Double-wire powering trolleybus pantograph

A trolleybus and pantograph technology, applied in the direction of collectors, electric vehicles, power collectors, etc., can solve problems such as difficulty in automatically rising to the line and connecting to the network.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

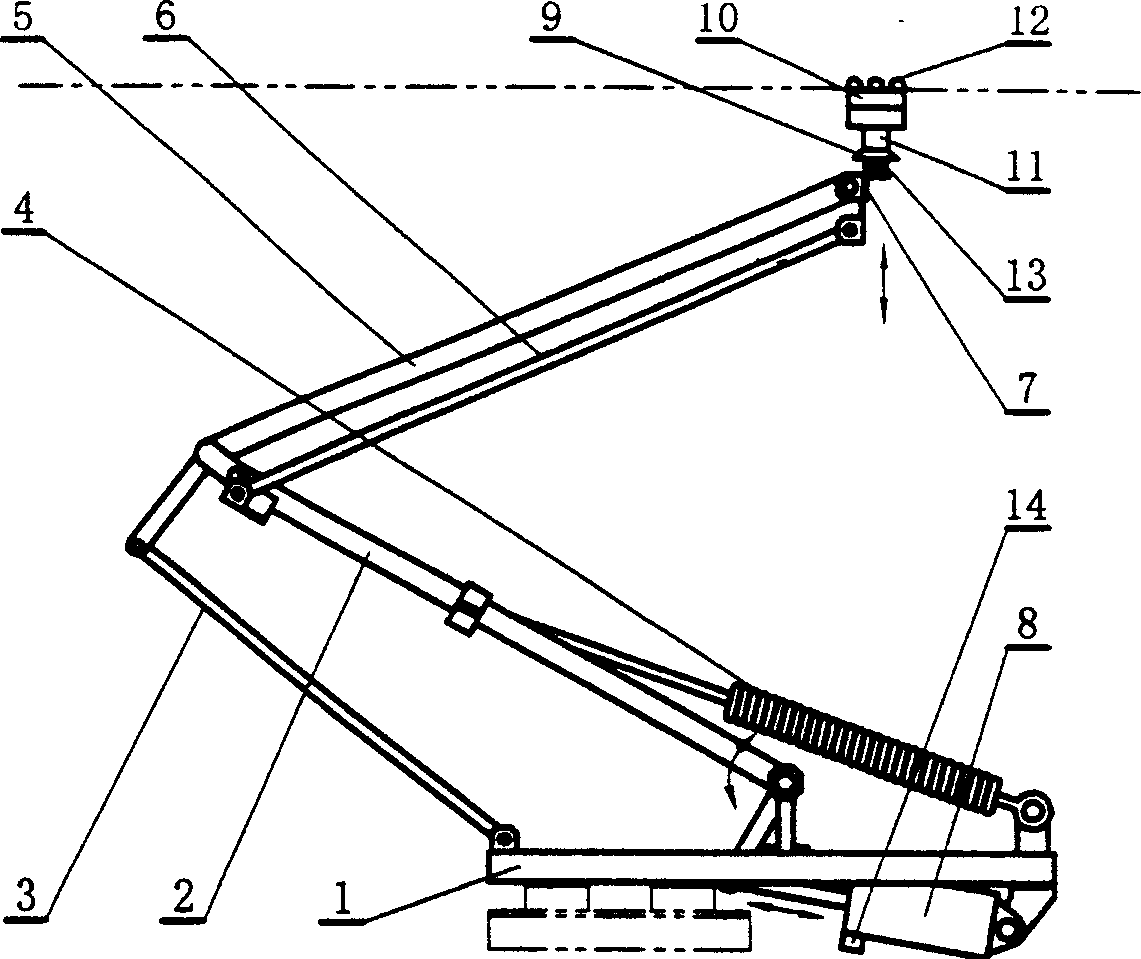

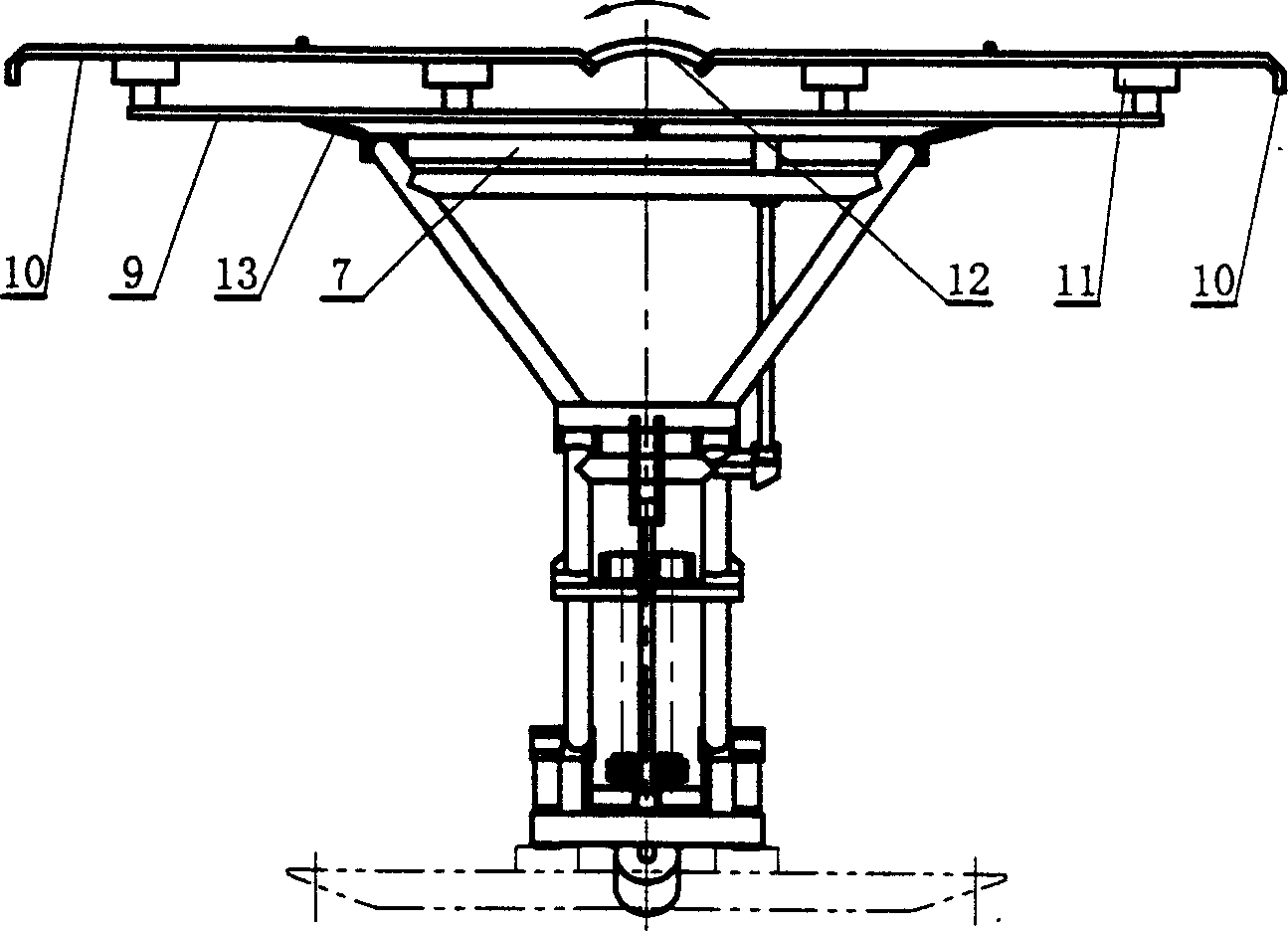

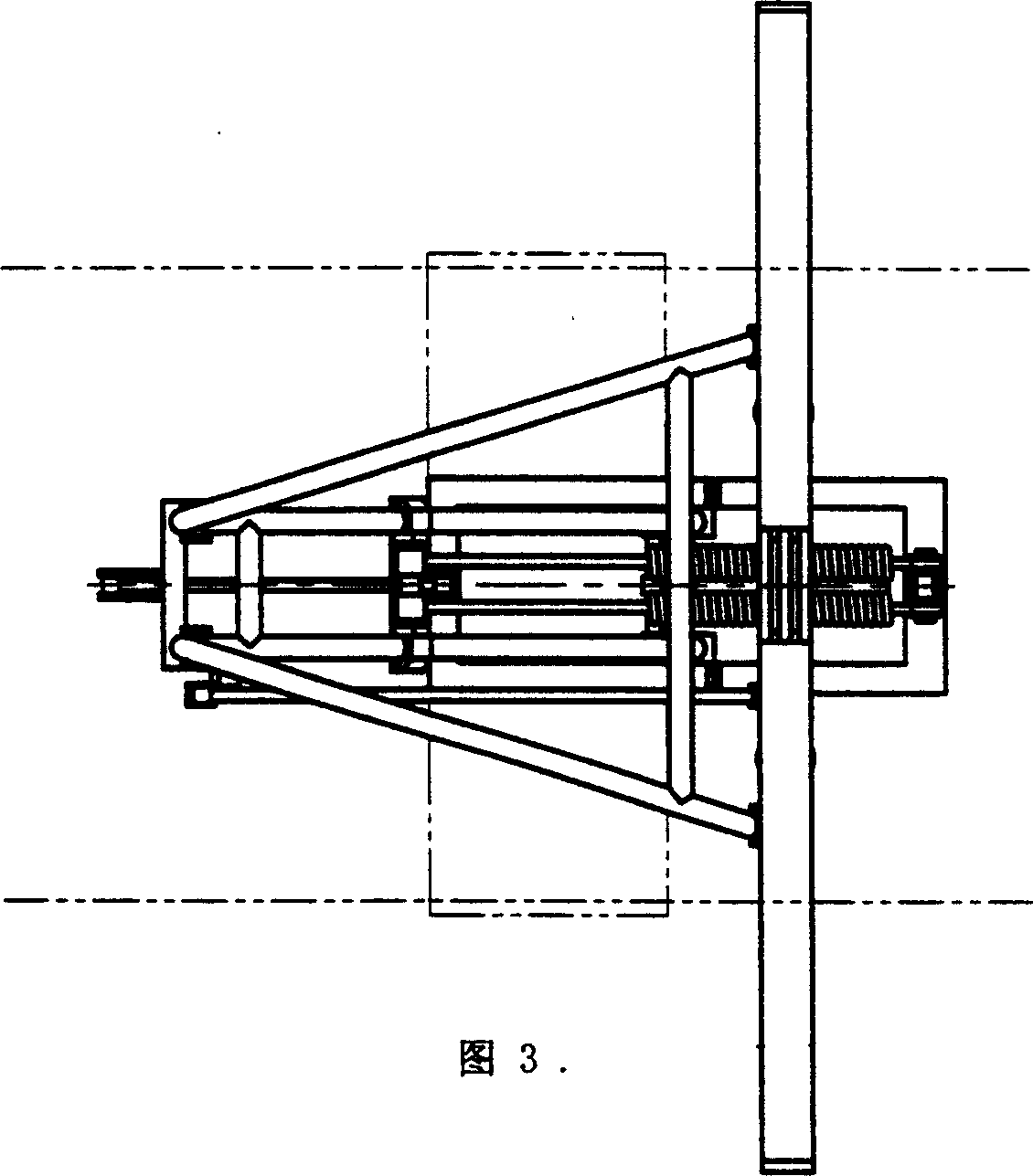

[0011] Such as figure 1 , Figure 2 and As shown in Fig. 3, the present invention includes: underframe 1, lower arm bar 2, pull bar 3, bow spring 4, upper arm bar 5, balance bar 6, bow head seat bar 7, cylinder 8, bow top bar 9, Bow top conductive slide plate 10, insulating seat 11, insulating rod 12, bow head spring 13, travel switch 14, the lower end of lower arm bar 2 and pull bar 3 are all movably connected with underframe 1, and the upper ends of lower arm bar 2 and pull bar 3 are all movably connected. It is movably connected with the lower end of the upper arm 5, the lower end of the balance bar 6 is movably connected with the upper end of the lower arm 2, and the upper ends of the upper arm 5 and the balance bar 6 are both movably connected with the cross bar 7 of the bow seat, and the bow top conductive slide plate 10 is in the The middle part is divided into two halves by several insulating rods 12, and the two halves of the bow top conductive slide plate 10 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com