Patents

Literature

52 results about "Cross Slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

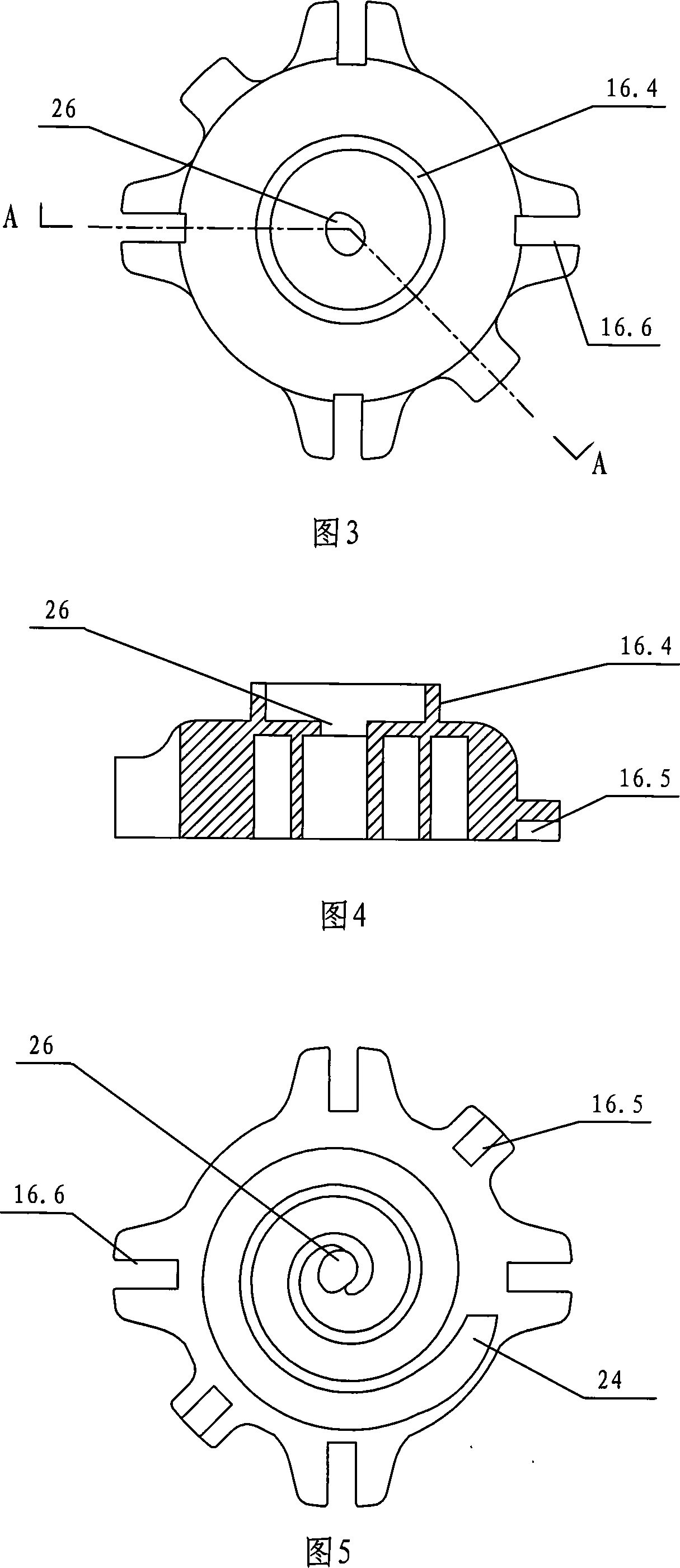

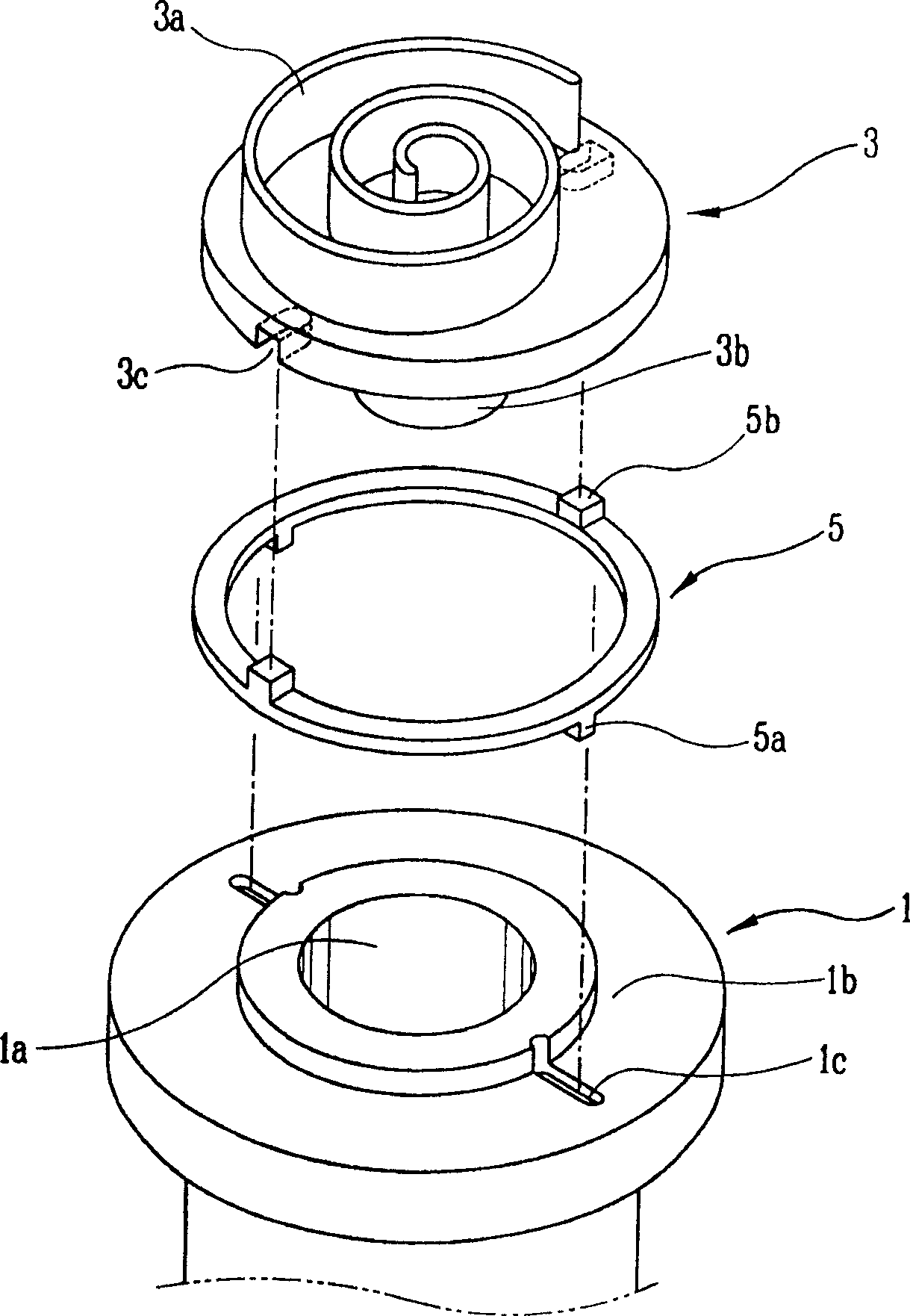

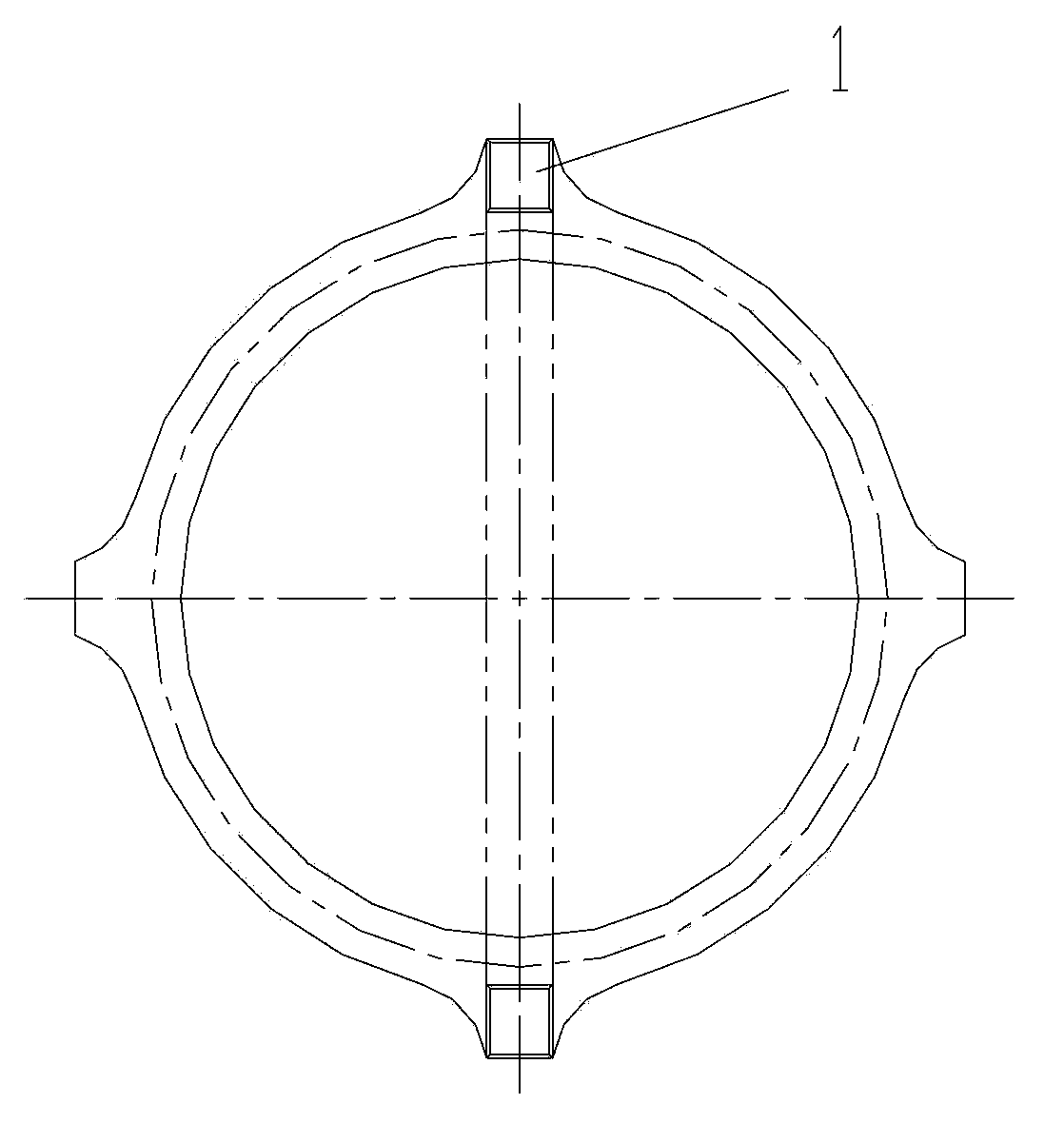

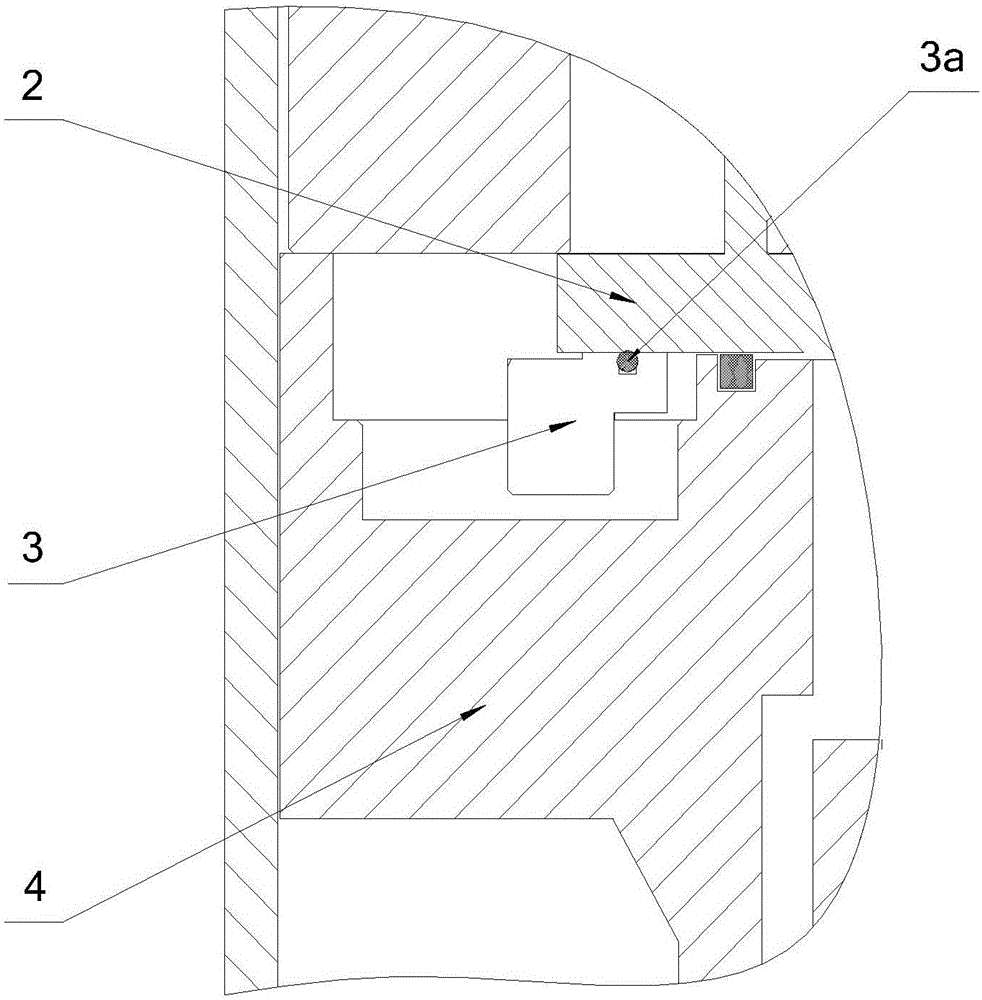

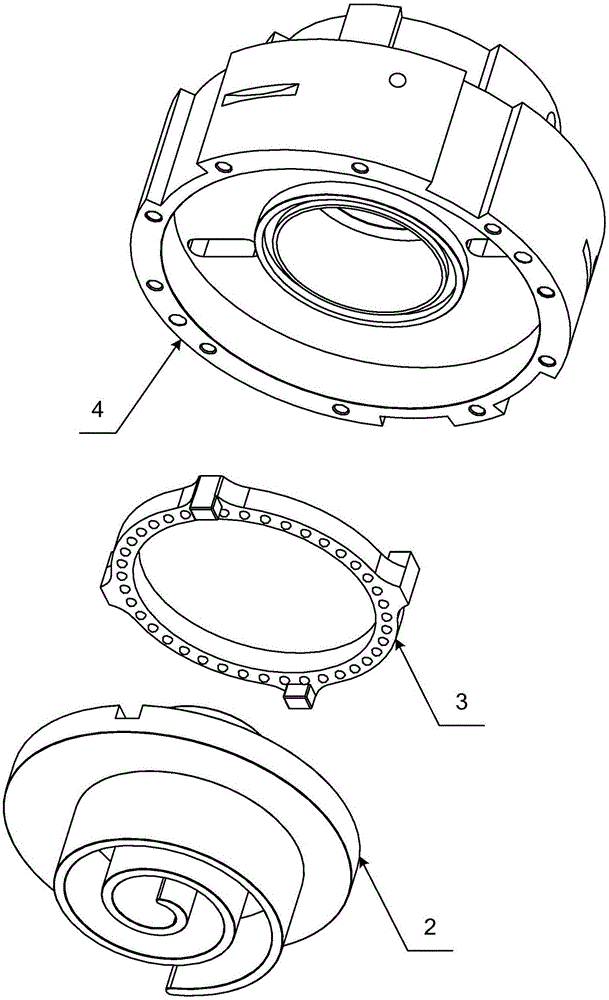

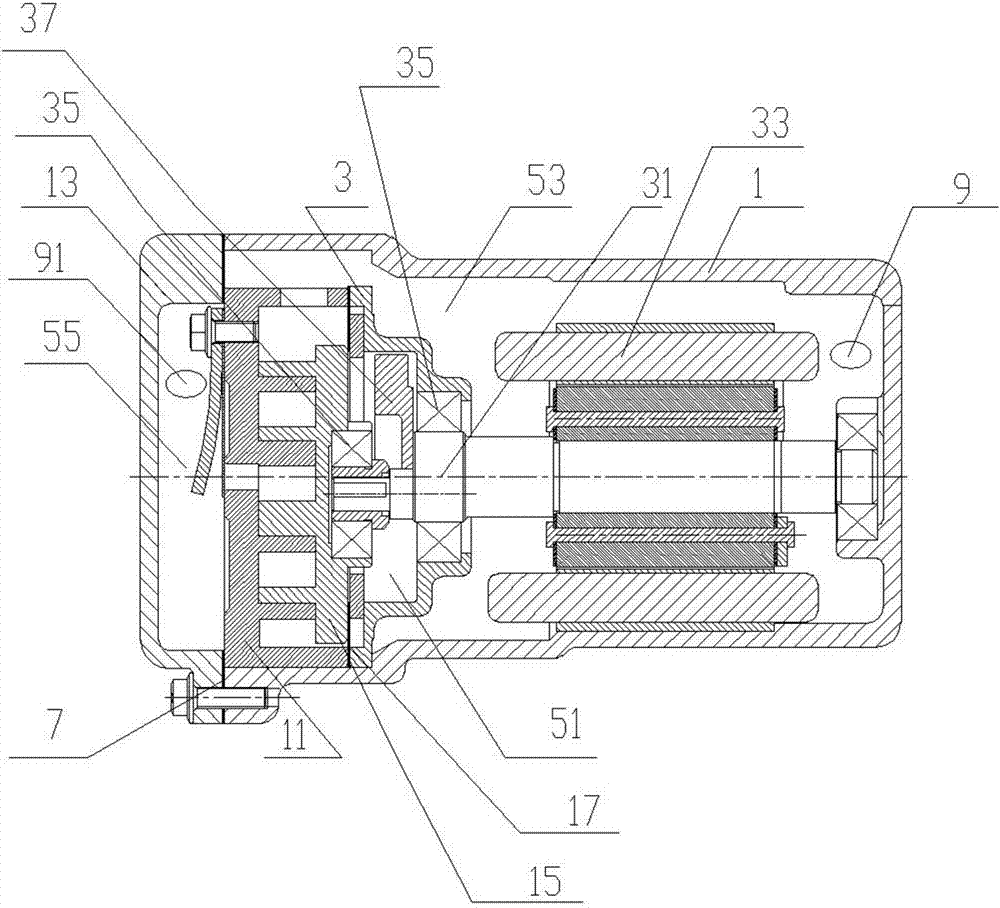

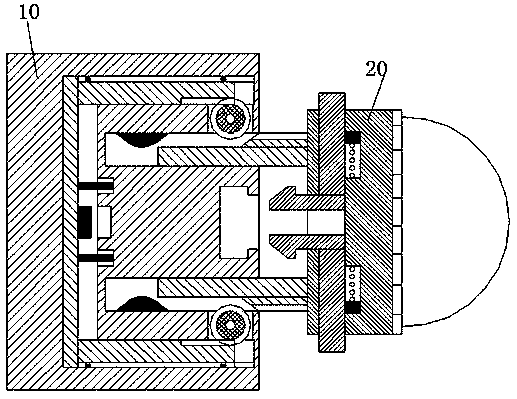

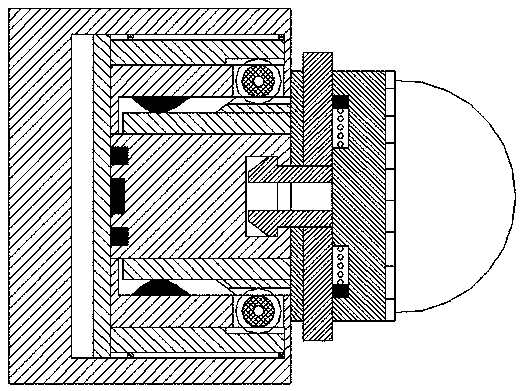

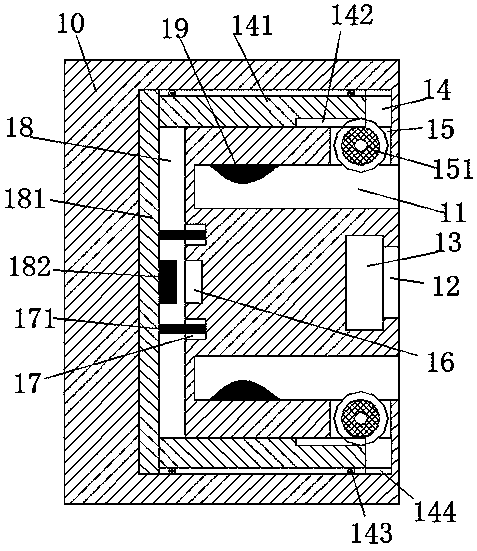

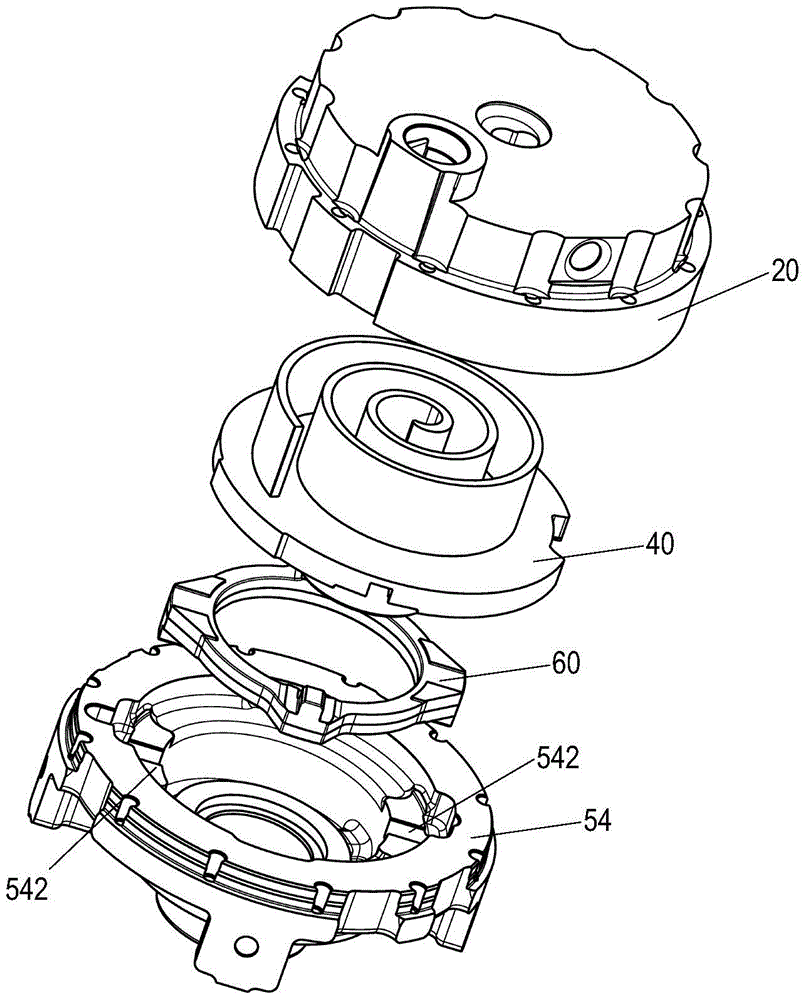

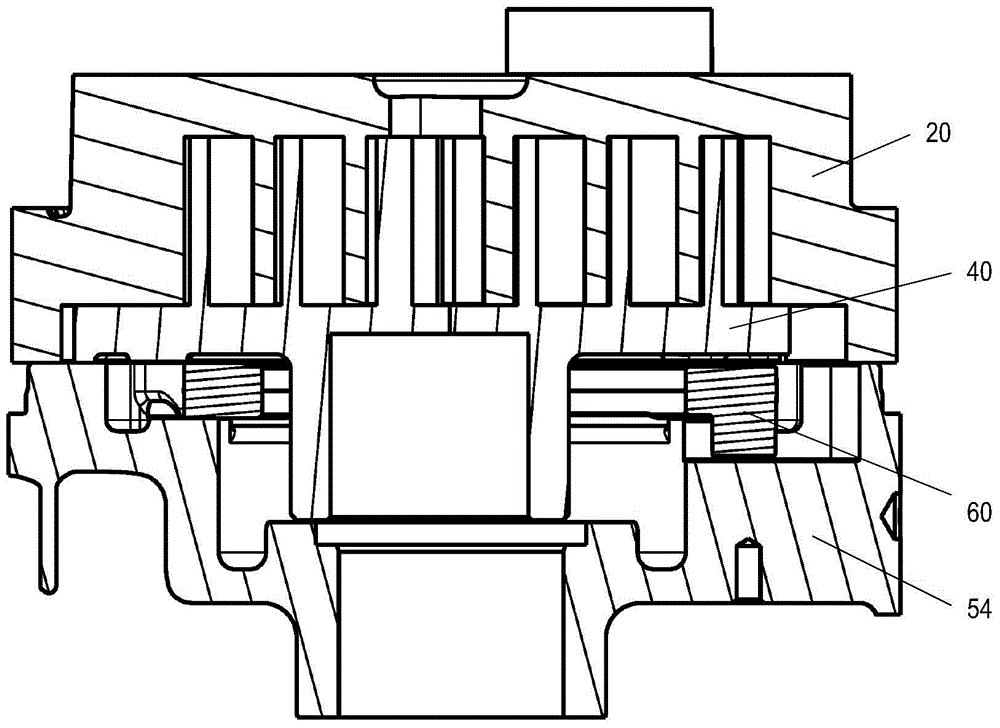

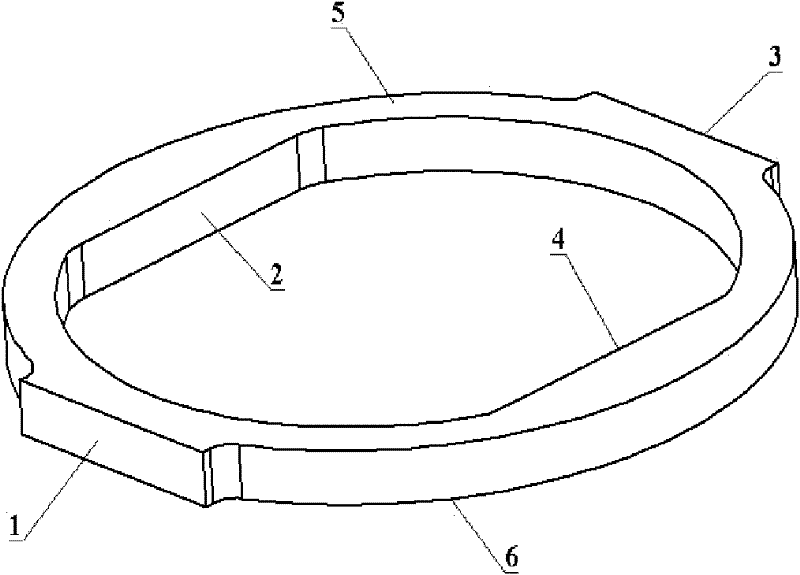

Plane cross slip ring for scroll compressor

InactiveCN102062098ACancel noiseImprove working conditionsRotary piston pumpsRotary piston liquid enginesEngineeringCross Slip

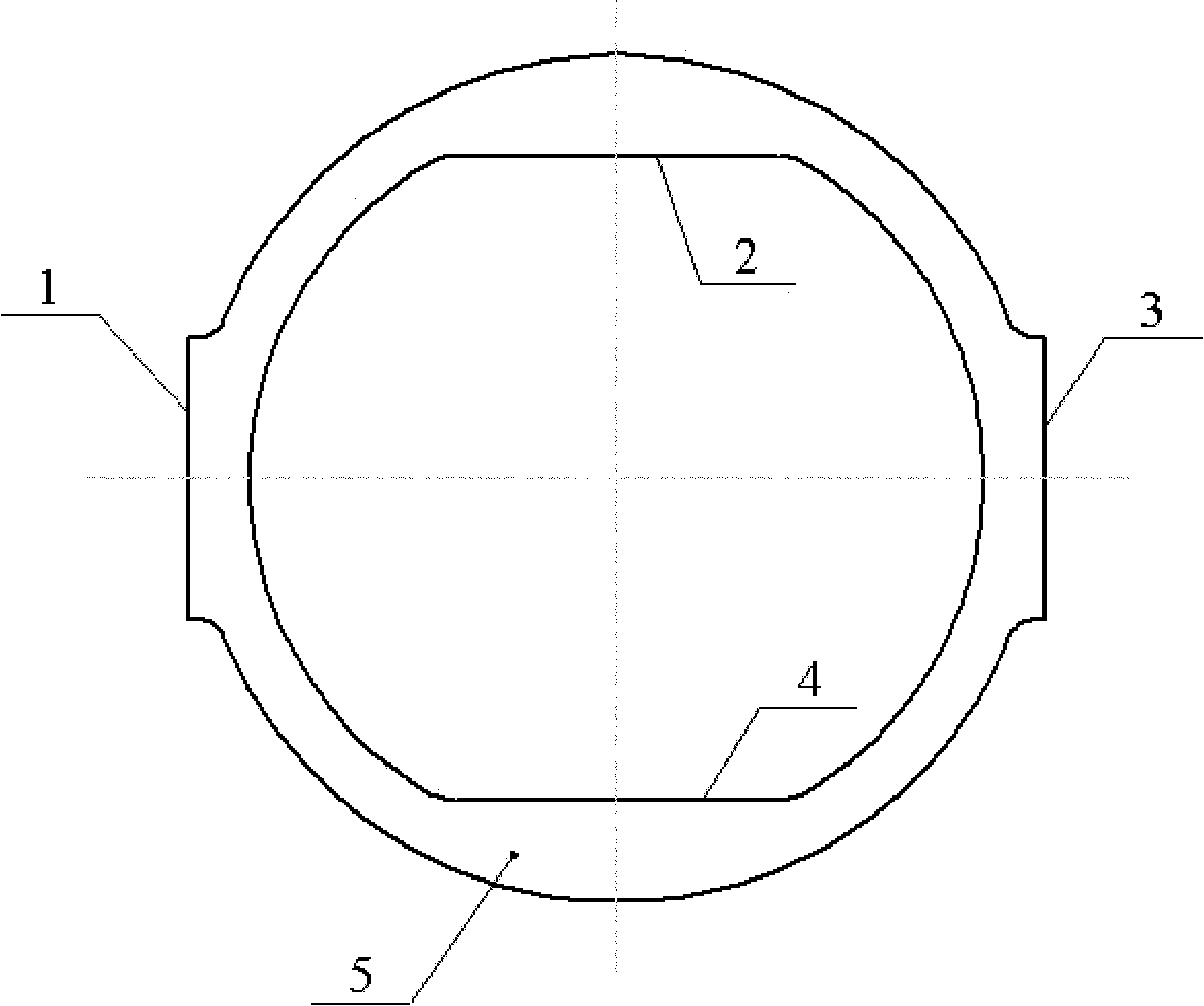

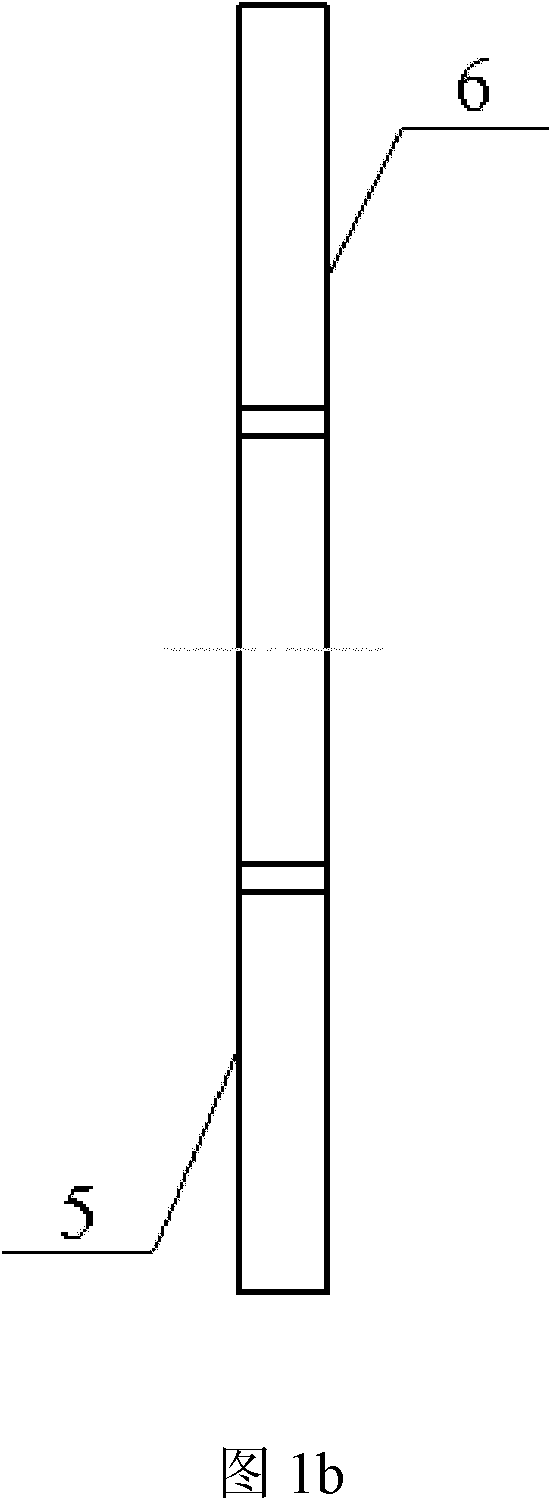

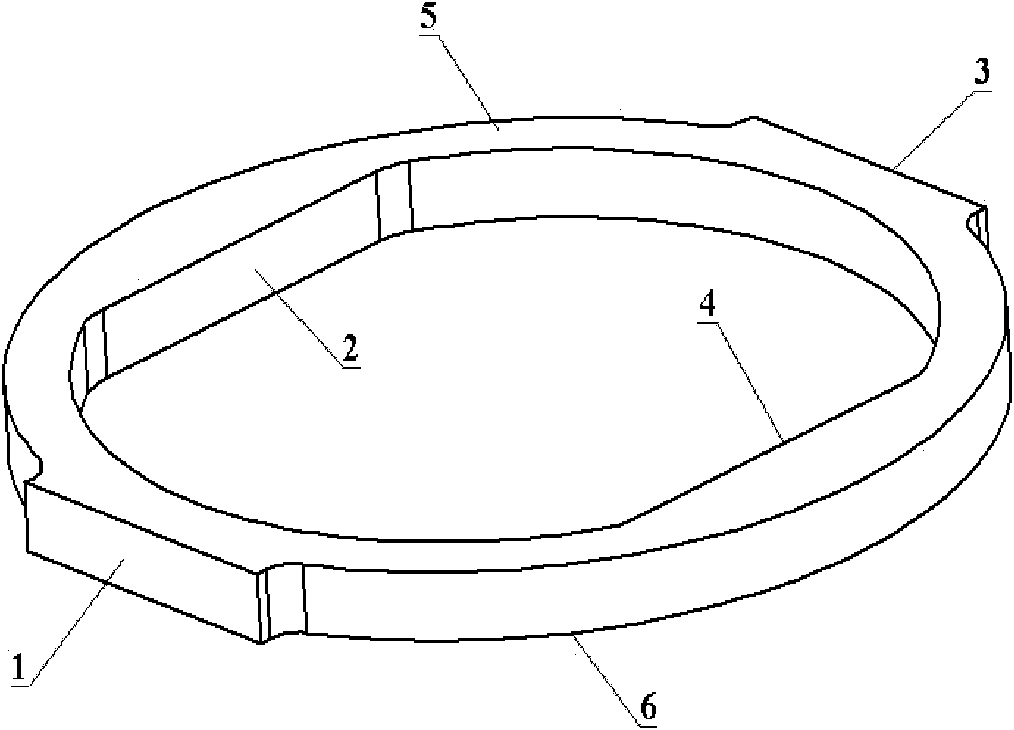

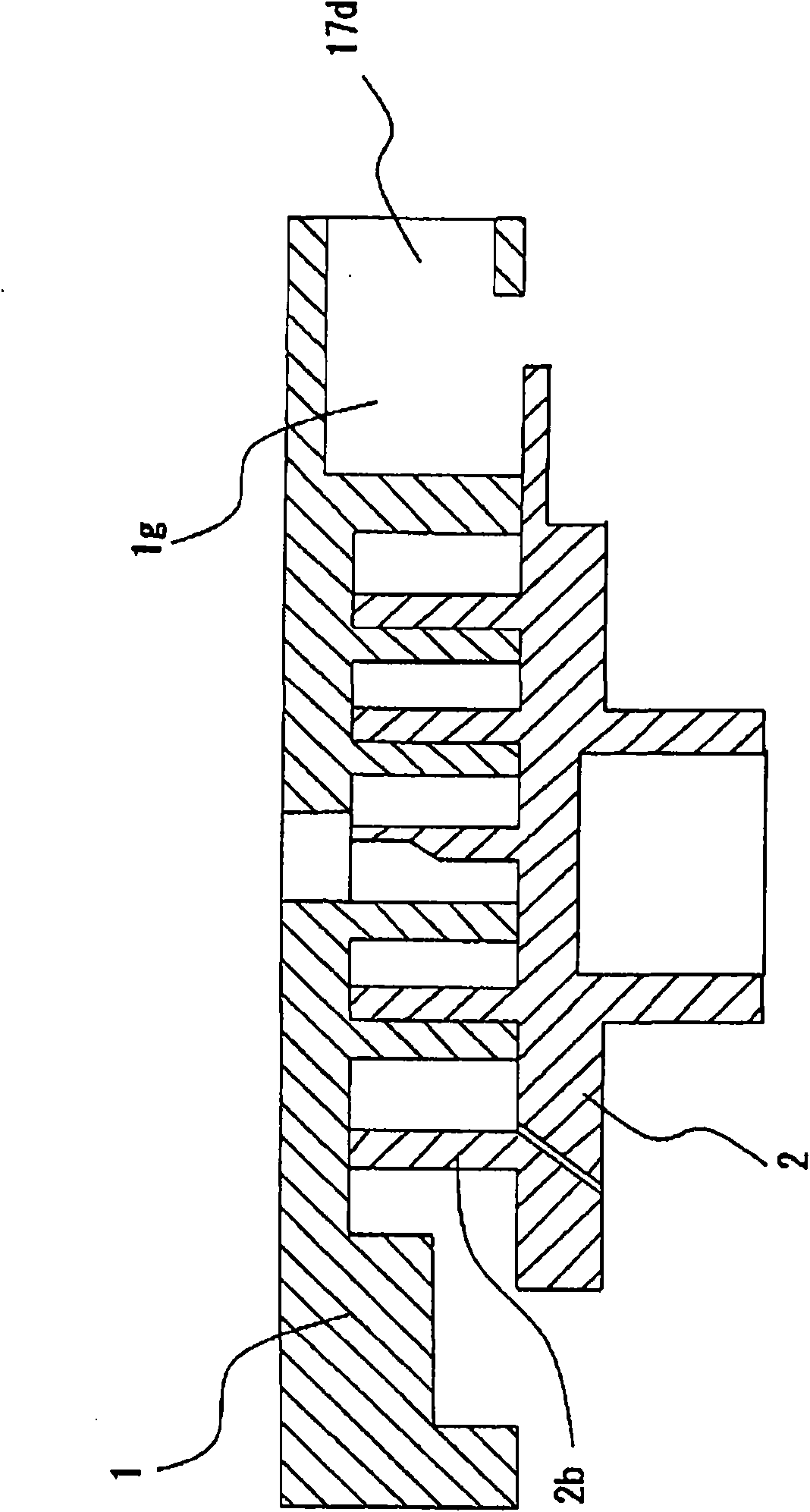

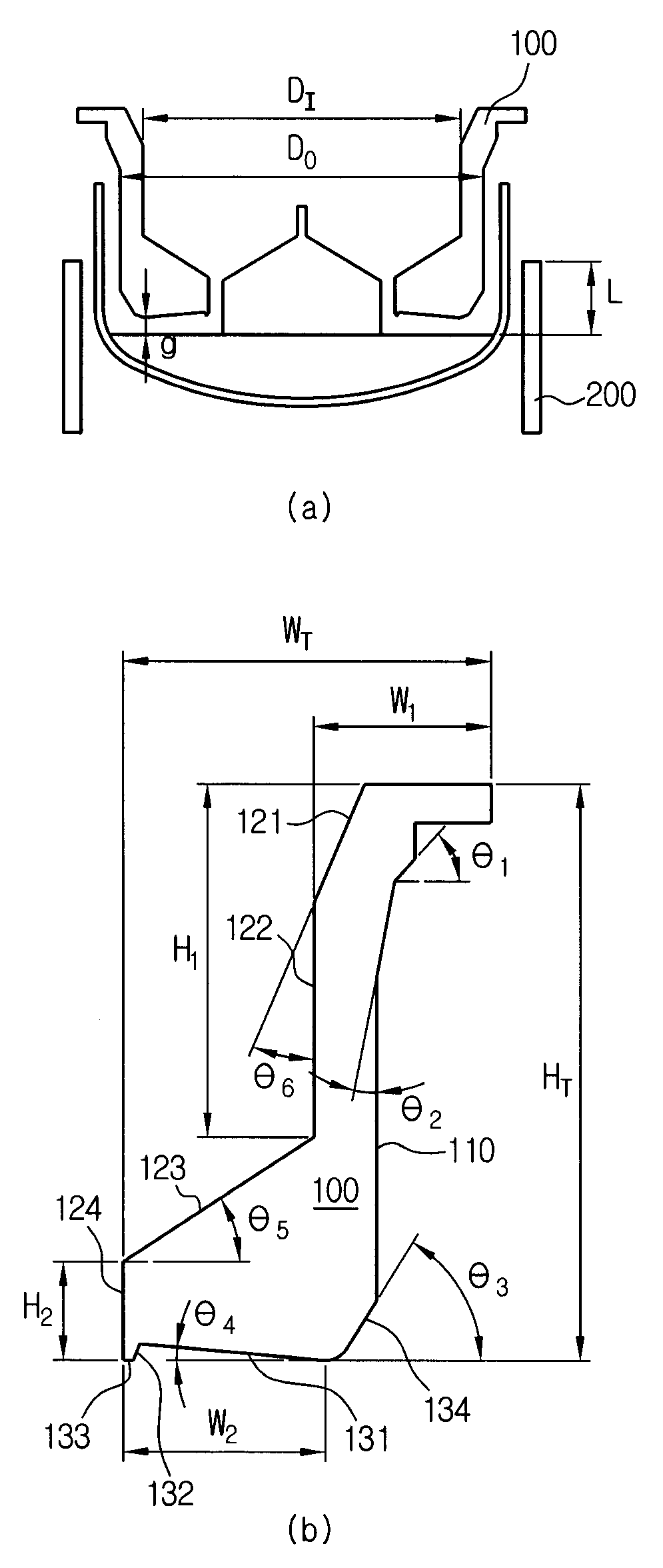

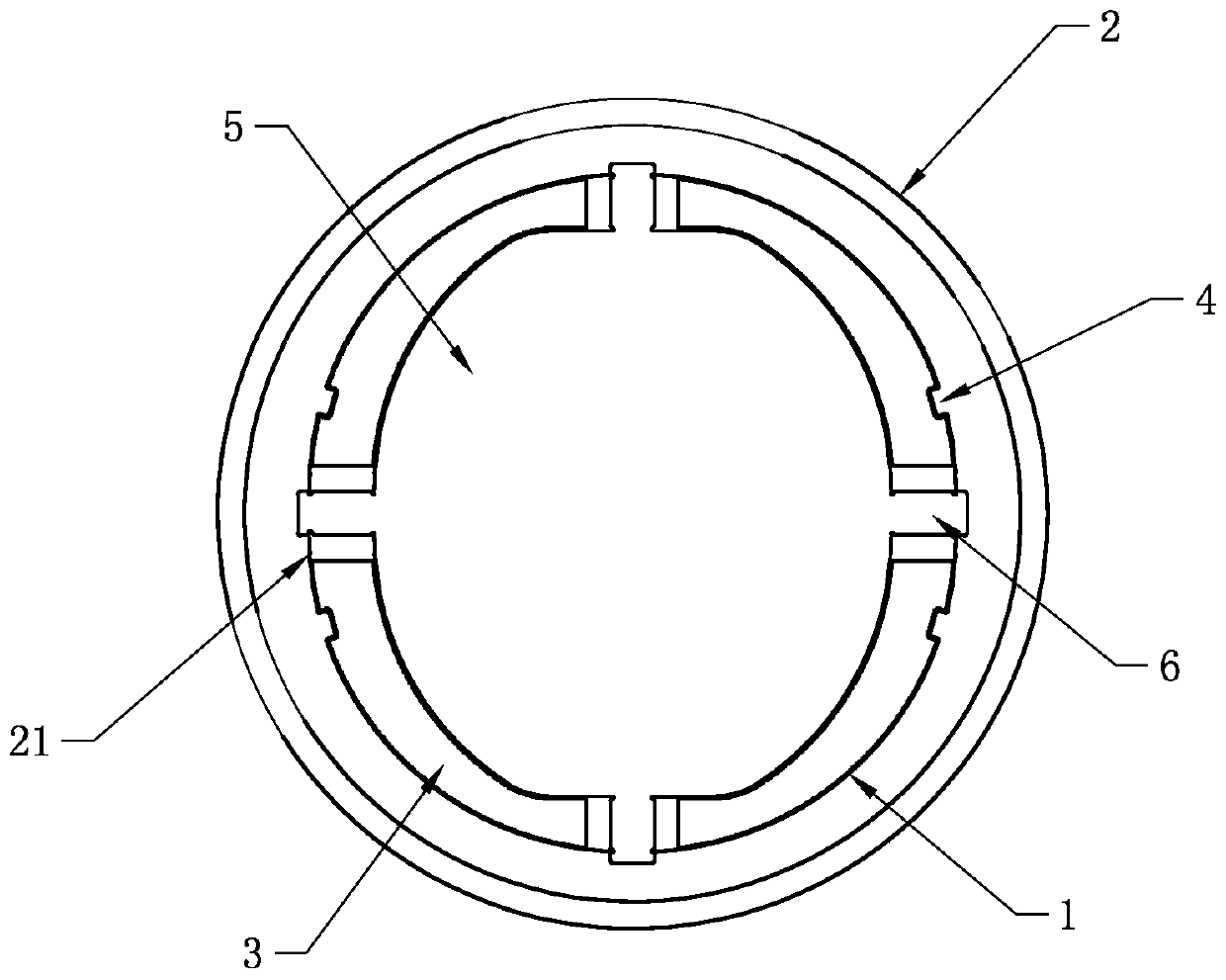

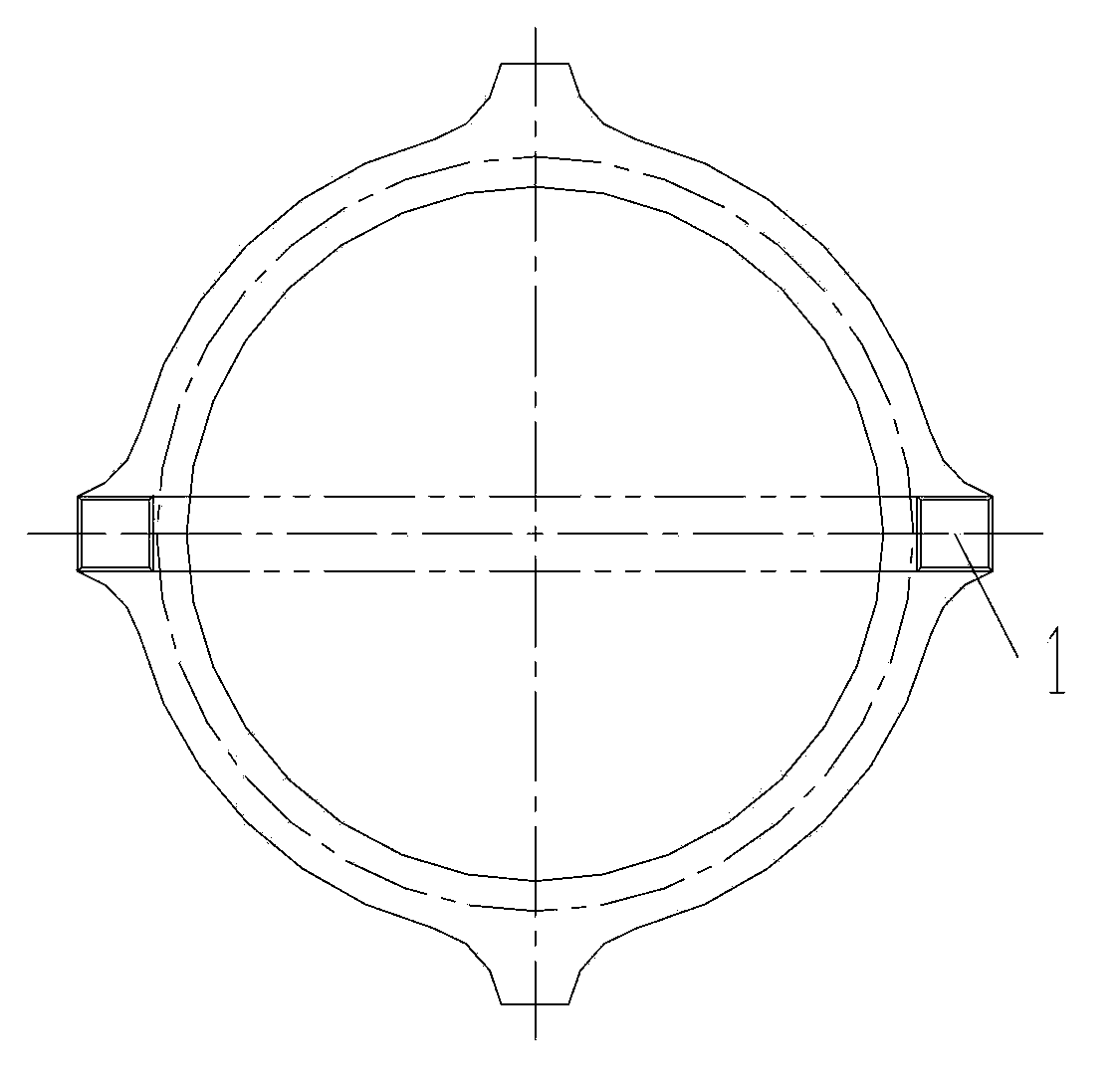

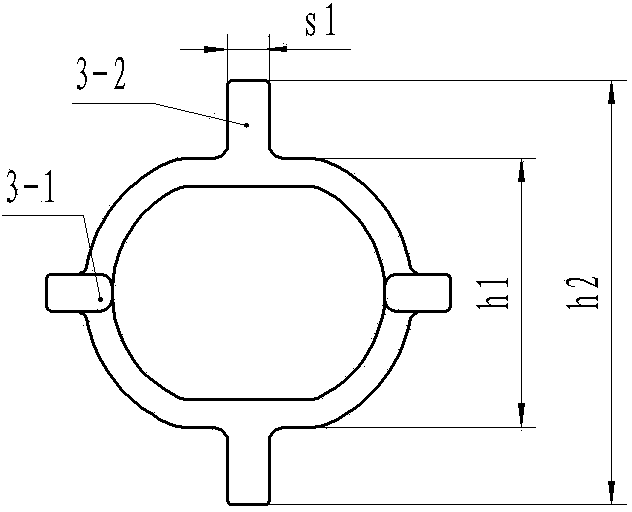

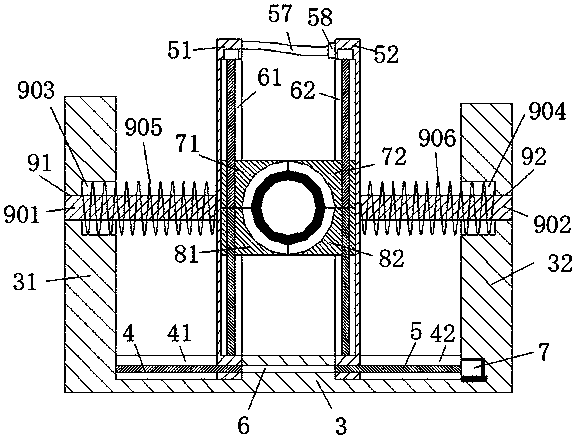

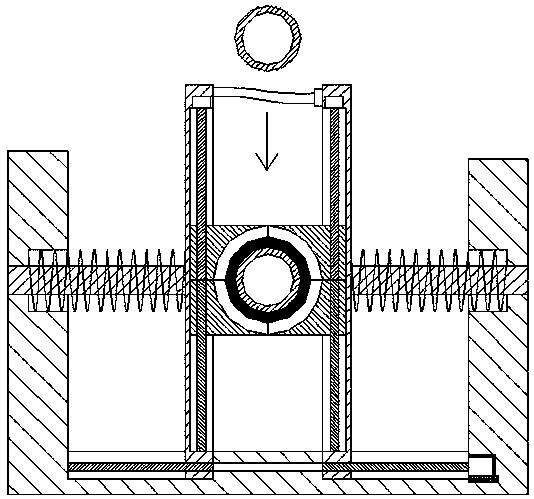

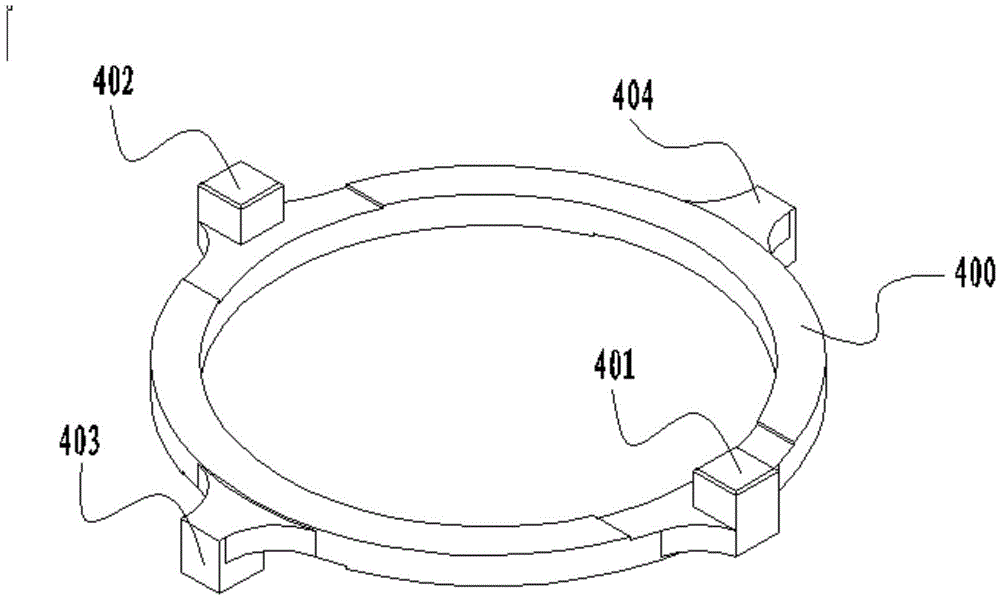

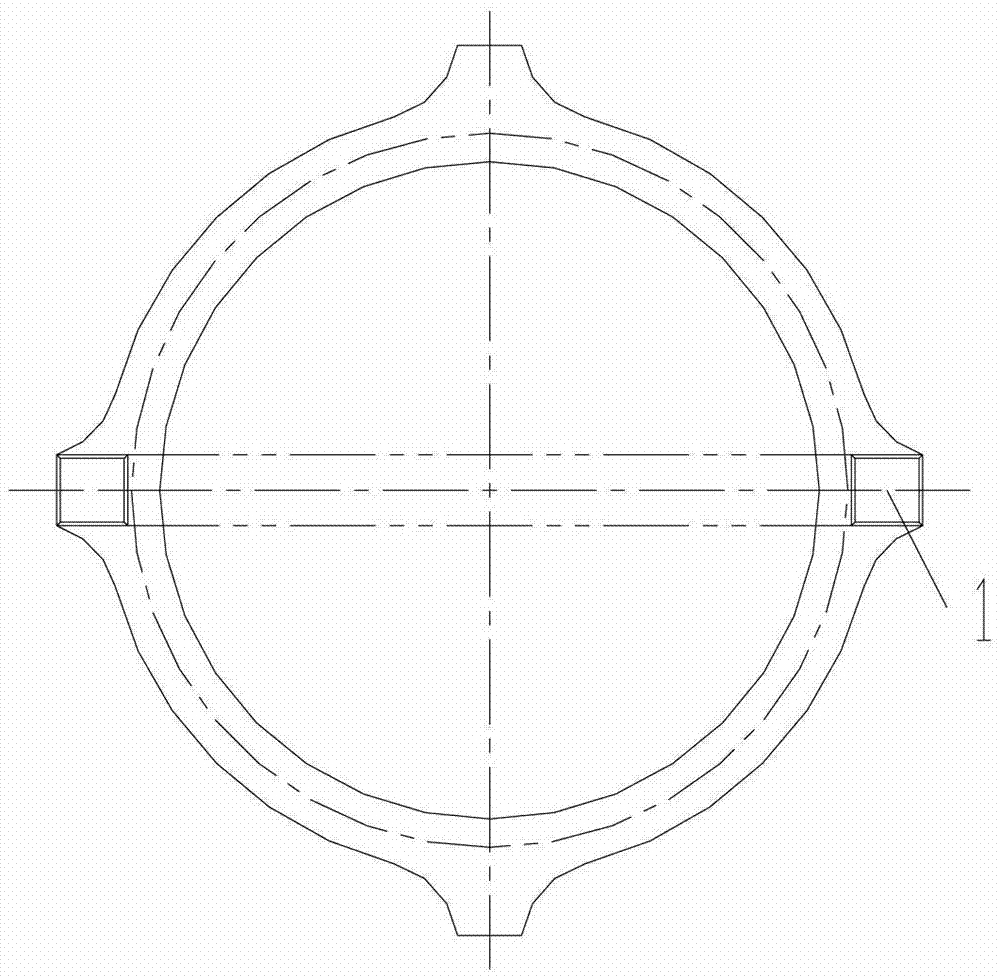

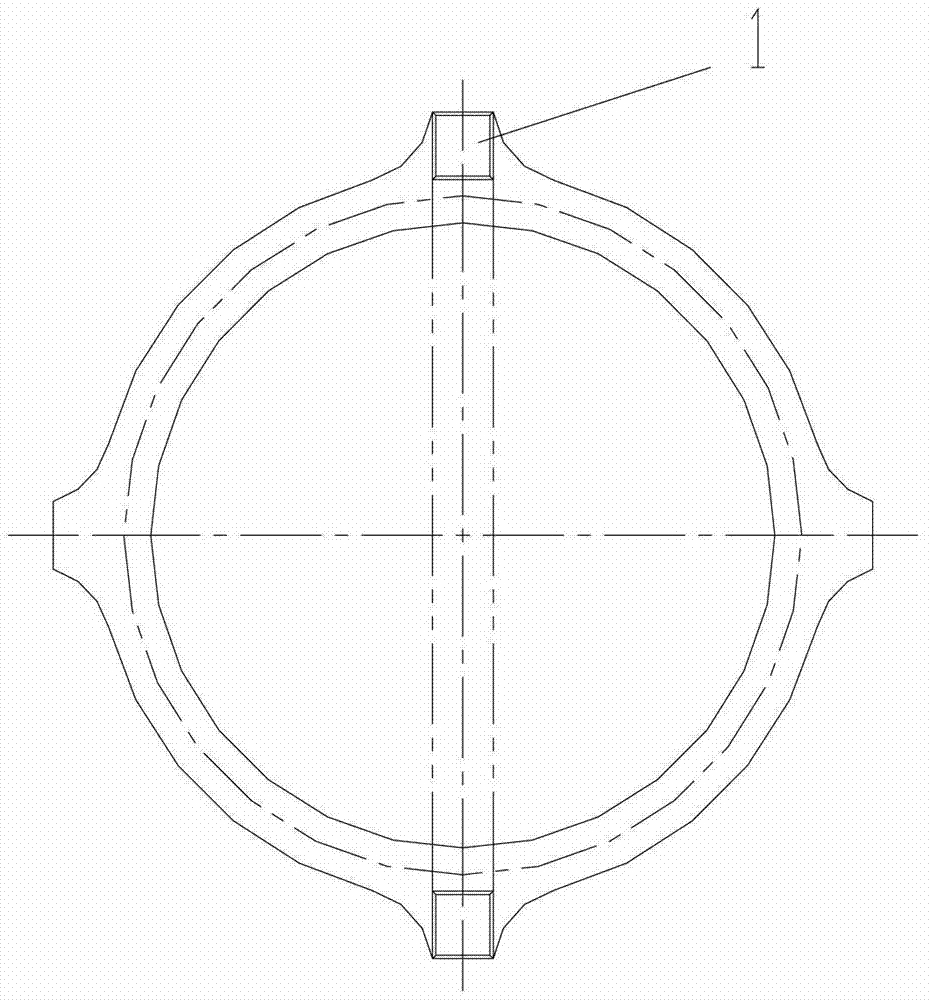

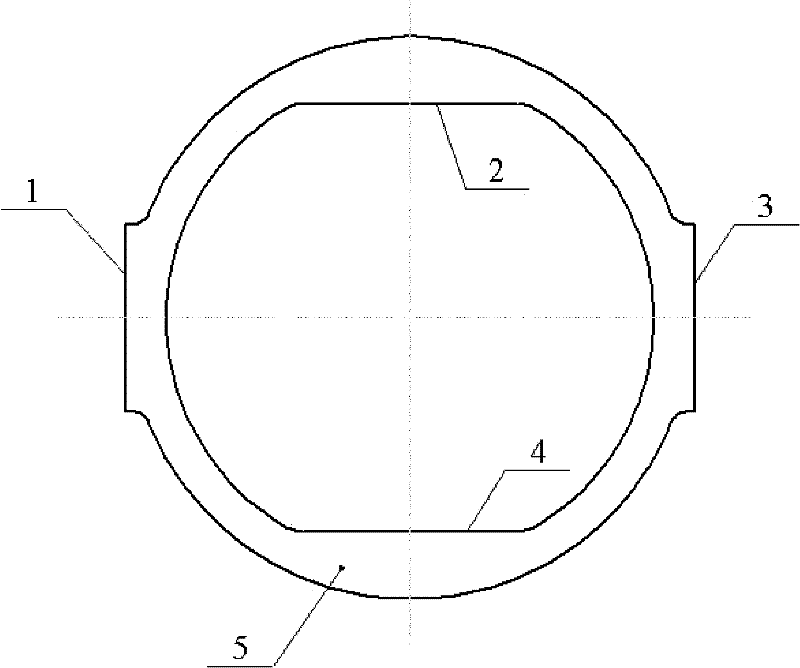

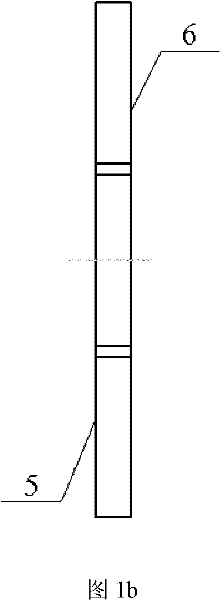

The invention discloses a plane cross slip ring for a scroll compressor. The plane cross slip ring is in a plane layout structure; working main bodies are two pairs of lug bosses crossly arranged on the plane cross slip ring; the spatial position of a working plane is positioned between two end planes of the plane cross slip ring; one pair of the lug bosses arranged on the plane cross slip ring are positioned at the excircle side of the plane cross slip ring, and the other pair of the lug bosses are positioned at the inner circle side of the plane cross slip ring; the working planes of the lug bosses are mutually perpendicular; the working planes of the first pair of the lug bosses of the plane cross slip ring are attached to the friction surfaces of a pair of lug bosses of a static scroll plate, and the working planes of the second pair of the lug bosses are attached to the friction surfaces of a pair of lug bosses of a dynamic scroll plate; and the working planes of the lug bosses of the plane cross slip ring, the friction surfaces of the dynamic scroll plate and the friction surfaces of the static scroll plate are all parallel to a central axis of the plane cross slip ring, thus the dynamic scroll plate takes plane circular motion under the driving of a bent axle. The invention effectively solves the problems of vibration, noise and short life of the traditional cross slip ring without a protruding guide slide block of the traditional cross slip ring.

Owner:XI AN JIAOTONG UNIV

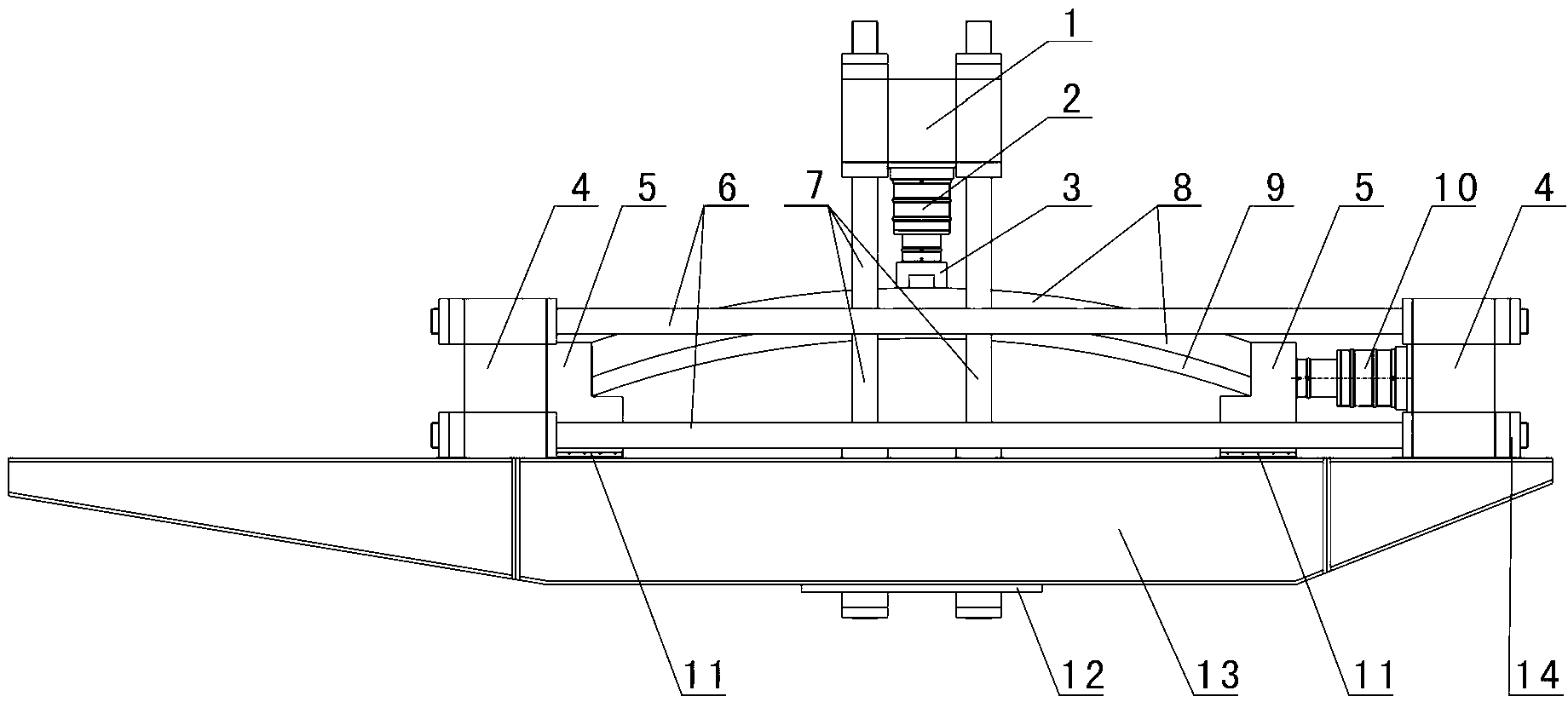

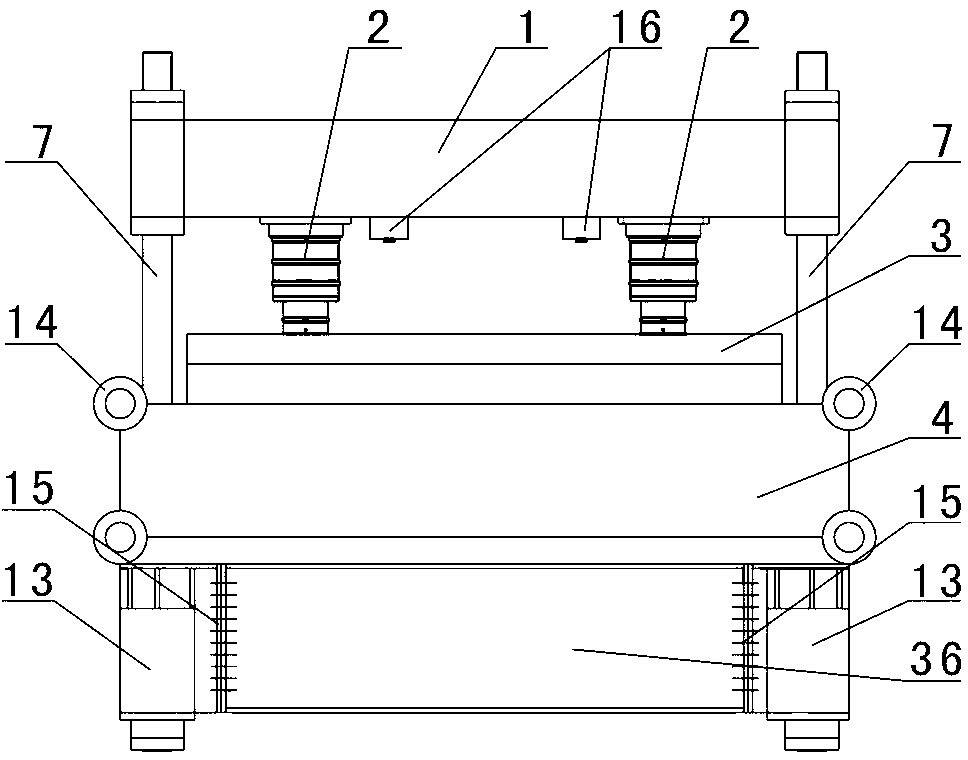

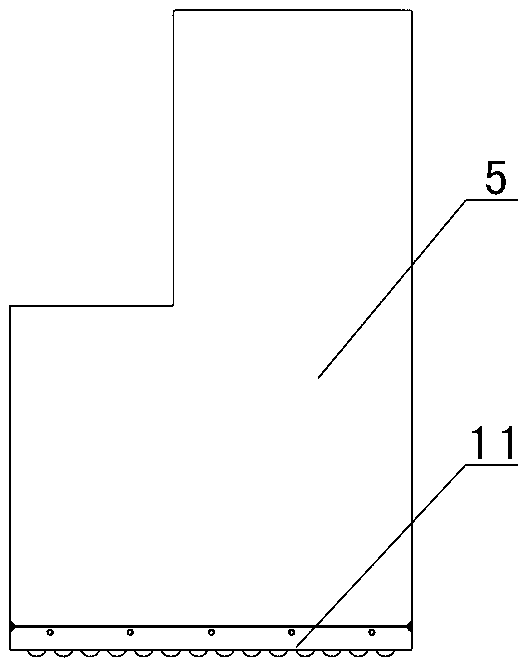

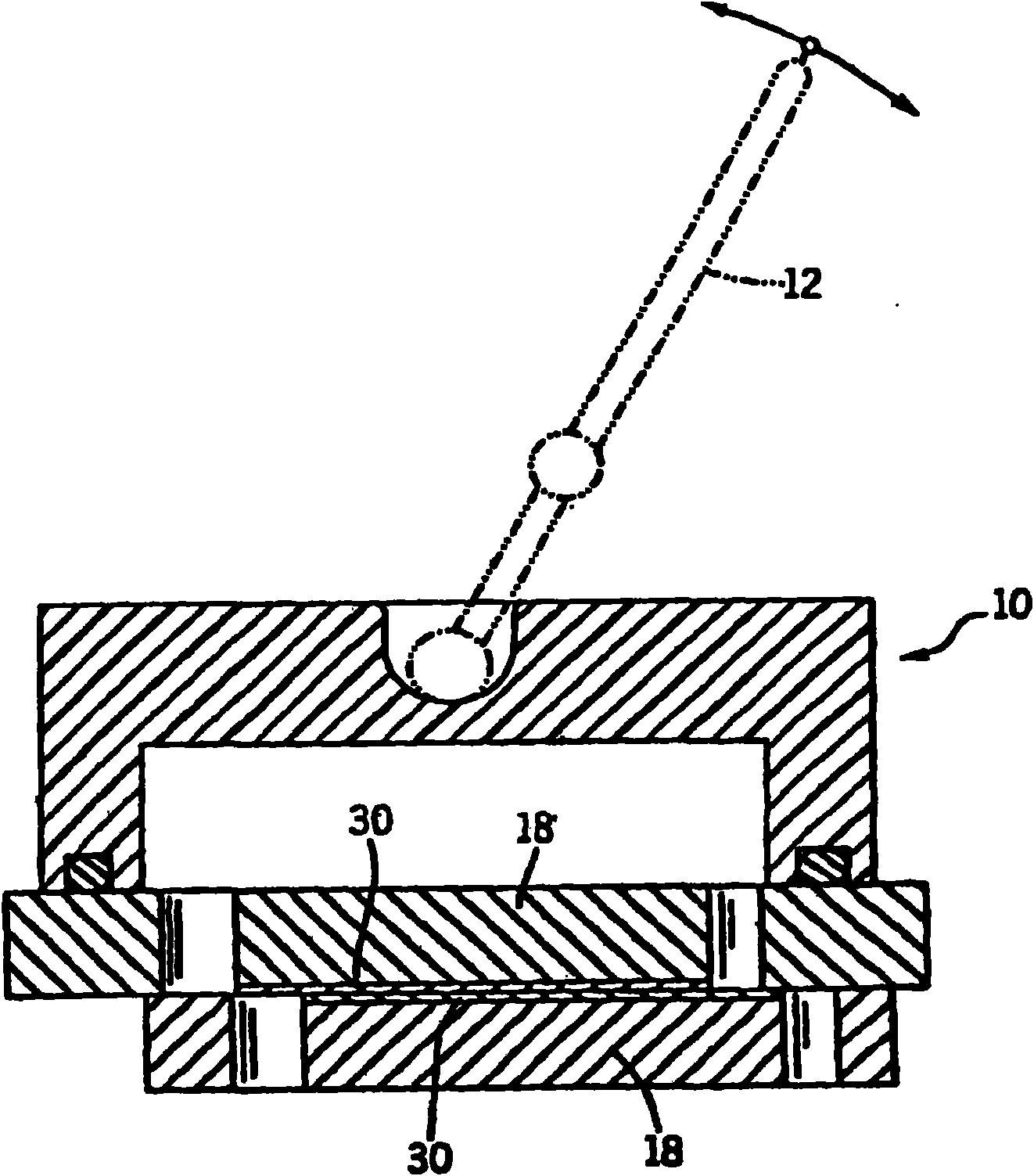

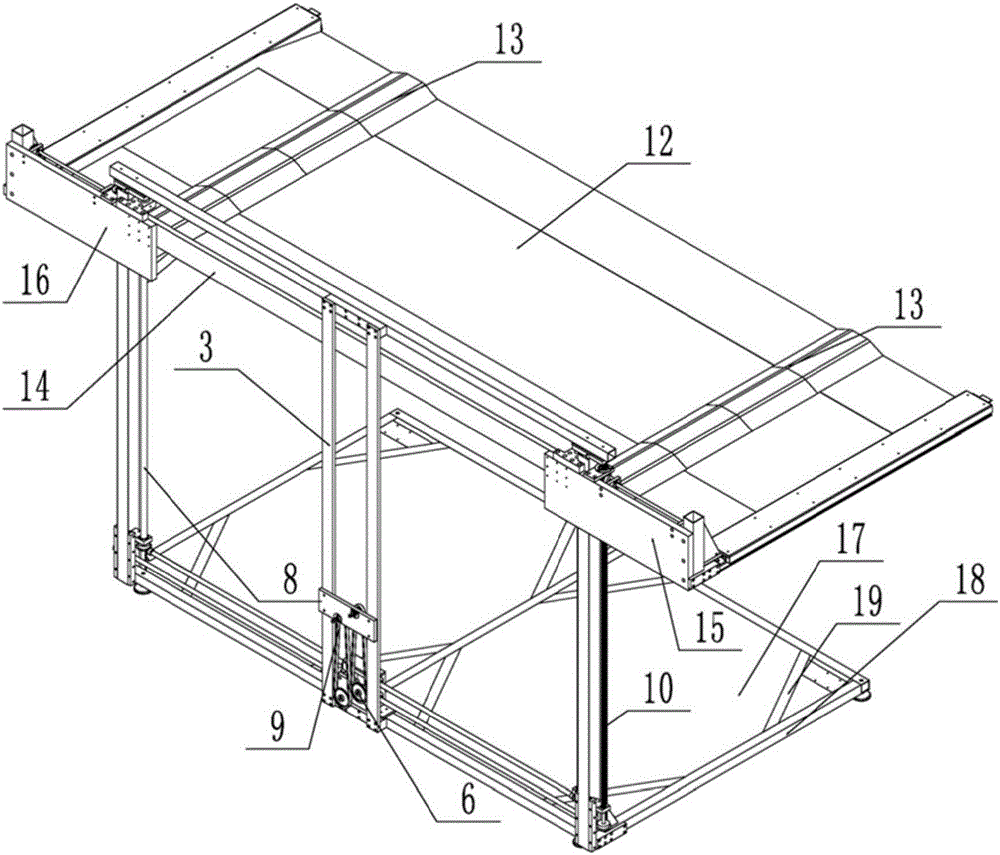

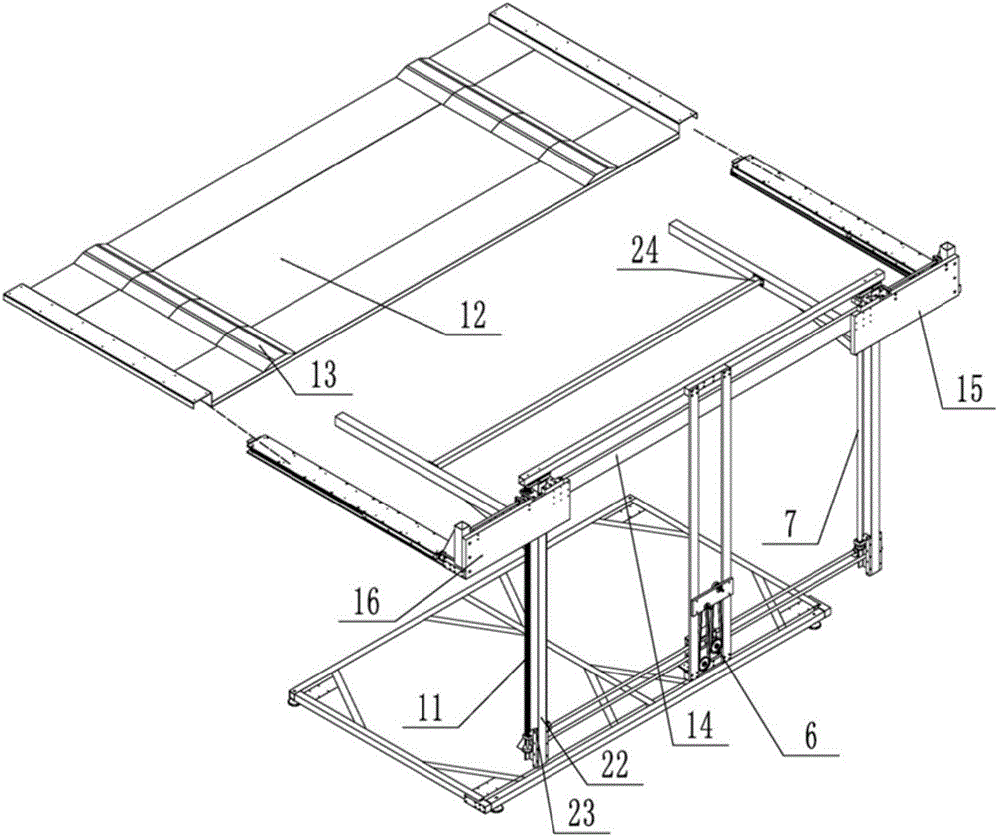

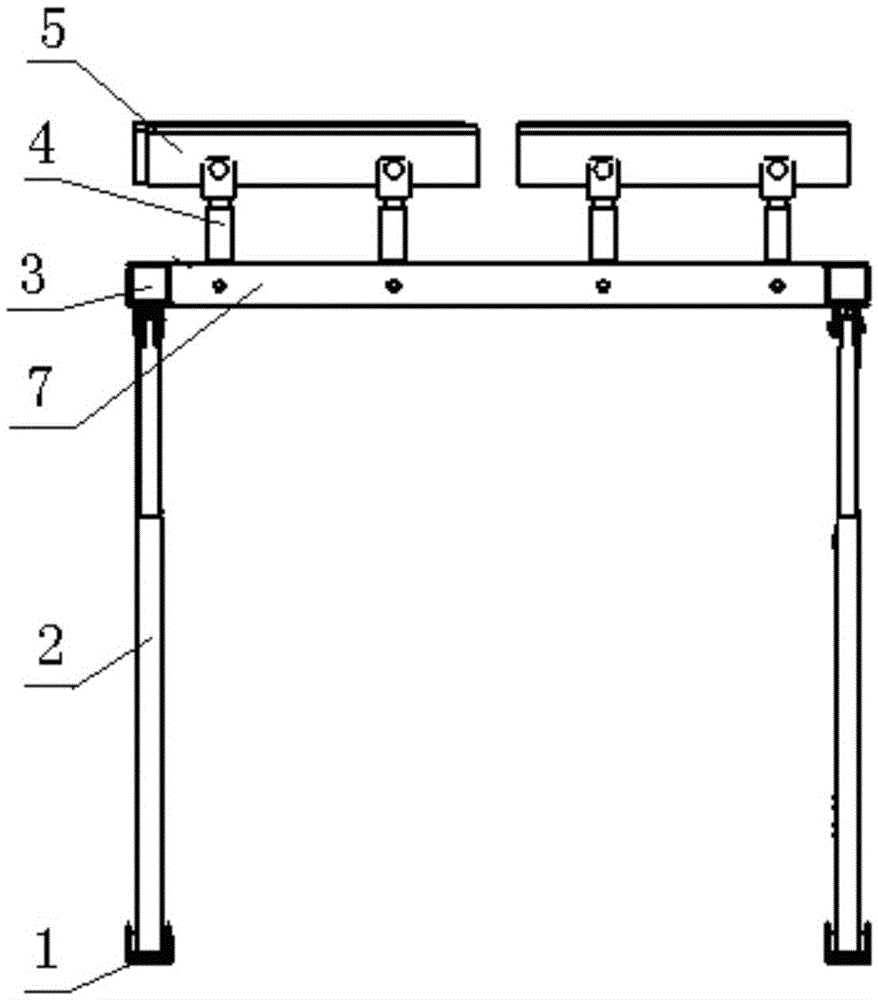

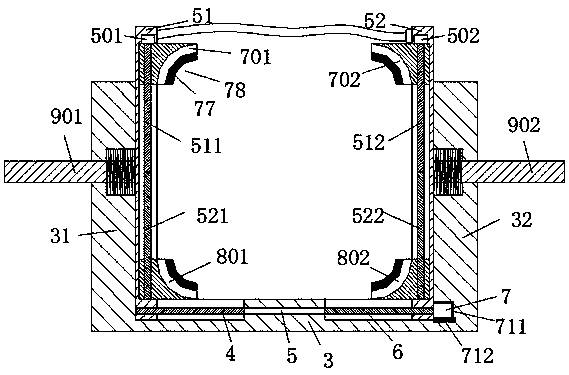

Prototype test device for shield tunnel dual-layer lining structure and secondary lining pouring device

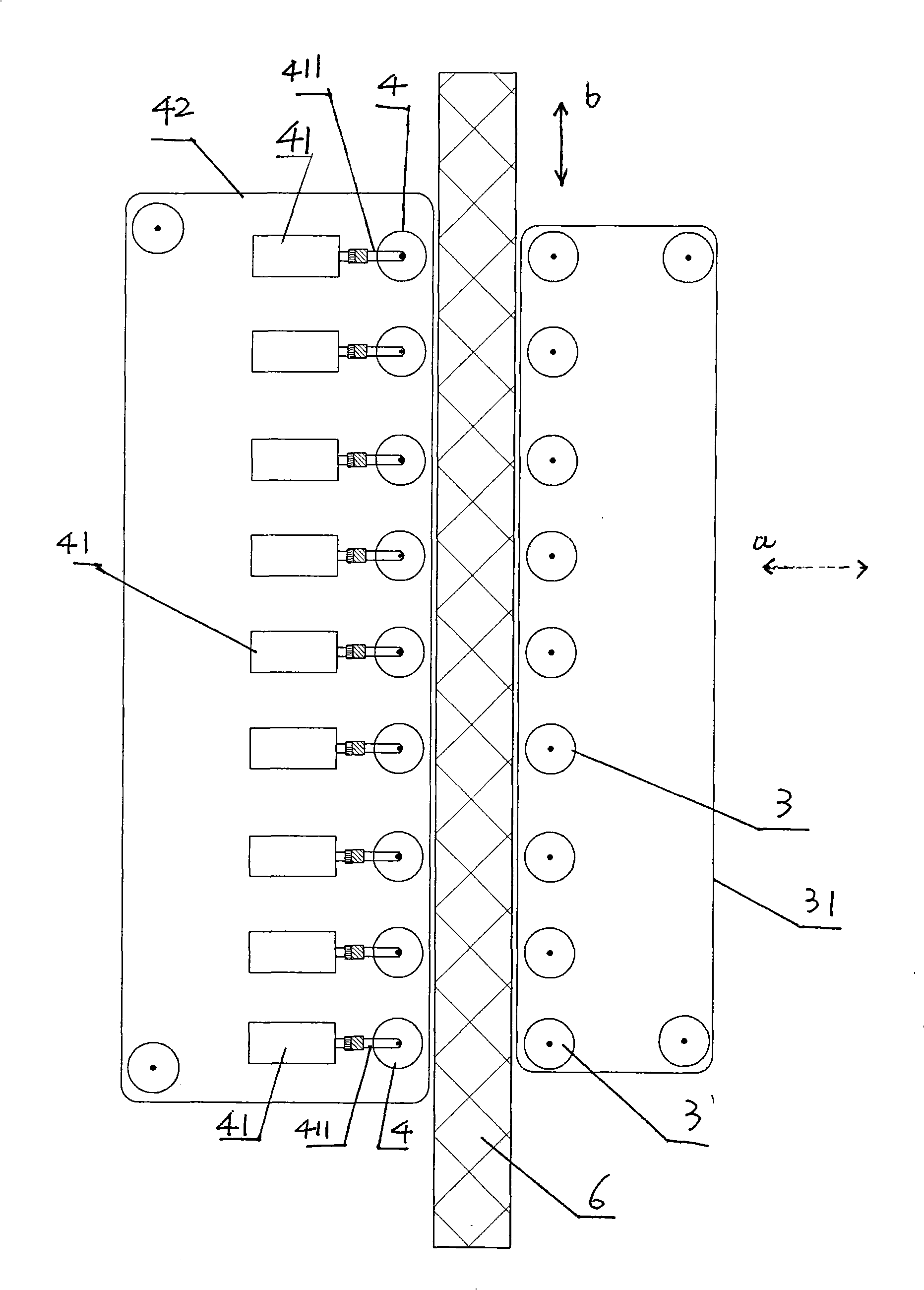

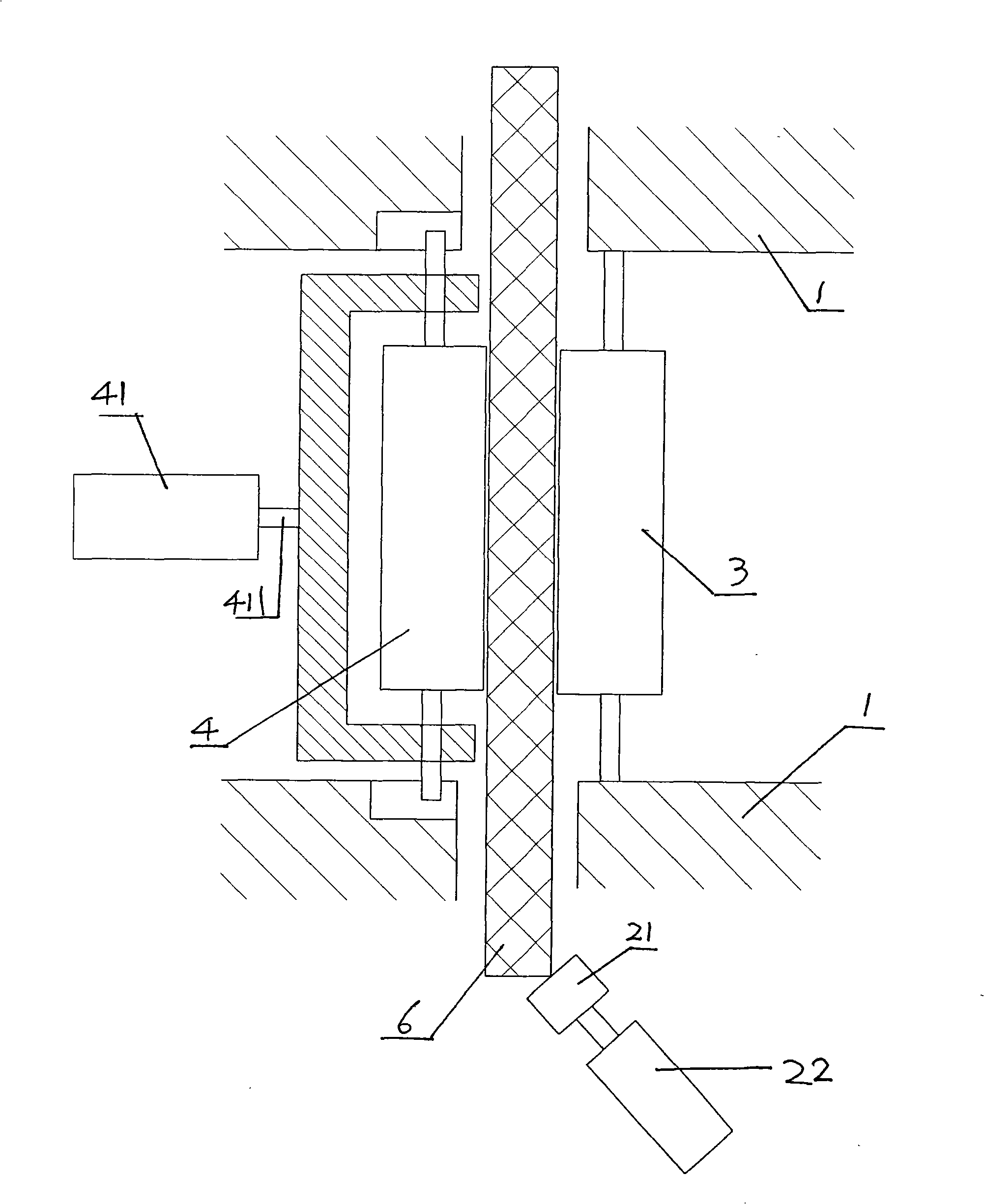

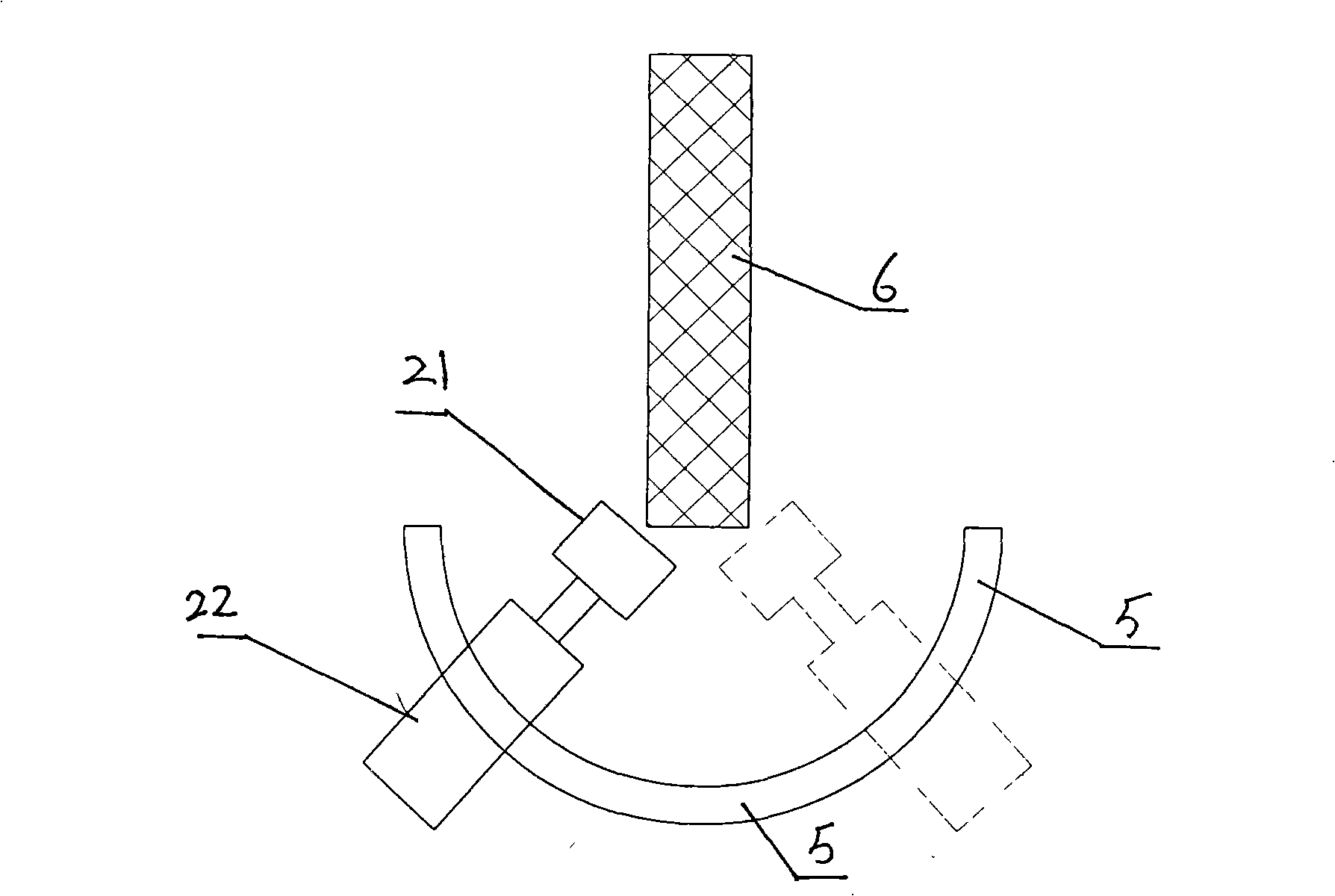

ActiveCN103257080AThe test data is accurateConsistent Test Loading ProcessMaterial strength using tensile/compressive forcesCross SlipVertical load

The invention discloses a prototype test device for a shield tunnel dual-layer lining structure. Two mudsills, two cross counter-force beams and a vertical counter-force beam form a test bed; two cross slip beams, two cross jacks, a vertical load transfer beam and two vertical jacks form a loading device; the both ends of the shield tunnel dual-layer lining structure formed by combining a duct piece lining and a secondary lining are respectively arranged on the stressed faces of the two cross slip beams; and the cross jacks and the vertical jacks respectively apply pressure to the duct piece lining and the secondary lining. The invention further discloses a pouring deice for the secondary lining, wherein two symmetrical connection lateral faces on a splicing module are in a splayed structure; and a concrete baffle is mounted at the outer side of an assembly of the splicing module and forms a pouring cavity. According to the invention, a dual-layer lining structure loading test can be realized at different stress states, a cracked duct piece lining and secondary lining reinforcing and supporting mechanical loading test is carried out, and the pouring of secondary linings with different sizes and different curvatures can be realized.

Owner:SOUTHWEST JIAOTONG UNIV

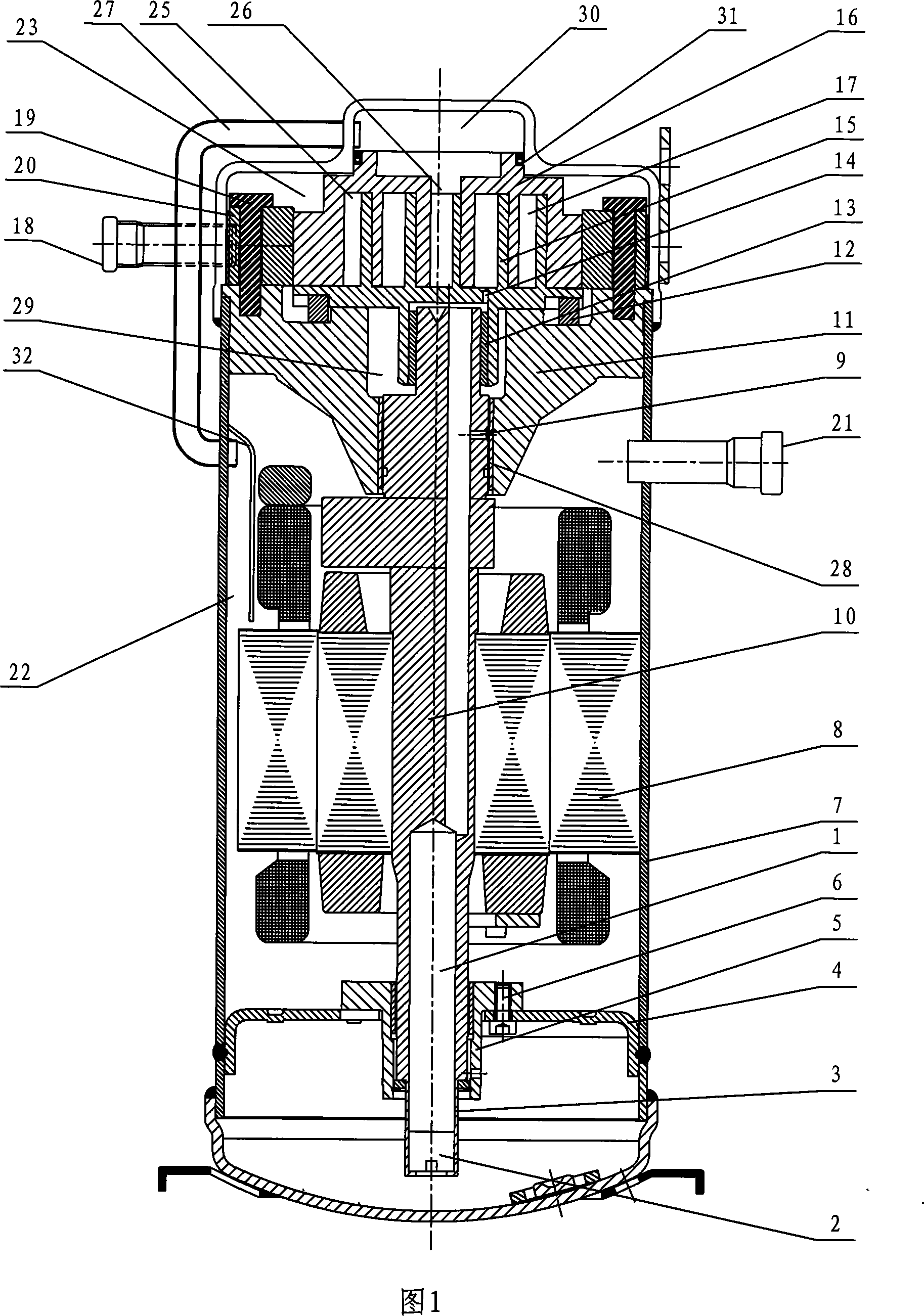

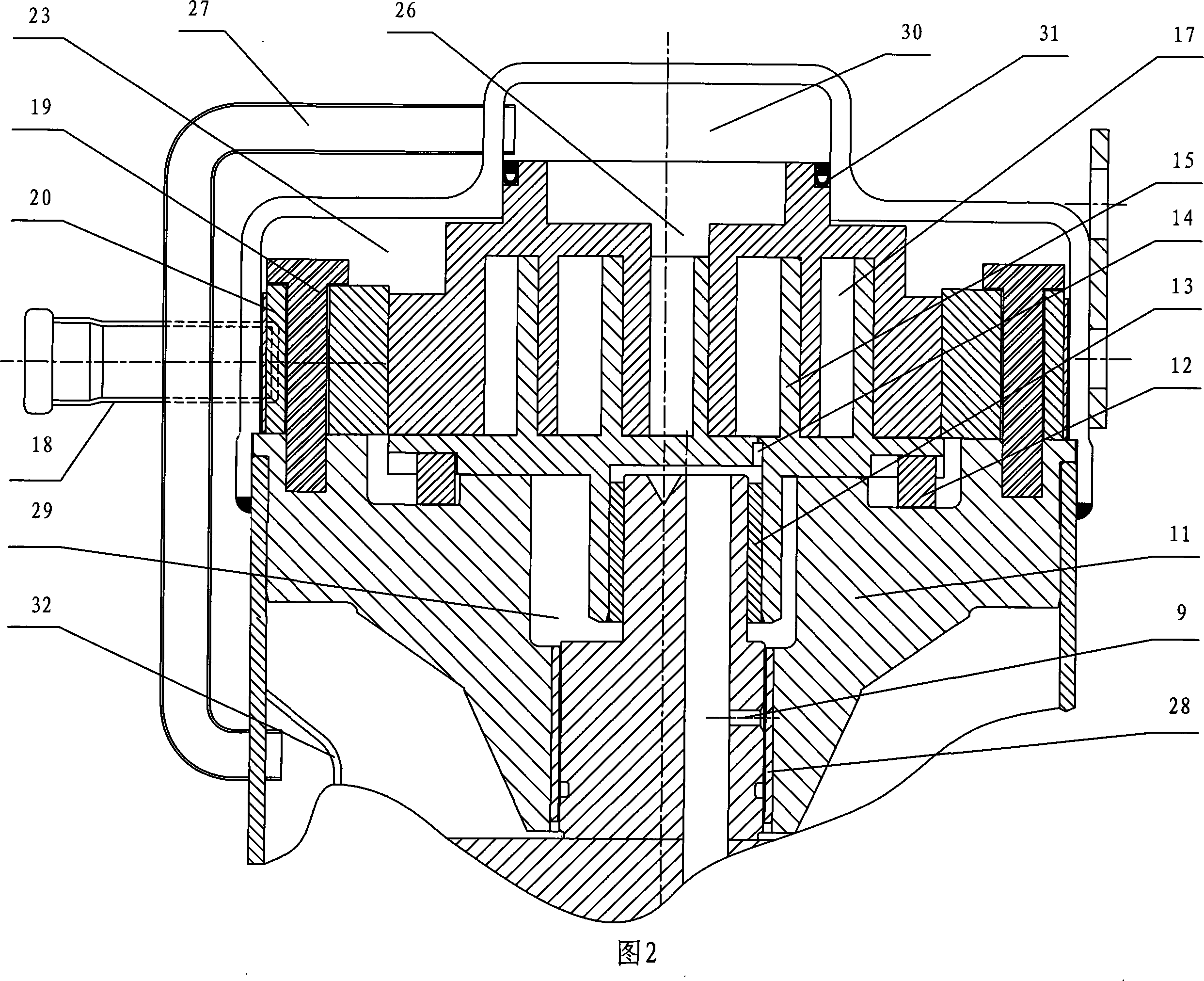

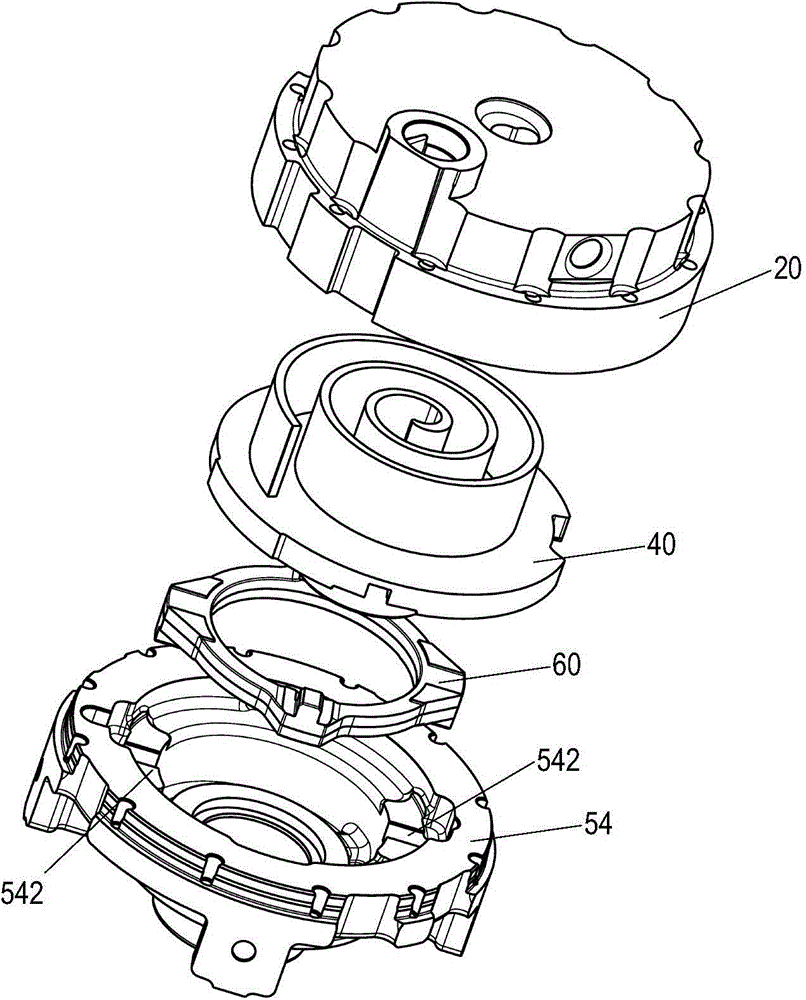

Swirl type compressor and its control method

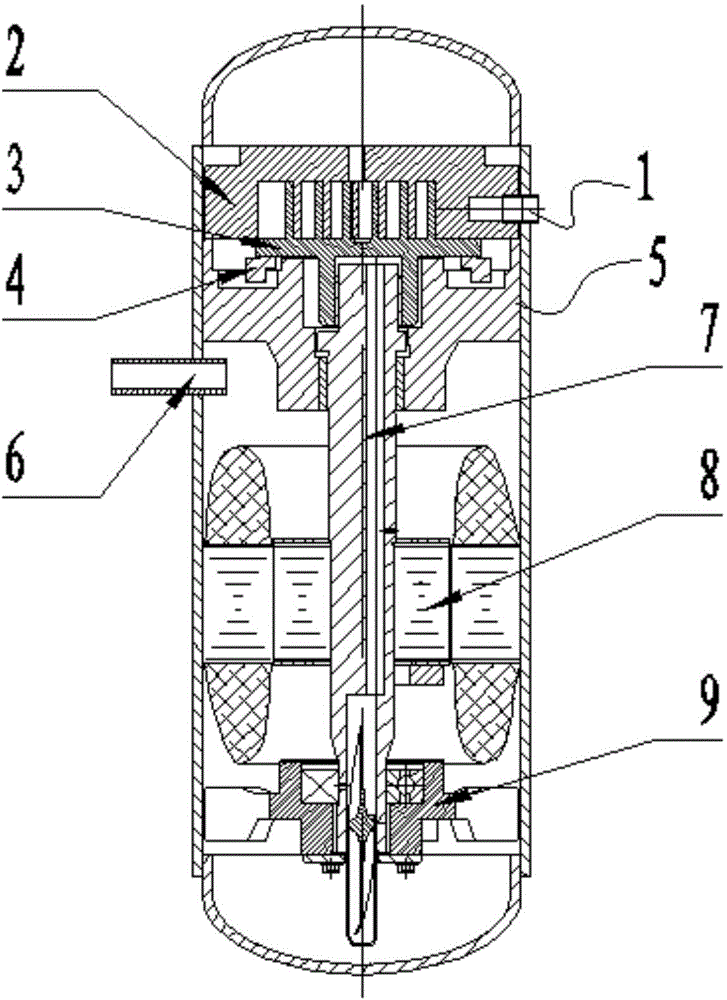

InactiveCN101216035ACool evenlyImprove performanceRotary piston pumpsRotary piston liquid enginesCross SlipHigh pressure

The invention relates to a scroll-type compressor and a control method thereof. The scroll compressor comprises a static scroll plate, a rotary scroll plate, a frame, a motor, a shaft, a cross slip ring, an oil application component, bearings, a sealing element, an exterior support component and a case. Two high-pressure chambers and a low-pressure chamber are arranged inside the case of the compressor. The lower space of the case and the upper exhaust cavity of the static scroll plate communicated with the lower space of the case are a low high-pressure exhaust chamber and an upper high-pressure exhaust chamber, respectively. A motor is arranged inside the lower high-pressure exhaust chamber. A cavity in the middle of the case communicated with a suction passage is a low pressure suction chamber. The invention provides the pressure force to push the static scroll plate towards the rotary scroll plate in the way that a vent is communicated with the upper high-pressure exhaust chamber so that the end plate faces of the static scroll plate and the rotary scroll plate touch each other tightly when the scroll-type compressor works without failure; and the static scroll plate and the rotary scroll plate can be separated timely in case of exceptions, and the rotary scroll plate is effectively prevented from overturning.

Owner:MIDEA GRP CO LTD

Faucet

The present invention relates to an article with cross-slip components, more concretely, discloses a faucet including a first valve plate comprising a base material and a strengthening layer provided above the base material. An amorphous diamond material is provided above the strengthening layer. The amorphous diamond material has a coefficient of friction that is lower than that of diamond-like carbon and has a hardness that is greater than that of diamond-like carbon.

Owner:DELTA FAUCET COMPANY

Multipurpose double latch adjustable bundle tie

InactiveUS20150321814A1Enhance insertionImprove retentionPipe supportsPackage recyclingCross SlipEngineering

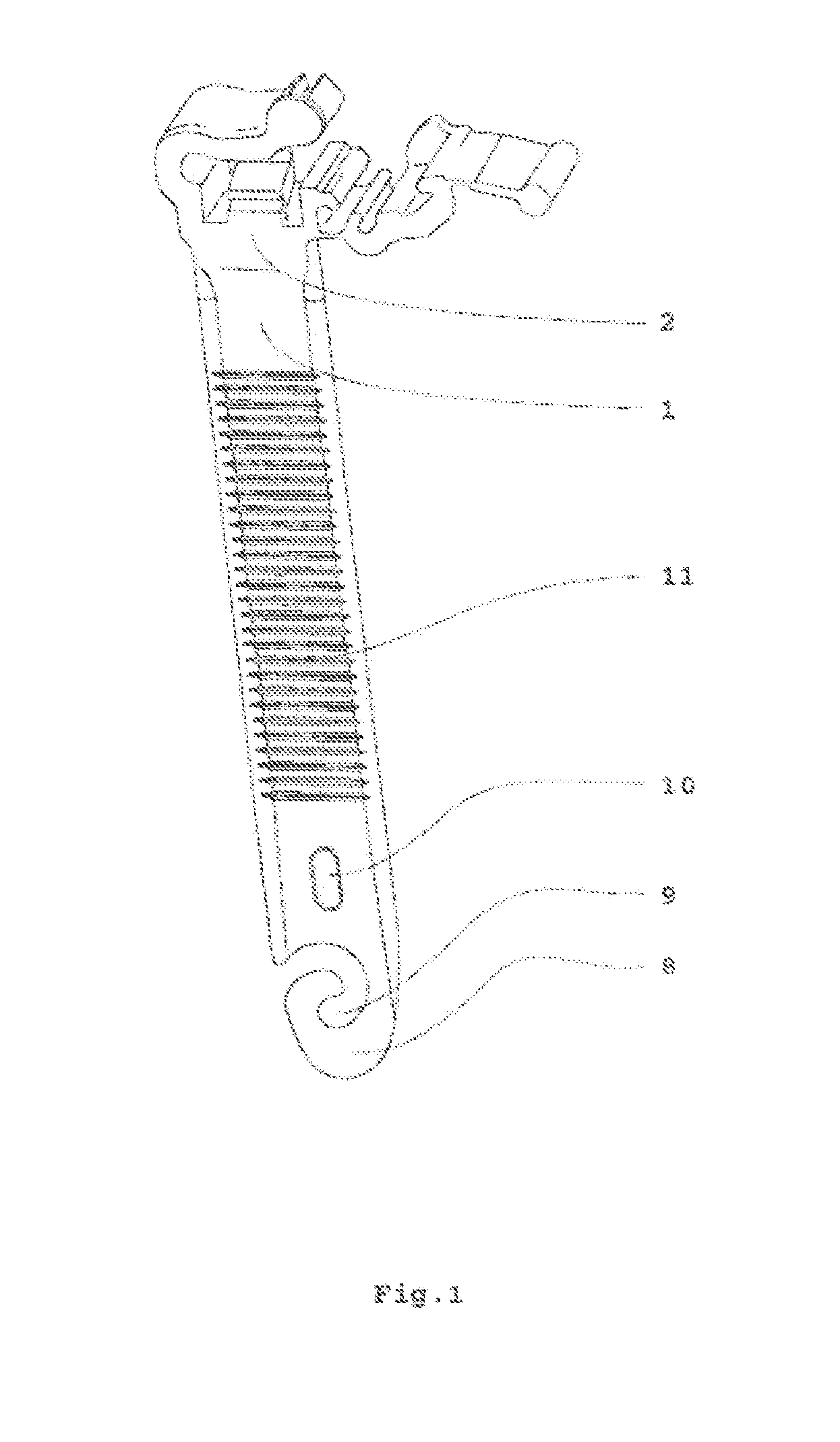

The present invention relates to reusable bundle tie devices, comprising a strap (1) with transversal knurl teeth (11), associated with an enclosement buckle with an upper top (4) elevated from the strap leading end (2) by a solid state side wall (3), forming a longitudinal channel (12) and aperture for transversal docking and undocking of the strap middle part by cross slipping over the tooth unit (7). The enclosement flap (6) linked to the leading end (2) by flexible state reduced portion (5) locks the buckle by means of one top latch between two cam locks (19 and 20) contiguous to each stopper (13 and 14) and one bottom latch between two cam locks (17 and 18) that replace the flexible portion (5) during enclosement. This enclosement buckle is opposite to the tail end (8), comprising a suspension hook (9) or slot (10).

Owner:RODRIGYES PEREIRA EDURARDO HENRIQUE

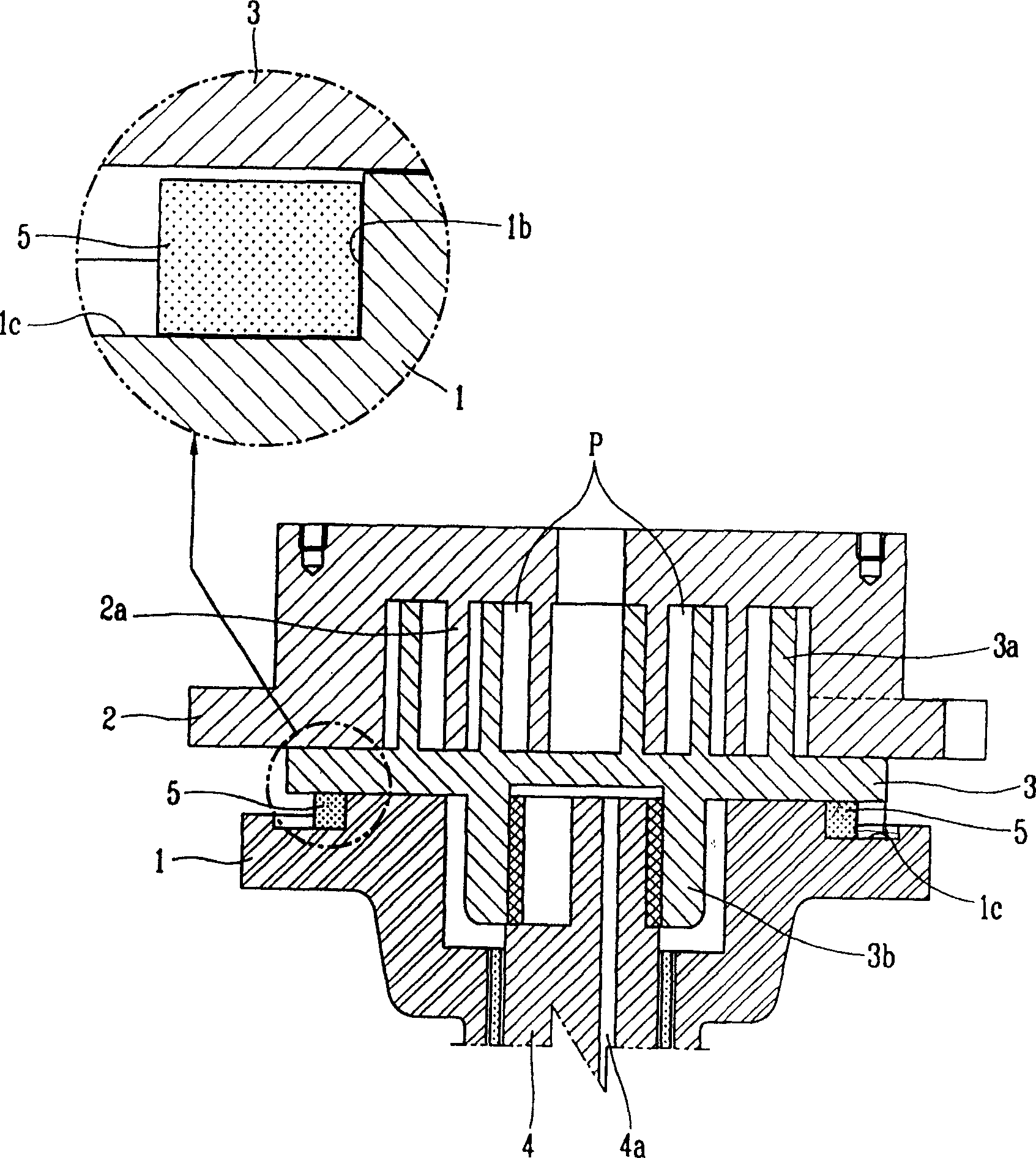

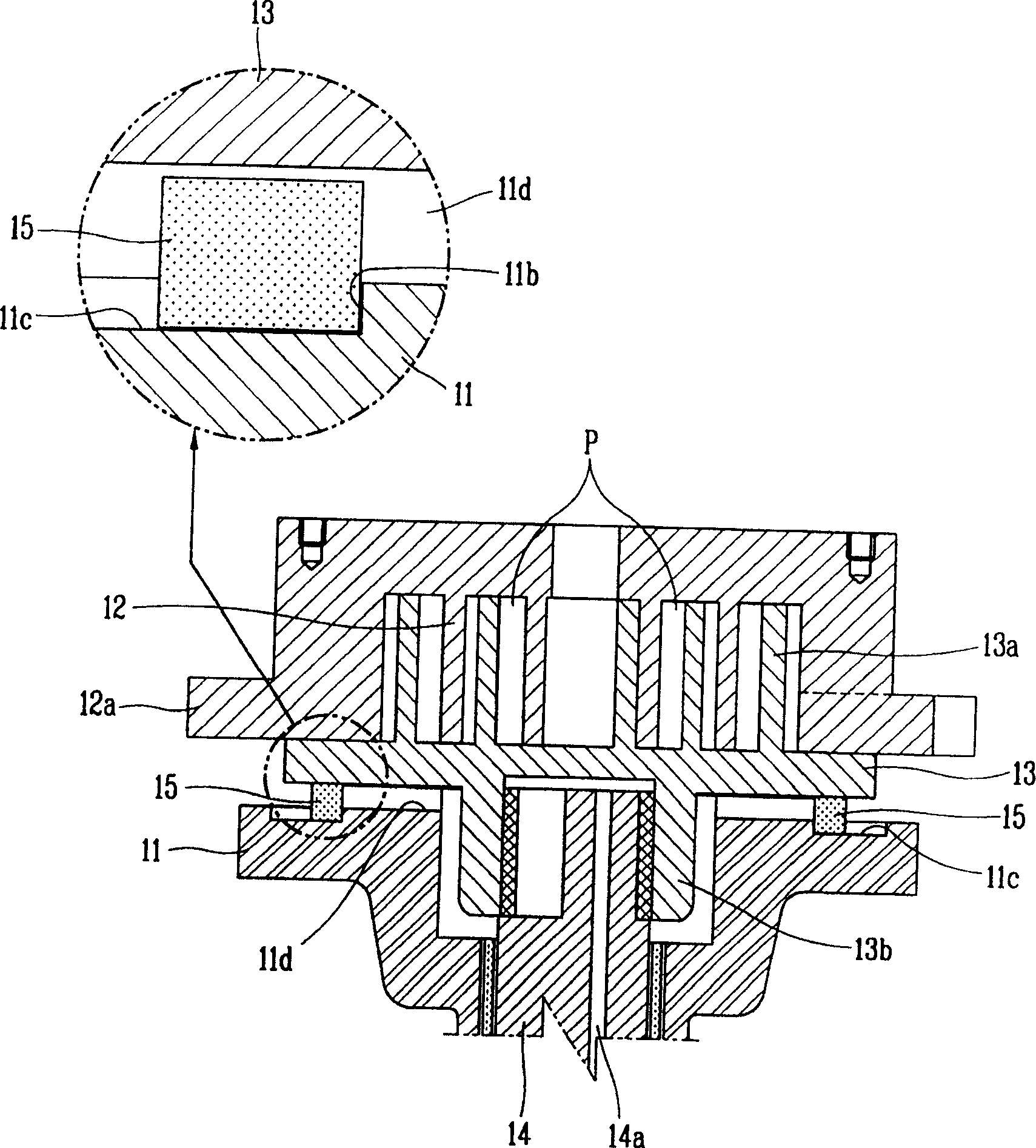

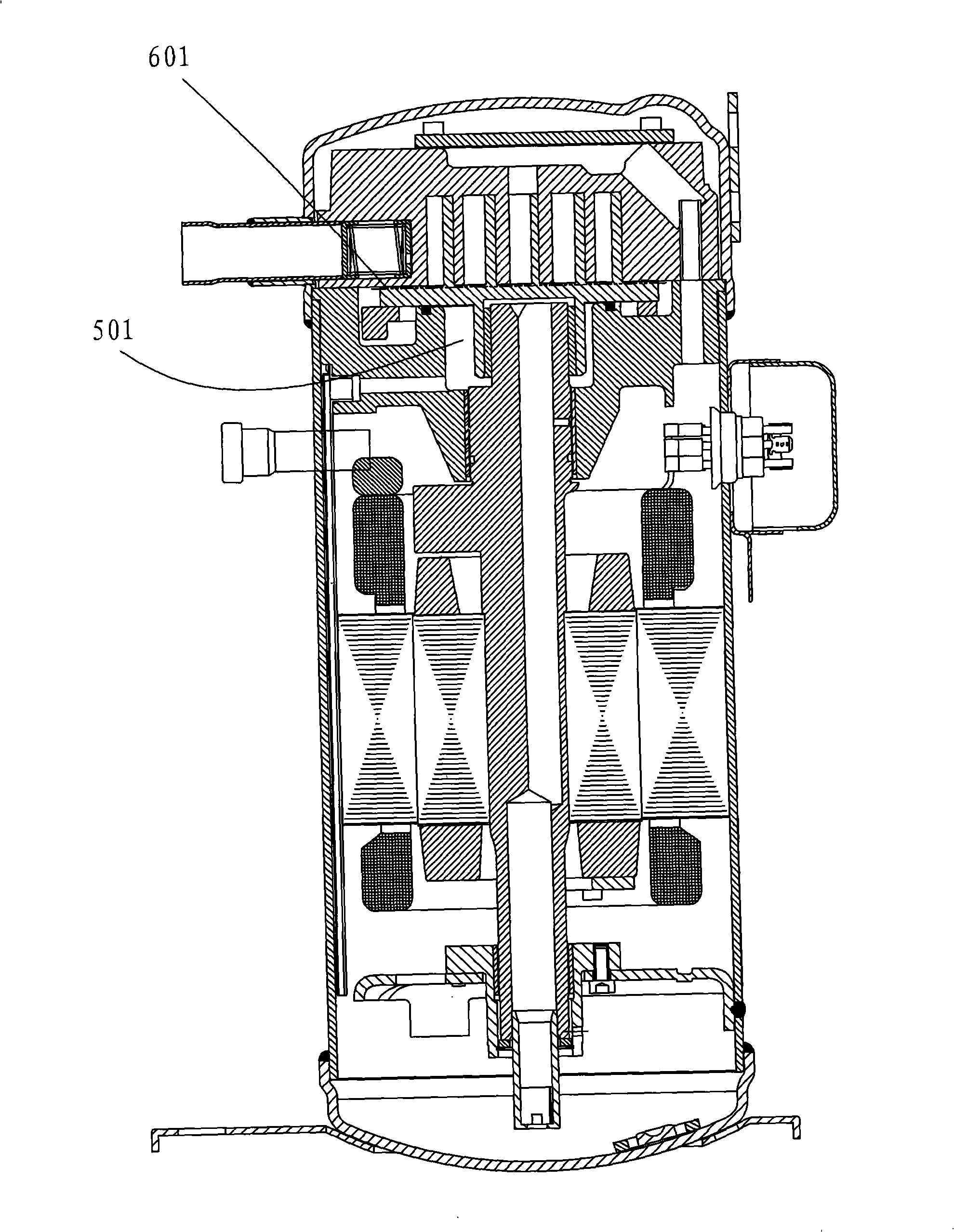

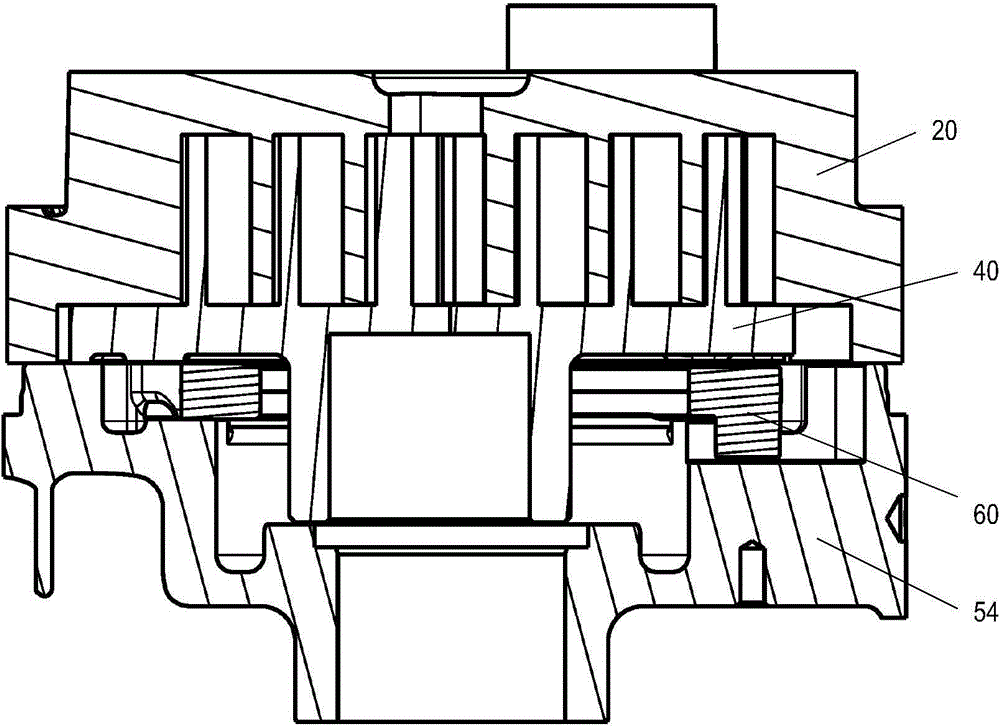

Cross slip-ring oil supply structure for vortex type compressor

InactiveCN1566696AReduce wearLow powerRotary piston pumpsRotary piston liquid enginesDrive shaftCross Slip

The invention is about a cross slip ring oil supply structure of scroll compressor, which comprises: a main frame fixed in the sealed container filled with some oil; a static scroll disk fixed in the main frame; a screw scroll formed for gearing with the scroll of the static scroll disk, a dynamic scroll disk, joined in the frame for rotary motion and for forming a compressing chambers capable of continuously moving together; a driving shaft combined in the dynamic scroll disk, capable of transferring the driving force of the motor, and supply the oil in the sealed container to the smooth part; and a cross slid ring between the frame and the dynamic scroll disk for preventing self-rotation of the dynamic scroll disk and guiding the rotary motion. The invention prevents the abrasion between the main frame and cross slid ring.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

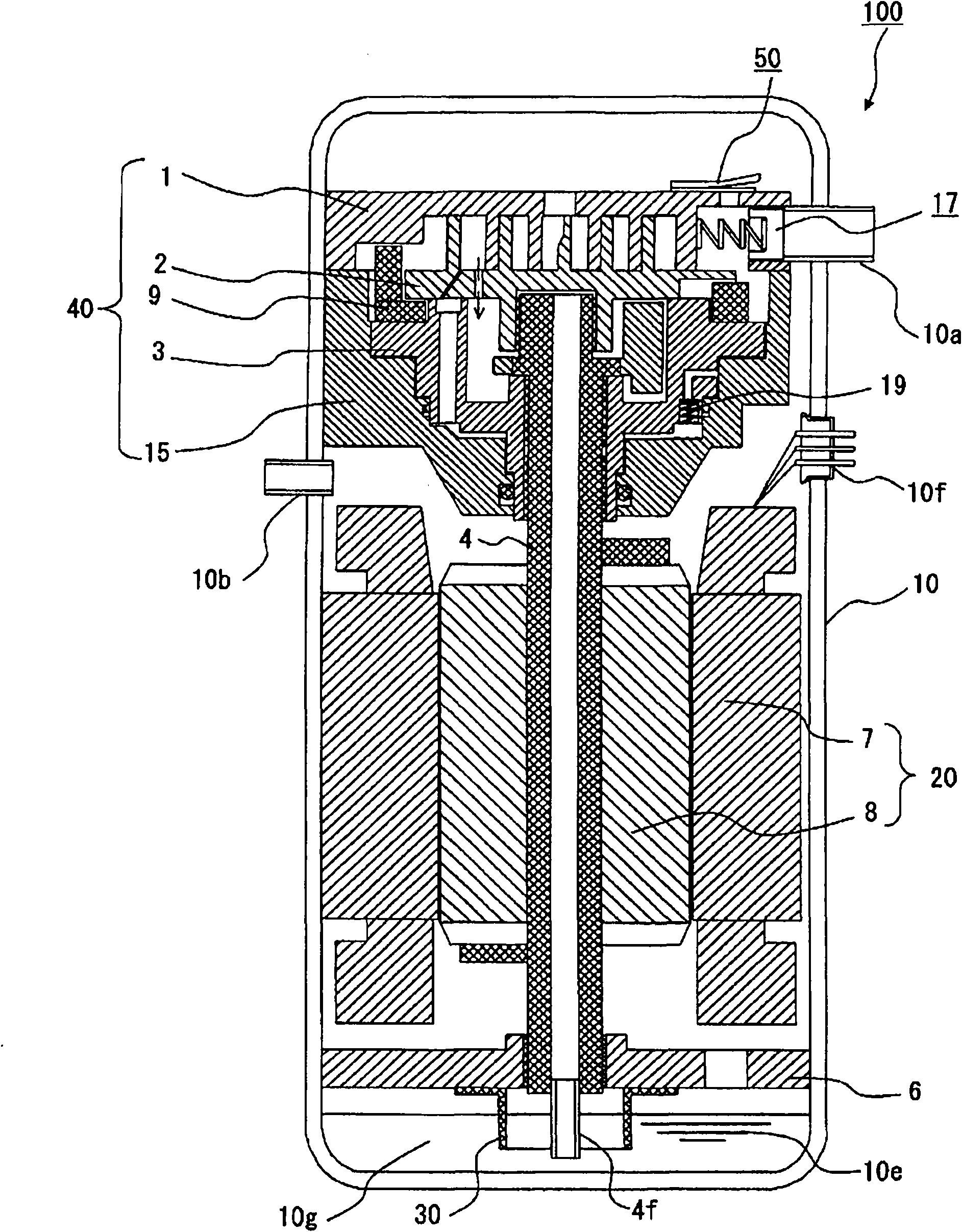

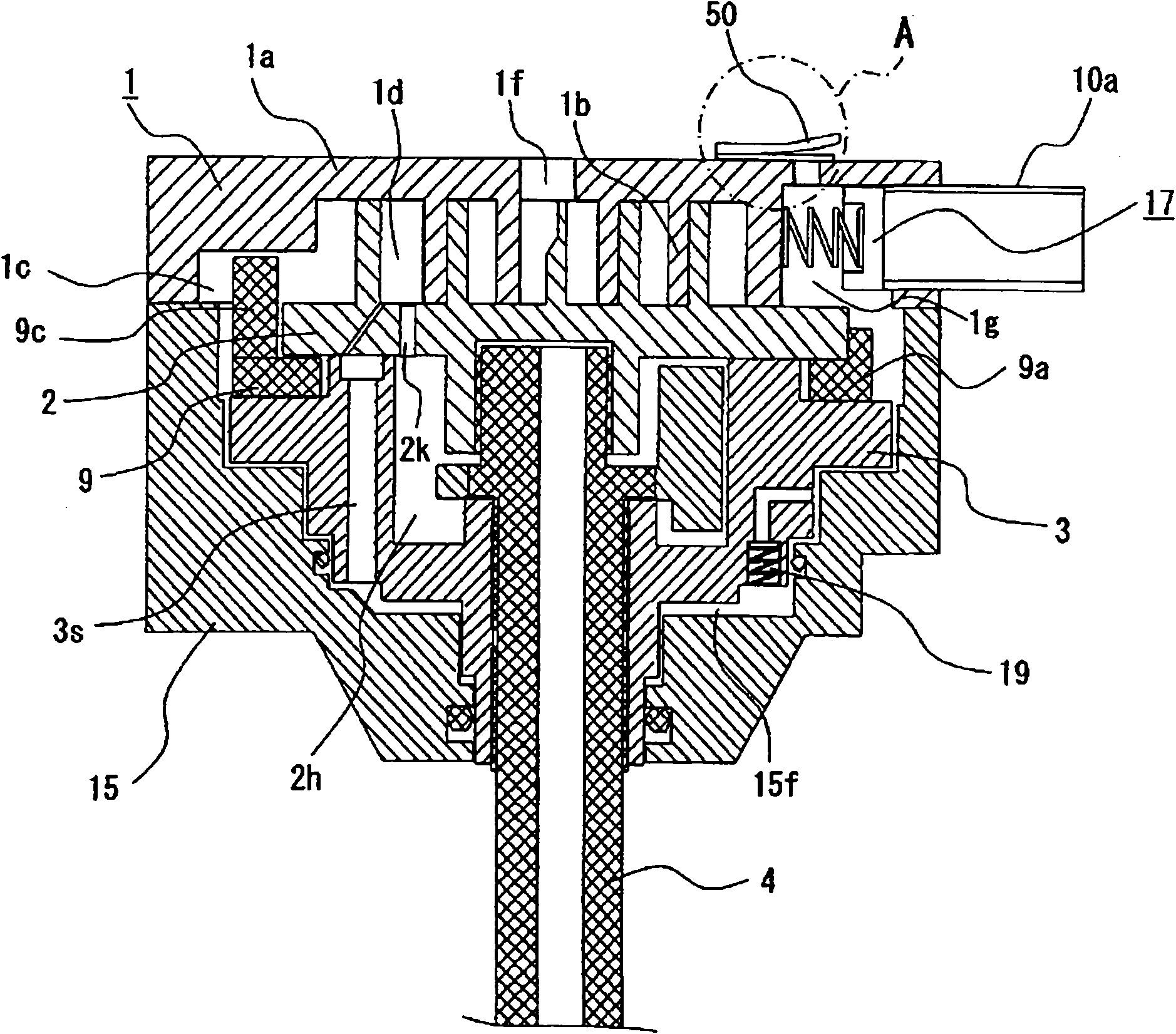

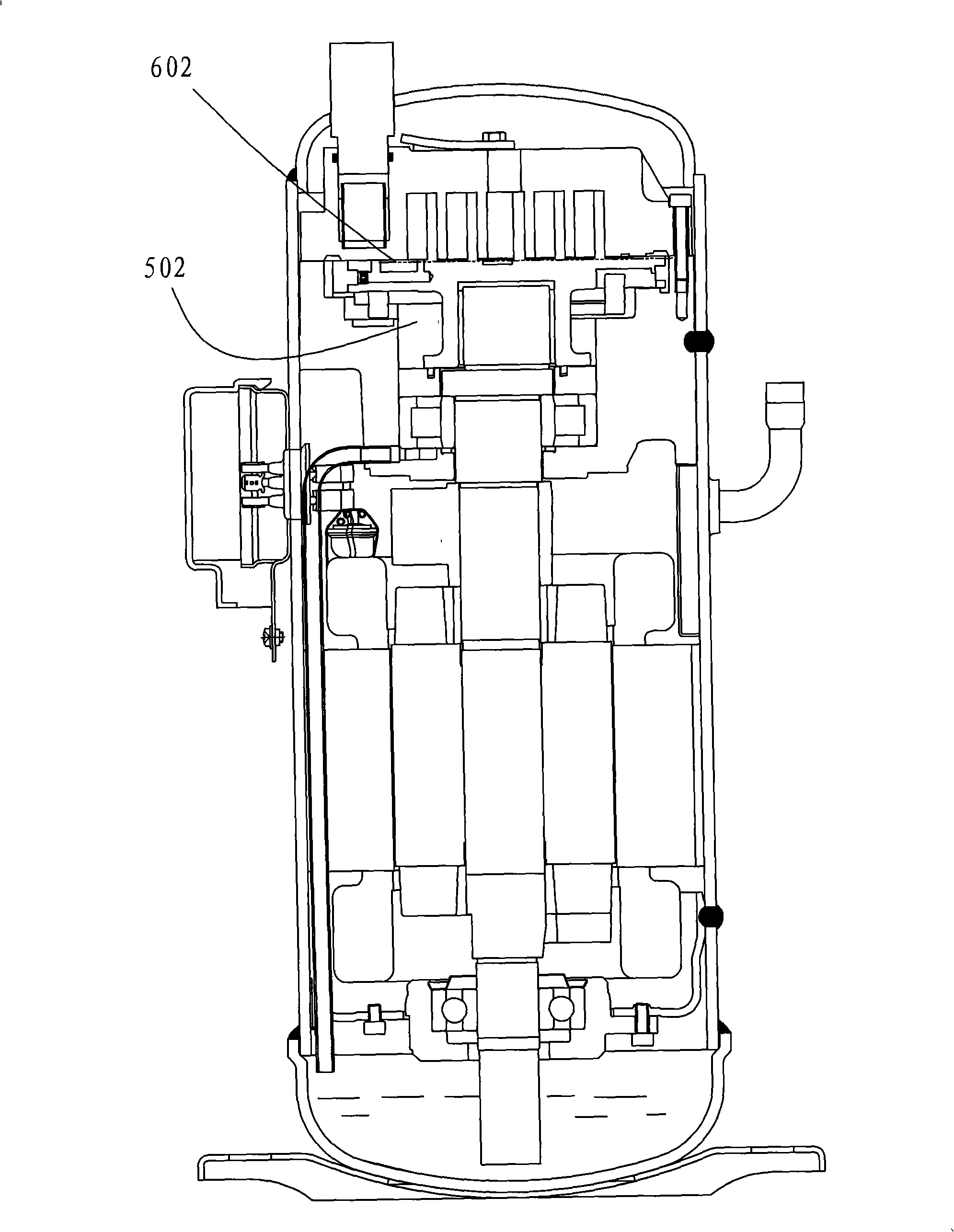

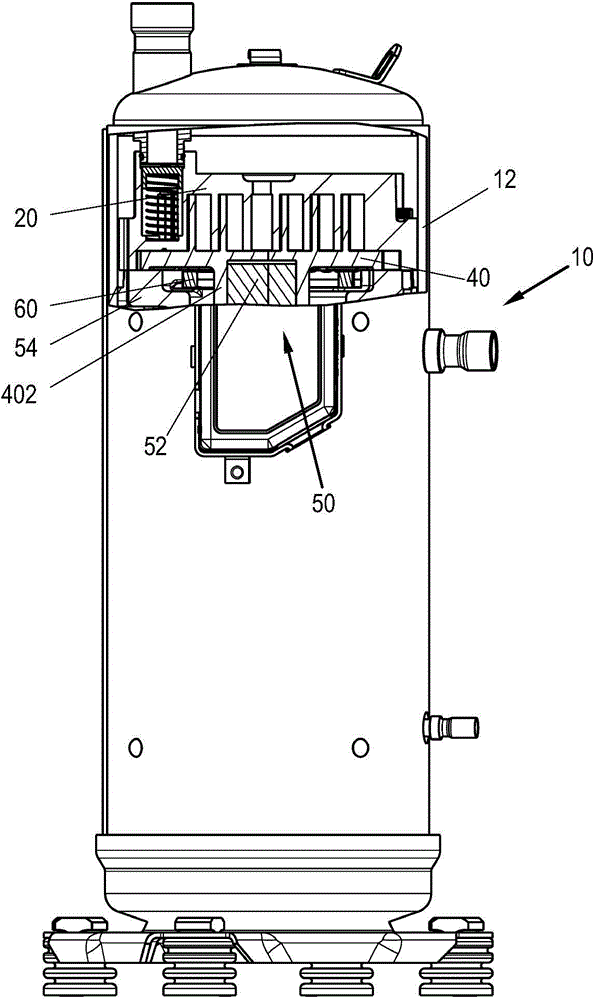

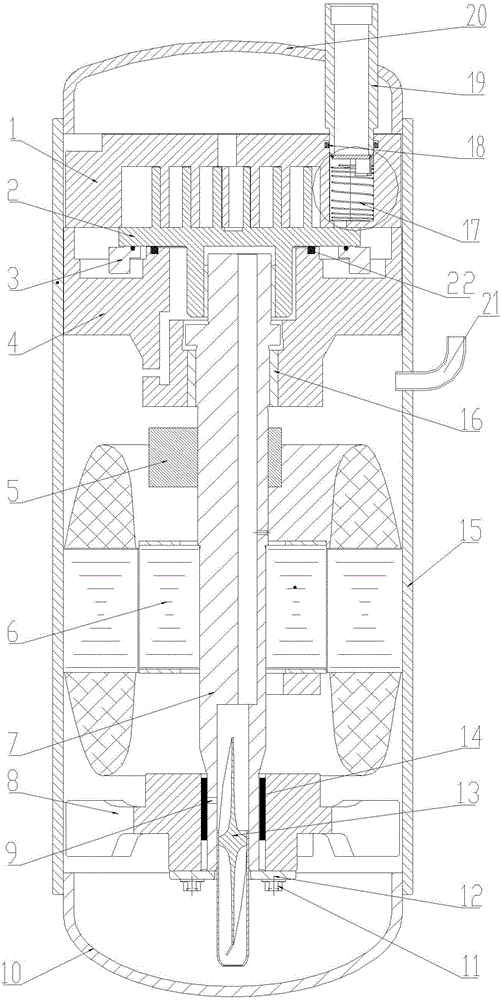

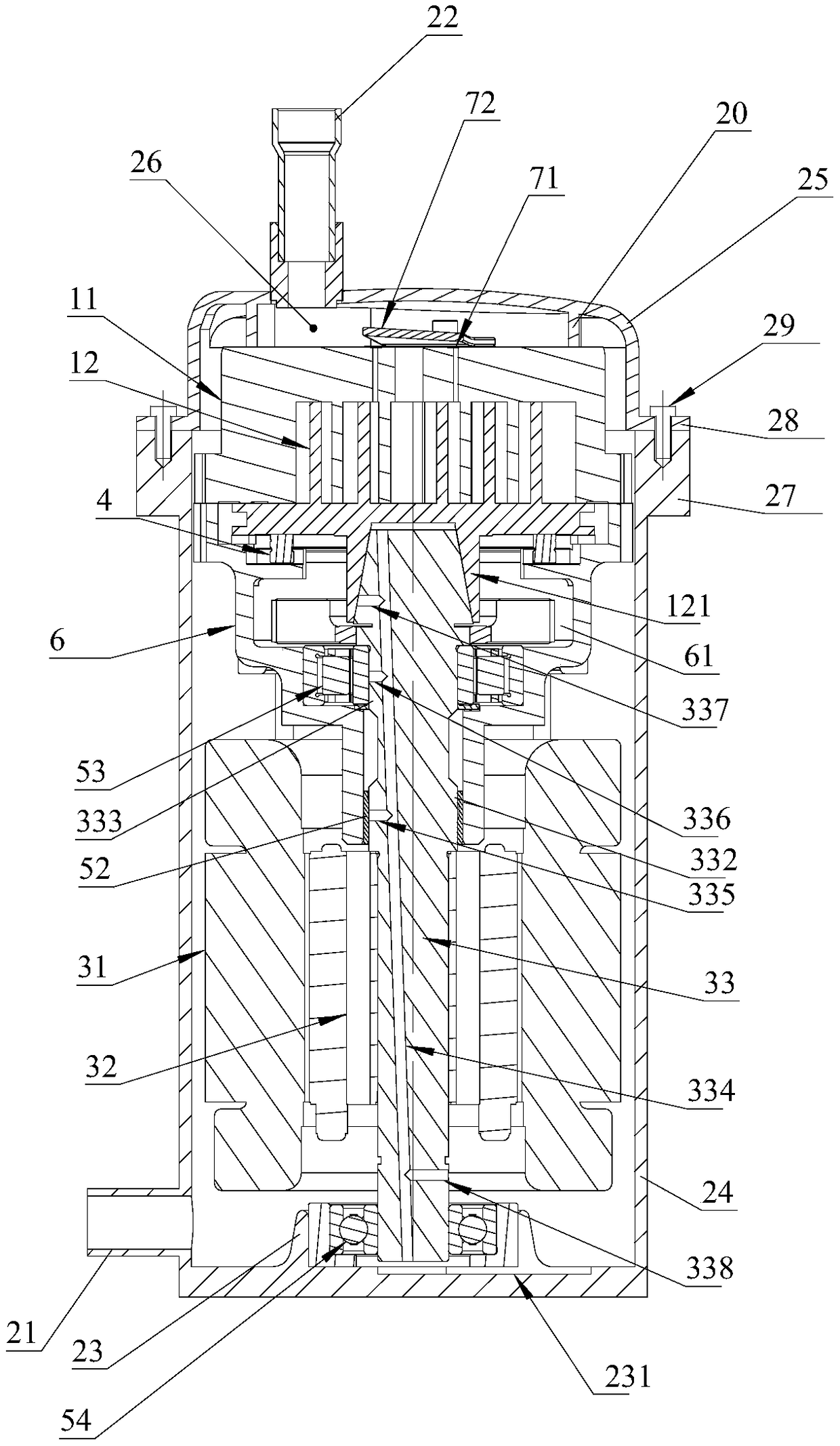

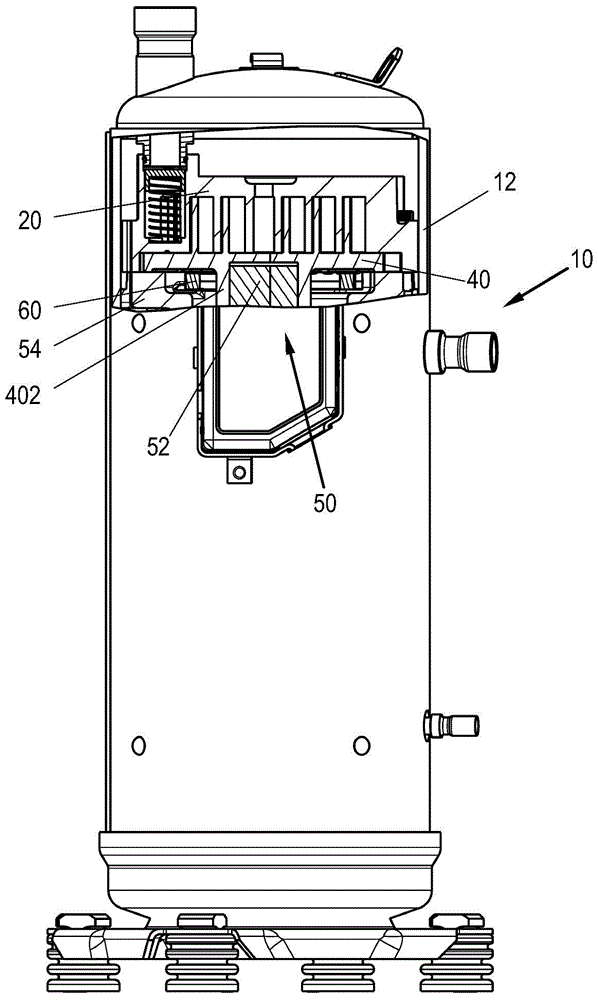

Scroll compressor

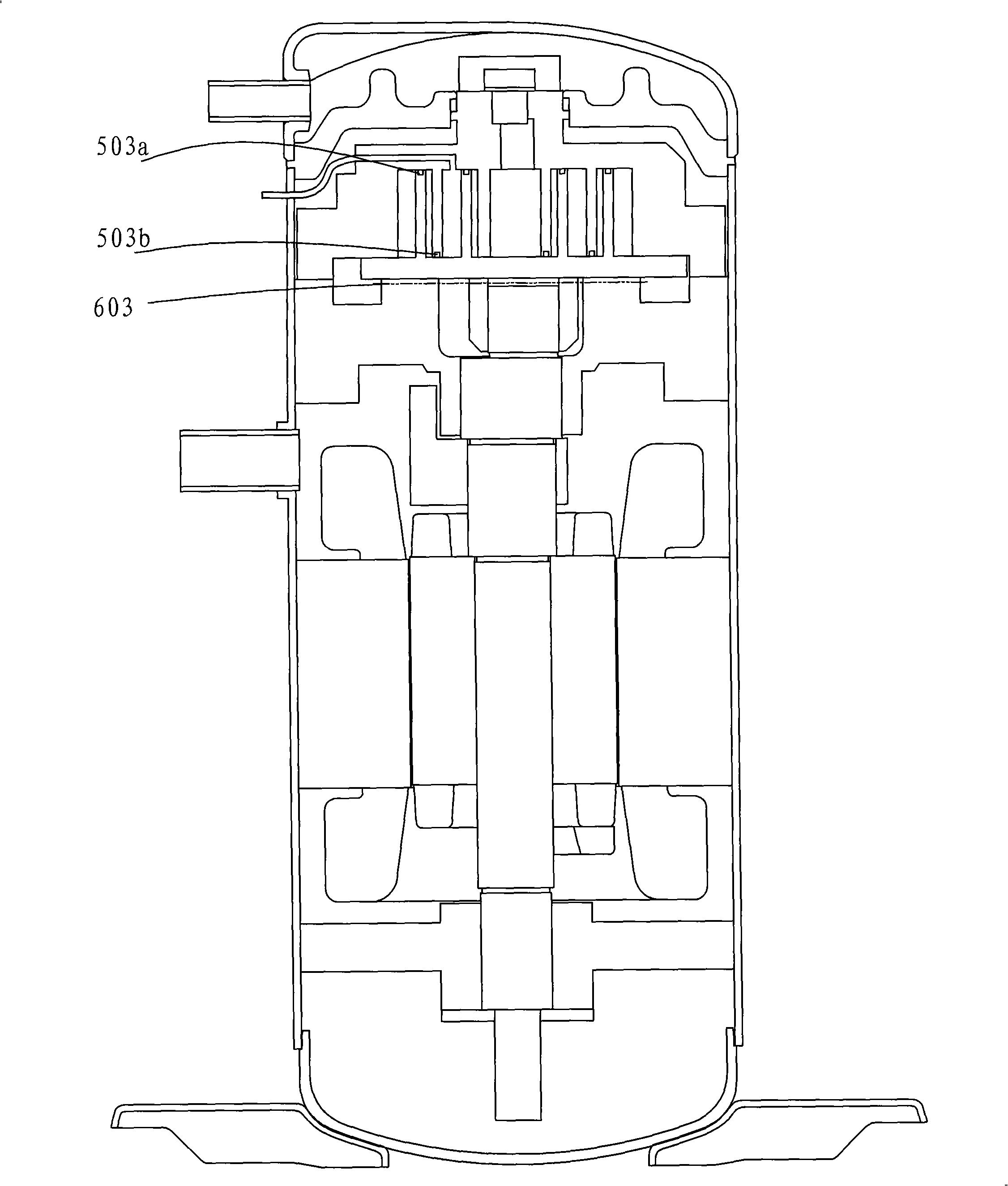

InactiveCN102062090APrevent sinteringImprove reliabilityRotary piston pumpsRotary piston liquid enginesDifferential pressureCross Slip

The invention provides a scroll compressor, which enables to avoid shaft sintering caused by poor lubrication of the bearing portion in the reverse operation and aims to achieve reliability enhancement and quality improvement. With respect to the scroll compressor (100) of the invention, a compression mechanism portion (40) comprises a fixed scroll pan (1), a swing scroll pan (2), a cross slip ring (9), a main shaft (4), a guiding frame (15), a soft frame (3), an suction check valve combination (17), a safety valve combination (50) arranged on the fixed scroll pan (1), and a check valve (19) which is disposed on the soft frame (3) and allows the communication between the suction pressure space and the frame space. A platen portion of the swing scroll pan (2) is provided with a through hole which enables the communication between the flange portion space (2h) and the compression chamber of the expansion stroke, in order that during the reverse operation of a motor (20), the pressure of the backpressure space of the swing scroll pan (2) is lower than that of a sealed container (10), and refrigerant oil (10e) is supplied to the compression mechanism portion (40) by the differential pressure.

Owner:MITSUBISHI ELECTRIC CORP

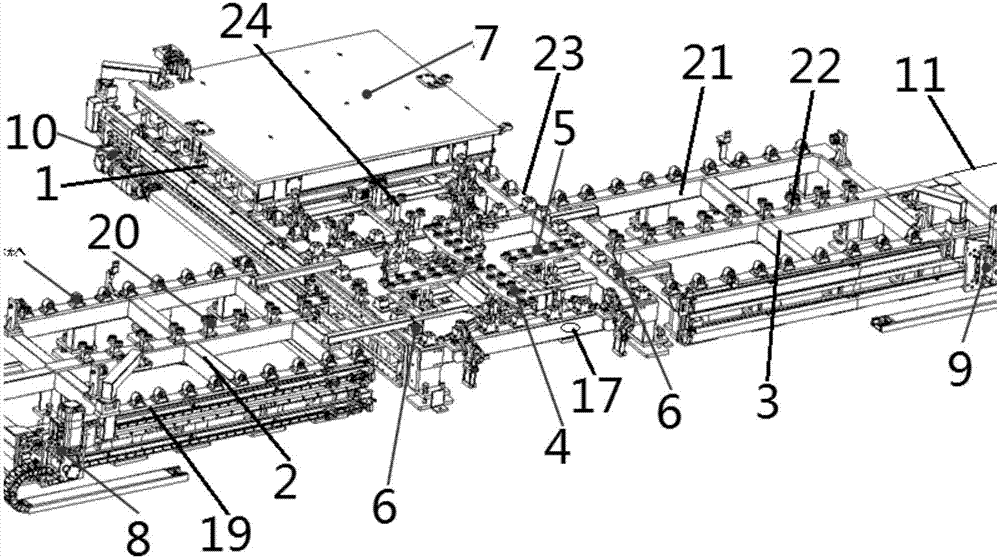

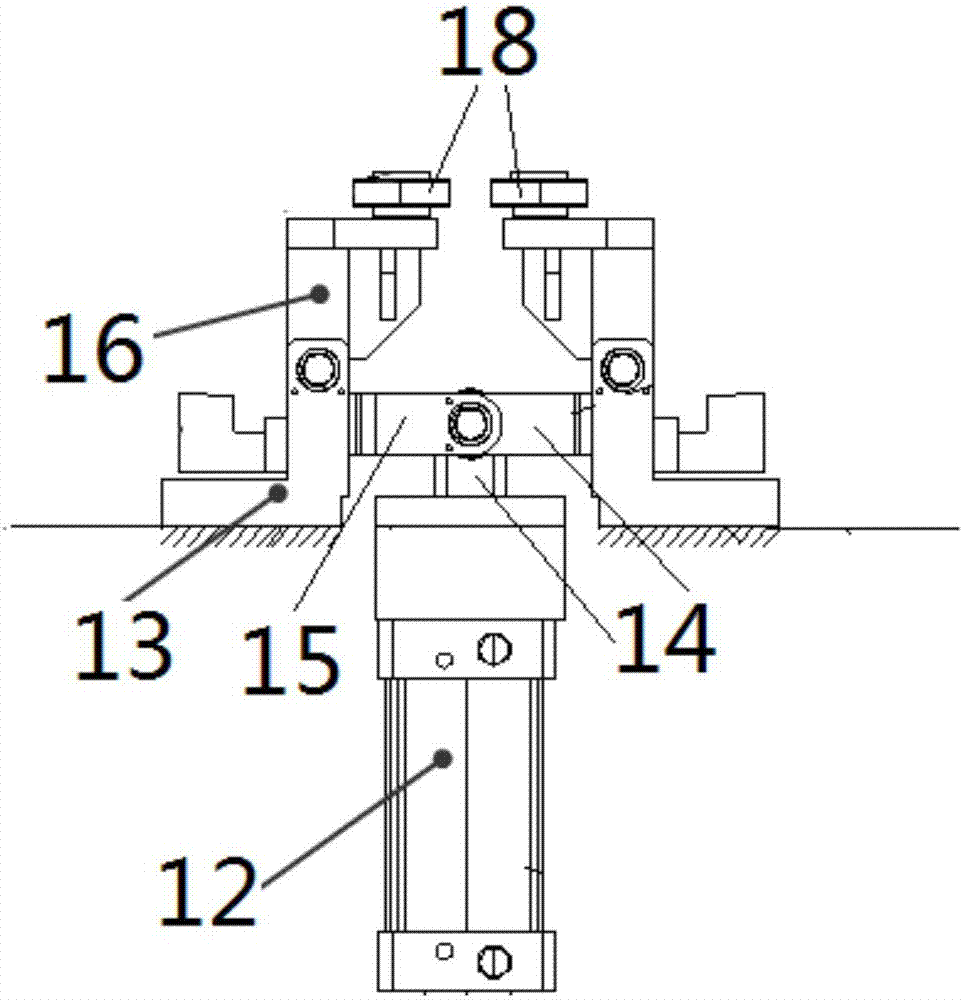

Full automatic stone slab edger unit

A fully automatic stone slab edger unit comprises a frame; the frame is provided with a milling machine and a clamp drive mechanism; the milling machine is arranged under the clamp drive mechanism; the clamp drive mechanism comprises two rows of gripping rolls which are vertically arranged, wherein, a bracket of the first row of the gripping rolls is arranged at the frame; the second row of the gripping rolls are rubber pressure rolls; a bracket of each rubber pressure roller is movably arranged at the frame in the manner of a cross slip; a bracket corresponding to each rubber pressure roll is provided with a transverse thrust cylinder; a piston rod of the transverse thrust cylinder is fixedly connected with the bracket of the rubber pressure rolls. The fully automatic stone slab edger unit of the invention can vertically clamp a stone slab and drive the stone slab to move back and forth, has firm gripping, and causes the stone slab to move stably.

Owner:李 新杰

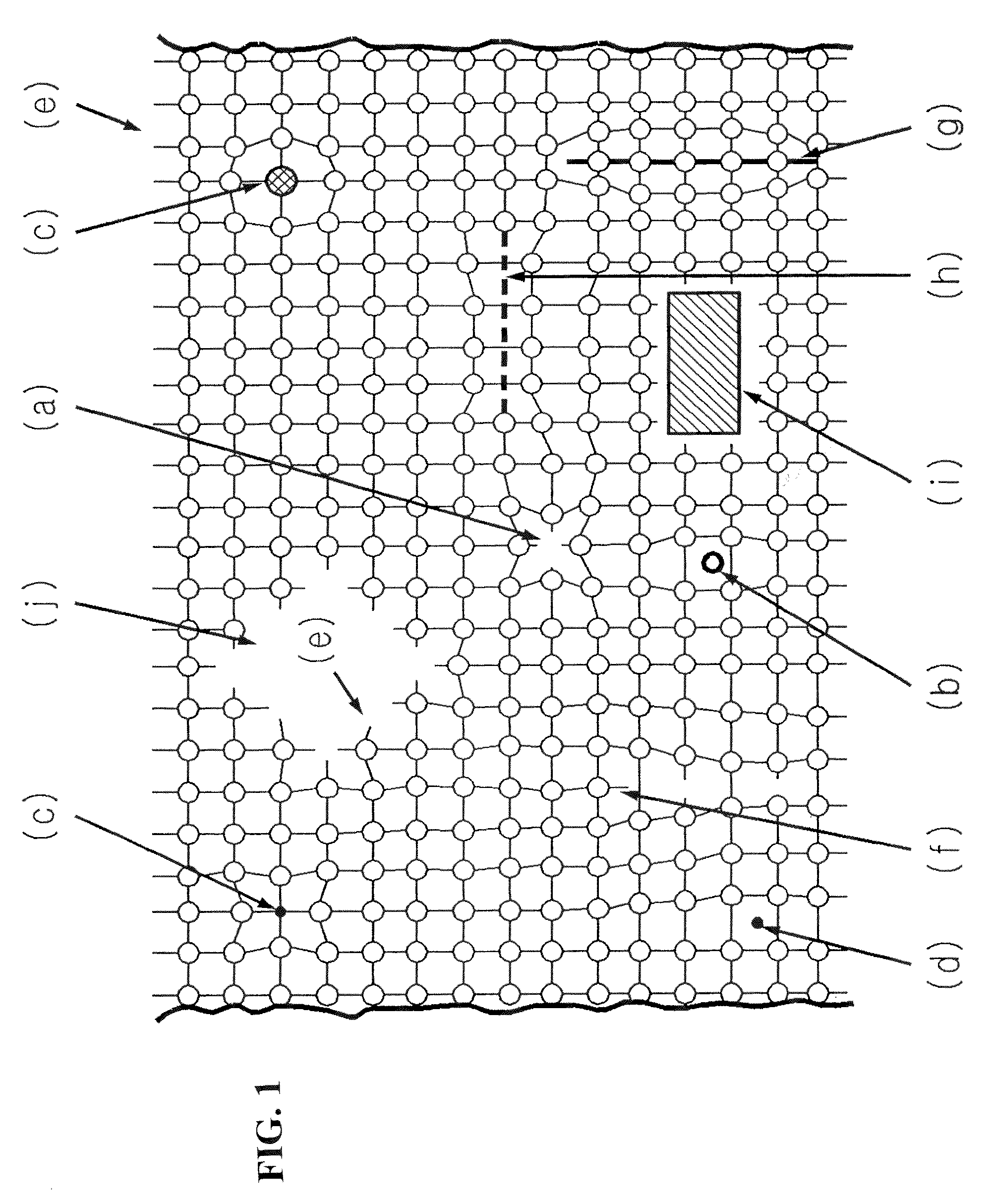

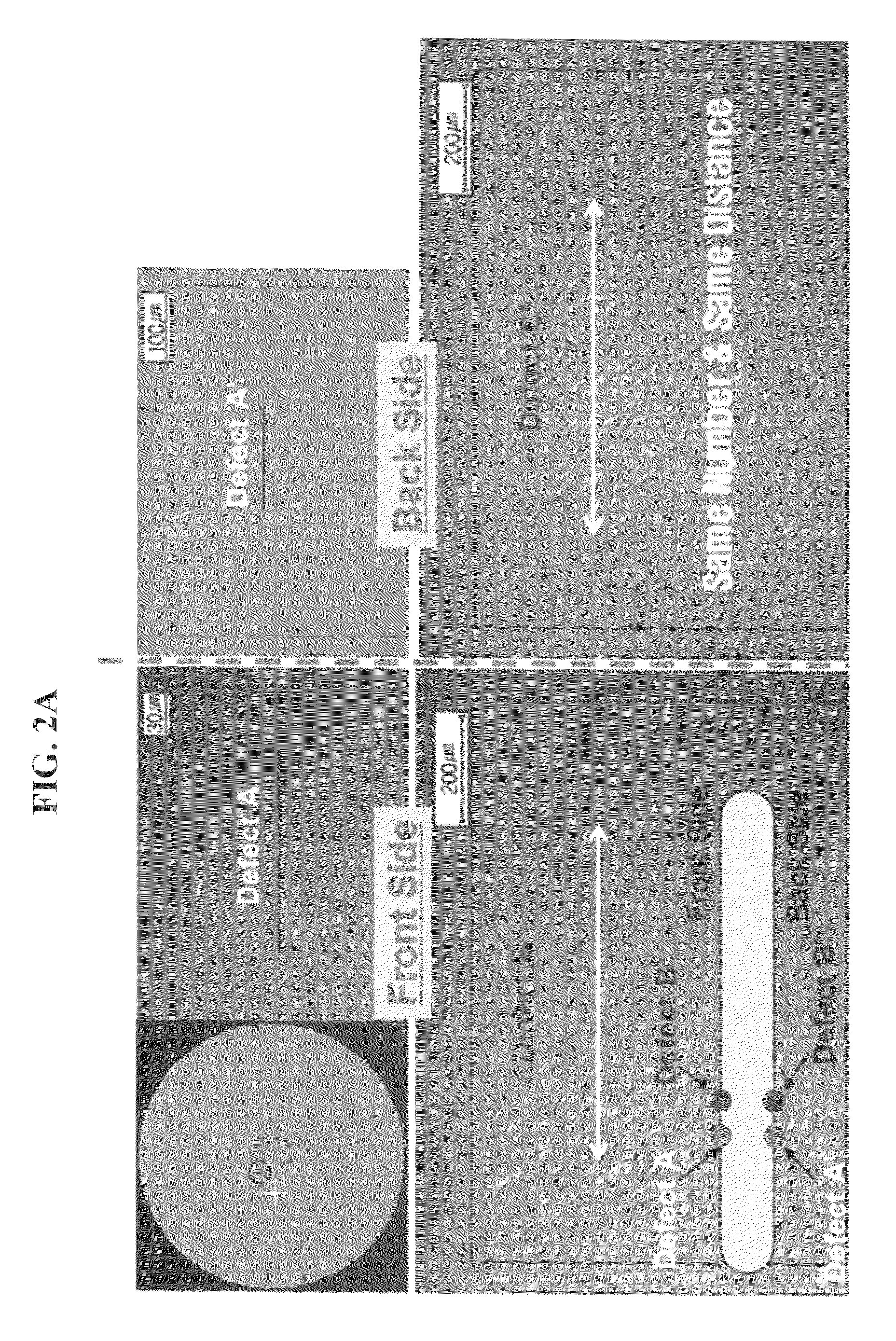

2-dimensional line-defects controlled silicon ingot, wafer and epitaxial wafer, and manufacturing process and apparatus therefor

ActiveUS8114215B2Reduce newly discovered crystal defectsHinders its propagationAfter-treatment apparatusPolycrystalline material growthIngotCross Slip

The present invention reports a defect that has not been reported, and discloses a defect-controlled silicon ingot, a defect-controlled wafer, and a process and apparatus for manufacturing the same. The new defect is a crystal defect generated when a screw dislocation caused by a HMCZ (Horizontal Magnetic Czochralski) method applying a strong horizontal magnetic field develops into a jogged screw dislocation and propagates to form a cross slip during thermal process wherein a crystal is cooled. The present invention changes the shape and structure of an upper heat shield structure arranged between a heater and an ingot above a silicon melt, and controls initial conditions or operation conditions of a silicon single crystalline ingot growth process to reduce a screw dislocation caused by a strong horizontal magnetic field and prevent the screw dislocation from propagating into a cross slip.

Owner:LG SILTRON

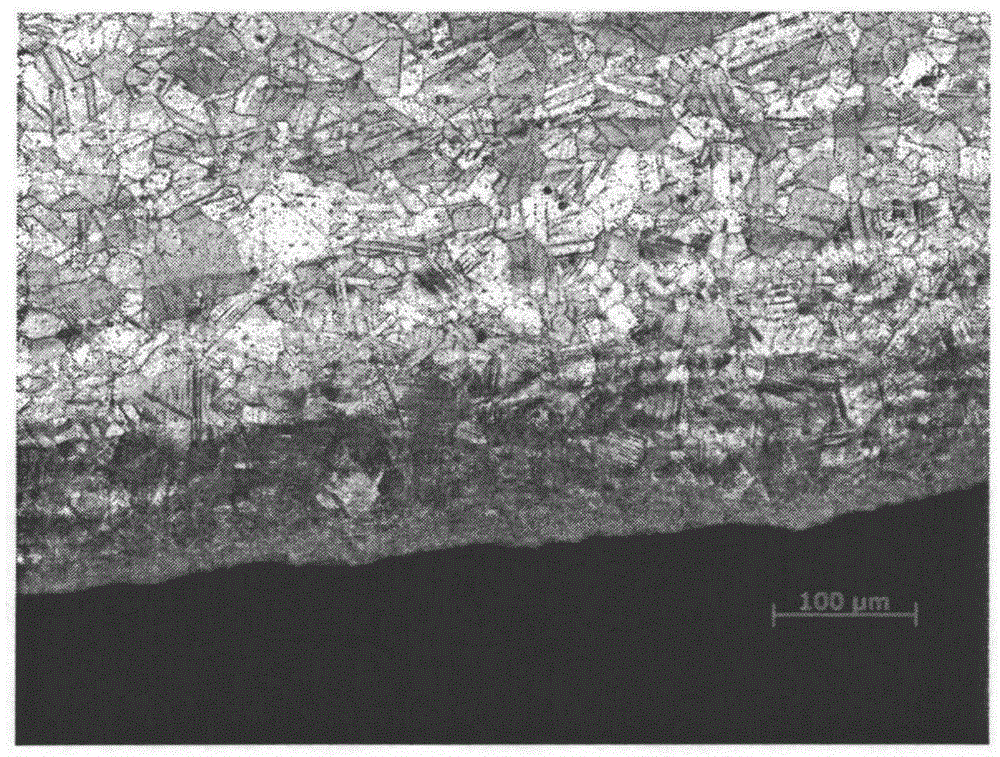

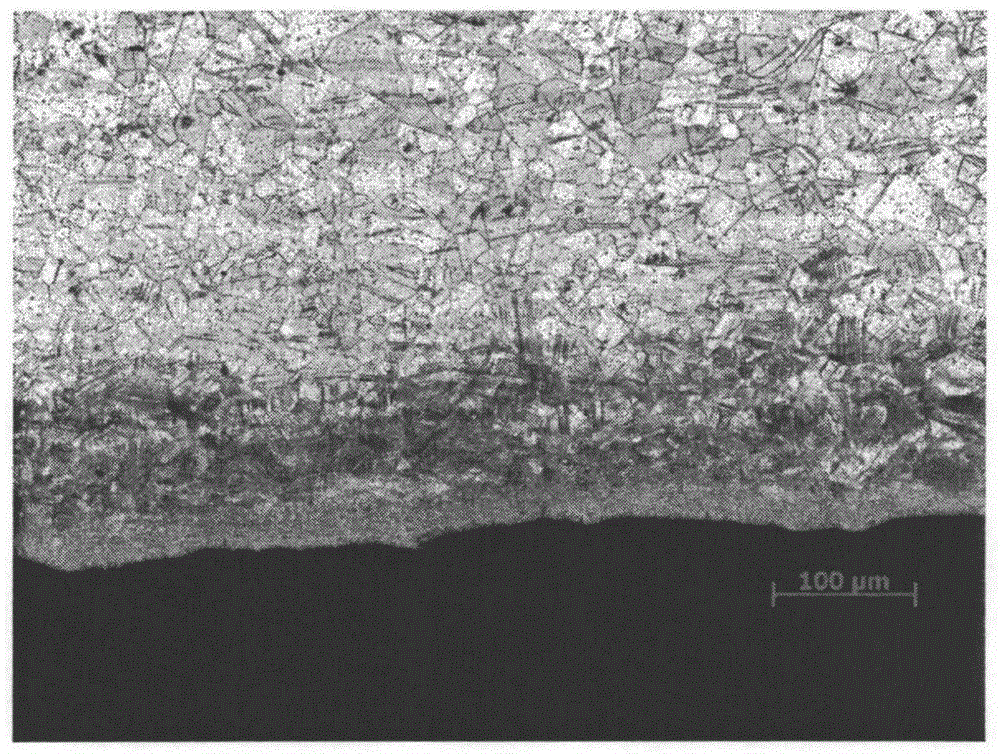

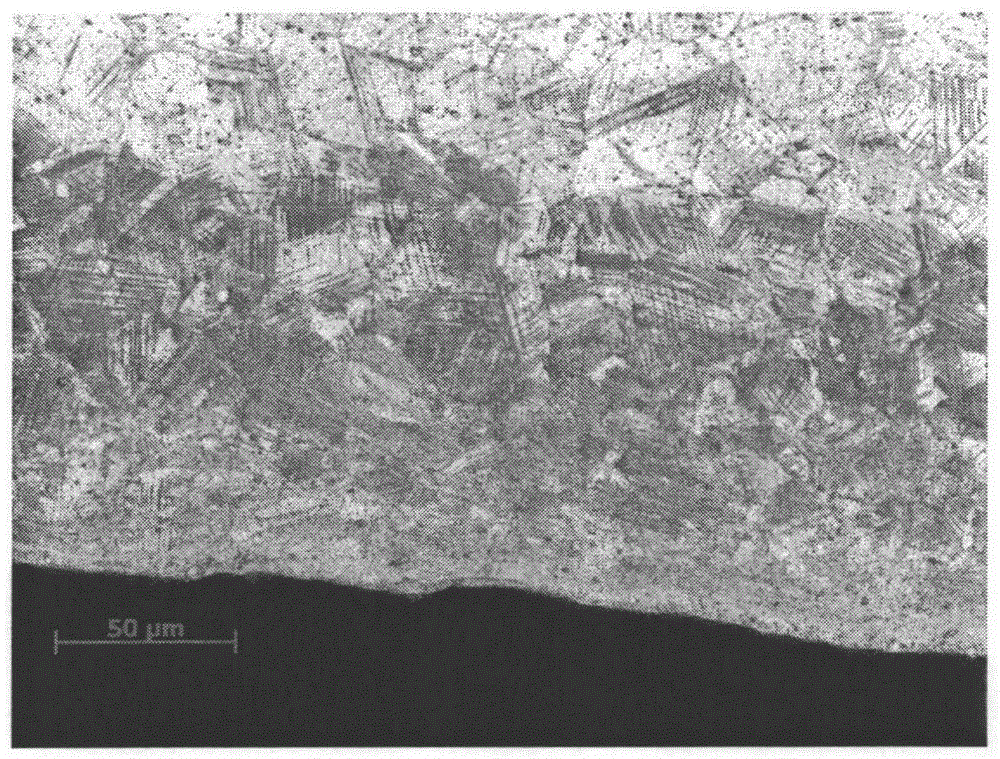

Corrosive agent for displaying slip band tissue of shot blasting layer

ActiveCN105603430AGood corrosion effectAccelerated corrosionPreparing sample for investigationCross SlipAustenite

The invention discloses a corrosive agent for displaying slip band tissue of a shot blasting layer and a preparing method thereof. Each 100 mL of a corrosive agent solution contains 35-70 mL of H2O, 12-35 mL of hydrochloric acid, 25-55 g of FeCl3.6H2O, 1-4 g of CuCl2.H2O, 4-15 mL of nitric acid, 1-10 drops of hydrogen peroxide and 1-5 mL of bromo-geramine. According to the preparing method, distilled water is added into a beaker, and then FeCl3.6H2O and CuCl2.H2O are sequentially added and fully stirred to be dissolved uniformly; hydrochloric acid is added and stirred uniformly, then nitric acid and bromo-geramine are added, and finally hydrogen peroxide is dripped and mixed uniformly. The corrosive agent for the tissue of the shot blasting layer of the austenitic stainless steel inner wall can clearly display the tissue of the austenitic stainless steel shot blasting layer, and an optical microscope can identify the shot blasting layer of the inner wall easily under 200 folds; the form of a fragmentation layer, a crossing slip layer and a single slip layer of the shot blasting layer can be identified under 500 folds.

Owner:SHANGHAI BOILER WORKS

Vortex compressor and operating mode thereof

InactiveCN101324233AGuaranteed reliabilityGuaranteed efficiencyRotary piston pumpsRotary piston liquid enginesSpring forceOperation mode

The invention relates to a vortex type compressor and an operation mode thereof, and the vortex type compressor includes a shell, a non-revolution vortex piece, a revolution vortex piece, a rack, a driving crankshaft, an installing mechanism and a cross slip ring; when the non-revolution vortex piece is assembled with the shell, an elastic exhaust pressure back pressure cavity for discharging gas is encircled corporately at the back side of the non-revolution vortex piece by the sealing of a seal assembly, the back side of the non-revolution vortex piece is pressed and contacted with the inner wall of the exhaust pressure back pressure cavity by the seal assembly in a sliding way, the non-revolution vortex piece is sheathed on a flexible assembly in the installing mechanism, and can slide up and down and move axially in a certain range. By taking the spring force as a third pressing force to be exerted on the back side of the non-revolution vortex piece, the optimization of the contact force between the end surfaces of the non-revolution vortex piece and the revolution vortex piece as well as the holding power of the back side of the revolution vortex piece is realized under the condition that no intermediate pressure is exerted on the back side of the non-revolution vortex piece. The vortex type compressor and the operation mode thereof have low manufacture cost and high working efficiency.

Owner:MIDEA GRP CO LTD

Cross slip ring and cross slide coupling and harmonic reducer

Owner:GREE ELECTRIC APPLIANCES INC

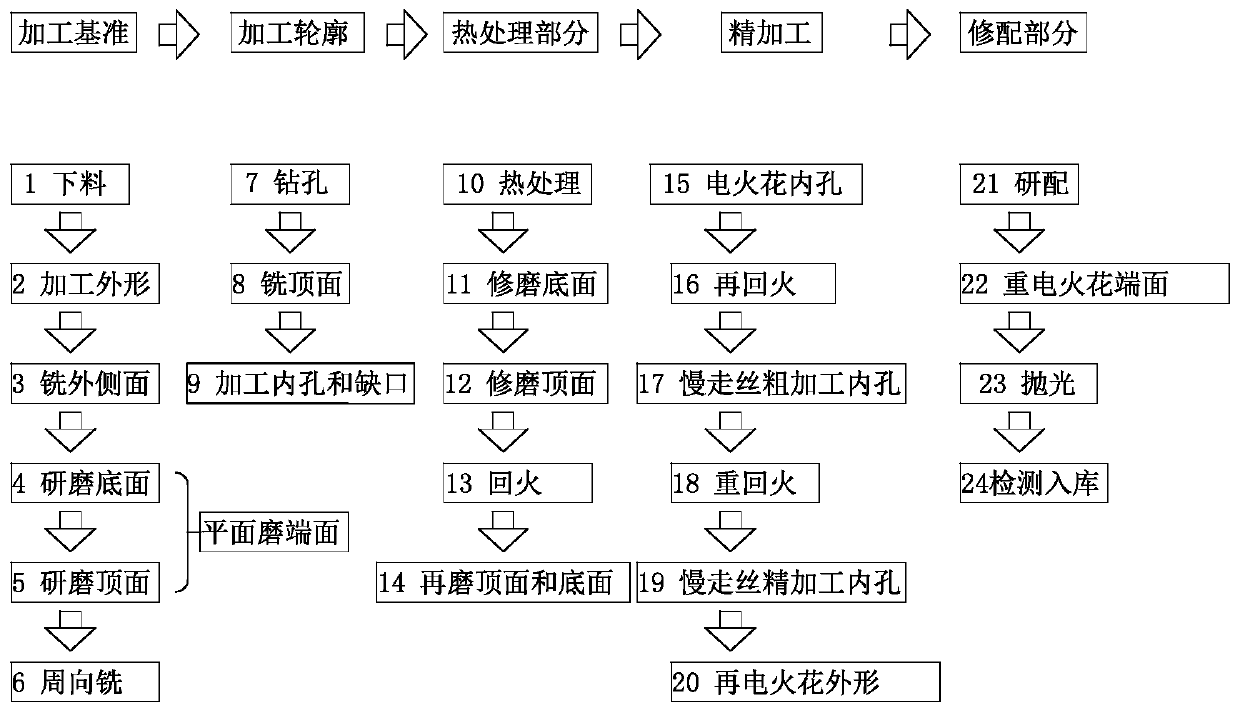

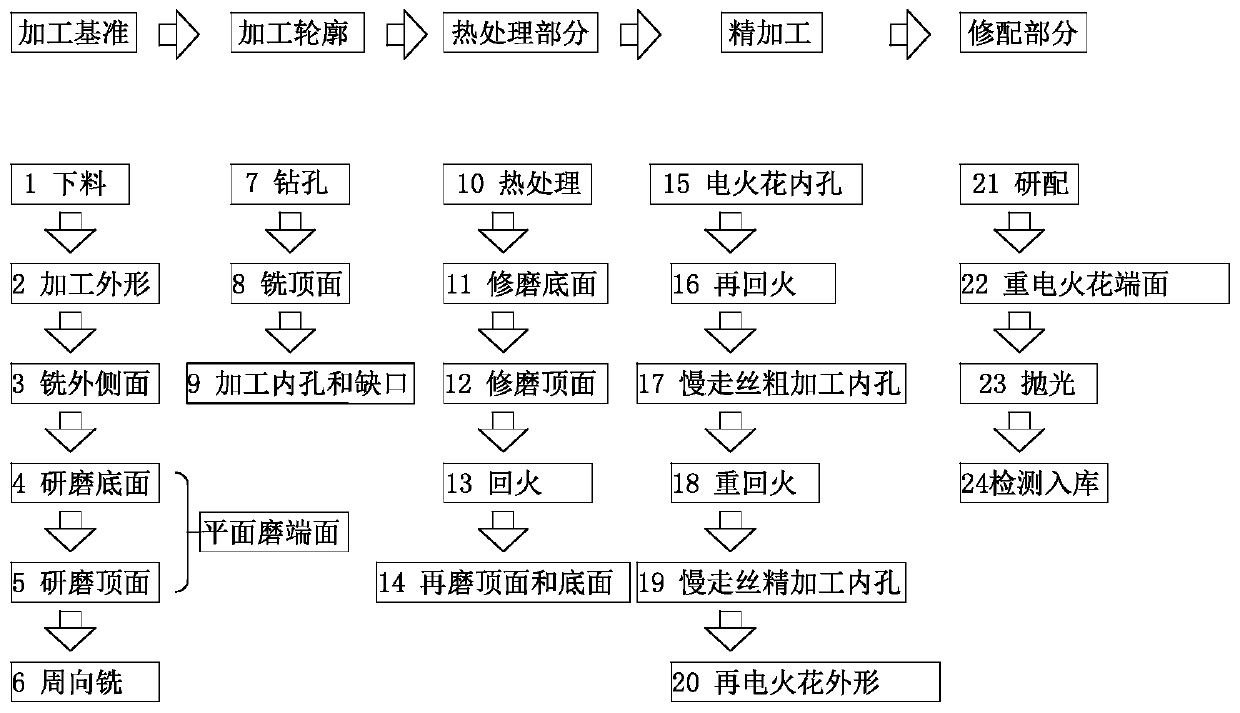

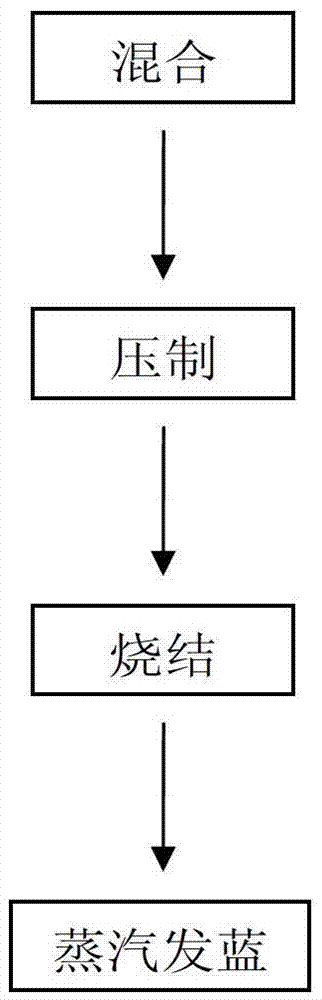

Machining method of powder metallurgy cross slip ring die

The invention discloses a machining method of a powder metallurgy cross slip ring die. The method comprises steps of processing a reference part, including a shape processing step and a bottom surfacegrinding step; machining a contour part, including an inner hole machining step and a notch machining step; a heat treatment part, including a tempering step and a bottom surface grinding step; a finish machining part, including a step of slowly threading an inner hole. The method is advantaged in that die precision can be improved, and deformation and scrapping are reduced.

Owner:GUANGDONG DONGMU NEW MATERIALS

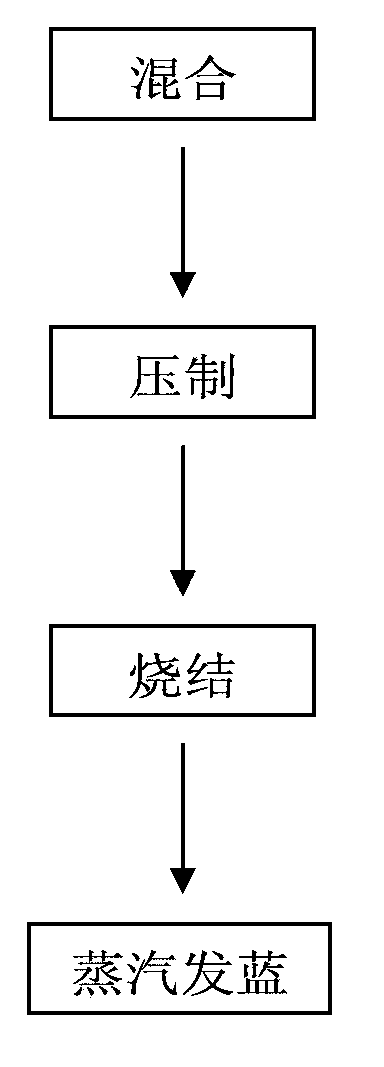

Powder metallurgy material, cross slip ring and manufacturing method of cross slip ring

ActiveCN103667914AWide variety of sourcesLow costRotary piston pumpsRotary piston liquid enginesManganeseCross Slip

The invention provides a powder metallurgy material, a cross slip ring and a manufacturing method of the cross slip ring. The powder metallurgy material comprises the following components in percentage by weight: 1.5-3.0% of copper, 0-0.6% of phosphorus, 0.5-1.0% of graphite, 0.5-2.0% of nickel, 0.5-1.0% of molybdenum, 0.3-0.6% of manganese, 0-0.2% of sulphur and 92-96% of ferrum. The components of the powder metallurgy material provided by the invention are wide in source and low in cost, so that the manufacturing cost of the product is greatly lowered. The powder metallurgy material through metallurgical treatment forms products in different shapes, and the hardness and strength of the products are remarkably improved compared with those of existing aluminum alloy products. The powder metallurgy material is good in wear resistance, so that a series of problems caused by abrasion are avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

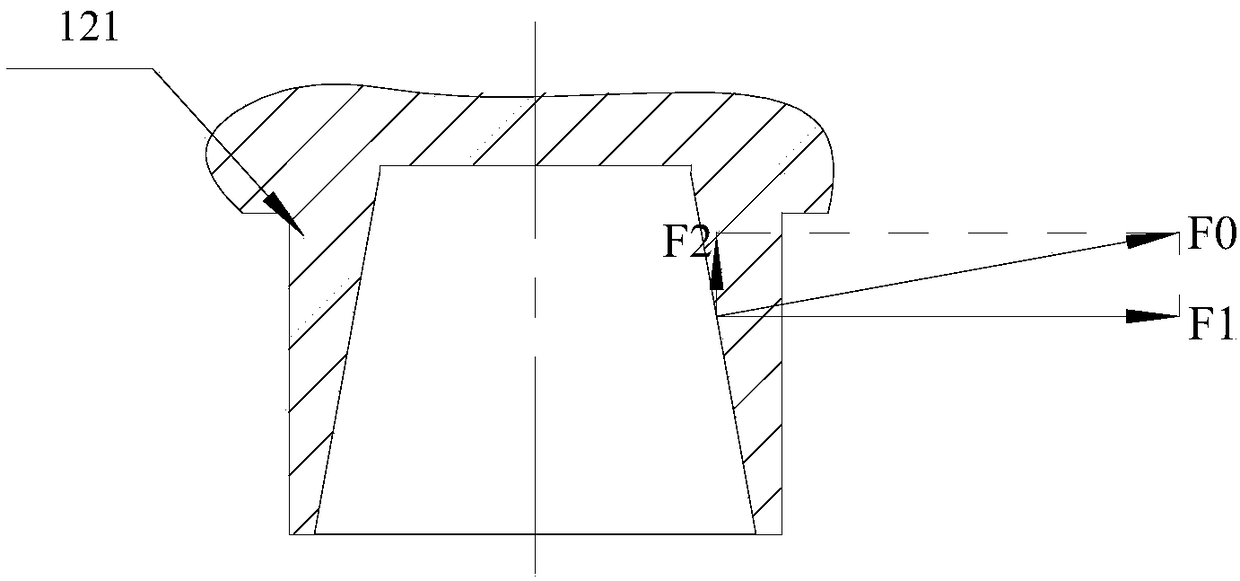

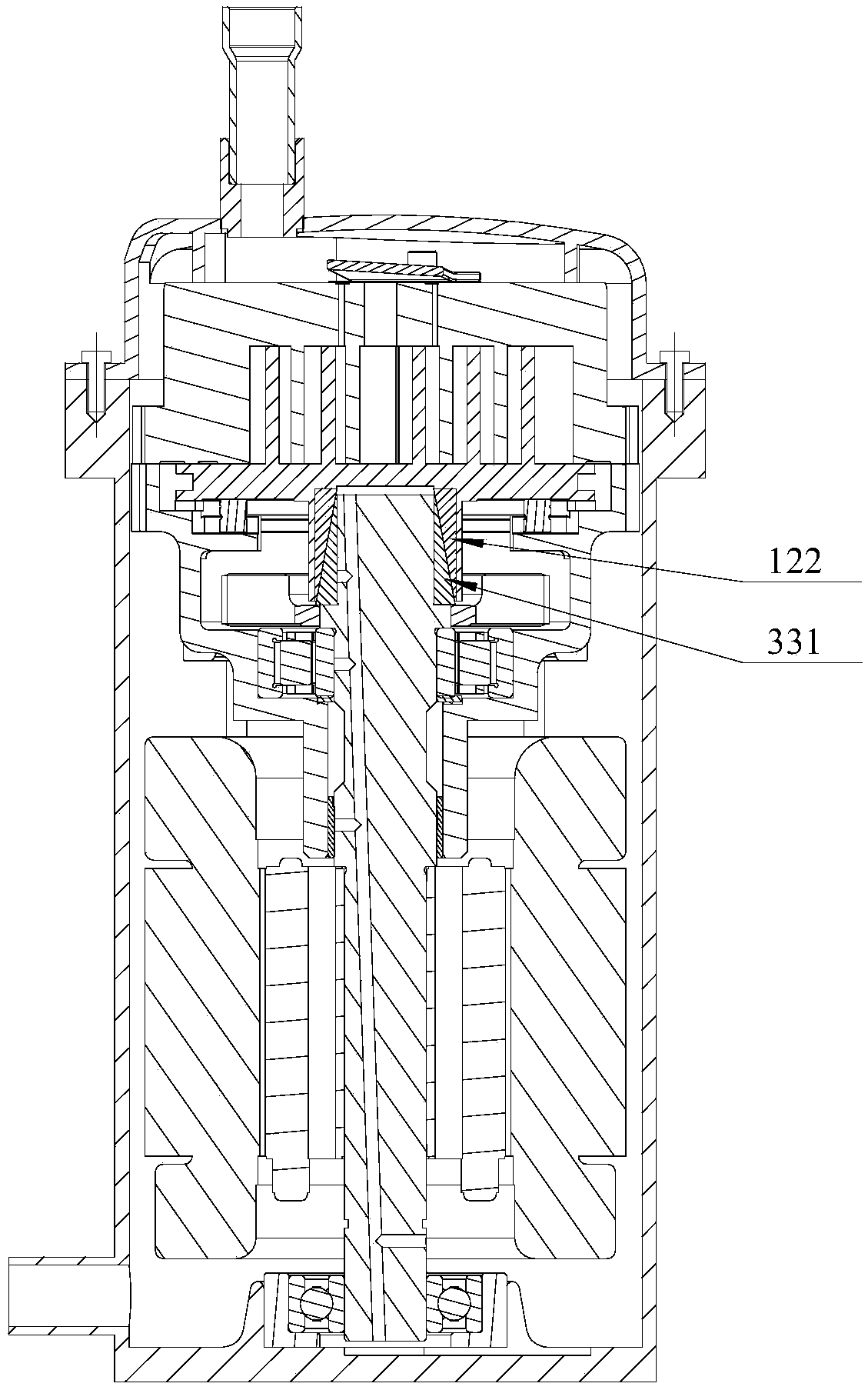

Kinetic scroll for scroll compressor and scroll compressor

The invention relates to a kinetic scroll for a scroll compressor. The kinetic scroll comprises a kinetic scroll end plate, kinetic scroll blades arranged on a first side of the kinetic scroll end plate, a boss arranged on a second side of the kinetic scroll end plate opposite to the first side, and a keyway formed on the second side of the kinetic scroll end plate. At least one raised part is formed on the second side of the kinetic scroll end plate, and the raised part contacts with a thrust surface of a crossed slip ring of the scroll compressor so that crossed slip ring overturn is prevented. Through the kinetic scroll, a cooperation precision of the kinetic scroll and the crossed slip ring is greatly improved, friction and collision between the kinetic scroll and the crossed slip ring are reduced, noise in scroll compressor running is reduced and scroll compressor work efficiency is improved. The invention also relates to a scroll compressor.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

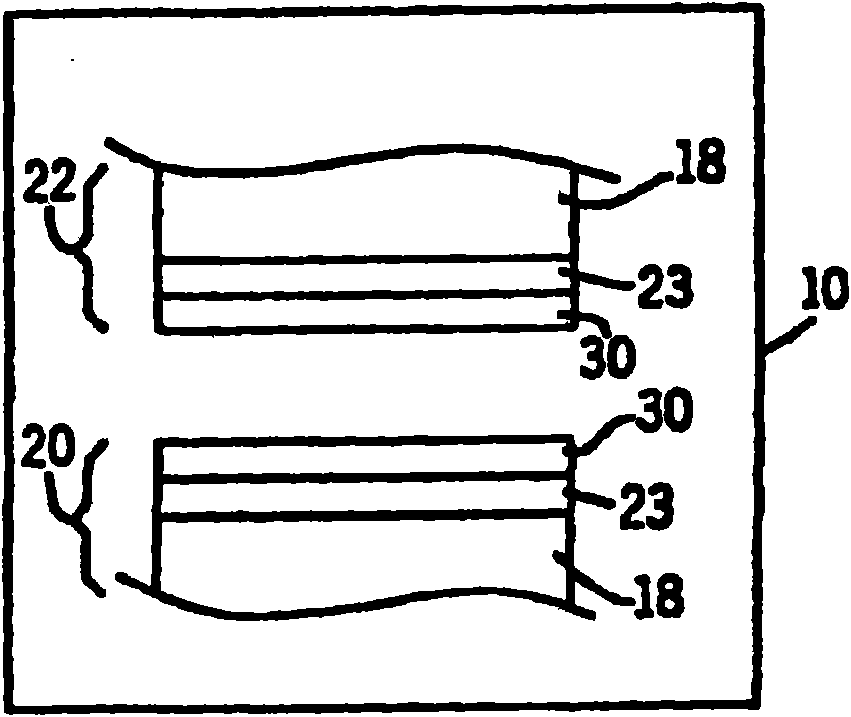

Scroll compressor and cross slip ring thereof

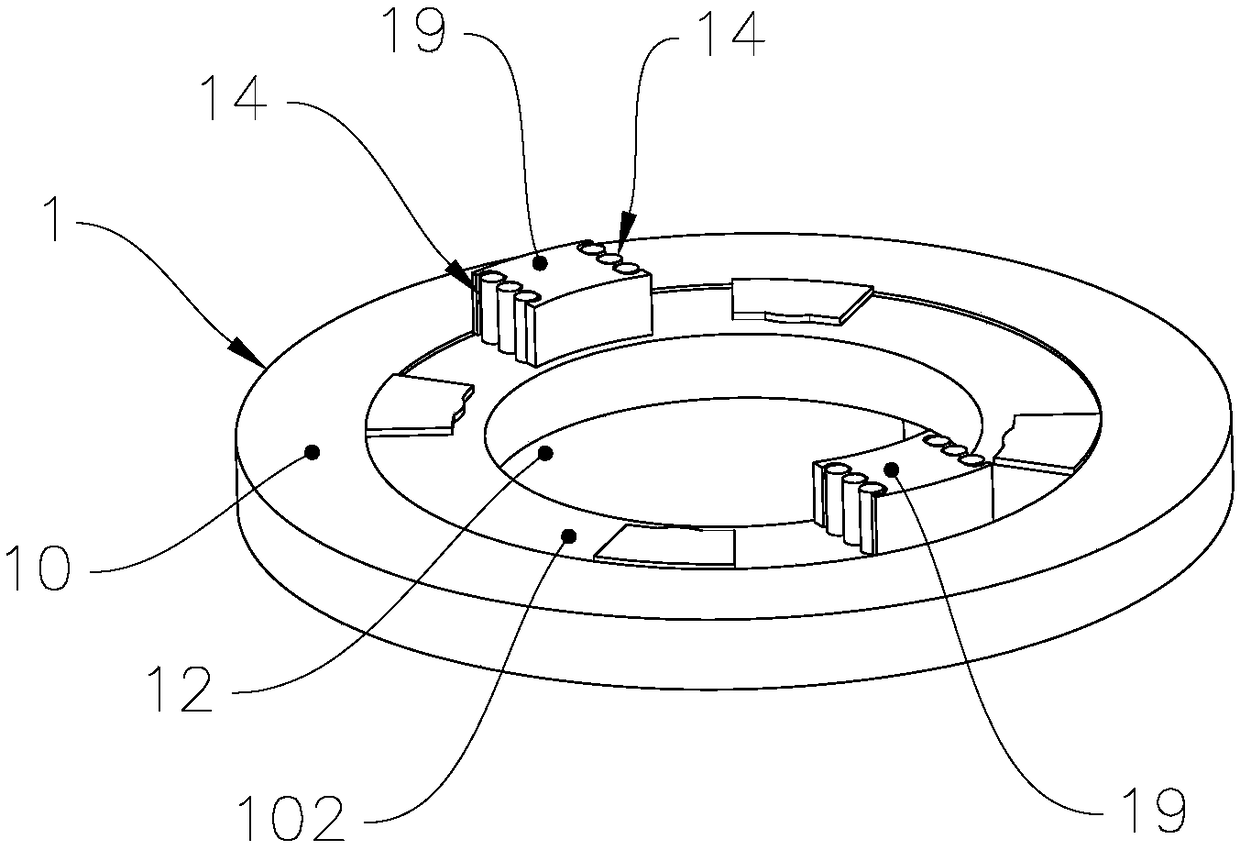

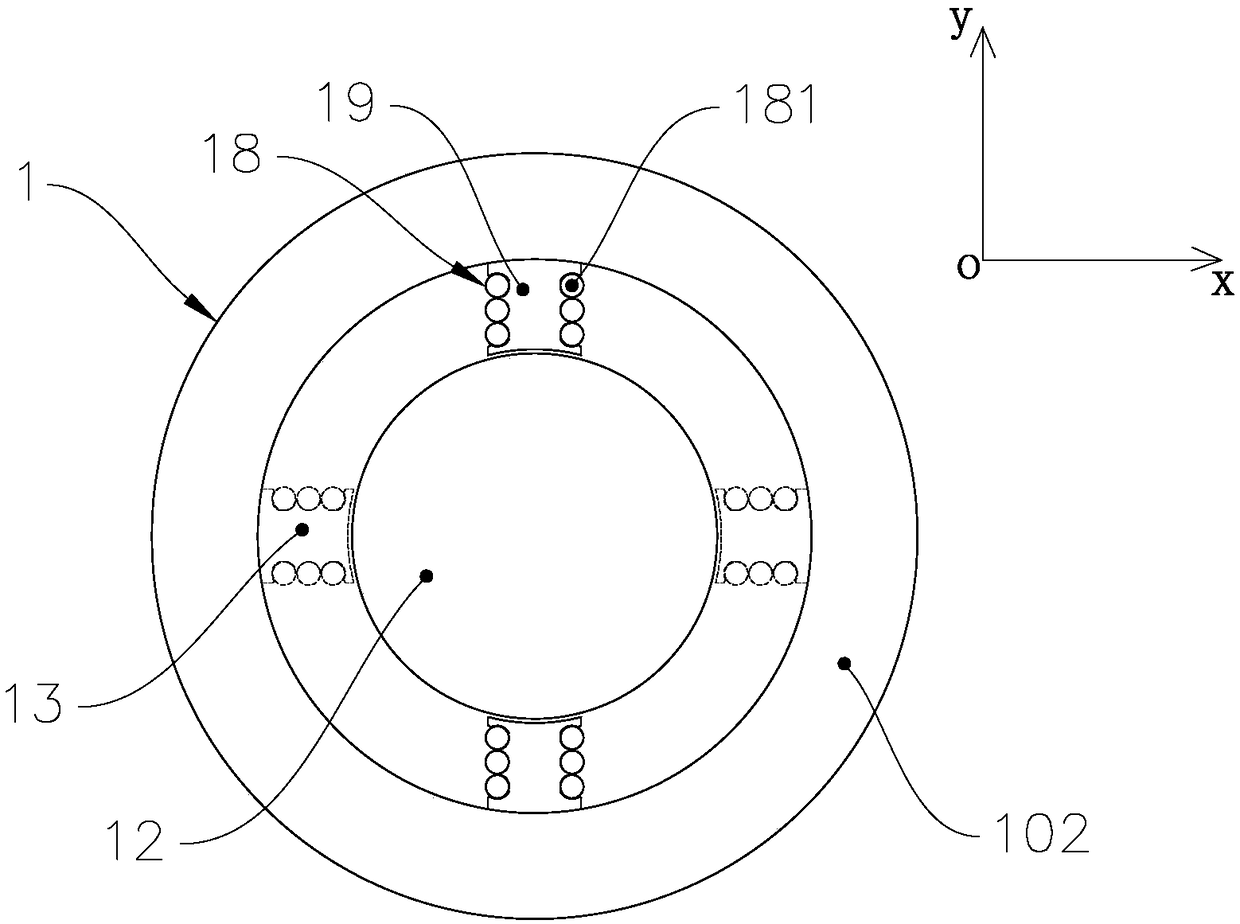

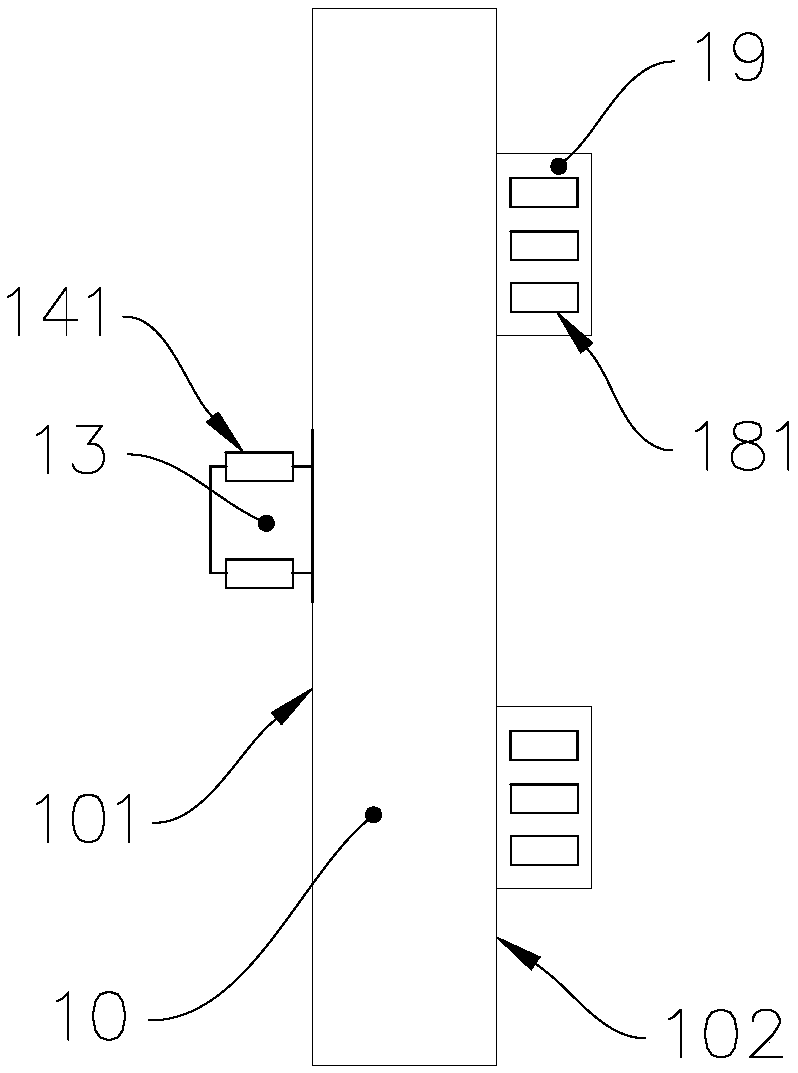

InactiveCN106481559AImprove serious wear and tear problemsReduce friction lossRotary piston pumpsRotary piston liquid enginesRolling resistanceFriction loss

The present invention discloses a cross slip ring which is arranged between a movable scroll plate and an upper bracket to support the floating of the movable scroll plate. A rolling friction mechanism is assembled on a fitting surface f the cross slip ring, the movable scroll plate and the upper bracket, so that the friction loss between parts is reduced. The rolling friction mechanism can reduce the friction loss between the cross slip ring and the movable scroll plate through a mode of the rolling friction instead of the sliding friction by specifically assembling a ball on an end face where the cross slip ring is cooperated with the movable scroll plate. The ball is instead of the end face of the cross slip ring, and processing procedures are reduced. The structure of the scheme is simple and the assembling is easy. The invention also discloses a scroll compressor using the cross slip ring. The friction between the cross slip ring and the movable scroll plate and the upper bracket is effectively reduced. The contact friction mode between the parts is changed, and the friction loss between the parts is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

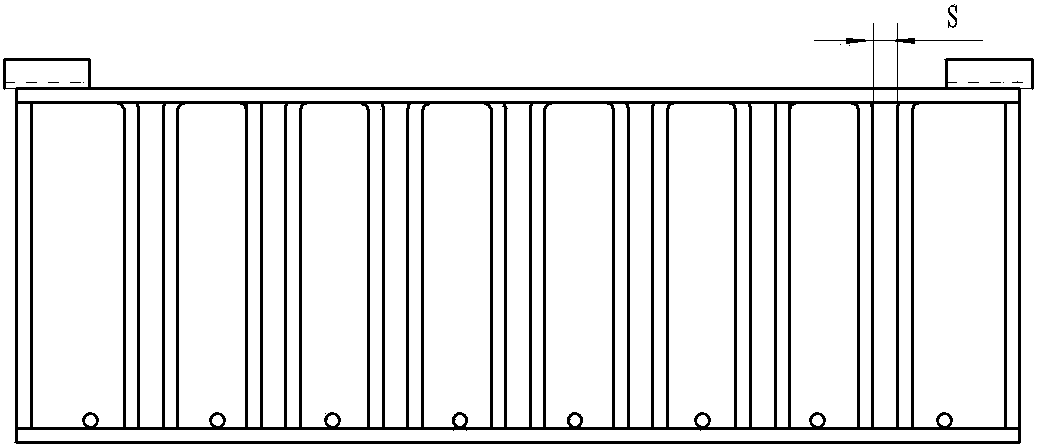

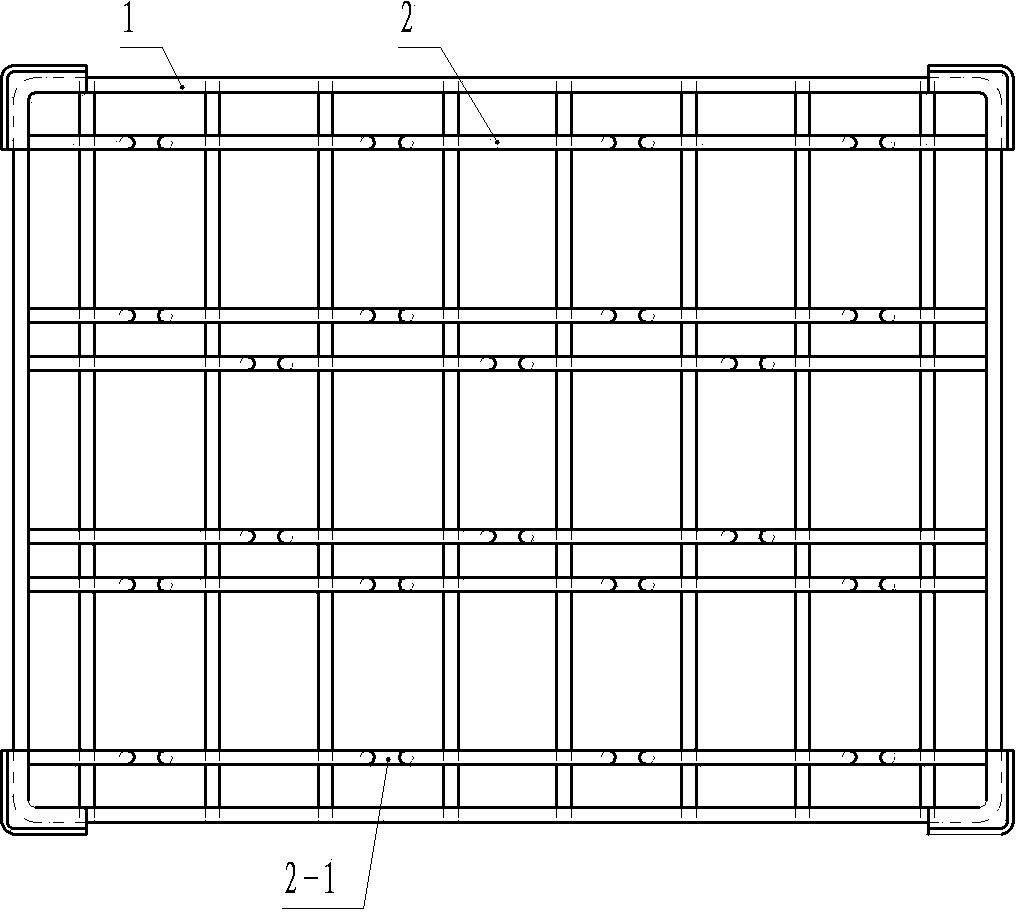

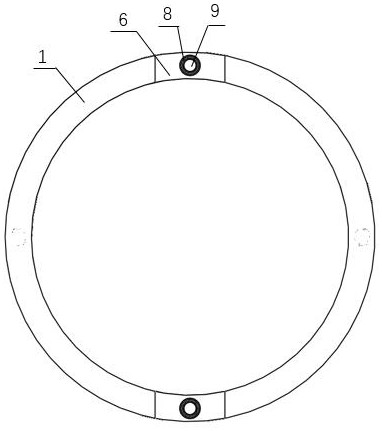

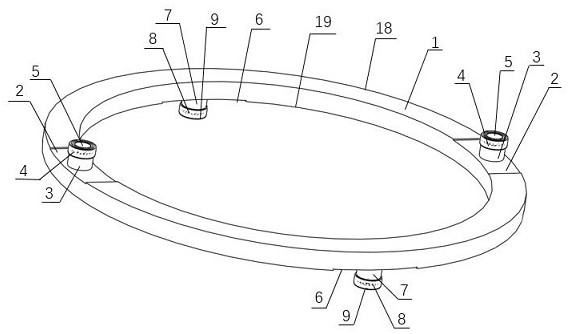

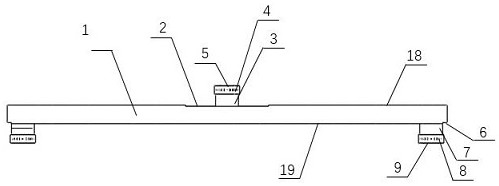

Cross slip ring storage rack

InactiveCN103465244AAvoid bumping into each otherConvenient statisticsWork tools storageManufacturing technologyCross Slip

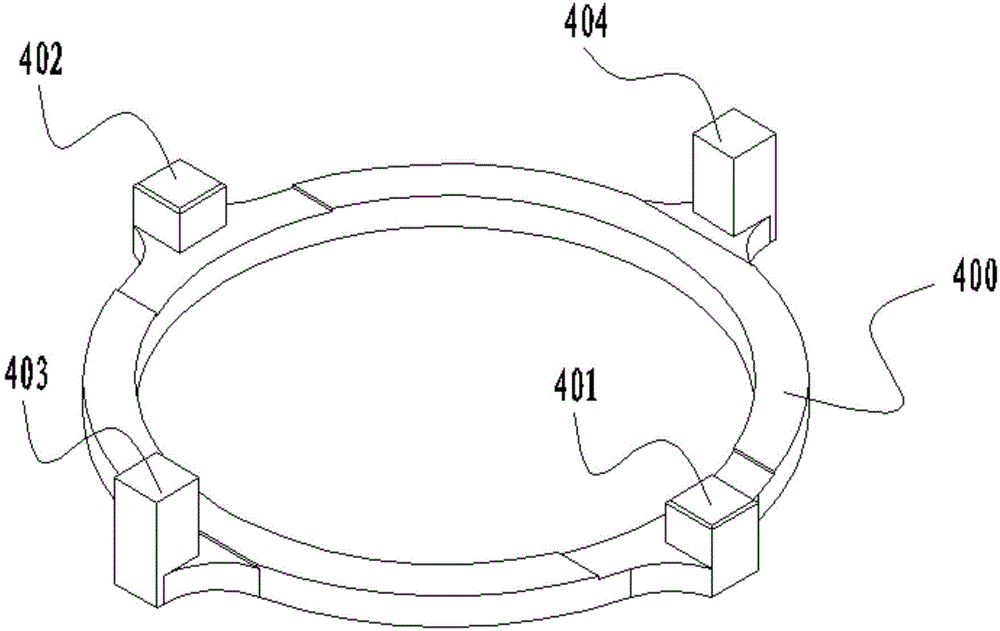

The invention discloses a cross slip ring storage rack, and belongs to the manufacture technical field of workstation tools. The cross slip ring storage rack comprises a frame body used for storing cross slip rings, wherein the cross slip ring is provided with an oval ring part, a pair of first bulges and a pair of second bulges; the pair of first bulges and the pair of second bulges stretch out from the periphery of the ring part; the first bulges and the second bulges are respectively arranged in the direction of a long shaft and the direction of a short shaft of the ring part; a plurality of storage units are arranged in the frame body; each storage unit is provided with two storage racks which are arranged oppositely; a plurality of upright locating slots which are arranged oppositely are distributed on the two storage racks. Compared with the prior art, the cross slip ring storage rack disclosed by the invention can solve the problem of low rate of qualified product caused by the fact that the cross slip rings are mutually collided when being stored by using the conventional storage rack.

Owner:LIUZHOU YIZHOU AUTOMOBILE AIR CONDITIONER

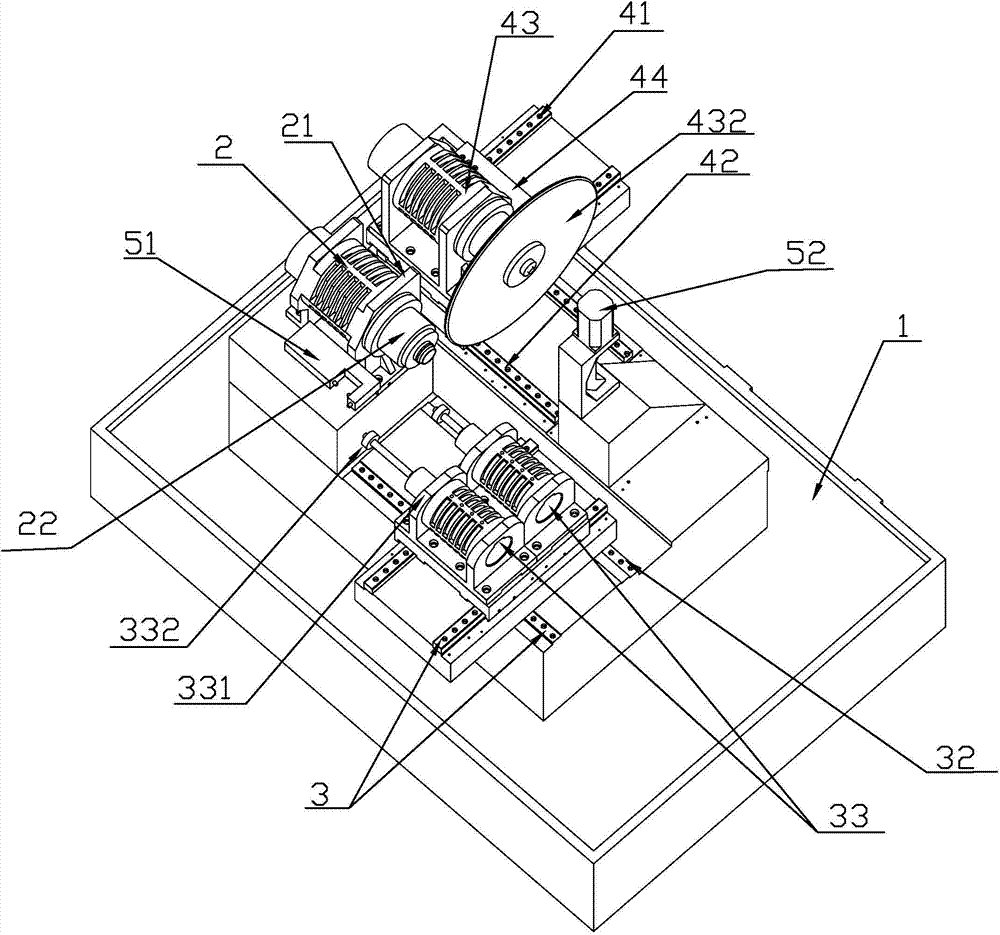

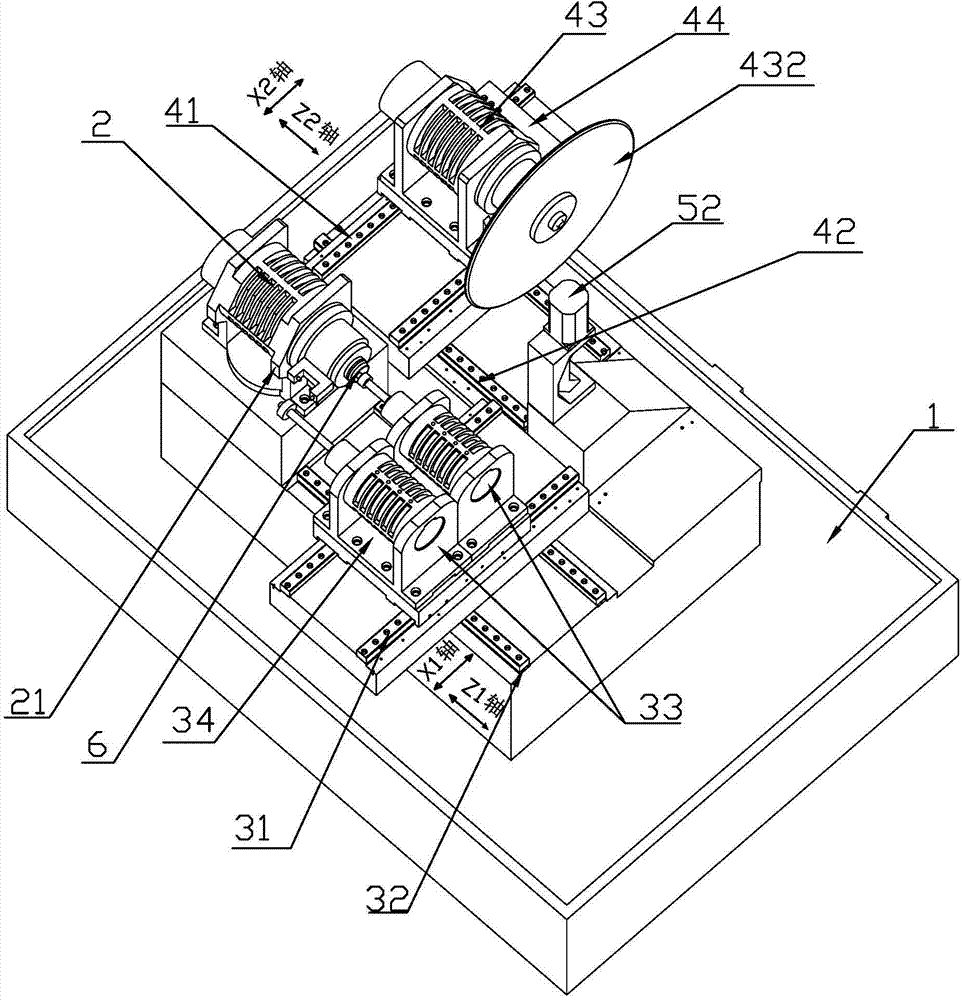

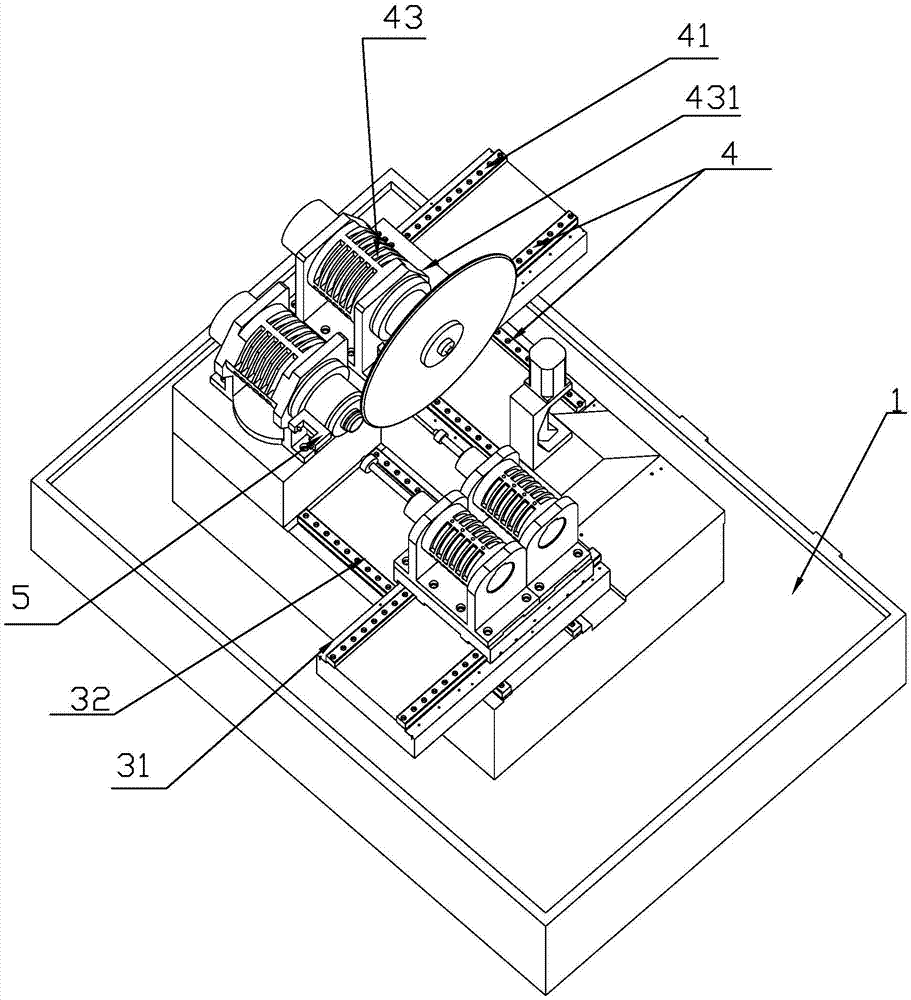

Bearing ring composite grinding device

ActiveCN104493646AEasy to adjustConvenient digital control operationLapping machinesWork carriersAutomatic controlMachine parts

The invention discloses a bearing ring composite grinding device which comprises a base and a workpiece spindle assembly located on the base. The workpiece spindle assembly comprises a workpiece spindle and a workpiece clamp used for clamping a bearing ring. The grinding device further comprises a first cross slip table used for adjusting the relative distance between an inner ring grinding assembly and the bearing ring to be machined on the workpiece clamp and aligned to the relative distance accurately and a second cross slip table used for adjusting the relative distance between an outer ring grinding assembly and the bearing ring to be machined on the workpiece clamp and aligned to the distance accurately. The grinding device can accurately and quickly adjust the machining part of the bearing ring to be machined, and automatic control operation is facilitated. A plurality of machining parts of the bearing ring can be machined on the same composite grinding device, so that the working efficiency is improved, and the manual cost is saved.

Owner:GUANGZHOU QUNCHUANG CNC MACHINE TOOL CO LTD

Edge covering mold switching mechanism

The invention provides an edge covering mold switching mechanism applied to the technical field of automobile part machining equipment. A mold storage station I (2) of the edge covering mold switching mechanism is located on the left side of a switching component (1), and a mold storage station II (3) is located on the right side of the switching component (1); multiple guide wheels I (4) and multiple guide wheels II (5) are arranged on the switching component (1); the guide wheels I (4) and the guide wheels II (5) are arranged to be of a structure in vertical angle arrangement; the guide wheels I (4) are arranged to be of structures capable of being switched between a vertical state and a horizontal state; and the guide wheels II (5) are arranged to be of structures capable of being switched between a vertical state and a horizontal state. The edge covering mold switching mechanism is simple in structure; an edge covering mold can be switched between the mold storage stations and the switching component conveniently and fast; the edge covering mold can achieve cross-slip motion in different directions; rail ascending and descending switching is not needed any more; and switching convenience is improved.

Owner:ANHUI RUIXIANG IND

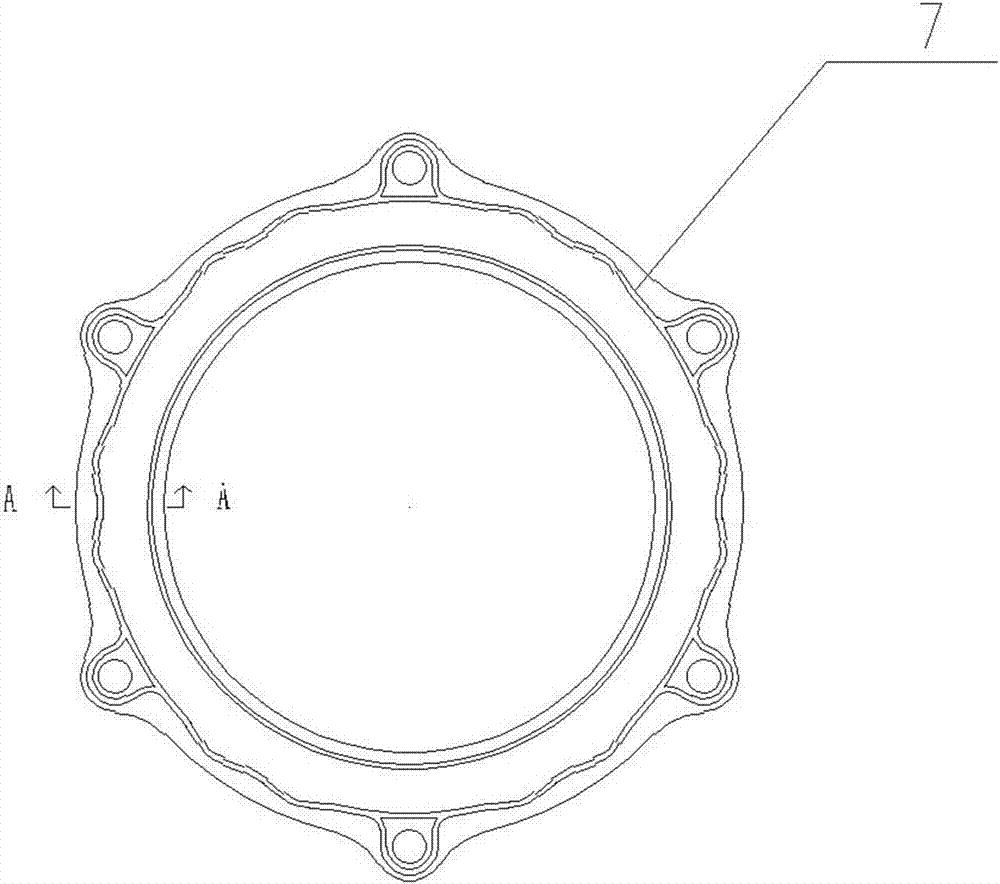

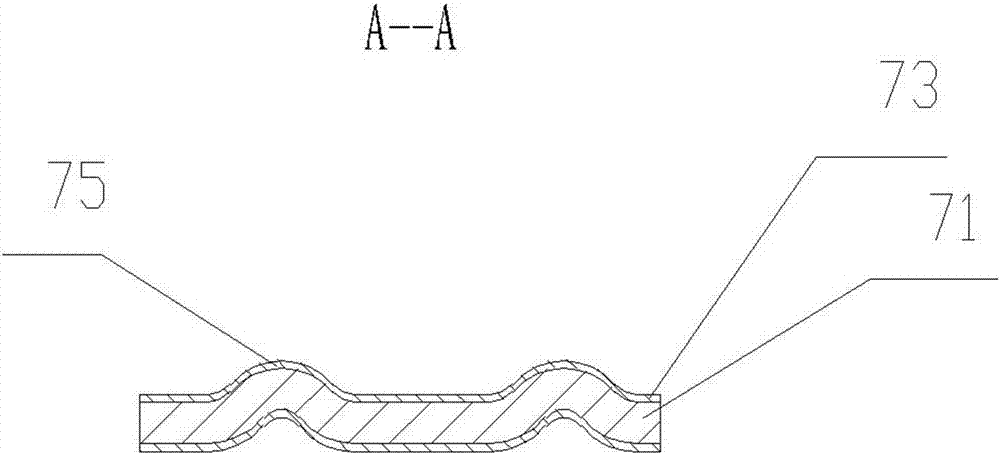

Sealing structure of scroll compressor

InactiveCN107255079ALow costSimple structureSealing arrangement for pumpsMachines/enginesCross SlipHigh pressure chamber

The invention provides a sealing structure of a scroll compressor. The sealing structure comprises a case, a static scroll plate, a balance block, a sealing pad, a main bearing, an air inlet, an air outlet, a bearing cavity, a low-pressure chamber, a high-pressure chamber, an end cover sealed in an opening in one end of the case, a dynamic scroll plate, an anti-wear pad, a cross slip ring, an engine base, a shaft and a motor, wherein the dynamic scroll plate, the anti-wear pad, the cross slip ring, the engine base, the shaft and the motor are arranged in the case. Separate treatment of two sealing parts of an existing compressor are changed into once treatment and the low-pressure chamber and the high-pressure chamber can be sealed by one sealing pad at the same time; the left side end surface of the static scroll plate and a flange surface of the case are located in the same plane and only one sealing pad is needed, so that the sealing structure is low in cost, simple in structure and small in size. The sealing pad comprises a stainless steel strip and rubber, and a convex mark is arranged on the stainless steel strip, so that the sealing effect is good.

Owner:湖南贝特新能源科技有限公司

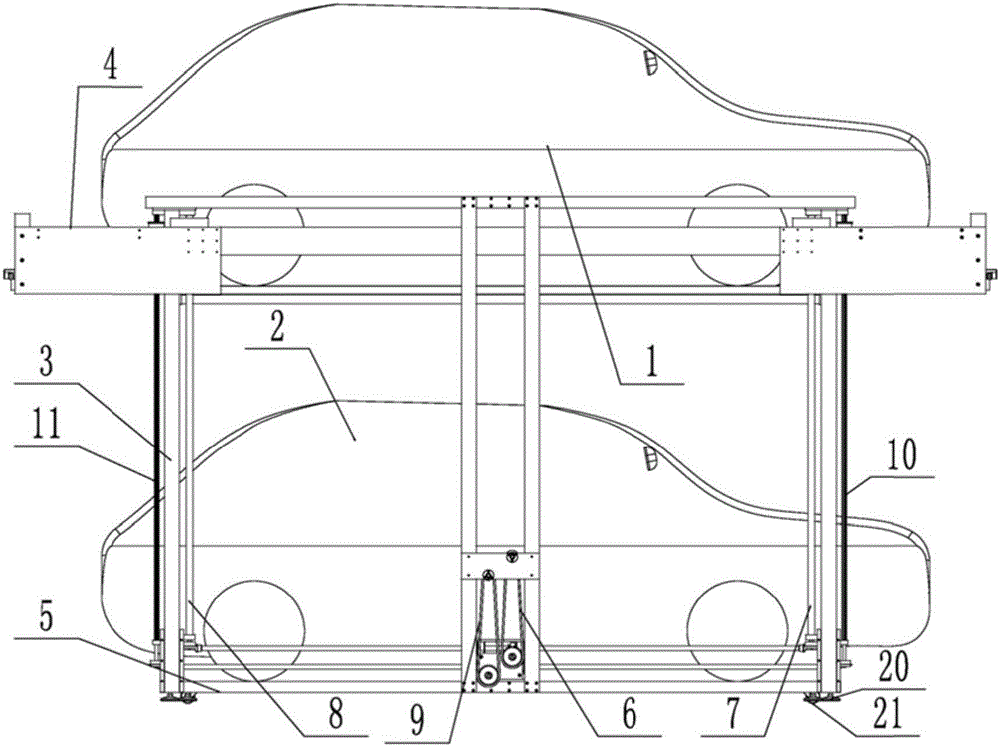

Stereo garage

ActiveCN106481115AAvoid the drawbacks of needing to move the underlying carReasonable structureParkingsEngineeringCross Slip

The invention relates to a stereo garage, comprising a frame, a lower garage assembly for placing cars at a lower layer, and an upper garage assembly moveably arranged on the frame and used for placing cars at an upper layer; a vertical supporting rail is fixedly and vertically arranged on the frame; the upper garage assembly includes an upper platform lifting base, and an upper platform installed on the upper platform lifting base in a linkage lifting form and used for placing cars at the upper layer; an upper layer platform cross slipping mechanism is arranged on the upper platform lifting base. The stereo garage is reasonable in structure, low in cost, firm and durable, convenient to use, saves space, convenient to repair, safe and reliable; the stereo garage avoids the shortcoming that the cars at the lower layer shall be moved when cars at the upper layer of the traditional stereo garage are accessed.

Owner:林凯

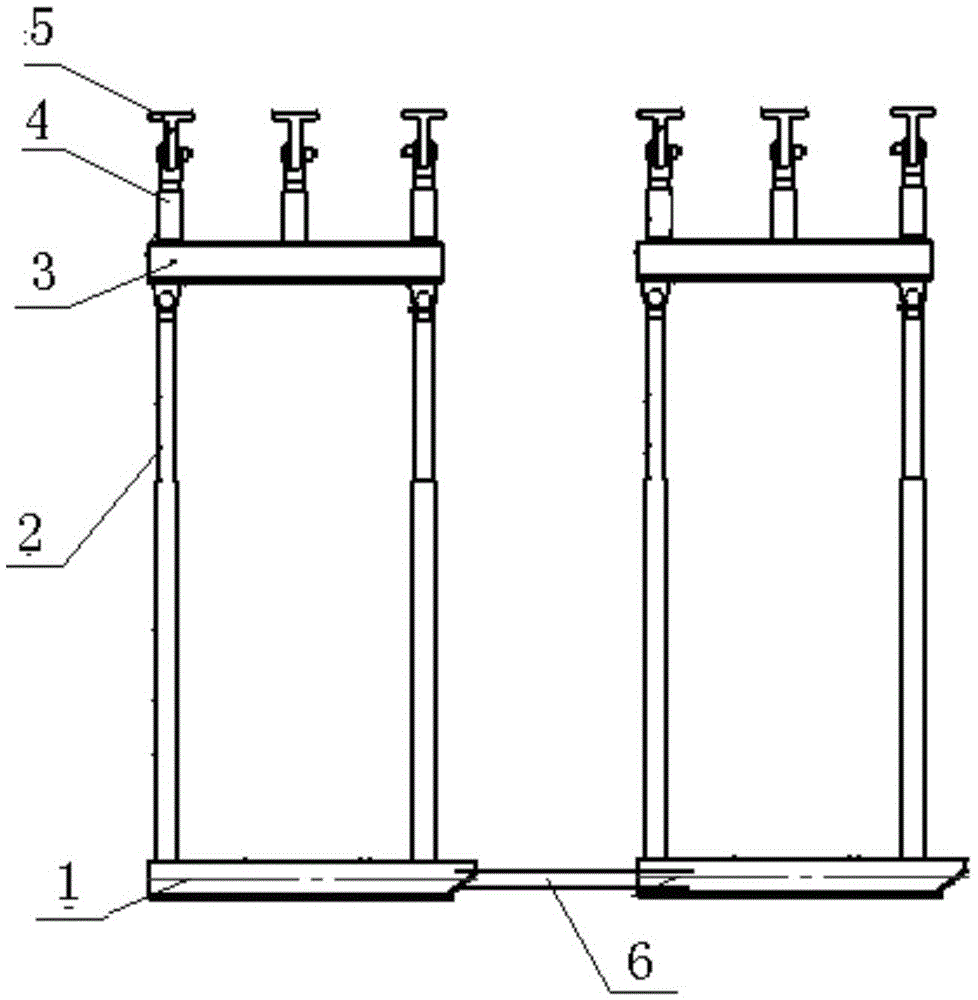

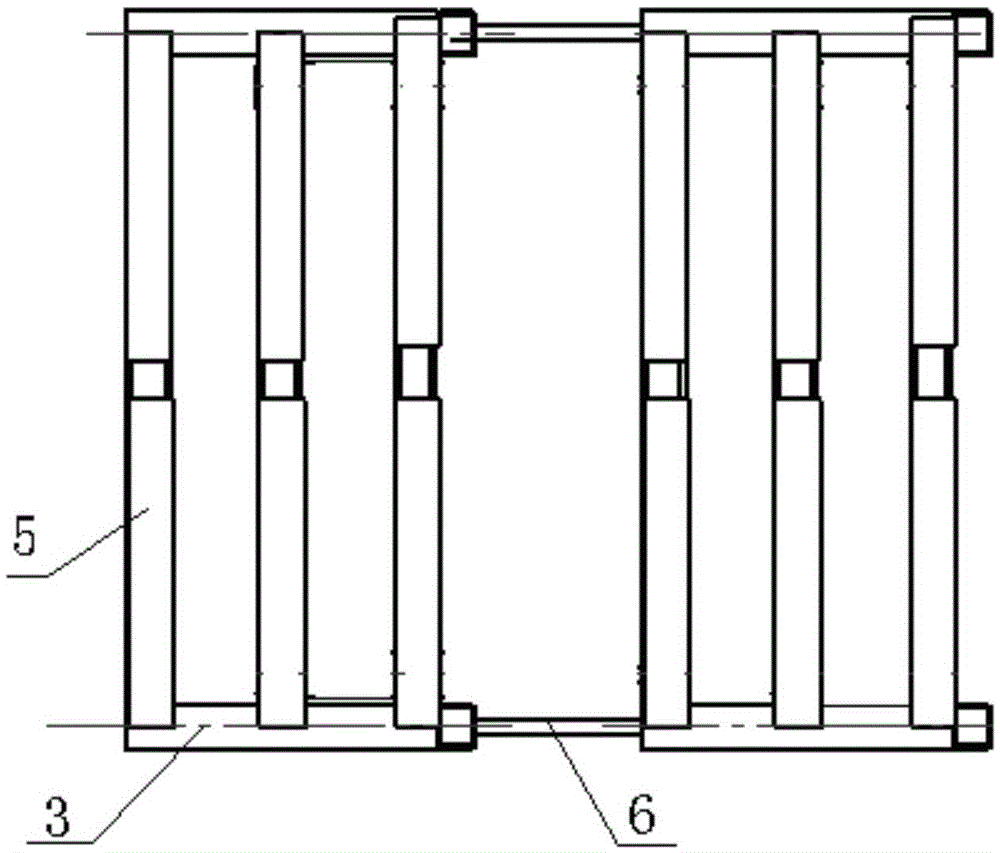

Support-shield-type cross-slip temporary support bracket and support method thereof

The invention discloses a support-shield-type cross-slip temporary support bracket and a support method thereof. The temporary bracket comprises two four-column bracket bodies with the same structure and a hydraulic system; the four-column bracket bodies are arranged front and back, push-pull oil cylinders are arranged between bottom beams of the front bracket body and bottom beams of the back bracket body, and then a front-pull back-push combined bracket body is formed; cross beams are provided with at least two pairs of jacks, each pair of the jacks are provided with short cross beams, and each short cross beam can rise and fall alone to achieve supporting on partial top plates. When temporary support on an excavation roadway is performed, one group serves as an external group, the other group serves as an internal group, the width of the internal group is smaller than that of the external group, the internal group can enter the external group and penetrate through the external group, therefore, the external group and the internal group achieve transposition and independently move, and the purposes that the temporary support bracket moves flexibly in actual application and can be supported on most of the top plates when the exploded top plates are not flat or the top plates are not a complete plane are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

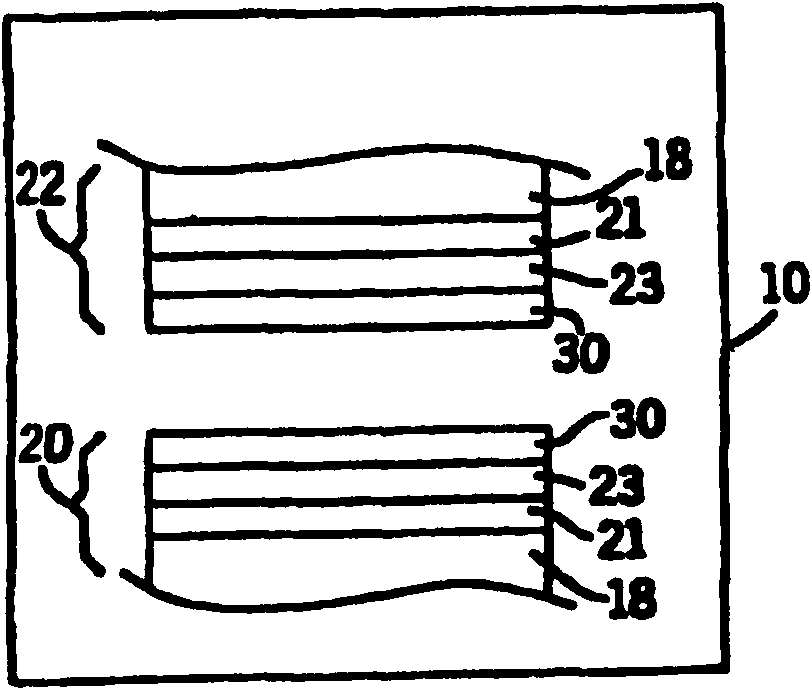

Vortex compression device with antifriction buffer cross-shaped slip ring

PendingCN114233622APrevent rotationAddress shockRotary piston pumpsRotary piston liquid enginesFriction lossClassical mechanics

The invention discloses a scroll compression device with an anti-friction buffer cross-shaped slip ring, which is used for preventing rotation and reducing friction of a scroll compressor. The cross-shaped sliding ring comprises a cross-shaped sliding ring body, a bearing, stepped-shaft-shaped sliding keys, oil passing grooves, a movable scroll plate and a rack, the movable scroll plate and the rack are matched with each other, the stepped-shaft-shaped sliding keys are sleeved with the bearing, and the sliding keys are distributed on the upper end face and the lower end face of the cross-shaped sliding ring in a cross-shaped symmetry mode. During working, the upper end face and the lower end face are attached to the movable scroll plate and the machine frame in a sliding mode respectively, the cross-shaped symmetrical sliding keys on the upper end face and the lower end face do reciprocating rolling motion in the guide sliding grooves in the movable scroll plate and the machine frame, and the lower portion of the stepped shaft sliding key does not make contact with the guide sliding grooves in the movable scroll plate and the machine frame. Generally, rolling friction is 1 / 40 of sliding friction, and according to the principle, the bearing sliding keys are adopted, so that the contact area and friction loss between the bearing sliding keys and the rack and between the bearing sliding keys and the guide sliding grooves of the movable scroll plate are reduced. The antifriction cross slip ring is easy to machine, low in cost and more stable and efficient in work.

Owner:SHANDONG UNIV OF TECH

Improved energy-saving lamp device

InactiveCN108071973AWill not cause electric shock accidentsRealize power supplyLighting support devicesElectric circuit arrangementsEngineeringCross Slip

The invention discloses an improved energy-saving lamp device comprising a lamp holder and a lamp cap. The lamp holder is provided with first slip connecting grooves equivalently up and down, and thefirst slip connecting grooves extend right and left; the part, located between the two first slip connecting grooves, of the lamp holder is internally provided with an insertion cavity of which a portfaces rightward and which is equivalent up and down; the insertion cavity is internally provided with an electric clip fixedly, and the lamp holder is further internally provided with second slip connecting grooves which communicate with the two first slip connecting grooves; the first slip connecting grooves are internally provided with slip connecting rods in a cross slip connection manner, andthe end faces, facing the insertion cavity, of the right sides of the slip connecting rods are provided with first racks; the second slip connecting grooves are internally provided with connecting rods in the cross slip connection manner, and the connecting rods are fixedly connected to the slip connecting rods; the middle part of the right end face of each connecting rod is fixedly provided withan energizing strip, and the middle part of the right end face of each second slip connecting groove is provided with an energizing cavity matched with the energizing strip; and the left end face ofthe lamp cap is provided with an insertion shaft equivalently up and down.

Owner:惠安先锋机械有限公司

Novel environmental protection device

The invention discloses a novel environmental protection device, which comprises a seat plate. A left frame plate and a right frame plate are arranged opposite to each other at the left and right ends of the top of the seat plate. Lead-in holes, the inner ends of the left frame plate and the right frame plate are respectively provided with a left sink hole and a right sink hole connected with the left lead hole and the right lead hole, and the top of the seat plate is located on the left frame plate and the right frame plate The inner side ends of the first left slide groove and the first right slide groove are respectively arranged opposite to each other, and the left slide frame which can slide left and right is respectively arranged opposite to each other in the first left slide groove and the first right slide groove and the right sliding frame, the inner ends of the left sliding frame and the right sliding frame are respectively provided with a second left sliding groove and a second right sliding groove. The device of the present invention has simple structure, low production cost, and can clamp Firmly fix PVC pipes of different diameters, and it is convenient and fast to remove and clamp the PVC pipes, which increases the efficiency of subsequent cutting and processing of PVC pipes. The operation is simple and convenient, and the overall structure is safe, reliable and reasonable in operation, suitable for popularization and use.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

Cross slip ring, scroll compressor with cross slip ring, air conditioner and heat pump water heater

InactiveCN104595193AMiniaturizationLightweightRotary piston pumpsRotary piston liquid enginesCross SlipMechanical engineering

The invention provides a cross slip ring, a scroll compressor with the cross slip ring, an air conditioner with the scroll compressor, and a heat pump water heater with the scroll compressor. The cross slip ring comprises a first annular pedestal and a second annular pedestal, the first annular pedestal is detachably combined with the second annular pedestal, the first annular pedestal is provided with a first key and a second key opposite to the first key, and the second annular pedestal is provided with a third key and a fourth key opposite to the third key. The cross slip ring is divided into a plurality of detachable portions in order to simplify processing, so the vertical precision of two pairs of keys of the cross slip ring is guaranteed, and the miniaturization and the lightening of the cross slip ring are realized.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Powder metallurgy material, cross slip ring and manufacturing method of the cross slip ring

ActiveCN103667914BWide variety of sourcesLow costRotary piston pumpsRotary piston liquid enginesManganeseCross Slip

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Scroll compressor

ActiveCN108612654ANo leaksGuaranteed tightnessRotary piston pumpsRotary piston liquid enginesCross SlipEngineering

The invention discloses a scroll compressor, belonging to the technical field of compressors. The scroll compressor comprises a shell, a compression mechanism and a driving mechanism. The compressionmechanism comprises a fixed scroll and an orbiting scroll, wherein the fixed scroll and the orbiting scroll cooperate with each other to form a compression chamber; the shell has an air suction pipe communicating with the air inlet end of the compression chamber and an air exhausting pipe communicating with the air exhausting end of the compression chamber; the driving mechanism comprises a stator, a rotor and a crankshaft connected with the rotor; the eccentric portion of the crankshaft is cooperated and connected with the orbiting scroll; the orbiting scroll has a cross slip ring and a driving seat; the driving seat is provided with a driving groove for embedding of the eccentric portion of the crankshaft; the driving groove has an inner conical surface; the eccentric portion of the crankshaft has an outer conical surface; and the inner conical surface and the outer conical surface cooperate with each other and provide an action force for pushing the orbiting scroll toward the fixedscroll. The scroll compressor of the invention adopts the design of no medium-pressure chamber, so the problem of leakage is overcome, the sealing performance of an end face is ensured, self-protection effect is obtained, and technical problems in the prior art are solved.

Owner:WANBAO GROUP COMPRESSOR CO LTD

Orbiting scroll and scroll compressors for scroll compressors

The invention relates to a kinetic scroll for a scroll compressor. The kinetic scroll comprises a kinetic scroll end plate, kinetic scroll blades arranged on a first side of the kinetic scroll end plate, a boss arranged on a second side of the kinetic scroll end plate opposite to the first side, and a keyway formed on the second side of the kinetic scroll end plate. At least one raised part is formed on the second side of the kinetic scroll end plate, and the raised part contacts with a thrust surface of a crossed slip ring of the scroll compressor so that crossed slip ring overturn is prevented. Through the kinetic scroll, a cooperation precision of the kinetic scroll and the crossed slip ring is greatly improved, friction and collision between the kinetic scroll and the crossed slip ring are reduced, noise in scroll compressor running is reduced and scroll compressor work efficiency is improved. The invention also relates to a scroll compressor.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

Plane cross slip ring for scroll compressor

InactiveCN102062098BCancel noiseImprove working conditionsRotary piston pumpsRotary piston liquid enginesEngineeringCross Slip

The invention discloses a plane cross slip ring for a scroll compressor. The plane cross slip ring is in a plane layout structure; working main bodies are two pairs of lug bosses crossly arranged on the plane cross slip ring; the spatial position of a working plane is positioned between two end planes of the plane cross slip ring; one pair of the lug bosses arranged on the plane cross slip ring are positioned at the excircle side of the plane cross slip ring, and the other pair of the lug bosses are positioned at the inner circle side of the plane cross slip ring; the working planes of the lug bosses are mutually perpendicular; the working planes of the first pair of the lug bosses of the plane cross slip ring are attached to the friction surfaces of a pair of lug bosses of a static scroll plate, and the working planes of the second pair of the lug bosses are attached to the friction surfaces of a pair of lug bosses of a dynamic scroll plate; and the working planes of the lug bosses of the plane cross slip ring, the friction surfaces of the dynamic scroll plate and the friction surfaces of the static scroll plate are all parallel to a central axis of the plane cross slip ring, thus the dynamic scroll plate takes plane circular motion under the driving of a bent axle. The invention effectively solves the problems of vibration, noise and short life of the traditional cross slip ring without a protruding guide slide block of the traditional cross slip ring.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com