Wavelength adjustable noise reduction tube of centrifugal pump

A centrifugal pump and noise reduction technology, applied in the field of adjustable wavelength centrifugal pump noise reduction tube, can solve the problems of difficult implementation, complicated improvement and high cost, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

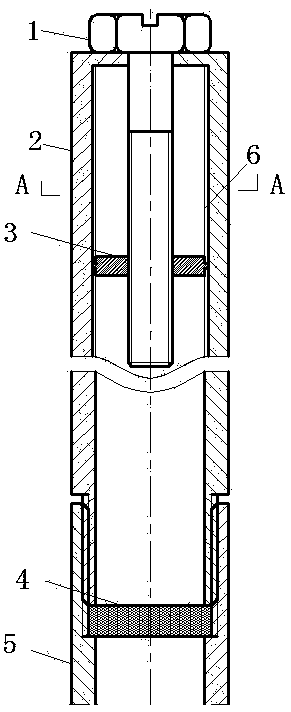

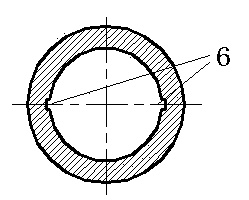

[0036] In addition, the diameters of the first pipe body 2 and the second pipe body 5 are both 0.2 to 0.4 times the diameter of the outlet of the volute, and the first pipe body 2 and the second pipe body 5 are connected by threads. The material of the sealing sound-transmitting sheet 4 is polyurethane with a thickness of 0.3 cm. The inner surface of the first pipe body 2 is provided with a card slot 6 , and the acoustic reflection cock 3 is provided with a protrusion corresponding to the card slot 6 ; the protrusion is locked in the card slot 6 . The materials of the wavelength adjusting device 1 , the first tube body 2 and the second tube body 5 are all stainless steel.

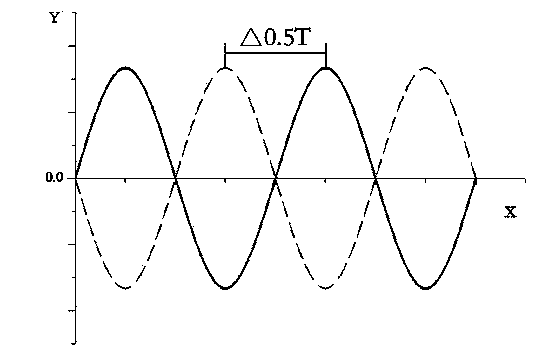

[0037]When the invention is working, it is installed on the volute of the centrifugal pump through the base thread. When the centrifugal pump is running stably, the blade frequency noise generated by the static and dynamic interference at the tongue is transmitted in the fluid, and enters the noise reductio...

Embodiment 2

[0041] Example 3

Embodiment 3

[0043] The specific implementation methods listed above are non-restrictive and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention should be included in the protection scope of the present invention Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com