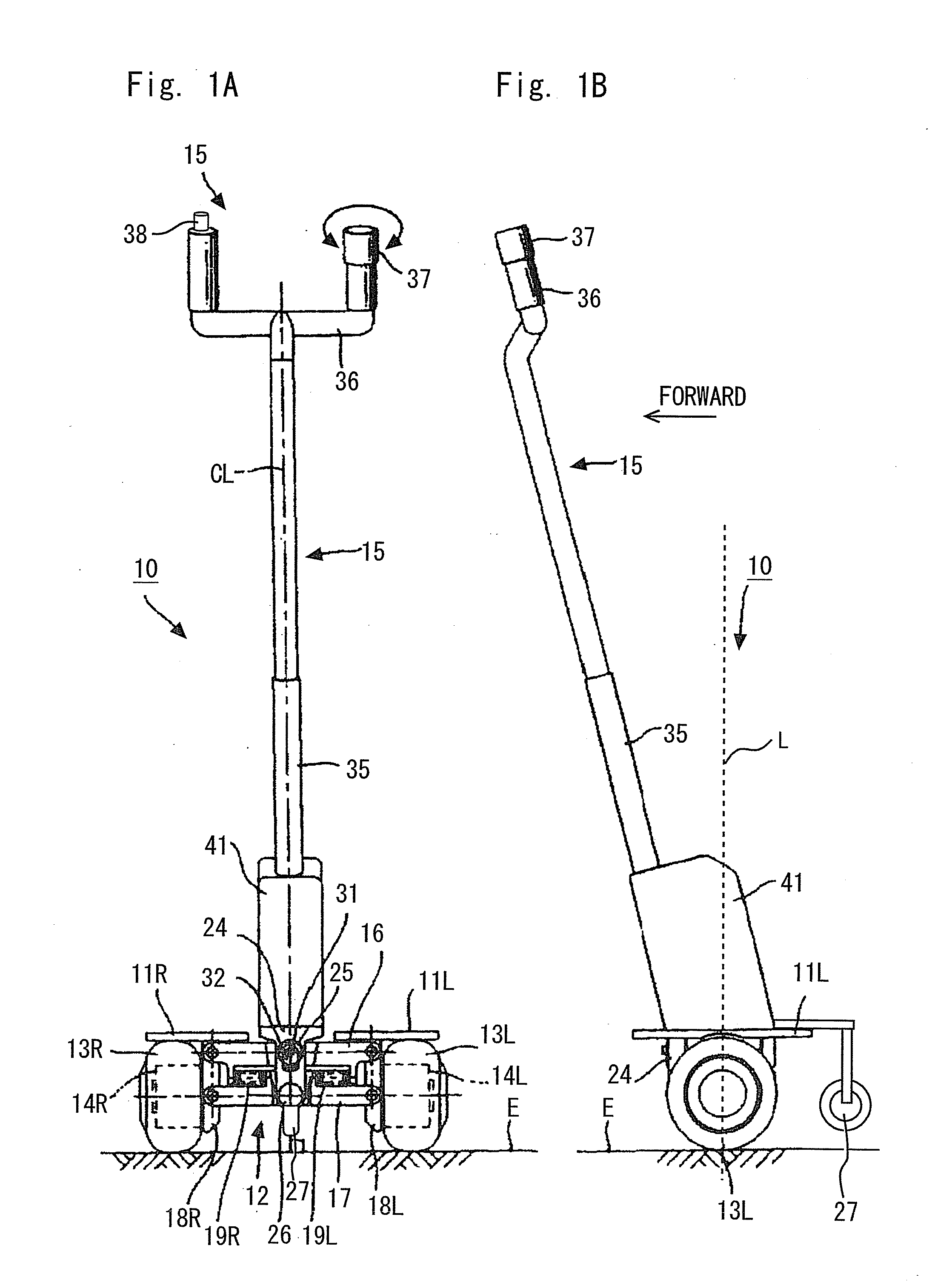

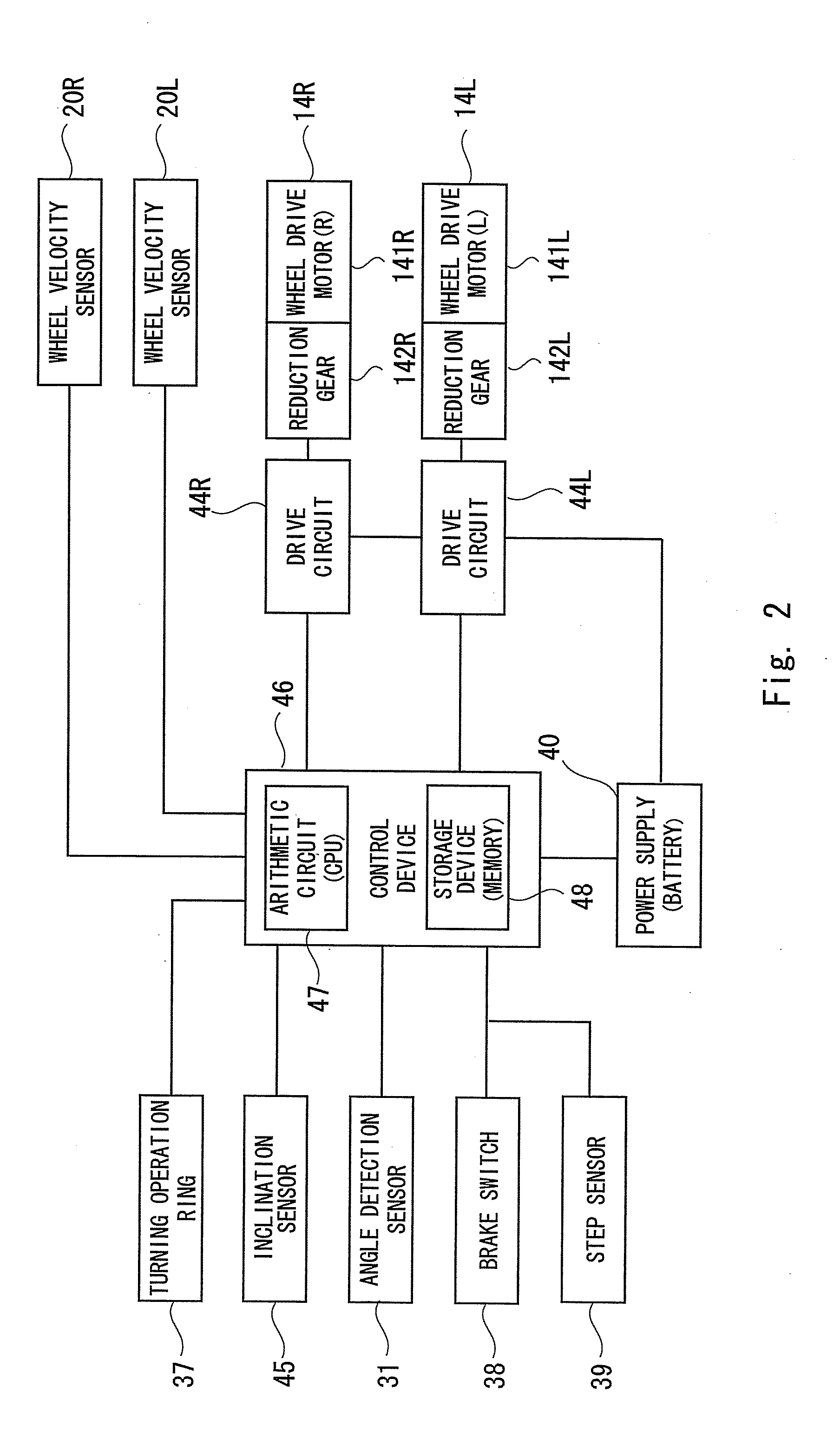

Traveling device and its control method

ActiveUS20100268446A1Smooth rideIncrease gain valueAttitude controlComplex mathematical operationsGround contactRoad surface

A traveling device 10 includes ground touching detection means to detect a ground touching state in which a ground touching member touches a road surface, and control means to perform inversion control by controlling the driving of a wheel. When a ground touching state of the ground touching member is detected by the ground touching detection means, the control means suspends the inversion control. Further, when the start of braking is detected by the braking detection means and a ground touching state of the ground touching member is detected by the ground touching means, the control means may suspend the inversion control.

Owner:TOYOTA JIDOSHA KK

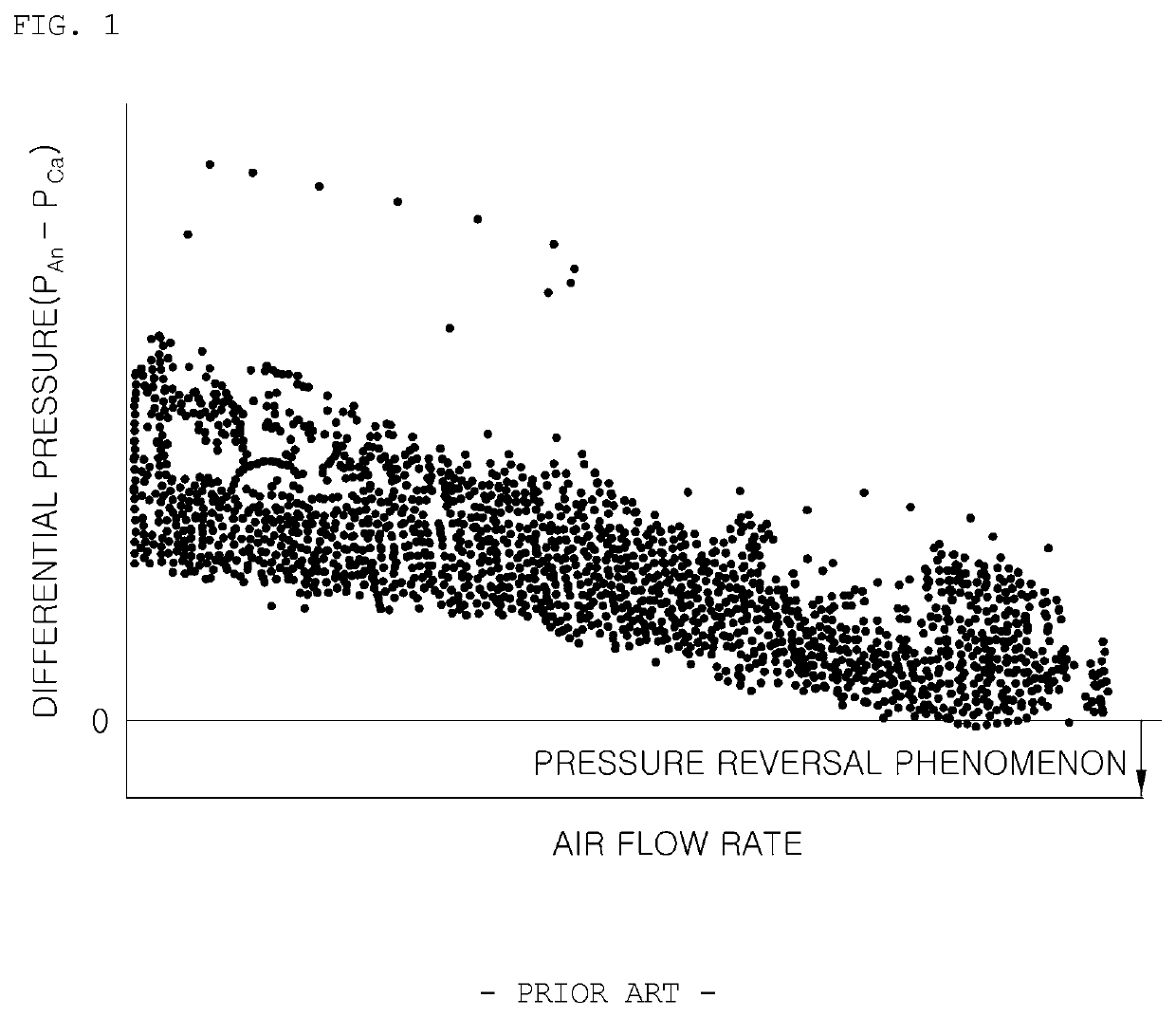

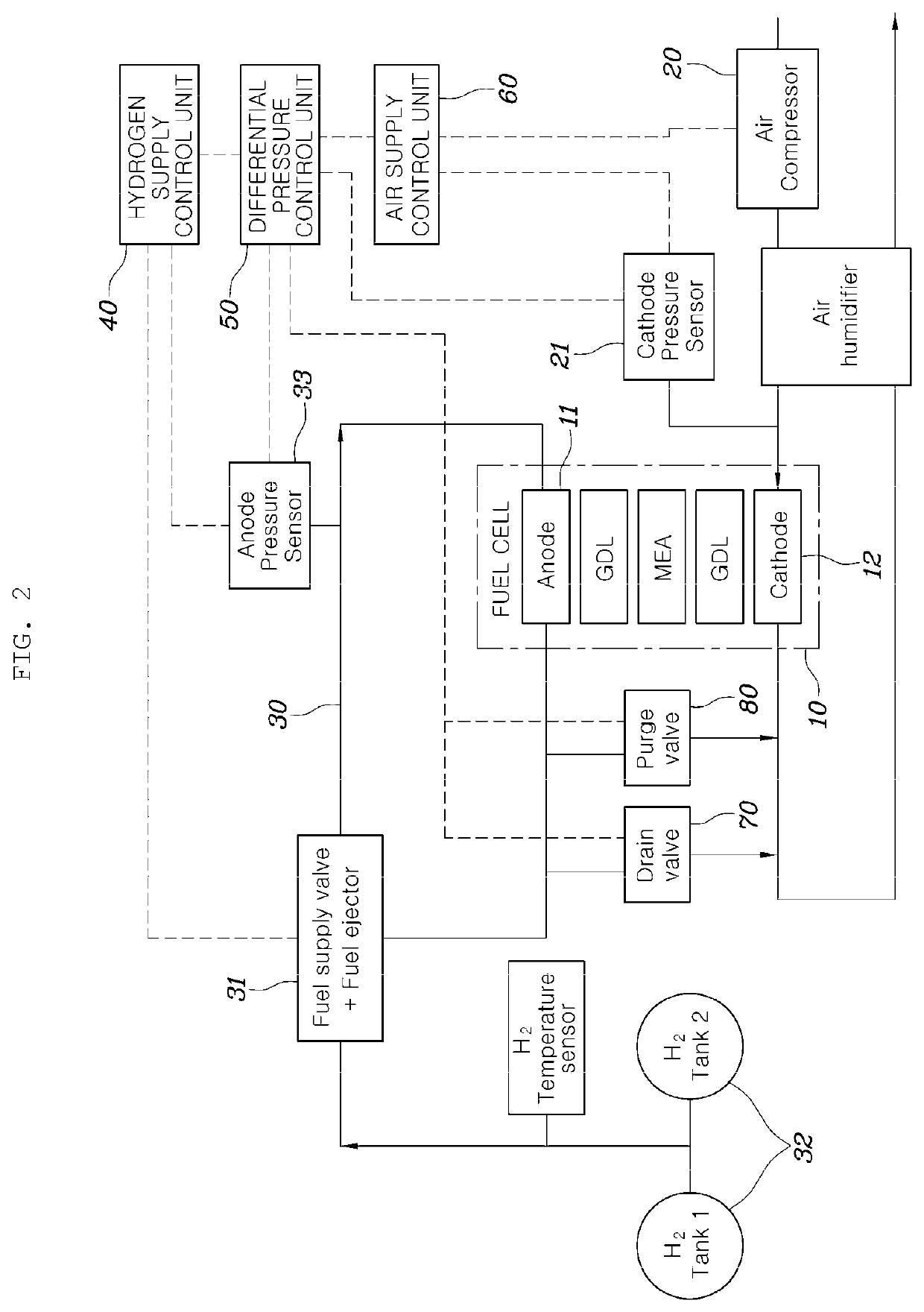

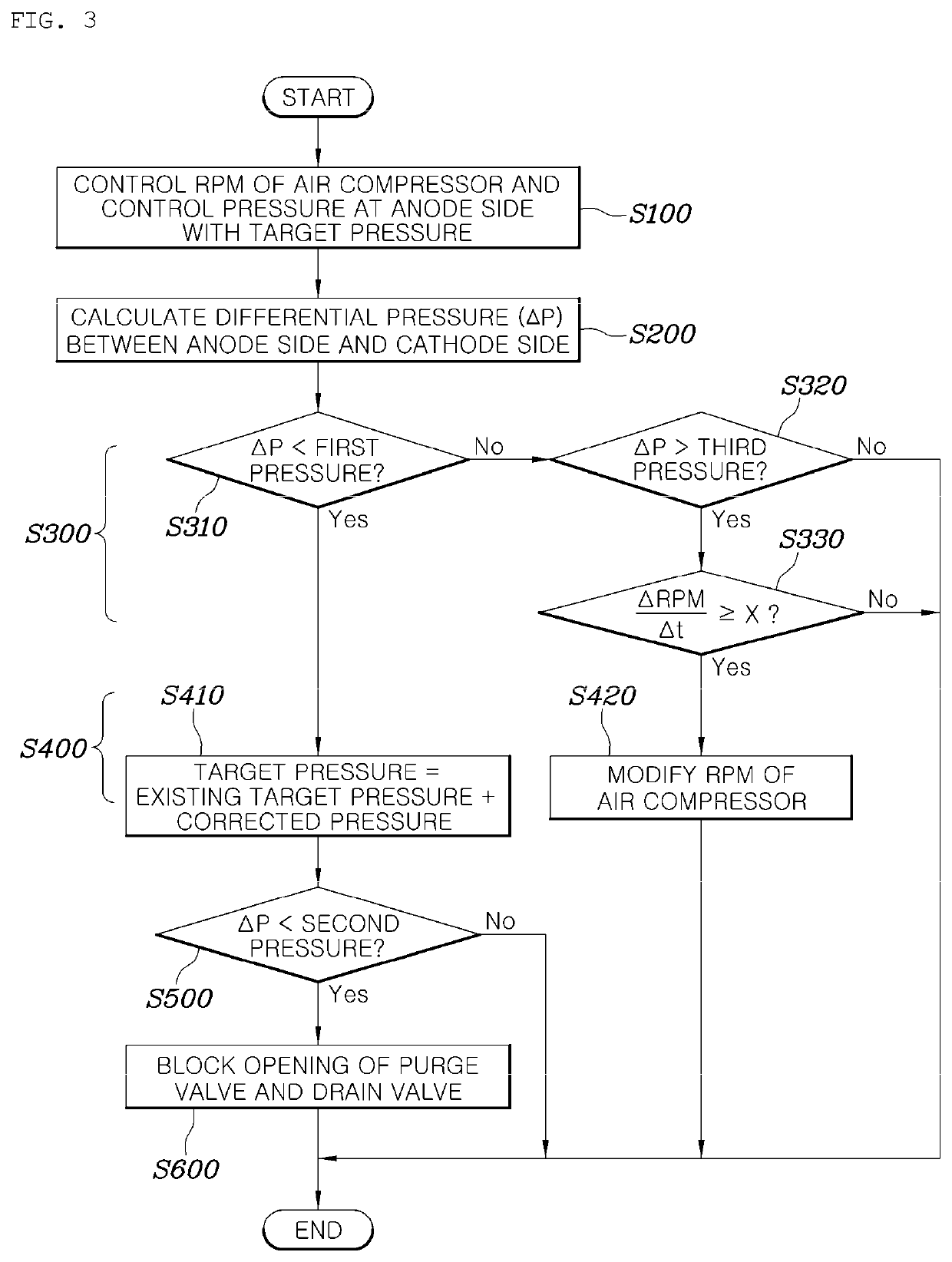

Pressure control system and control method of fuel cell stack

ActiveUS20200161682A1Reduce volatilityUniform maintenanceReactant parameters controlControl systemEngineering

A pressure control system of a fuel cell stack includes: an air supply control unit for controlling a revolutions per minute (RPM) of an air compressor for supplying air to a cathode side of the fuel cell stack based on a required output of the fuel cell stack; a hydrogen supply control unit for controlling a pressure at an anode side of the fuel cell stack with a target pressure based on the required output of the fuel cell stack; and a differential pressure control unit for controlling the air supply control unit or the hydrogen supply control unit to calculate a differential pressure between the anode side and the cathode side of the fuel cell stack, and to modify the target pressure or the RPM of the air compressor based on the calculated differential pressure.

Owner:HYUNDAI MOTOR CO LTD +1

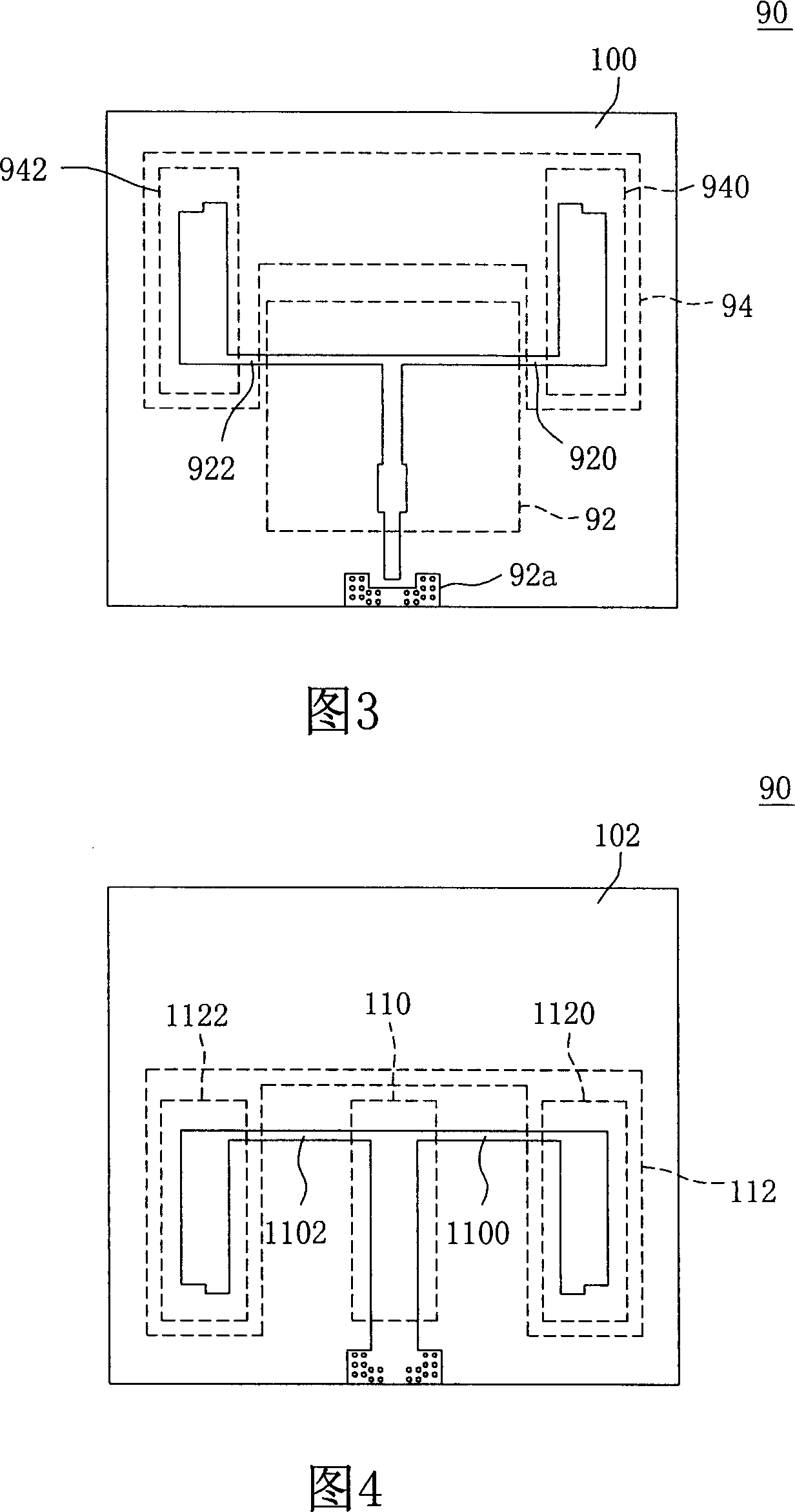

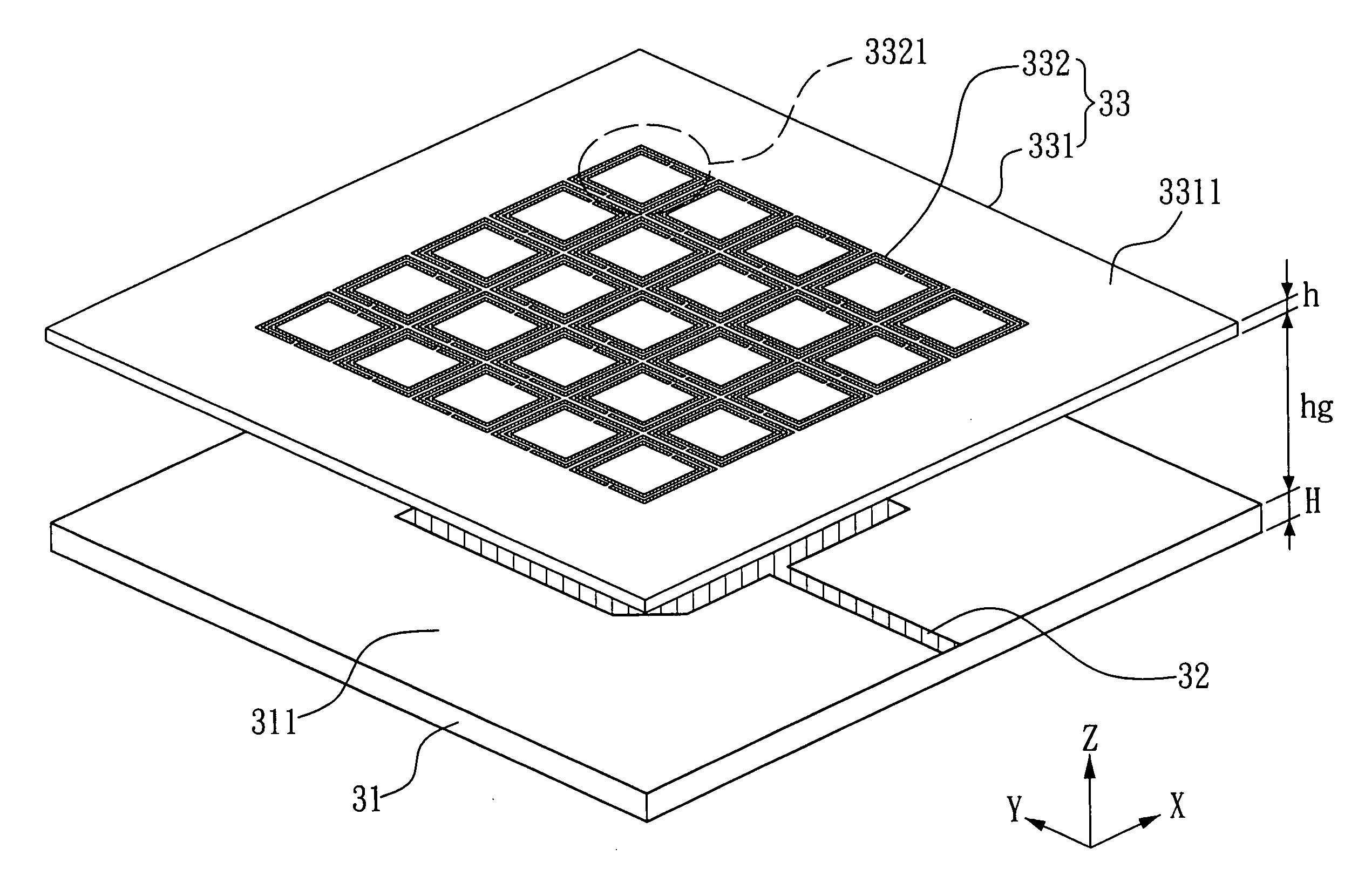

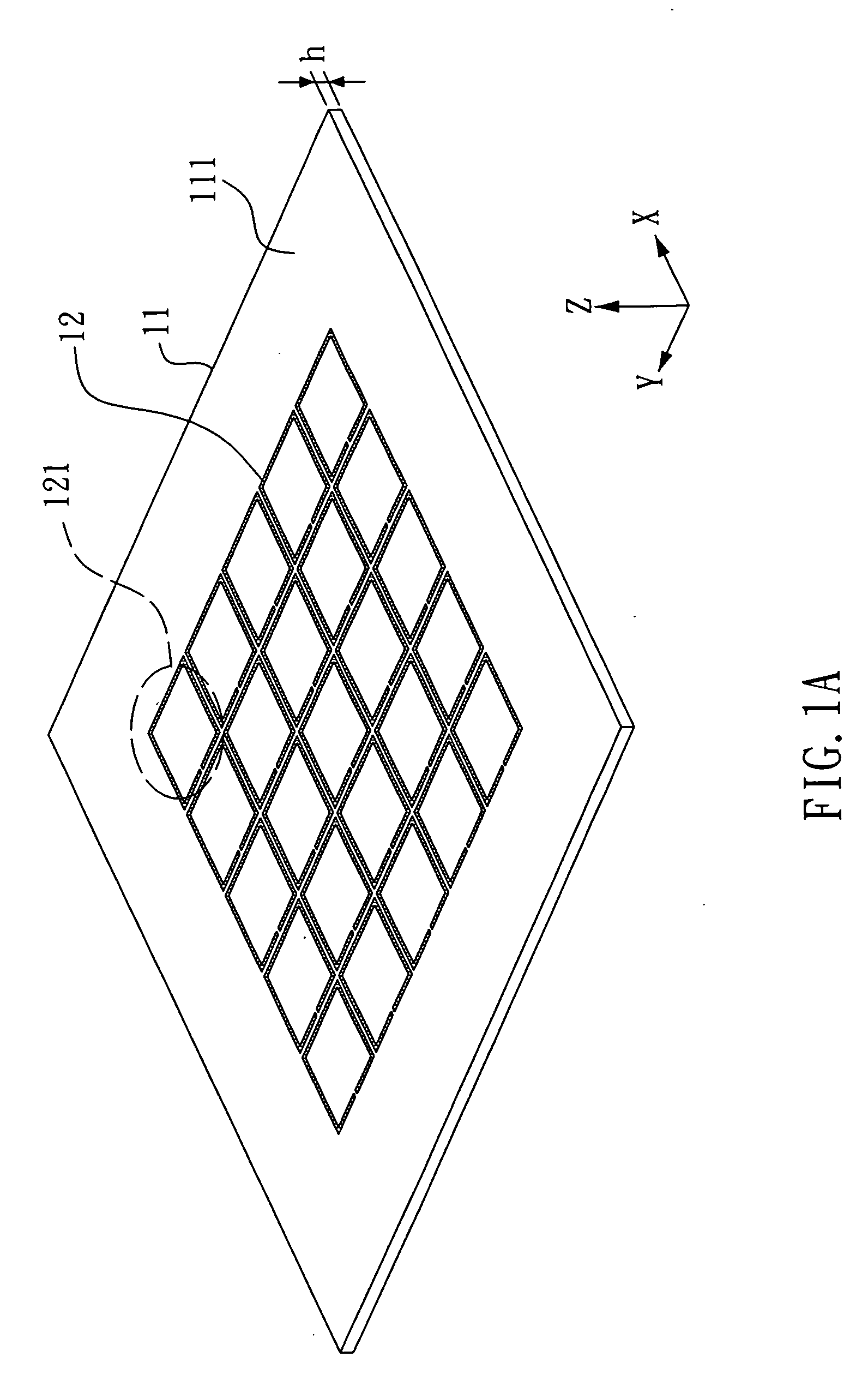

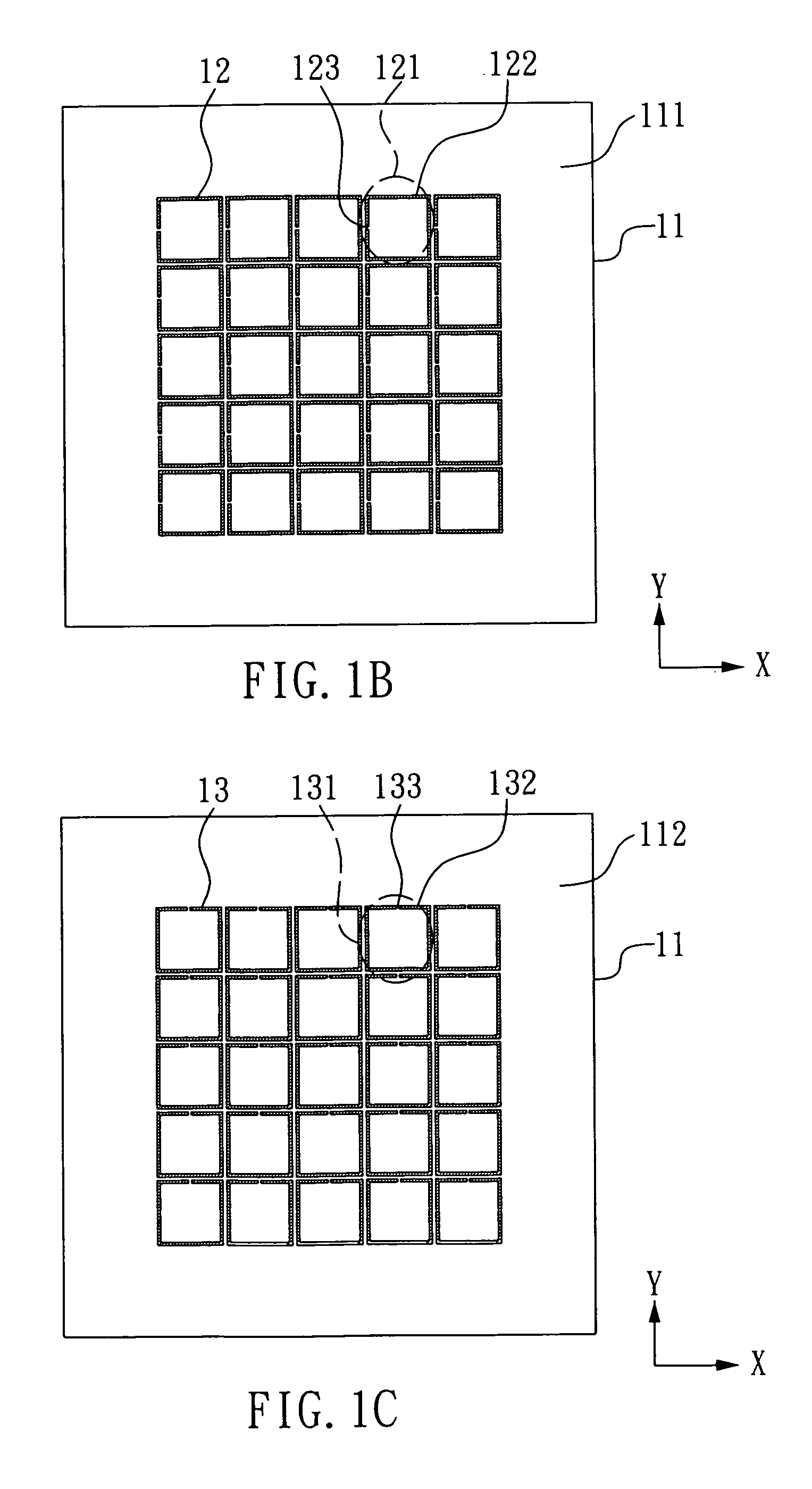

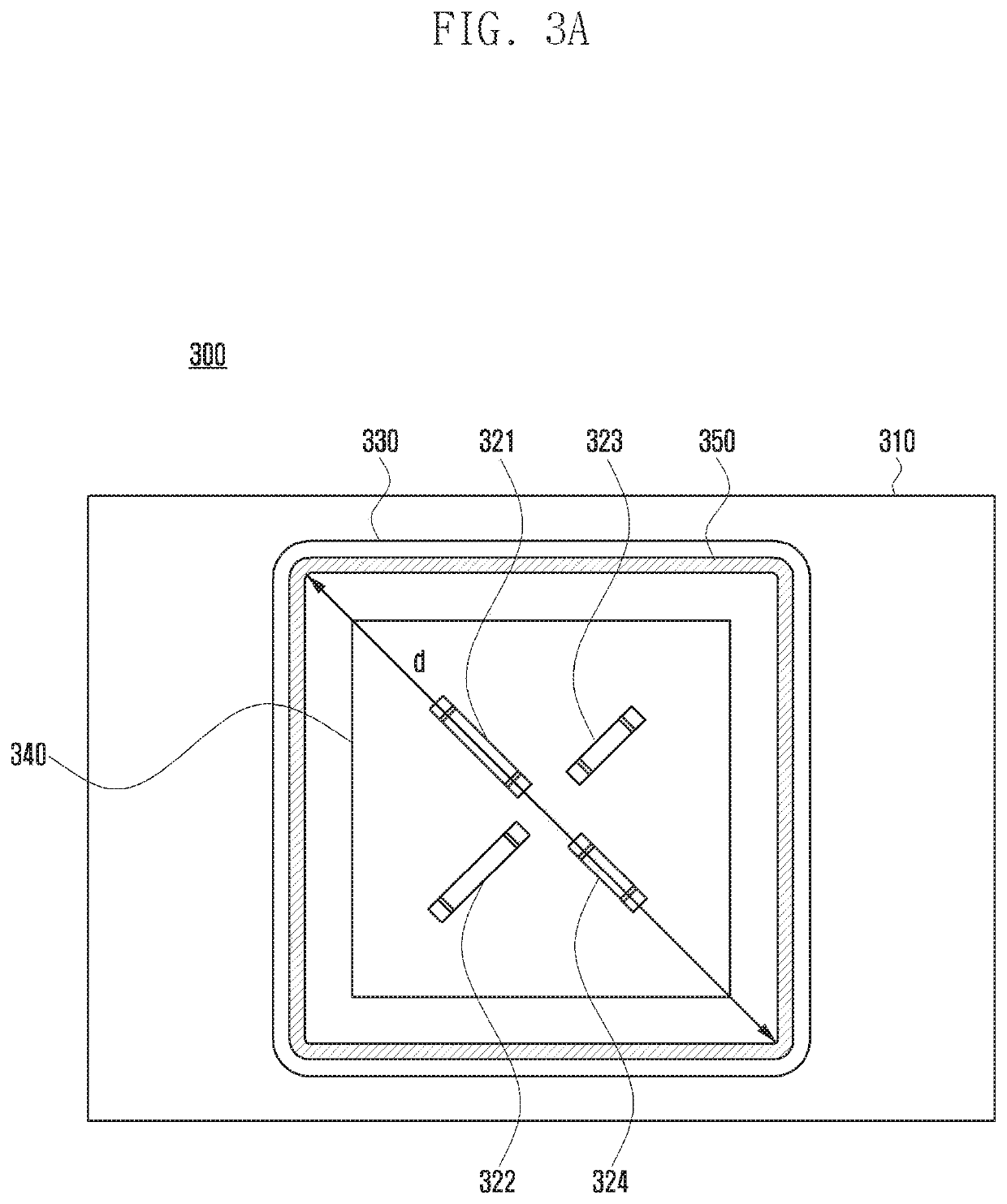

Radome and microstrip patch antenna having the same

InactiveUS20100097271A1Improve performanceIncrease gain valueSimultaneous aerial operationsRadiating elements structural formsPhysicsRadome

A radome and a microstrip patch antenna having the same are disclosed. The gain value of the microstrip patch antenna having the disclosed radome can be increased while the size thereof remains in a limited size. The disclosed radome comprises: a radome body, having an upper surface and a lower surface; a first gain-enhancing pattern, locating on the upper surface and including a plurality of first ring gain-enhancing units; and a second gain-enhancing pattern, locating on the lower surface and including a plurality of second ring gain-enhancing units. The first ring gain-enhancing unit includes a first conductive ring and a second conductive ring, and the second ring gain-enhancing unit includes a third conductive ring and a fourth conductive ring. Besides, the opening direction of the third conductive ring is perpendicular to the opening direction of the first conductive ring.

Owner:TATUNG UNIVERSITY +1

Monopole antenna and wireless network device having the same

InactiveUS20090146888A1Improved radiation patternHigh gainAntenna supports/mountingsRadiating elements structural formsThin metalMonopole antenna

The present invention discloses a monopole antenna adapted for a wireless network device. The antenna includes a base portion, a ground portion, a radiating portion and a signal portion. The ground portion extends a predetermined height upwardly from the base portion. The radiating portion is connected to an end of the ground portion away from the base portion and is substantially perpendicular to the ground portion. The signal portion is connected to the radiating portion and is substantially and respectively perpendicular to the signal portion and the ground portion. The signal portion has a feed terminal formed on an end thereof away from the radiating portion. A connecting side, where the ground portion and the base portion are connected, has a width that is smaller than a width of another connecting side, where the ground portion and the radiating portion are connected; and a connecting side, where the signal portion and the radiating portion are connected, has a width that is larger than a width of the end of signal portion away from the radiating portion. The antenna is a single component integrally formed by stamping an electrically conductive thin metal plate, which facilitates not only fabrication thereof, but also the assembly of the antenna to a substrate of the wireless network device and increases the gain and bandwidth of the wireless network device along a vertical direction as well.

Owner:CAMEO COMM

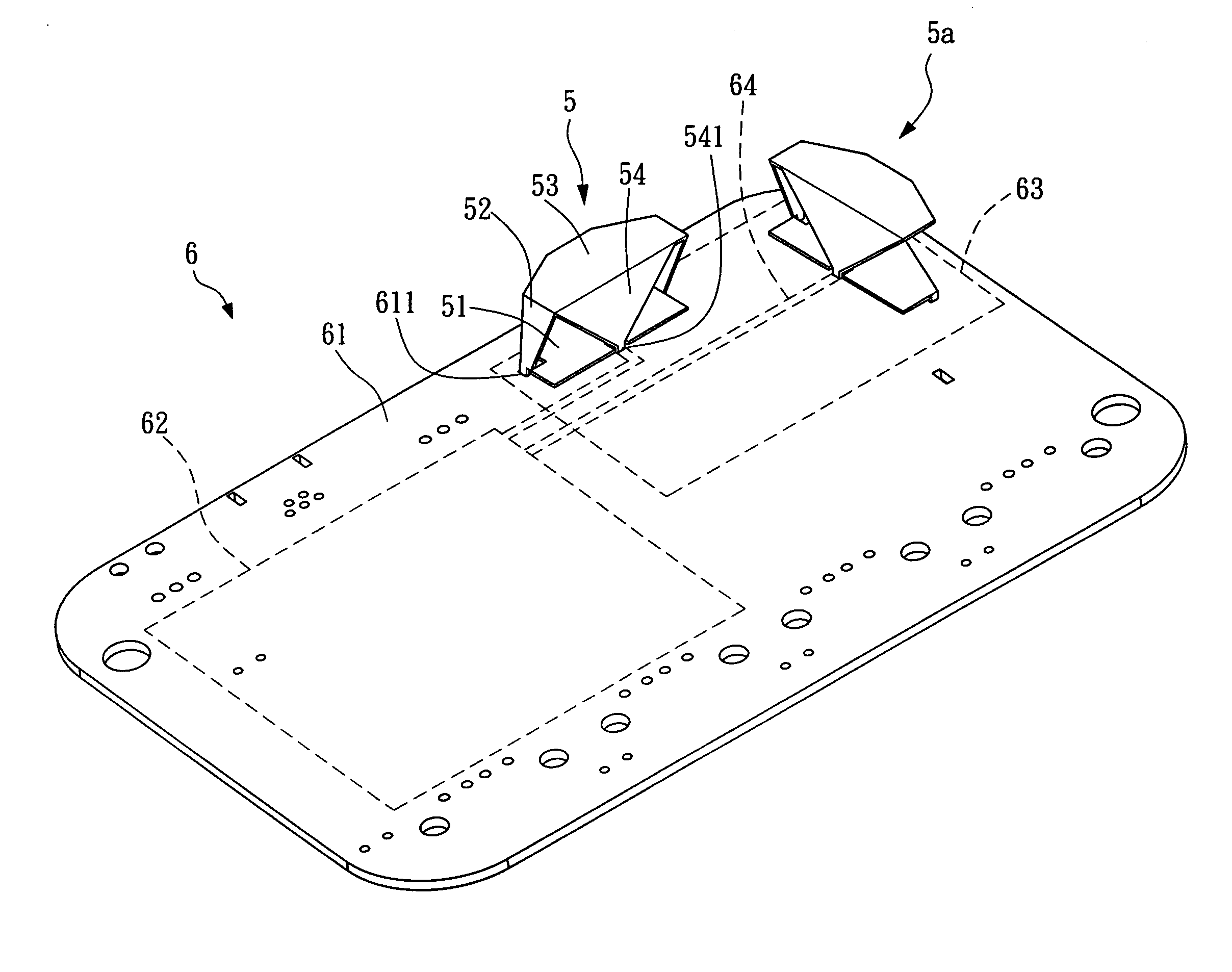

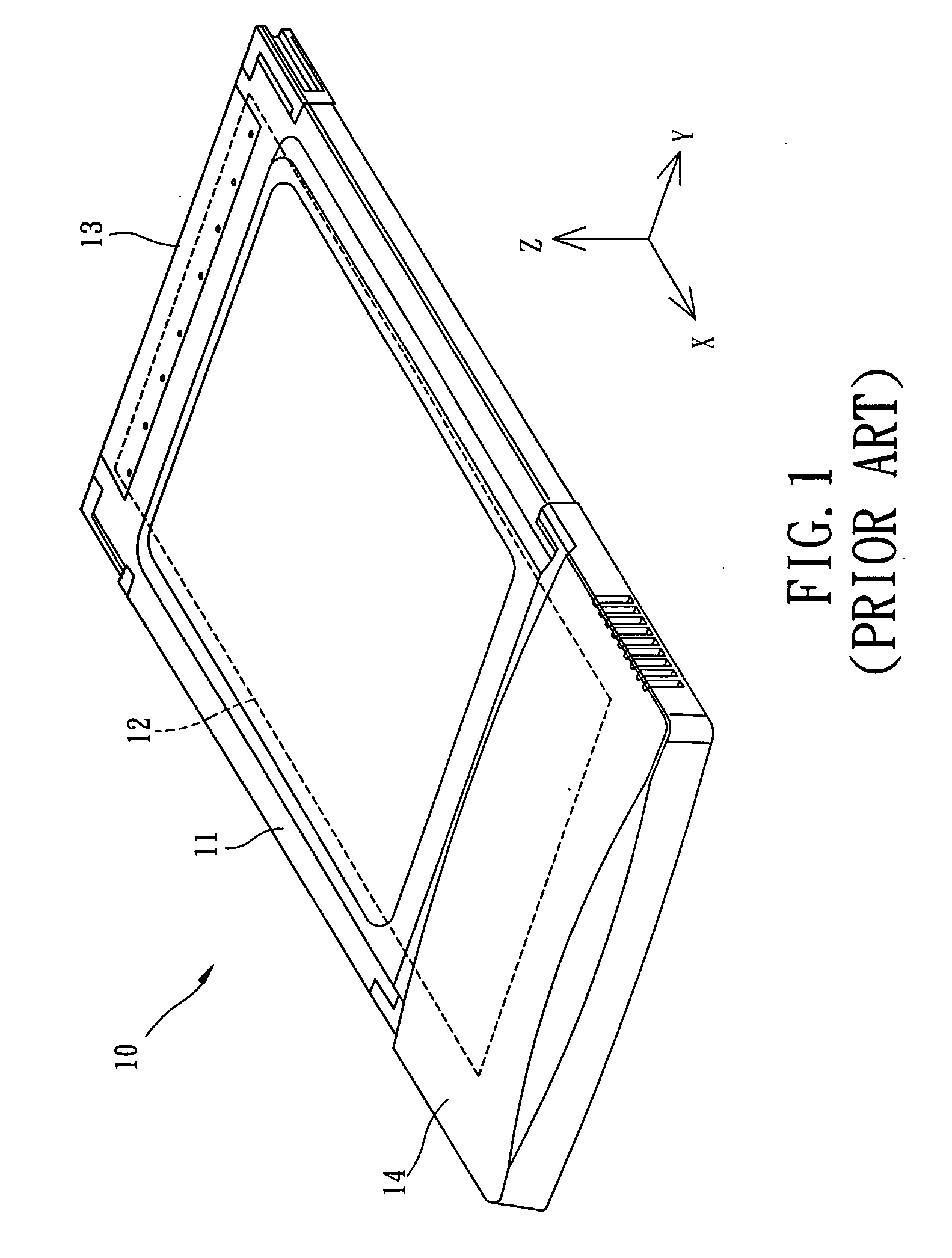

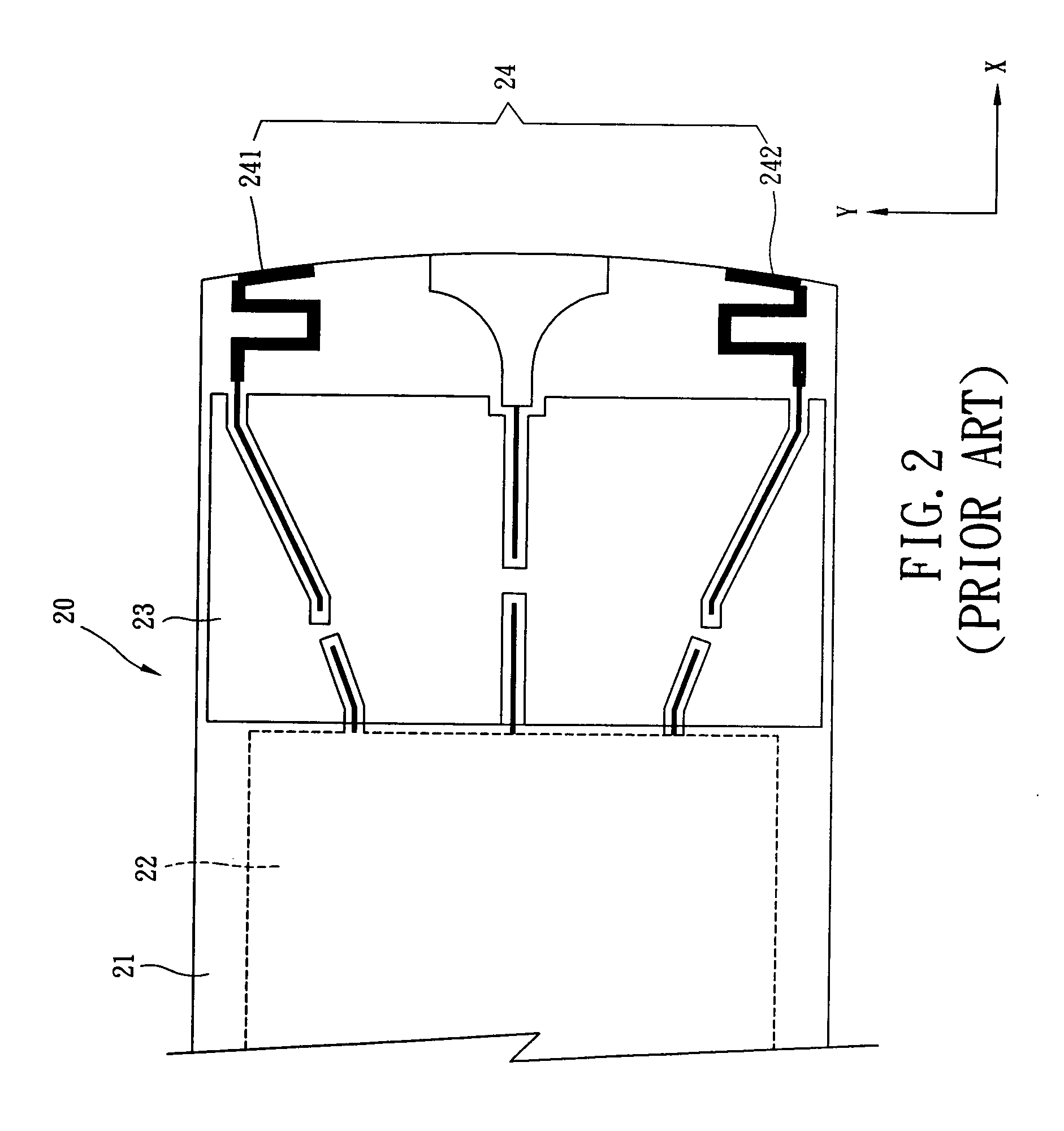

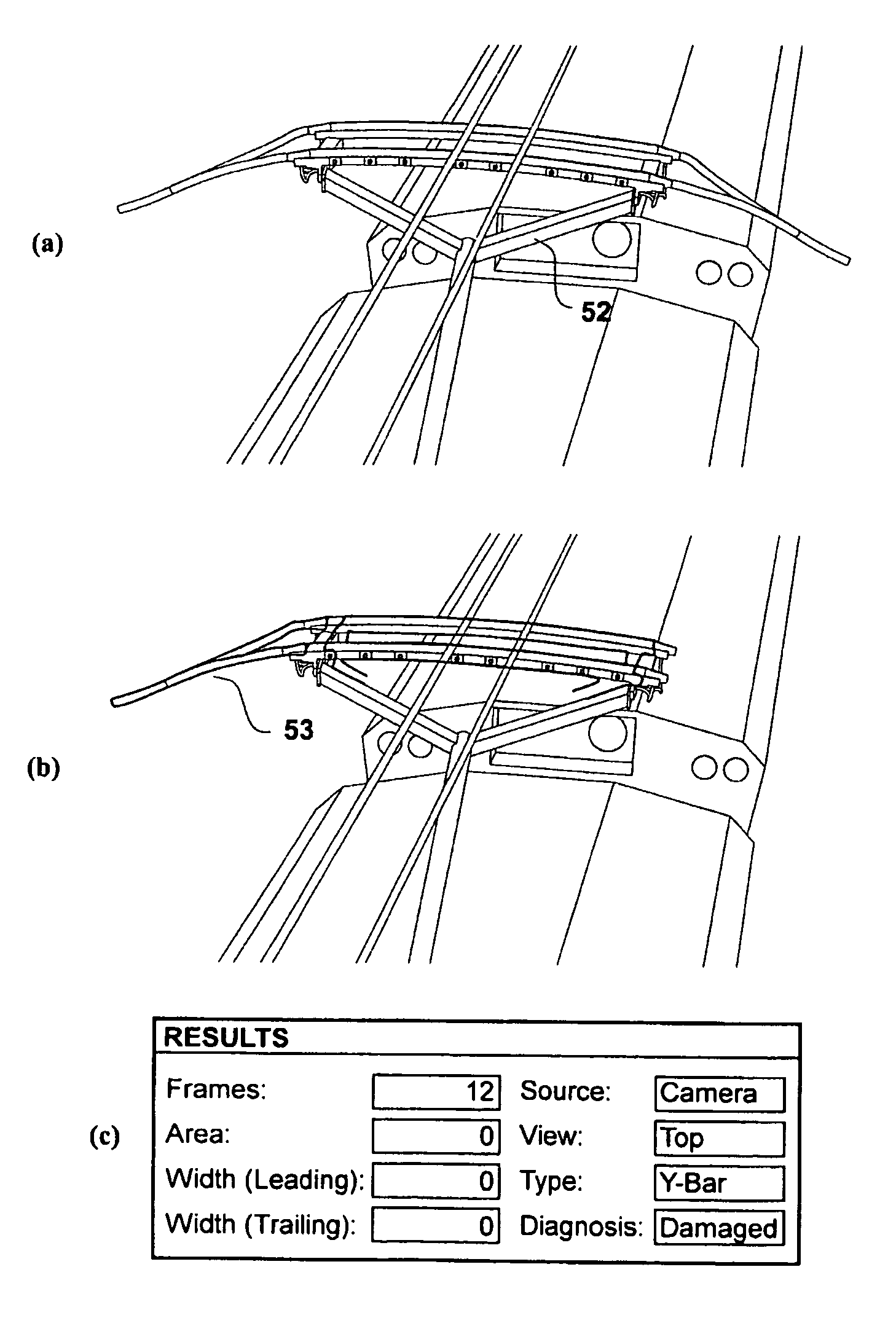

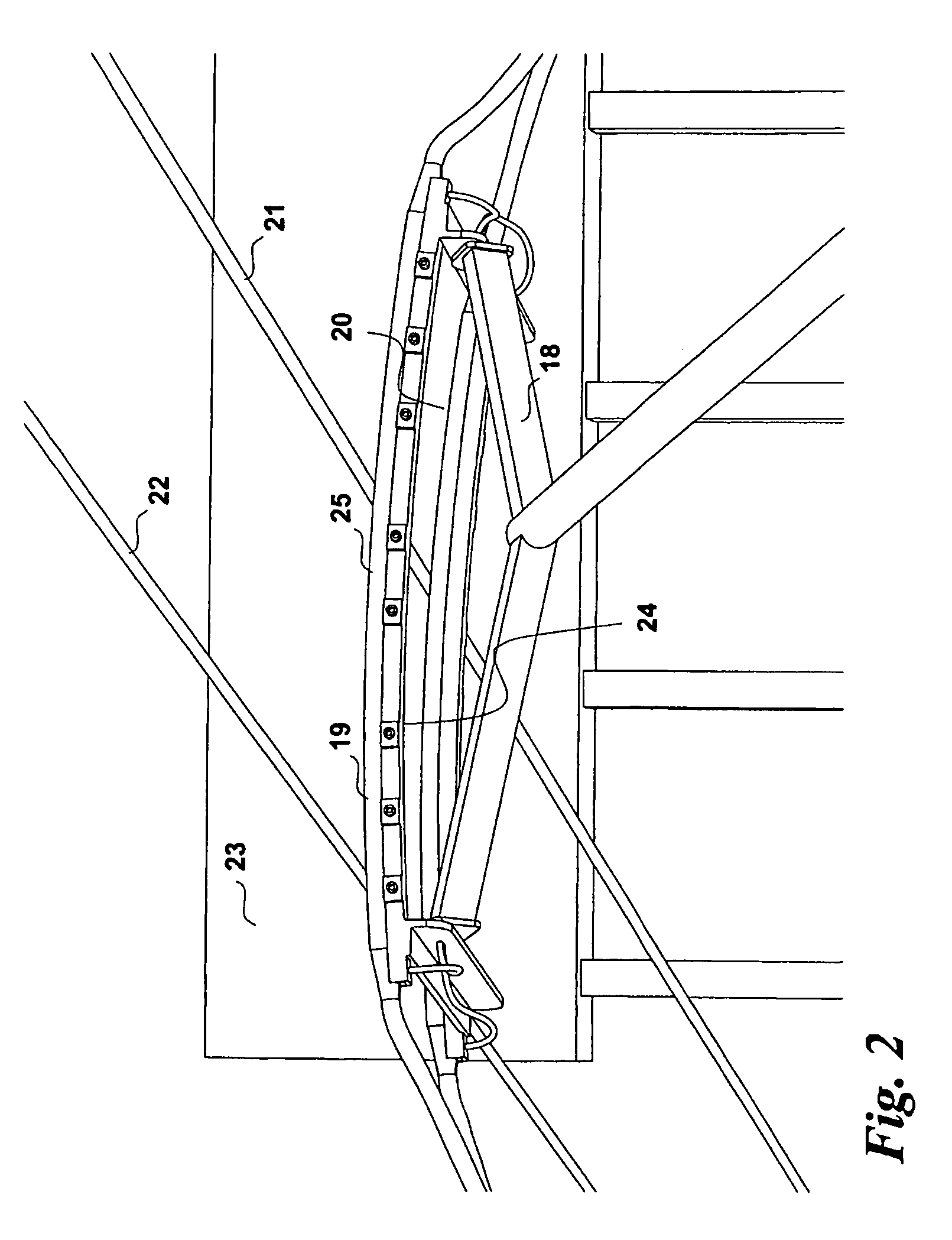

Pantograph damage and wear monitoring system

InactiveUS9061594B2Facilitate communicationLong exposure timeImage analysisRailway vehiclesMonitoring siteControl system

A system for evaluating the condition of a pantograph, the system comprising: a track-side pantograph monitoring station that captures one or more images of a pantograph, while a locomotive comprising the pantograph is in normal service; a station management system that analyzes one or more images captured at the monitoring site and determines the condition of the pantograph; and a user interface that controls the system and presents the results of the analysis to the user. A user may control the track-side monitoring station and station management system remotely.

Owner:QUEENSLAND RAIL LIMITED

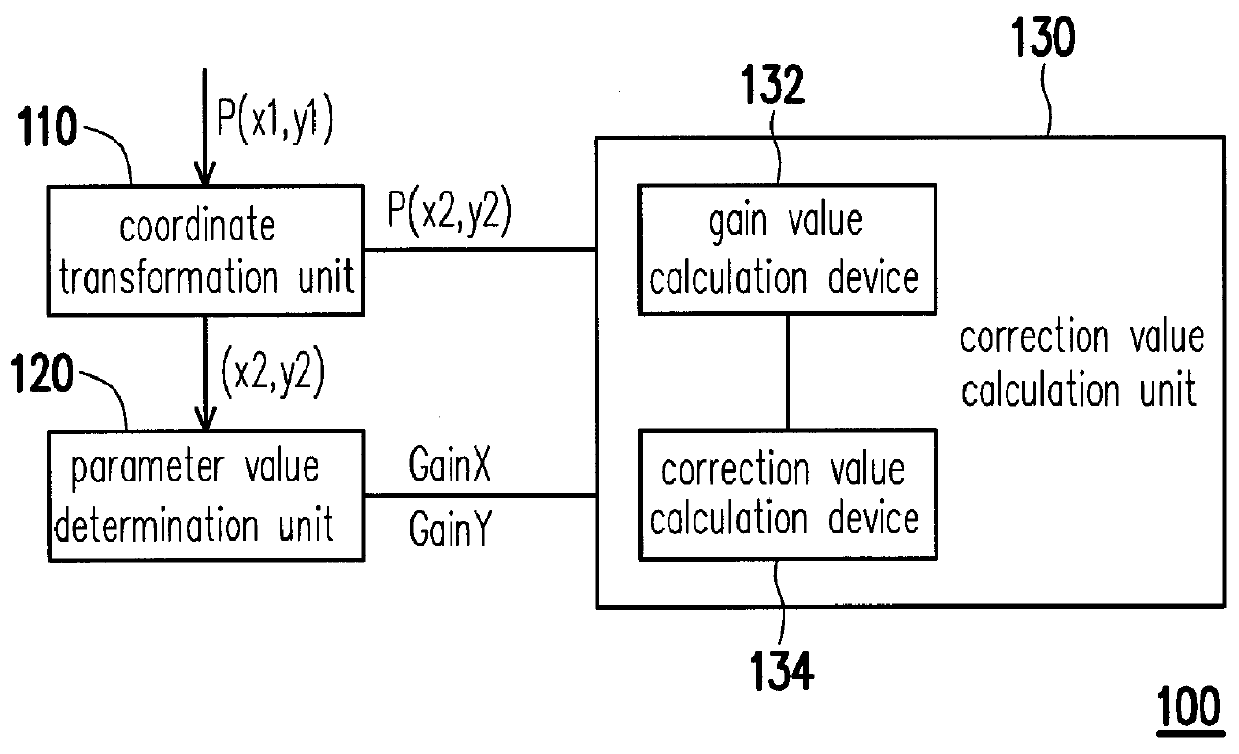

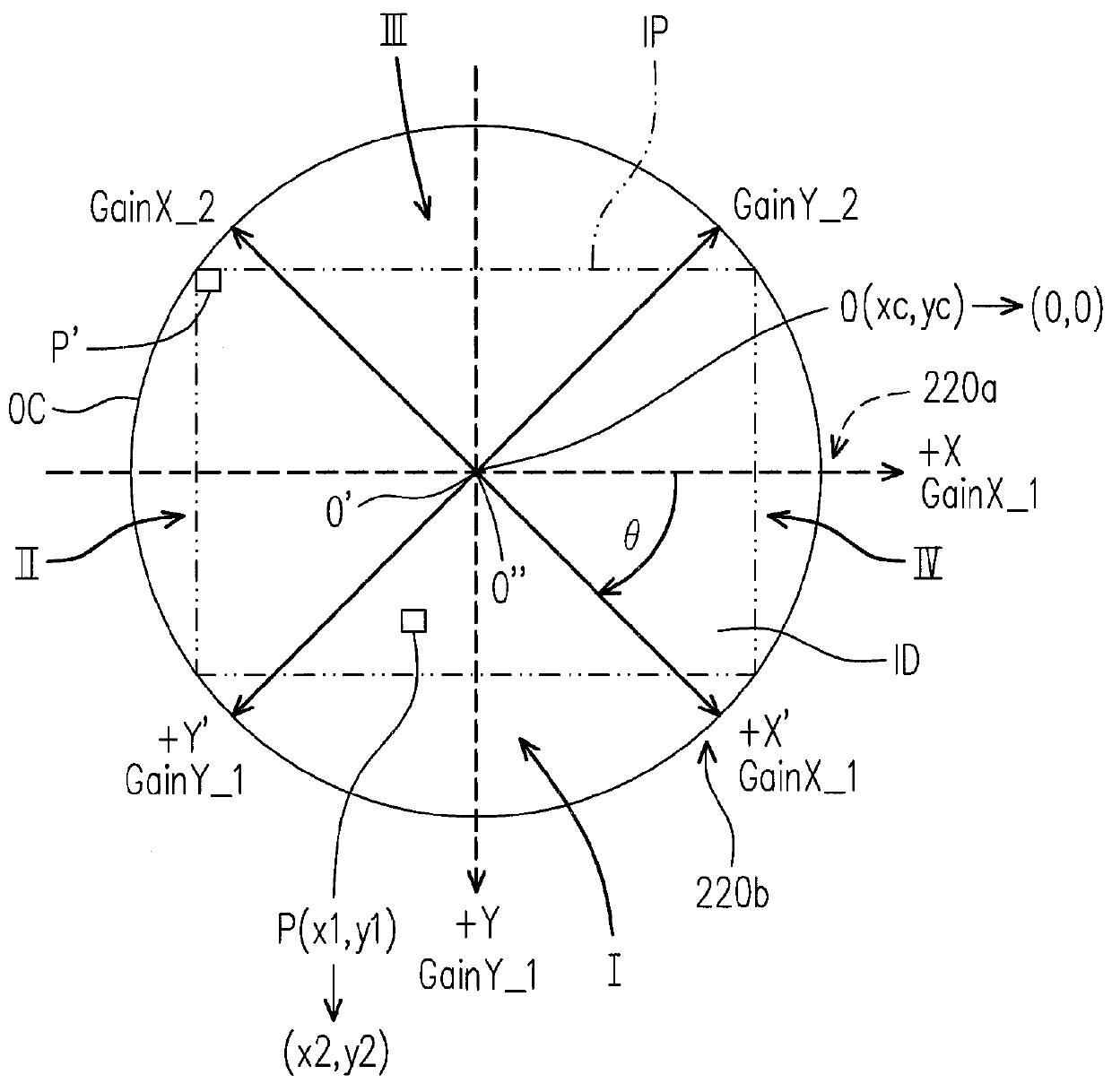

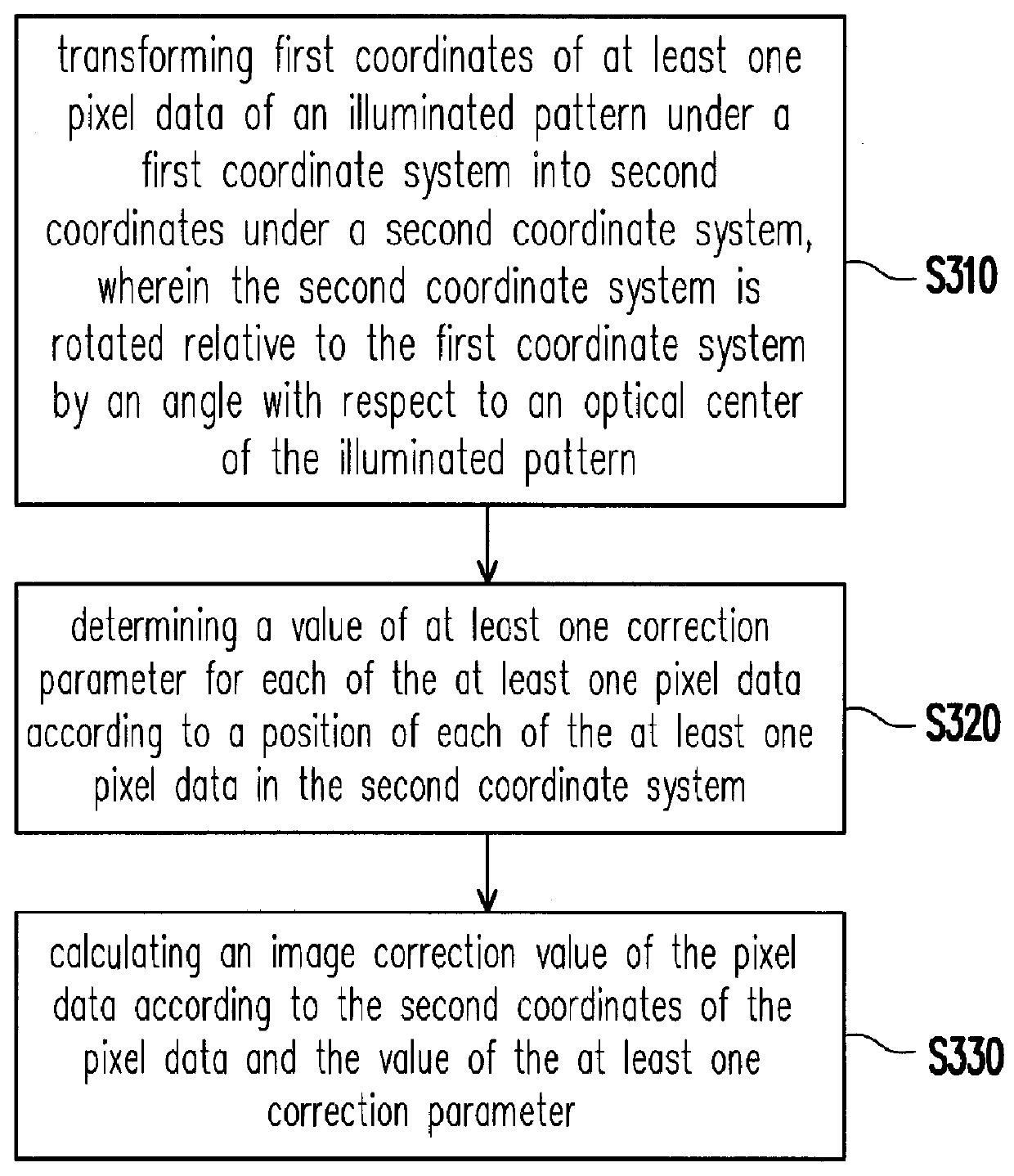

Image correction device and image correction method

ActiveUS20130050537A1Improve uniformityIncrease gain valueImage enhancementTelevision system detailsImage correctionTransformation unit

An image correction device includes a coordinate transformation unit, a parameter value determination unit, and a correction value calculation unit. The coordinate transformation unit receives first coordinates of at least one pixel data of an illuminated pattern under a first coordinate system, and transforms the first coordinates into second coordinates under a second coordinate system, wherein the second coordinate system is rotated relative to the first coordinate system by an angle with respect to an optical center of the illuminated pattern. The parameter value determination unit determines a respective value of at least one correction parameter according to the position of each of the at least one pixel data in the second coordinate system. The correction value calculation unit calculates an image correction value of each of the at least one pixel data according to the second coordinates and the respective value of the at least one correction parameter.

Owner:NOVATEK MICROELECTRONICS CORP

AMC-based low-profile circularly-polarized cross dipole antenna and communication equipment

PendingCN112072283AReduce section heightHigh gainRadiating elements structural formsAntenna earthingsDielectric substrateComputational physics

The invention discloses an AMC-based low-profile circularly-polarized cross dipole antenna and communication equipment. The AMC-based low-profile circularly-polarized cross dipole antenna comprises anupper dielectric substrate, a lower dielectric substrate, a main radiation unit, a parasitic unit, an AMC metasurface and a reflection floor, wherein the upper dielectric substrate and the lower dielectric substrate are arranged in parallel at a certain interval; the main radiation unit and the parasitic unit are arranged on the upper dielectric substrate; the upper surface of the lower dielectric substrate is provided with the AMC metasurface, and the lower surface of the lower dielectric substrate is provided with the reflection floor; and the main radiation unit comprises two pairs of dipoles, the two pairs of dipoles are of a cross-shaped cross structure, and a cross point is located at the center point of the upper dielectric substrate. The antenna has the characteristics of good circular polarization radiation performance, low profile and high gain, and can cover a part of C frequency bands of satellite communication.

Owner:SOUTH CHINA UNIV OF TECH

Stabilization of closed loop operation of a torsional hinged device

ActiveUS7126744B2Reduced amplificationReduce pumpingStatic indicating devicesNon-linear opticsClosed loopAsymmetry

Owner:TEXAS INSTR INC

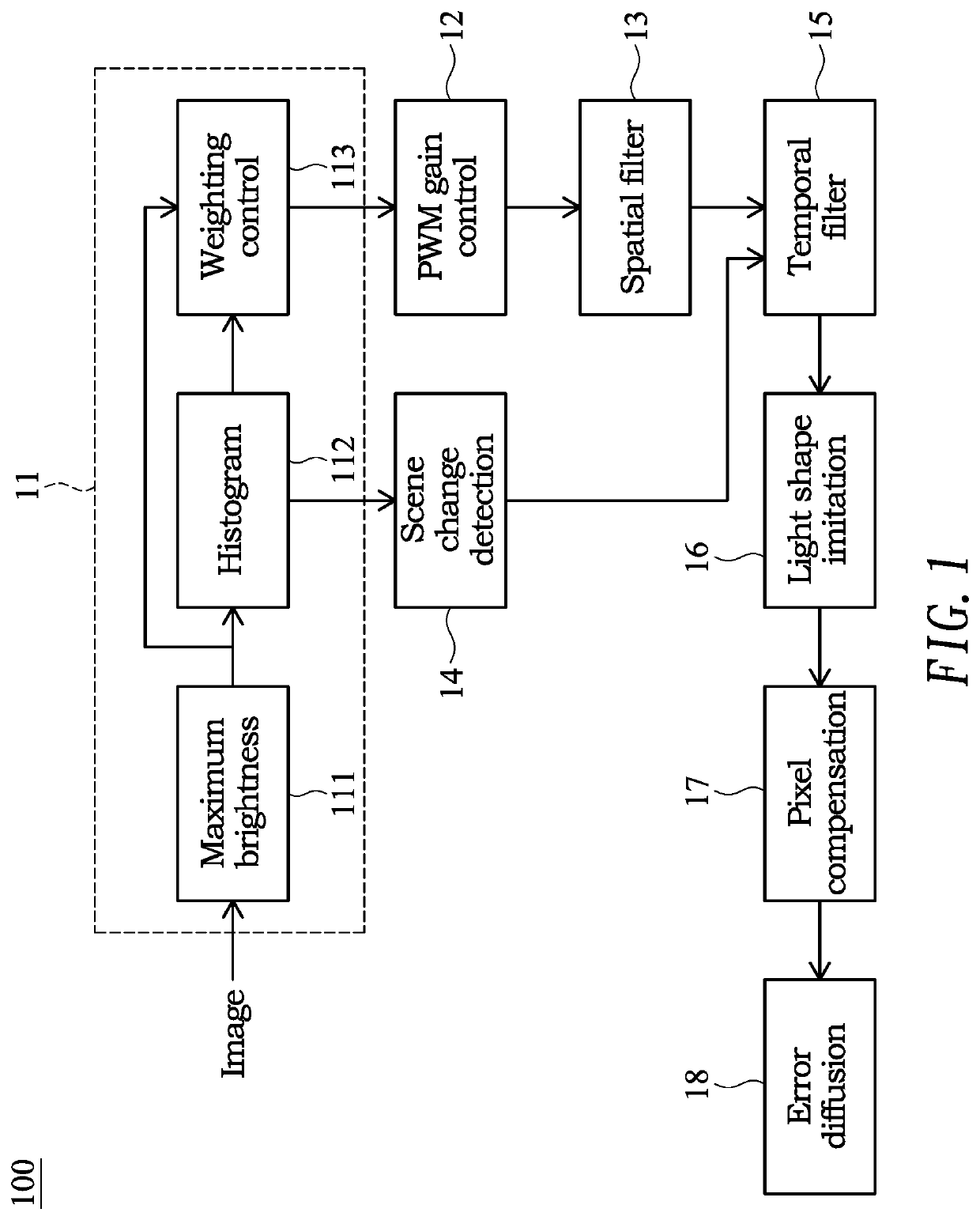

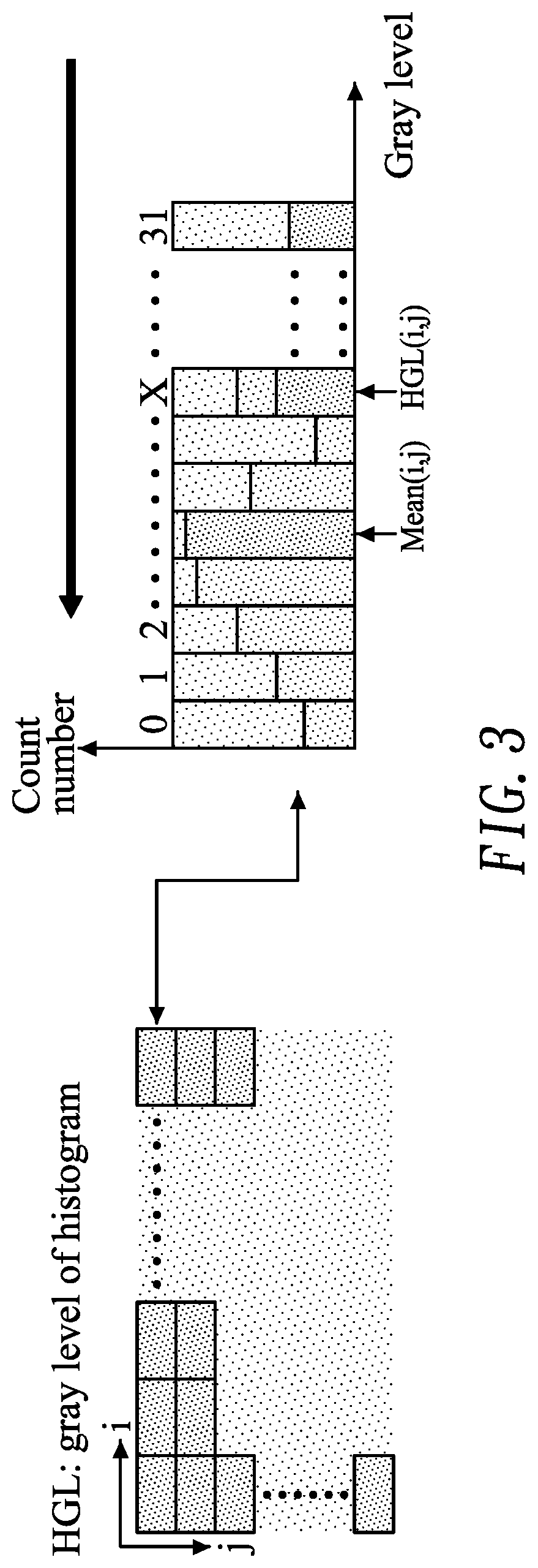

Local dimming system adaptable to a backlight of a display

ActiveUS20200066214A1Reduce power consumptionAvoid flickeringStatic indicating devicesDisplay deviceHistogram

A local dimming system includes a mean estimation unit that estimates a mean value of an image; a PWM gain control unit that generates a PWM gain value according to the mean value; a spatial filter that performs on a plurality of the mean values in spatial domain to enhance a plurality of the PWM gain values, thereby generating enhanced PWM gain values; a scene change detection unit that detects scene change according to a histogram mean value generated by the mean estimation unit; a temporal filter that performs in temporal domain according to the enhanced PWM gain values and a result of scene change detection, thereby generating PWM values; a light shape imitation (LSI) unit that generates luminance gain according to the PWM value; and a pixel compensation unit that performs pixel compensation on the image according to the luminance gain, thereby resulting in a compensated image.

Owner:HIMAX TECH LTD

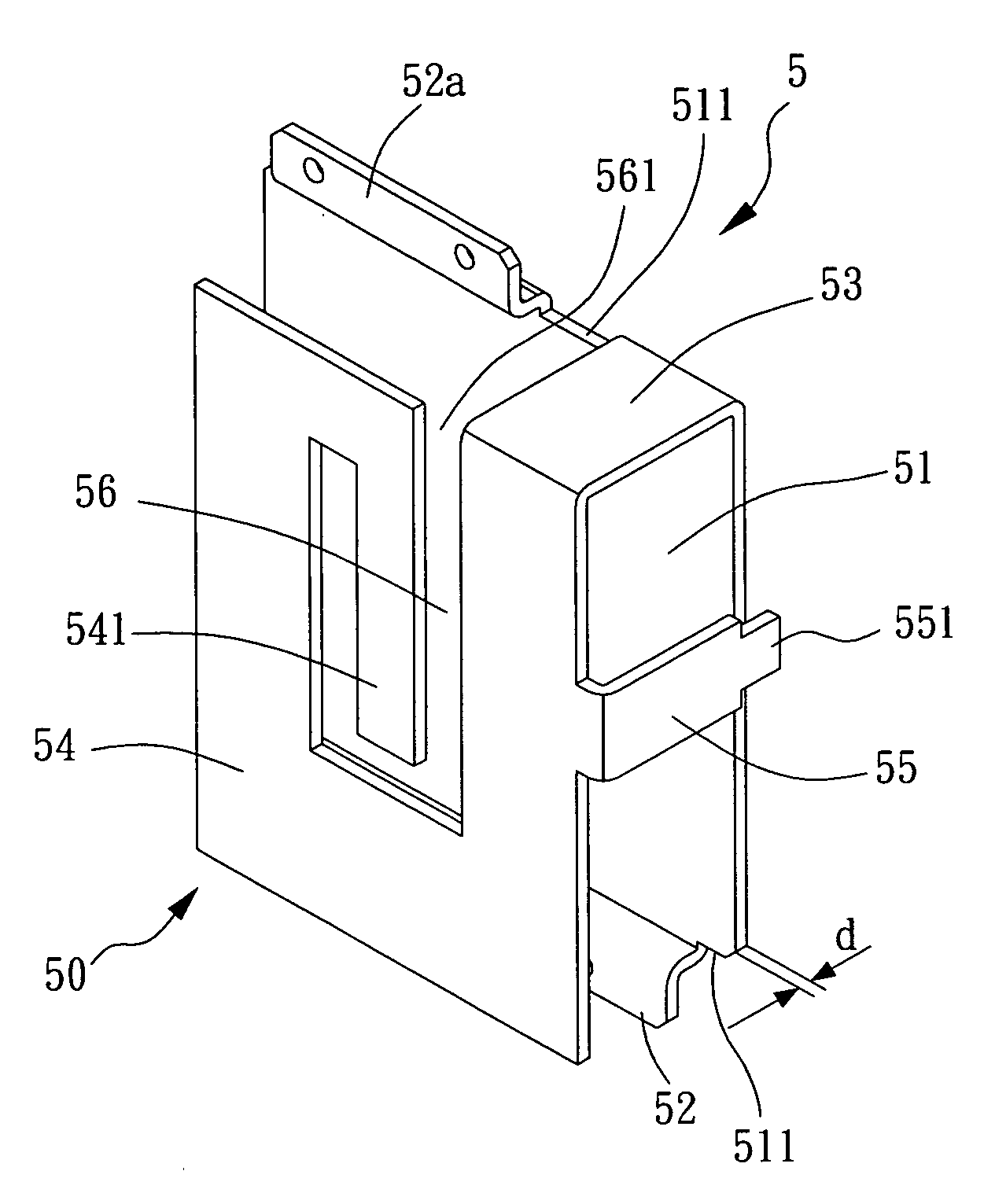

Antenna and wireless network device having the same

InactiveUS20080268908A1Reduce the overall heightImproved radiation patternAntenna supports/mountingsProtective material radiating elementsHeight differenceWireless network

An antenna applied to a wireless network device comprises a base, a pair of embedded portions, and an antenna portion. The base has two sides opposite to each other. Each of the embedded portions has a side wall portion and a locking wing portion. The side wall portion is substantially vertical to the base and connected to the sides of the base, while the locking wing portion is connected to the side wall portion, substantially parallel to the base, and spaced apart from the base with a first height. The antenna portion is provided with a ground member, a radiation member, and a signal member. The ground member is substantially vertical to the base, connected to one of the two sides of the base, and spaced apart from the embedded portion with an interval. The radiation member is connected to the ground member, substantially parallel to the base, and spaced apart from the base with a second height. The signal member is connected to the radiation member, substantially vertical to the base, and formed with a free end separated from the base. When the antenna is positioned in at least one slot formed on a substrate of the wireless network device, the radiation member is spaced apart from the substrate with a height difference between the second height and the first height.

Owner:CAMEO COMM

Differential amplifier with current source controlled through differential feedback

ActiveUS20080106336A1Increase gain valueDifferential amplifiersDc-amplifiers with dc-coupled stagesDifferential amplifierFully differential amplifier

A differential amplifier includes a first electrical path formed between a first transistor and a first load impedance; a second electrical path formed between a second transistor and a second load impedance; a tail-current transistor coupled to the first and second transistors; an input end of a feedback amplifier coupled directly to the first and second electrical paths for receiving a differential voltage output signal; and an output end of the feedback amplifier coupled directly to the tail-current transistor for adjusting the current provided through each of the first and second electrical paths. The feedback amplifier includes a non-inverting input node and an inverting input node, each node coupled directly to one or the other of the first and second electrical paths.

Owner:HARRIS GLOBAL COMMUNICATIONS INC

Antenna module including plurality of radiators, and base station including the antenna module

ActiveUS20190393619A1Increase the effective areaIncrease gain valueAntenna supports/mountingsRadiating elements structural formsDielectricElectricity

A technique for converging Internet of things (IoT) technology with a fifth generation (5G) communication system for supporting data rates beyond a fourth generation (4G) system can be applied to intelligent services. An antenna module includes a first radiator radiating a radio wave through an upper surface, a second radiator formed surrounding an outer periphery of the first radiator, a dielectric having an upper surface disposed under a lower surface of the first radiator, the dielectric being formed to fix the first radiator and the second radiator to be separated based on a first length, a feeder having an upper surface disposed under a lower surface of the dielectric, the feeder coupling an electrical signal to at least one of the radiator or second radiators through the dielectric, and a printed circuit board electrically connected to the feeder by a conductive pattern and supplying the electrical signal to the feeder.

Owner:SAMSUNG ELECTRONICS CO LTD

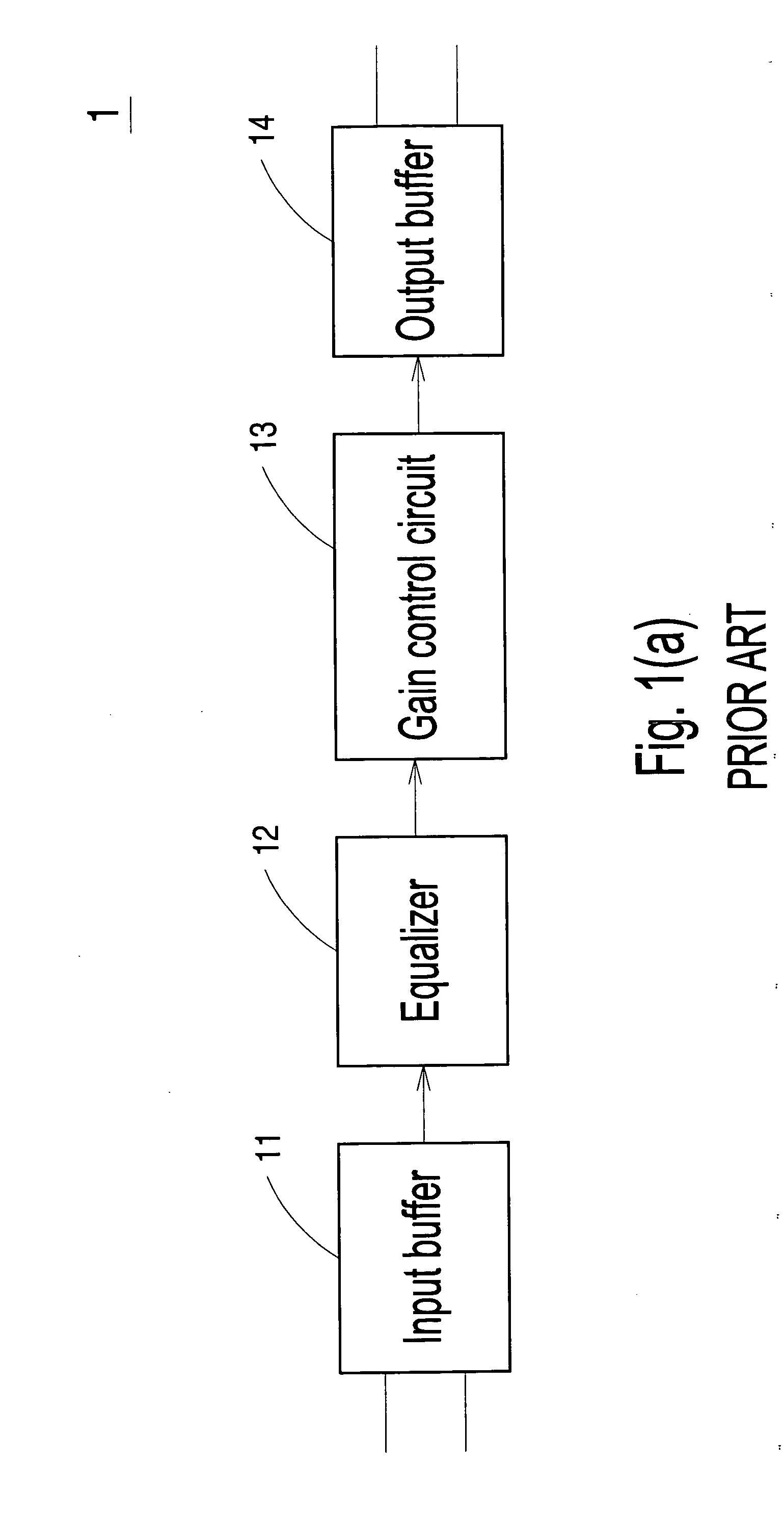

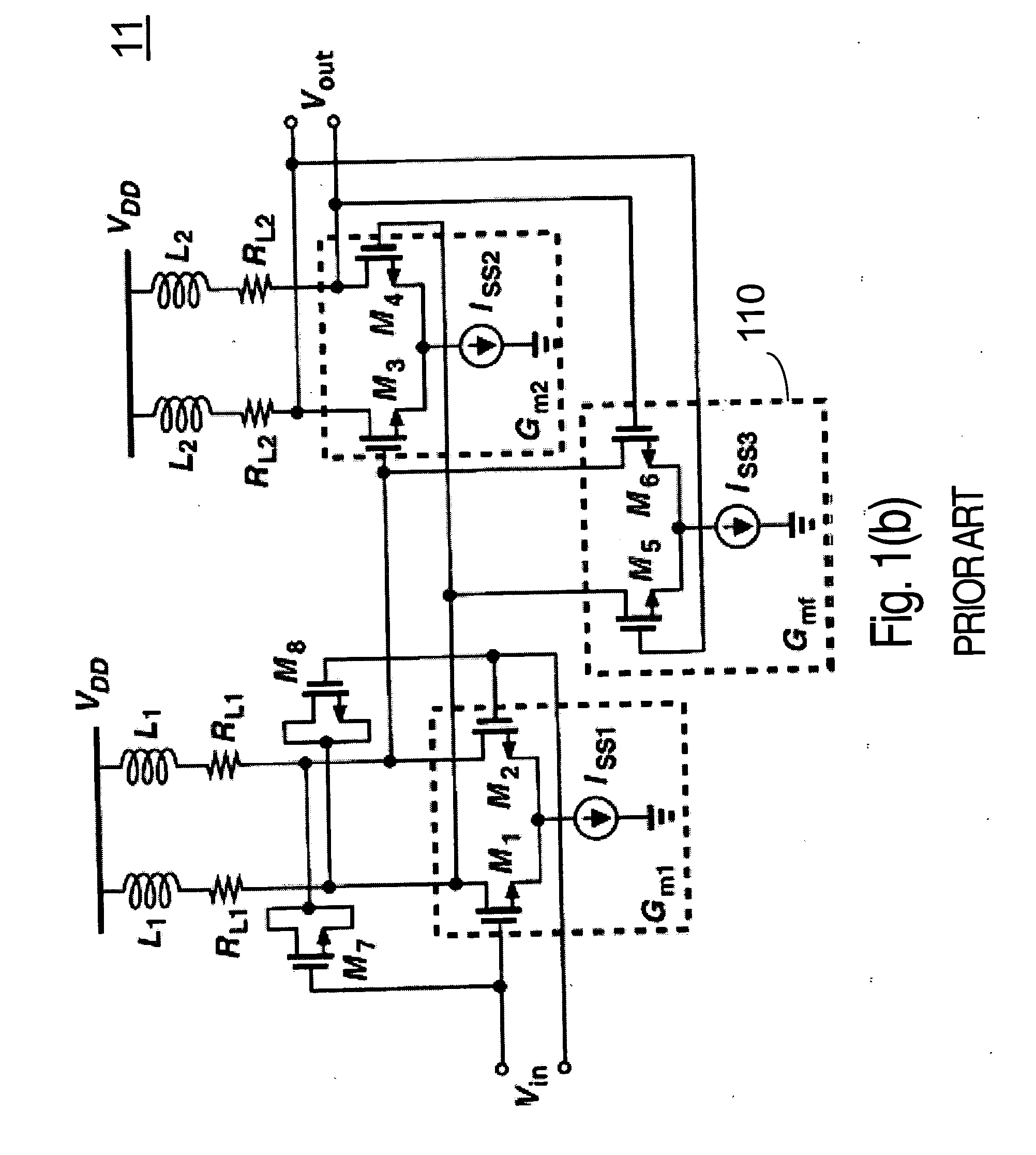

Transmission circuit for use in input/output interface

InactiveUS20070069769A1Enhance bandwidthHigh bandwidthNegative-feedback-circuit arrangementsAmplifier with semiconductor-devices/discharge-tubesActive feedbackEngineering

A transmission circuit includes a first-stage circuit, a second-stage circuit, a negative active feedback circuit and a current buffer. The first-stage circuit includes at least an active MOS device for receiving an input voltage and issuing a first voltage signal. The active MOS device has an inductive feature during operation in a high frequency mode to compensate the first voltage signal. In response to the first voltage signal, the second-stage circuit outputs a first output voltage. The negative active feedback circuit may enhance the bandwidth of the first output voltage. The current buffer may enhance the gain value of the first output voltage. A second voltage signal is issued from the first-stage circuit and compensated by the first output voltage transmitted from the current buffer to enhance the bandwidth and the gain value thereof. In response to the compensated second voltage signal, the second-stage circuit outputs a second output voltage.

Owner:NATIONAL TSING HUA UNIVERSITY

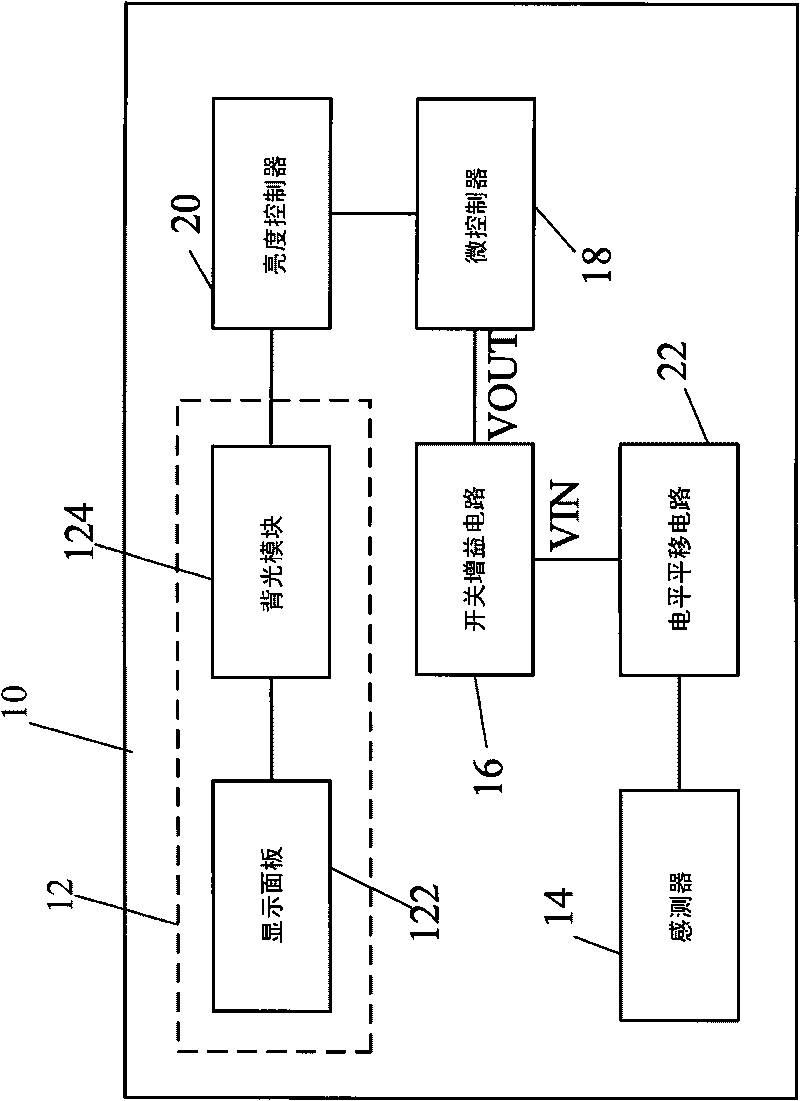

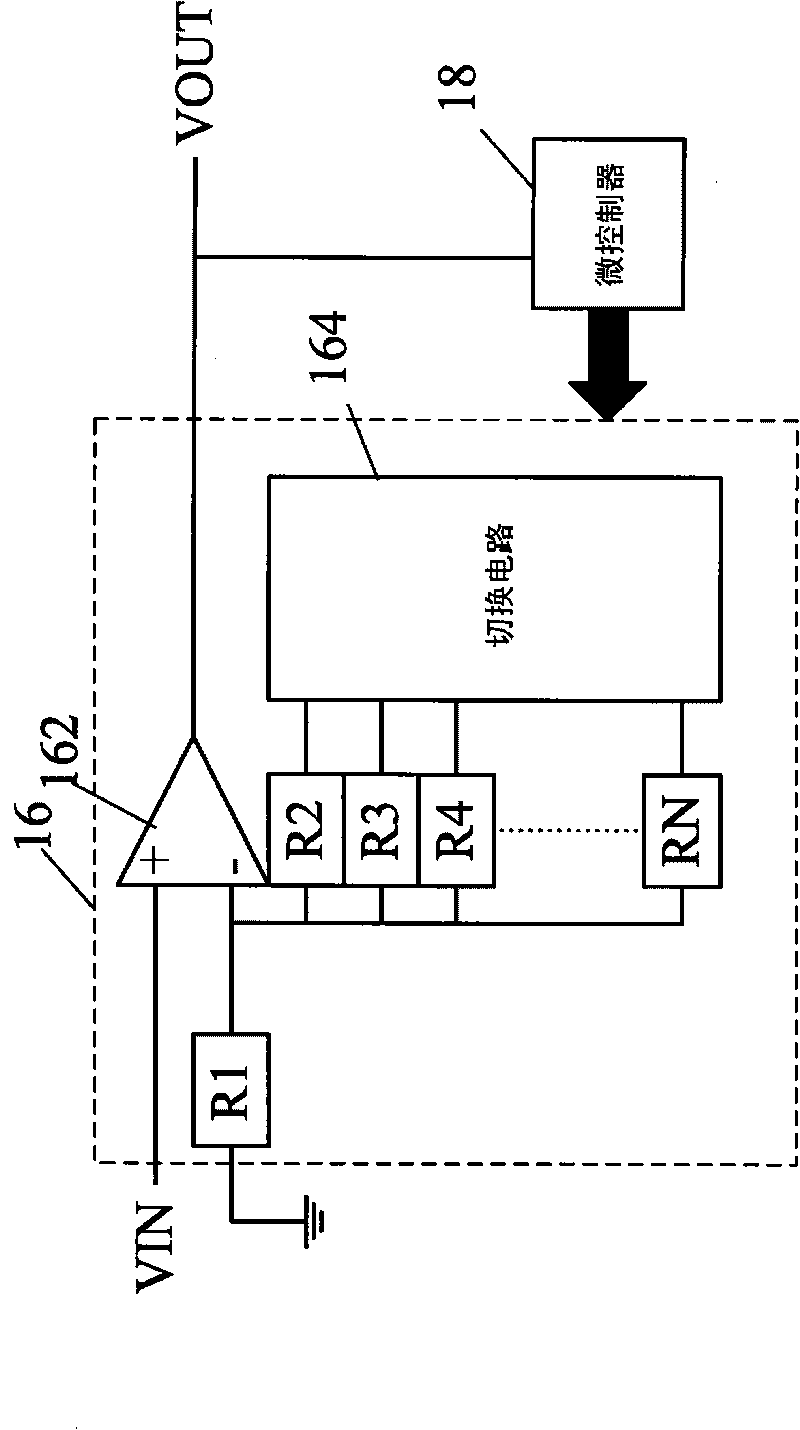

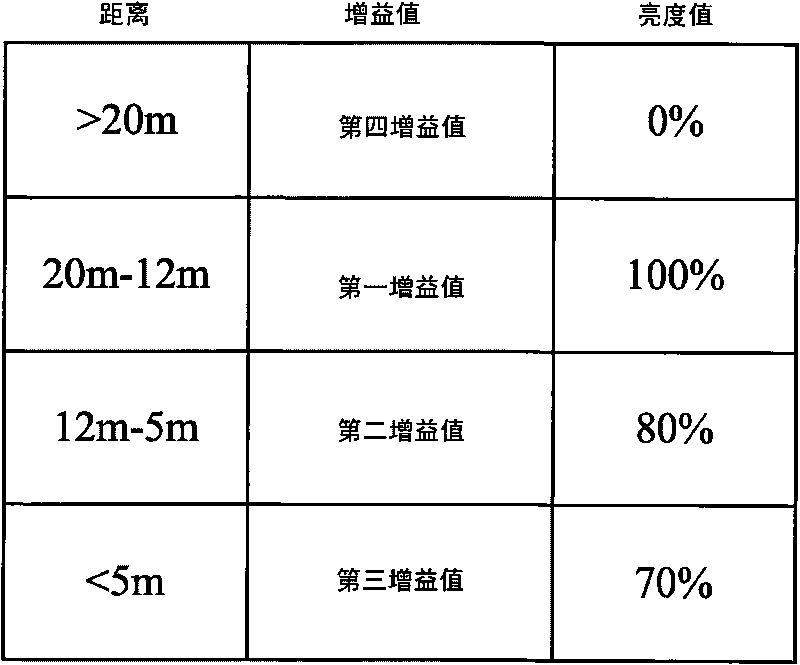

Display adjusting brightness according to display distance

InactiveCN101710483AComfortable viewing brightnessRealize the purpose of energy savingStatic indicating devicesMicrocontrollerDisplay device

The invention discloses a display adjusting the brightness according to a display distance, which comprises a liquid crystal module, a sensor, a switch gain circuitry, a microcontroller and a brightness controller, wherein the liquid crystal module comprises a display panel and a backlight module and the display panel is used for displaying images according to the light of the backlight module; the sensor is arranged on one side of the liquid crystal module and is used for generating a sense signal according to the distance between the backlight module and a user; the switch gain circuitry is coupled with the sensor and is used for comparing the sense signal with a plurality of gain values so as to output a measuring voltage; the microcontroller is coupled with the switch gain circuitry and is used for determining the distance between the liquid crystal module and the user according to the measuring voltage; and the brightness controller is coupled with the microcontroller and the liquid crystal module and is used for adjusting the brightness of the display panel according to the distance, which is determined by the microcontroller, between the liquid crystal module and the user,. Because the display of the invention can automatically detect the relative distance between a relatively distant moving object and the liquid crystal module, the display has the characteristic which is not possessed by the traditional liquid crystal module using a sensing element.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com