An a-Si:H solar battery with the boron mixing non-crystal diamond film as the window layer and its making method

An amorphous diamond and solar cell technology, which is applied in the field of amorphous silicon solar cells and their preparation, can solve the problems of low conversion efficiency of p-type amorphous silicon layer solar cells and the like, and achieves good doping properties and wide transmittance. , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

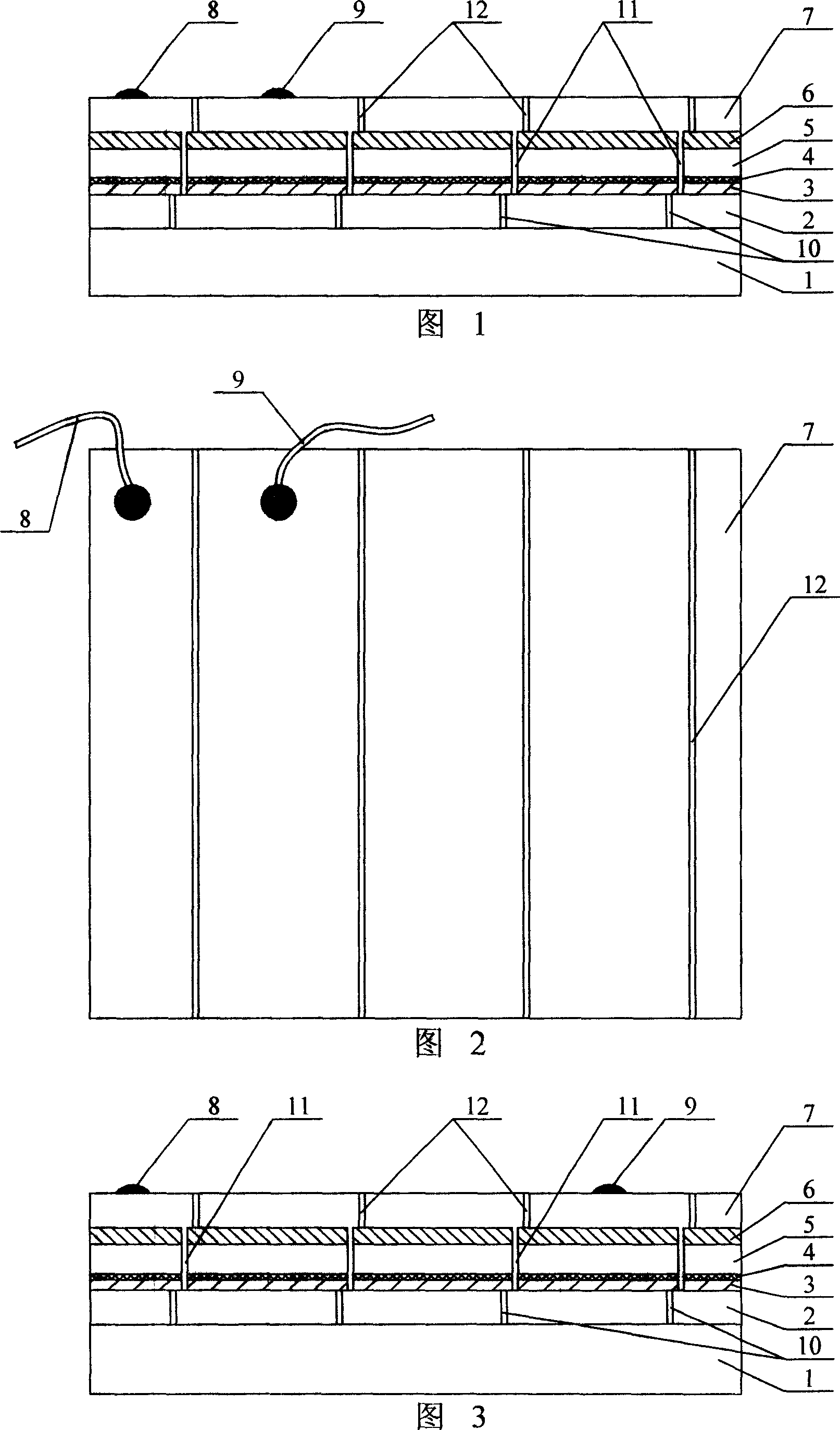

[0016] Specific Embodiment 1: (See Figures 1 to 3) In this embodiment, the a-Si:H solar cell with boron-doped amorphous diamond film as the window layer is formed from bottom to top by Corning glass 1, SnO 2 :F conductive film 2, p-ta-C:B film 3, transition p-a-Si:H(C) film 4, i-a-Si:H film 5, n-a-Si:H film 6, aluminum film 7, anode connection 8 and cathode wiring 9; SnO 2 :F conductive film 2 has laser scribed lines 10 with an interval of 10±0.3mm, p-ta-C:B film 3, transition p-a-Si:H(C) film 4, i-a-Si:H film 5 And n-a-Si: H thin film 6 has the first silicon scribe line 11 that is parallel to the direction of laser scribe line 10 and the spacing with laser scribe line 10 is 1 ± 0.1mm; The direction of the line 11 is parallel to the second silicon scribe line 12 with a distance of 1 ± 0.1mm from the first silicon scribe line 11, the upper end surface of the Corning glass 1 and the SnO 2 : The lower end surface of F conductive film 2 is fixedly connected, SnO 2 : The upper e...

specific Embodiment approach 2

[0017] Embodiment 2: In this embodiment, there are five second silicon scribe lines 12 between the anode wire 8 and the cathode wire 9 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: In this embodiment, there are ten second silicon scribe lines 12 between the anode wire 8 and the cathode wire 9 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com