Pantograph type current collector of electric automobile and automatic rapid charging station

An electric vehicle, fast charging technology, applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of failure to meet reliable practical requirements, high manufacturing costs, and inability to use charging stations to start vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

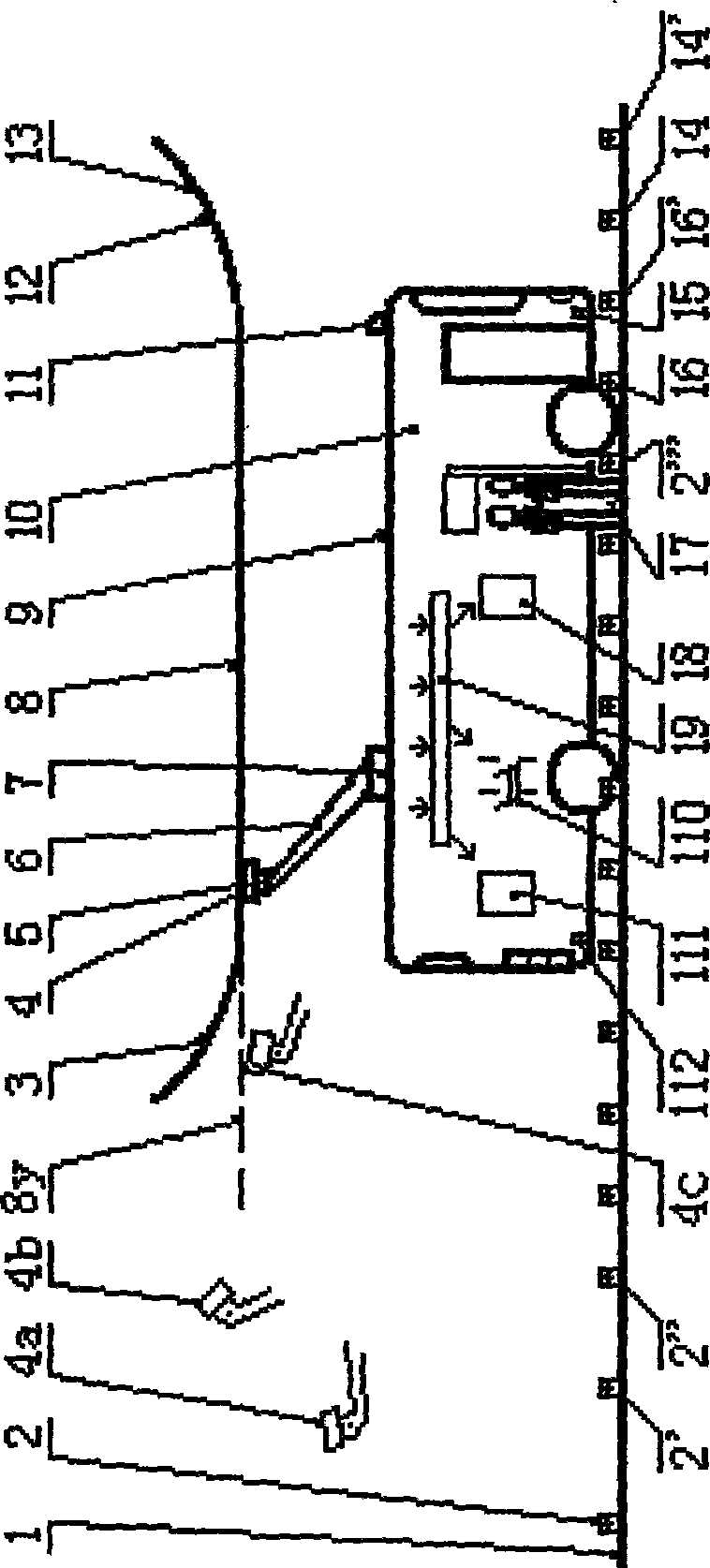

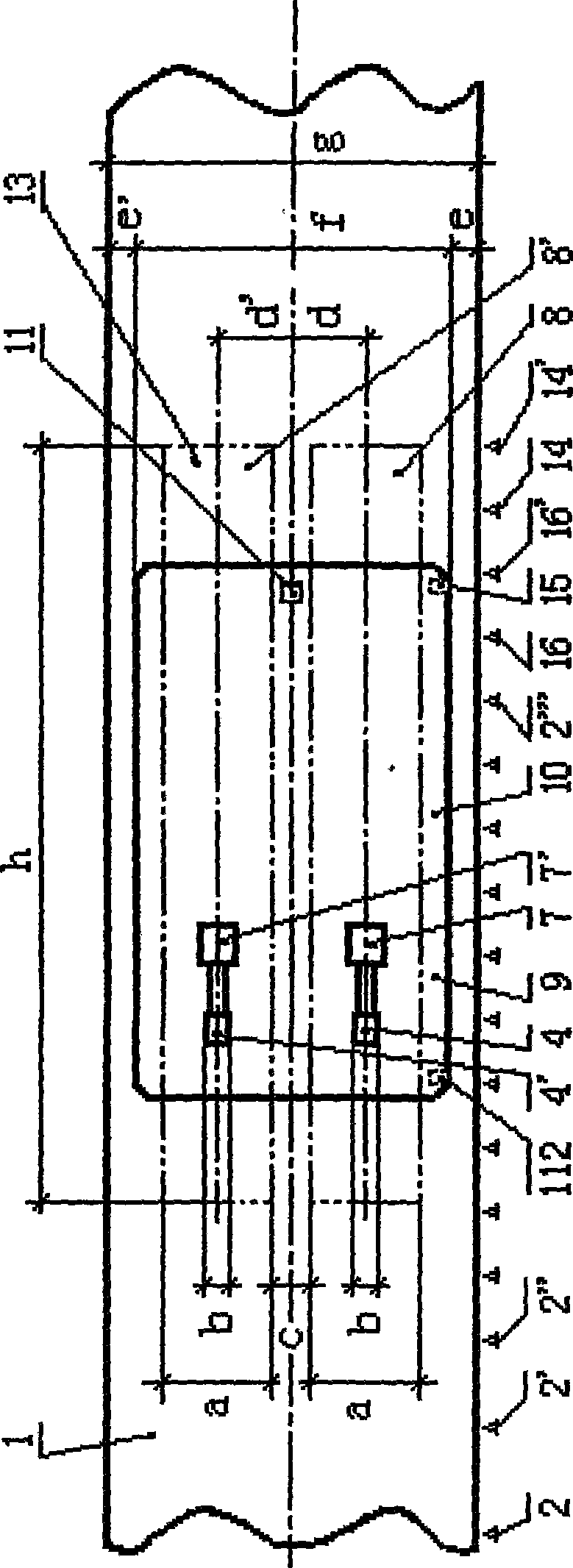

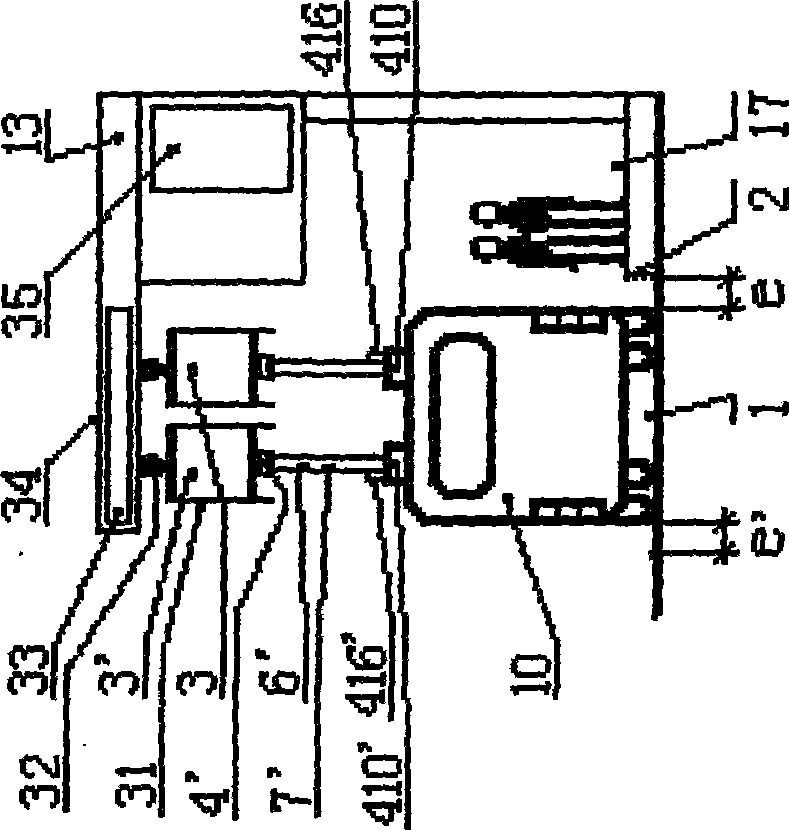

[0049] [1], figure 1 Is: A schematic right side view of a pantograph and an automatic fast charging station for an electric vehicle. figure 1 Including: lane 1, bow signal point 2, contact plate introduction arc 3, electric slider 4, universal head 5, bow arm 6, pantograph assembly 7, contact plate 8, roof 9, electric vehicle 10. Camera 11, contact plate lead-out arc 12, electric vehicle charging station 13, power-off bow down signal point 14, signal receiver 15, charging signal point 16, bus station 17, acoustic signaler 18, controller 19, contact Device 110, gas circuit switch 111, signal receiver 112, point 2', 2", 2"' after the bow-up signal, point 16' after the charging signal, point 14' after the bow-down signal after power-off; bow down, receiving power The lowest position of the slider 4 is represented as 4a; the bow is raised to adjust the highest position of the receiving slider 4, and its position is represented as 4b; the bow is charged, and the receiving slider 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com