Catenary geometrical parameter dynamic detection method based on triangulation

A geometric parameter and dynamic detection technology, applied in the field of detection, can solve the problems of difficult high-precision measurement, detection data varies from person to person, and high installation requirements, and achieve the effect of simple and reliable algorithm, comprehensive measurement data and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

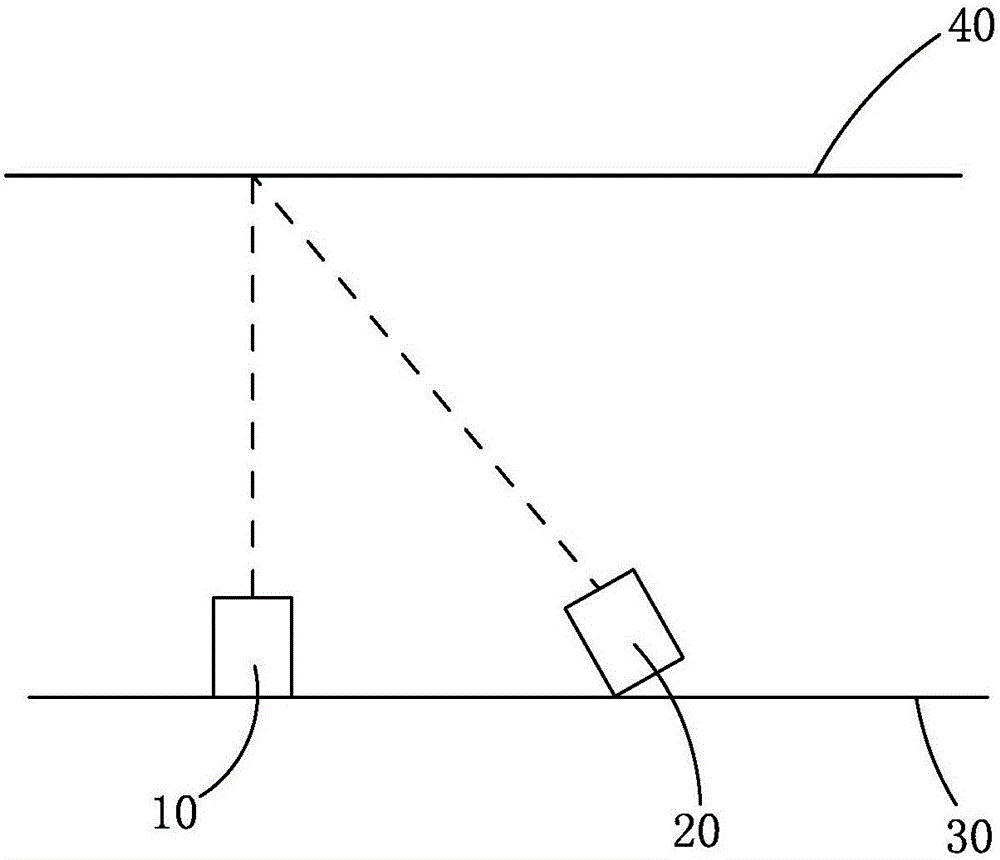

[0014] Such as figure 1 As shown, the present invention provides a dynamic detection method for catenary geometric parameters based on triangulation, which can be used in a vehicle-mounted pantograph-catenary dynamic monitoring system or a hand-push catenary inspection vehicle to detect relevant parameters of the catenary. The dynamic detection method of catenary geometric parameters based on triangulation includes the following steps:

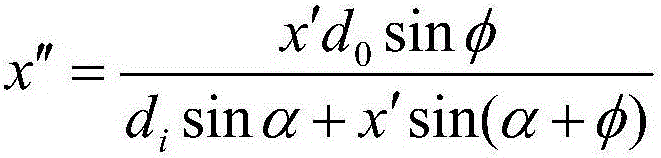

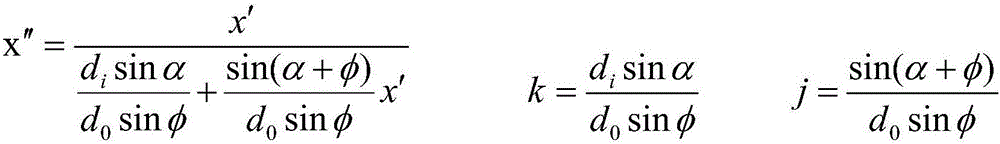

[0015] Step (1), obtain the pixel coordinates (xPixel, yPixel) and angle change (xAngle, yAngle) of catenary in the image, the present invention provides a detection device, this detection device comprises line laser 10, industrial camera 20, an inclination sensor, Horizontal displacement sensor (not shown in the figure), limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com