Solidly mounted film bulk acoustic resonator and method for preparing fully insulated Bragg reflecting grating thereof

A thin-film bulk acoustic wave and Bragg reflection technology, which is applied in the direction of electrical components and impedance networks, can solve the problems of device electroacoustic performance degradation and instability, and achieve the effects of eliminating parasitic capacitance, excellent sound wave reflection effect, and good sound wave reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

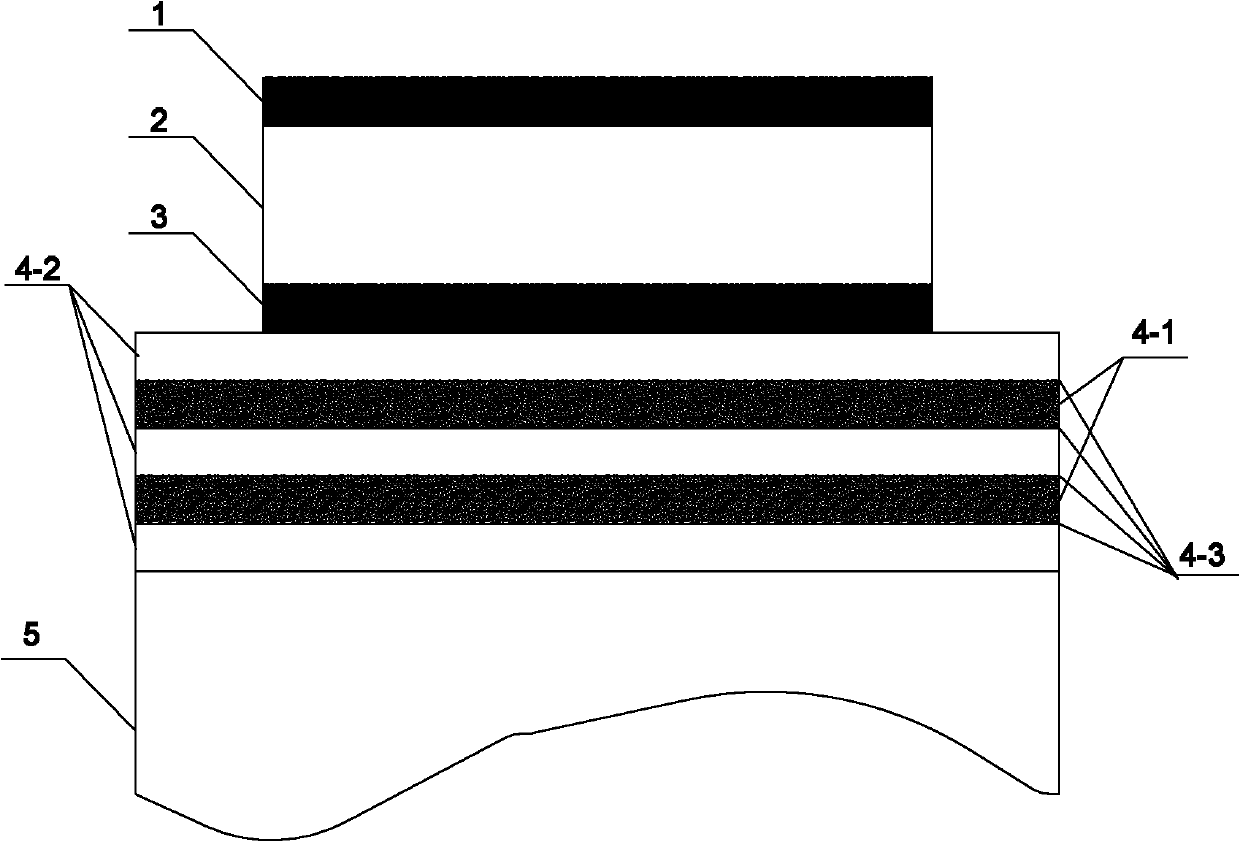

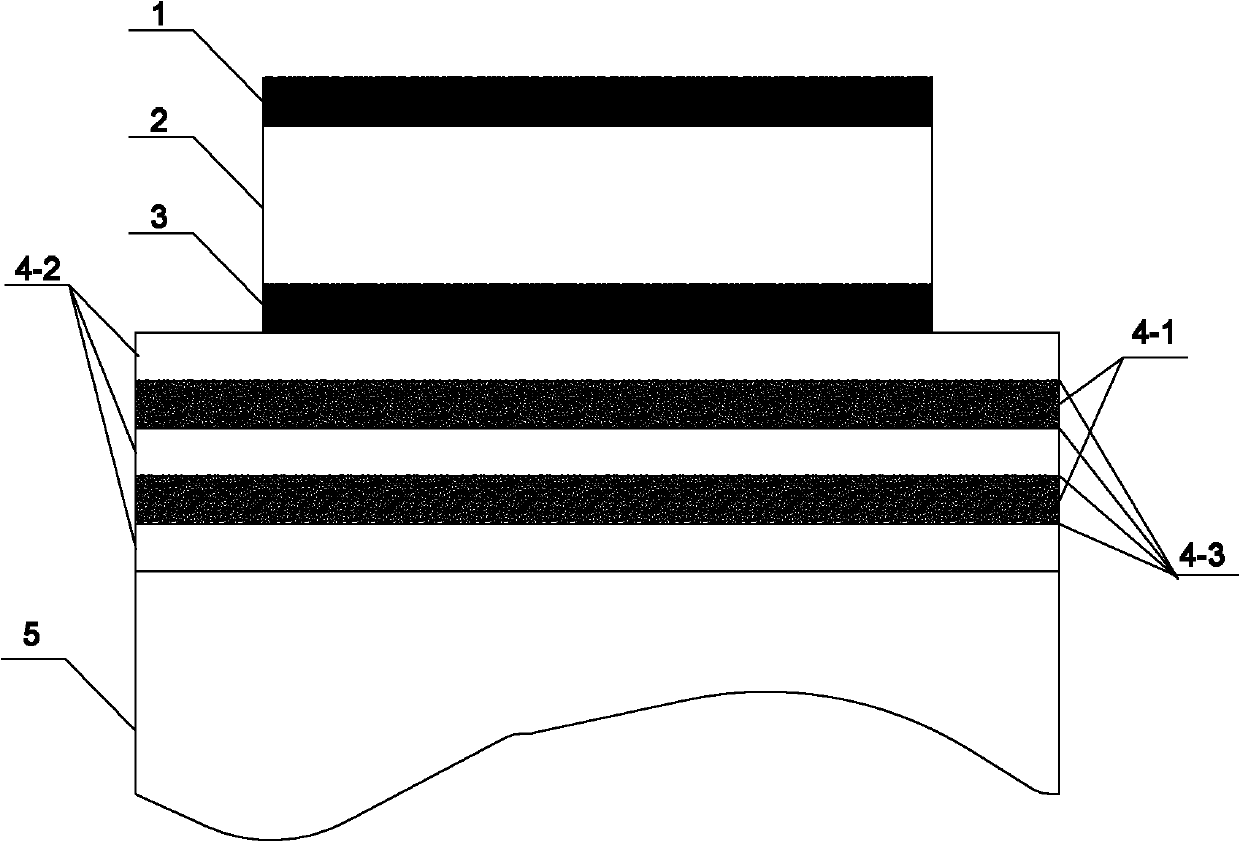

[0019] Specific implementation mode one, combination figure 1 Description of this embodiment, a fixed film bulk acoustic resonator, which includes an upper electrode 1, a lower electrode 2, a piezoelectric film 3, a fully insulated Bragg reflector 4 and a Si substrate 5, an upper electrode 1, a lower electrode 2 and a piezoelectric The film 3 constitutes a sandwich structure of piezoelectric oscillator stack centered on the piezoelectric film 3, the piezoelectric oscillator stack is directly grown on the fully insulated Bragg reflector 4, and the fully insulated Bragg reflector 4 is grown on the Si substrate 5.

specific Embodiment approach 2

[0020] The second embodiment is that the difference between this embodiment and the fixed film bulk acoustic resonator described in the first embodiment is that the fully insulated Bragg reflector 4 is a layer of low acoustic impedance film 4-2. Low acoustic impedance film 4-2 is SiO 2 film.

[0021] The fully insulated Bragg reflector grid 4 described in this embodiment is a low acoustic impedance film layer 4-2 with a simple structure. The low acoustic impedance film layer 4-2 can be SiO deposited by a radio frequency magnetron sputtering system 2 film.

specific Embodiment approach 3

[0022] Embodiment 3 This embodiment is a further limitation of the fixed film bulk acoustic resonator described in Embodiment 2, and the film thickness of the low acoustic impedance film layer 4-2 is 300-2000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com