Motor heat dissipation structure

A motor and structure technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of inability to directly transport the forward airflow, danger, and the motor is easy to accumulate heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Since the operating principle and internal related structures of the motor are already quite common and publicly known technologies, they will not be described in detail in this specification.

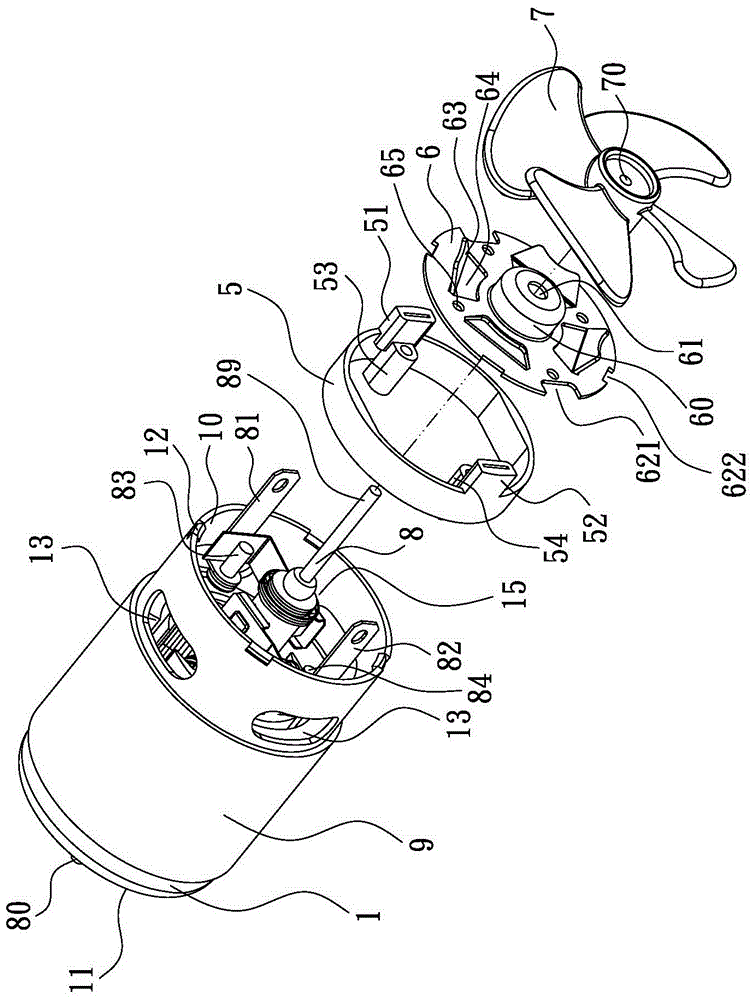

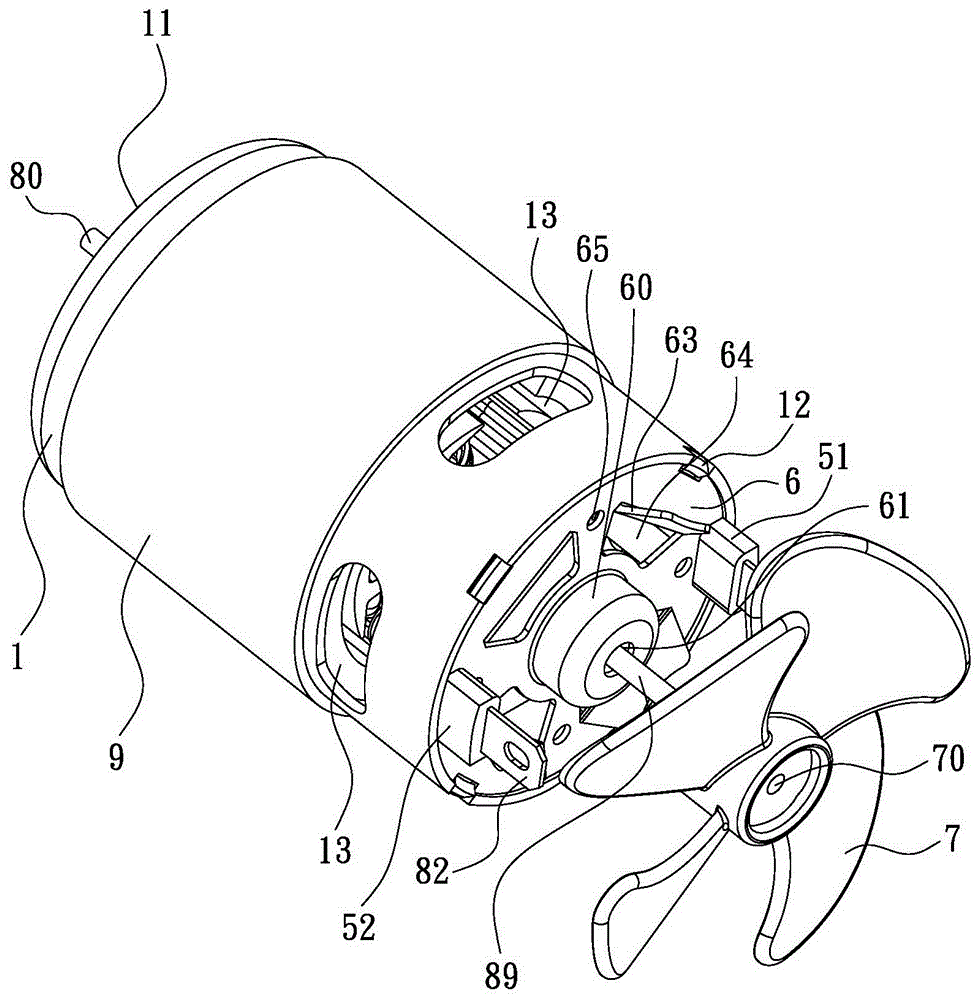

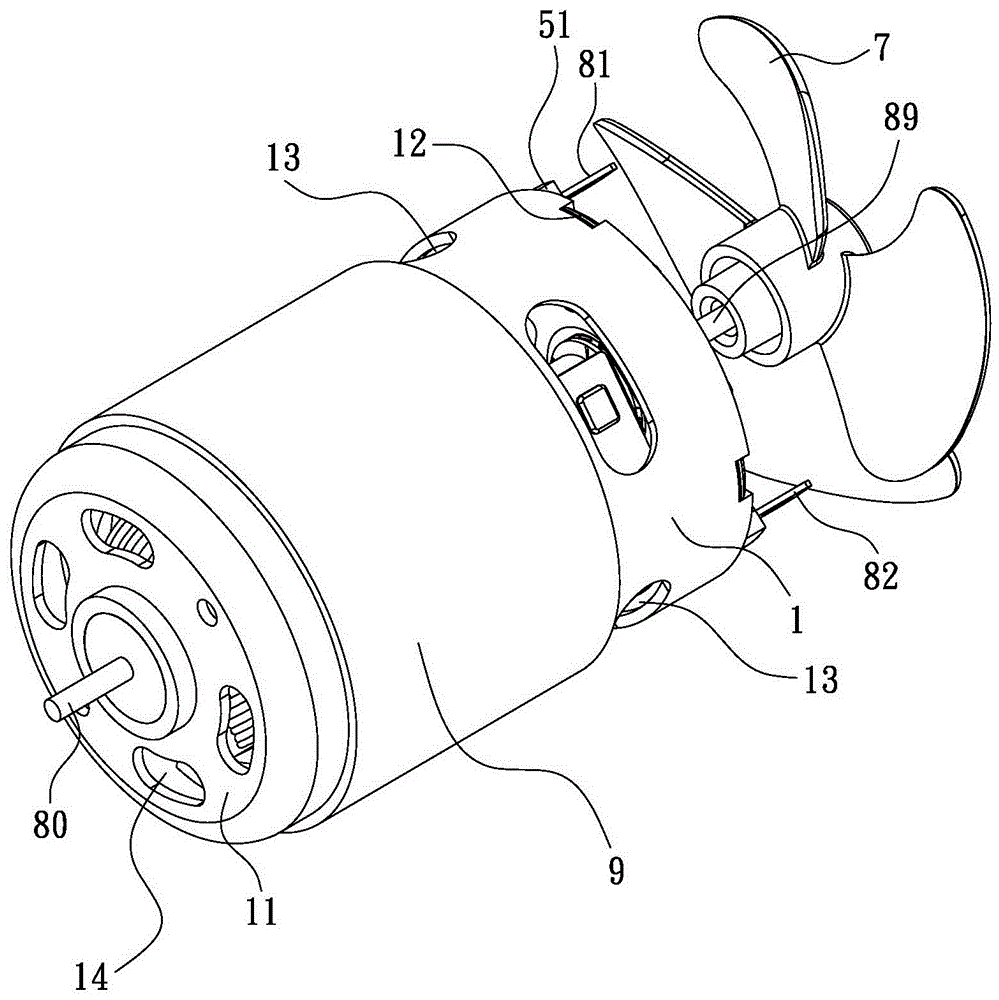

[0035] Please refer to Figure 1 to Figure 3 , the present invention is a heat dissipation structure of a motor, which basically includes a housing 1 with an internal space 15, a forward opening 10 is formed at one end of the housing 1, and a plurality of corresponding openings are arranged on the edge of the forward opening 10. Spaced positioning buckles 12, the other end of the housing 1 forms a closed rearward wall 11, the rearward wall 11 is pierced with a plurality of isolated air outlets 14, and is provided on the circumferential surface of the housing 1. There is at least one convection hole 13 completely through, so that the inside of the motor housing 1 and the outside of the motor housing 1 can generate air flow. The housing 1 is provided with the necessary elements o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com