Permanent magnetic contactor and control device thereof

A control device and contactor technology, applied in emergency protection circuit devices, relays, non-polar relays, etc., can solve problems such as power consumption, large working current, and wire package burning, and achieve strong breaking capacity, simple structure, and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

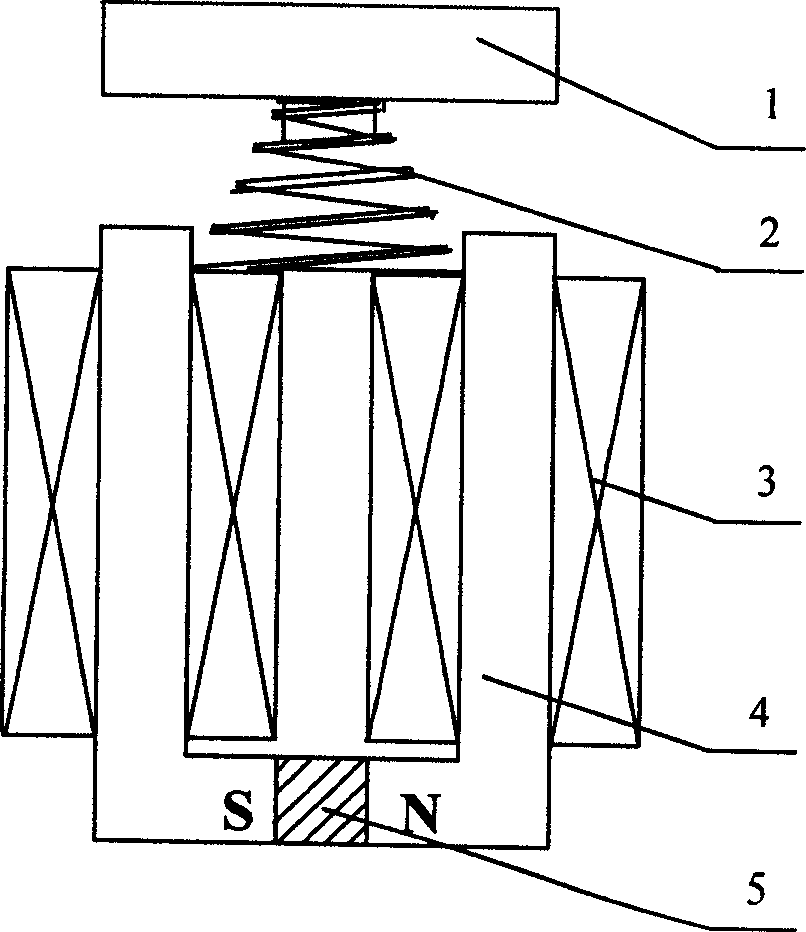

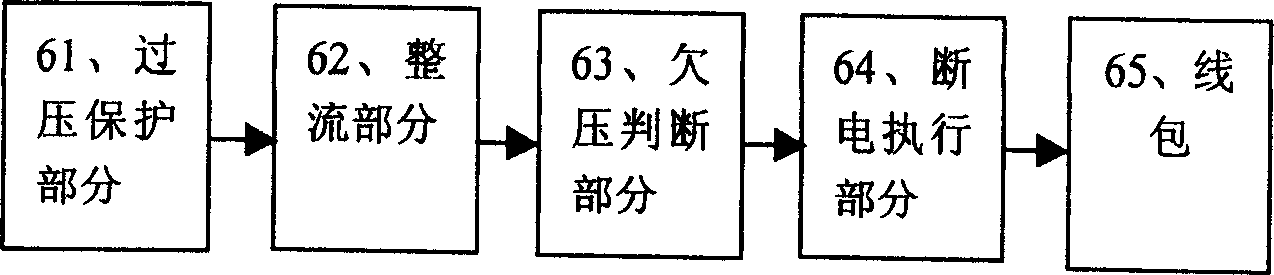

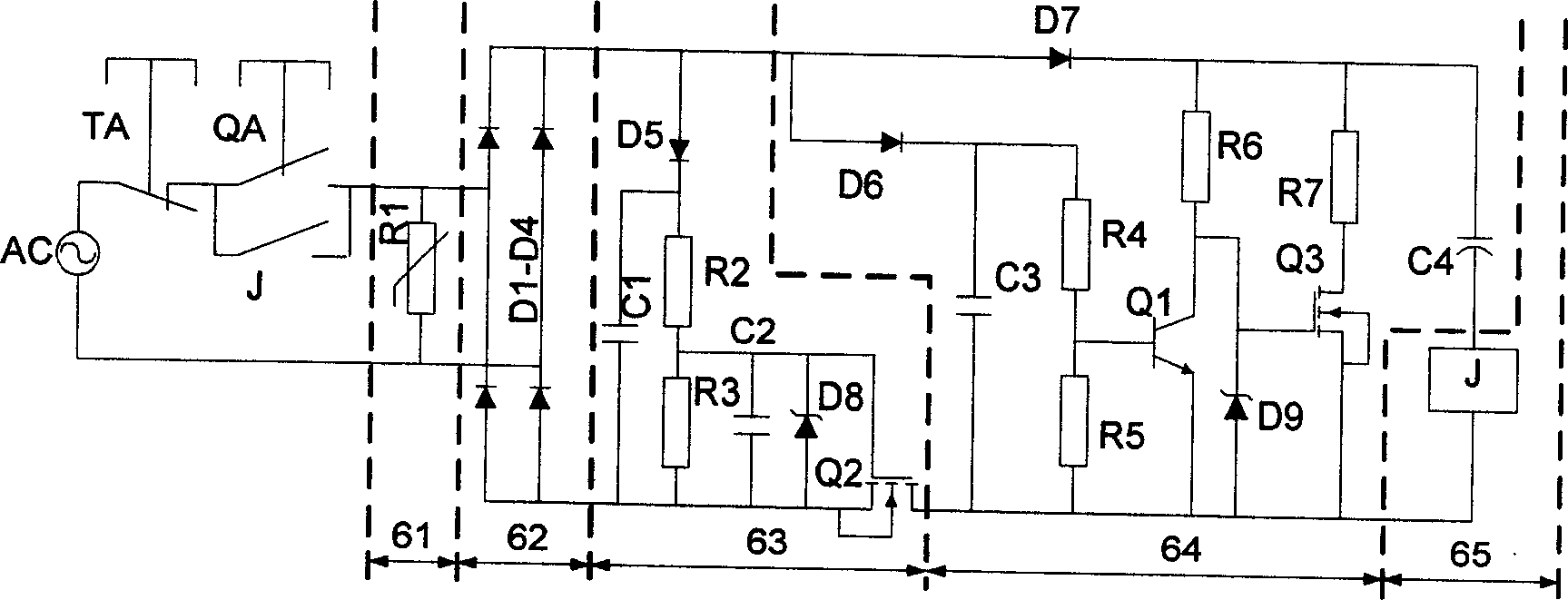

[0017] The permanent magnet contactor of the present invention is composed of a moving iron core 1, a static iron core 4, a permanent magnetic steel 5, a wire wrap 3, a tower spring 2 and a control circuit, and is characterized in that: between the two static iron cores 4 A piece of permanent magnet steel 5 is provided, so that the two static iron cores 4 and one piece of permanent magnet steel 5 form a "U"-shaped whole. They are connected in series and have the same polarity direction; the tower spring 2 is supported on the skeleton of the wire package 3 ; the upper end of the tower spring 2 is connected to the moving iron core 1 . The moving iron core 1 and the static iron core 4 are made of ordinary electrical pure iron, and the permanent magnet steel 5 is made of NdFeB material with high magnetic energy product.

[0018] like figure 1 As shown in the figure, when the switch is closed, the coil passes through the forward current, which is consistent with the magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com