Continuous charcoal production equipment and method

A technology for production equipment and biochar, which is applied in the fields of biofuels, special forms of dry distillation, coke ovens, etc., can solve the problem of easy clogging of pipelines by tar, and achieve the effect of prolonging carbonization time, saving carbonized fuel and facilitating storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

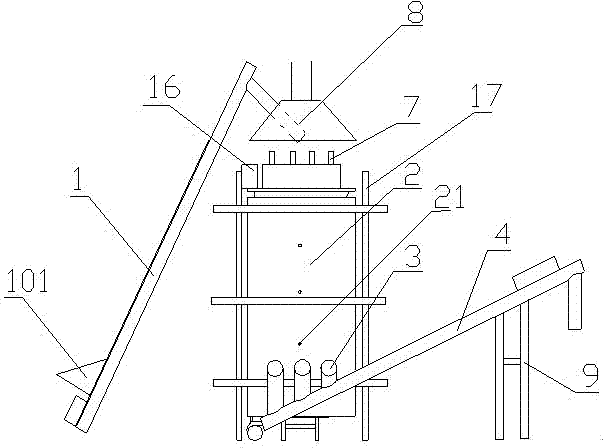

[0033] refer to Figure 1 to Figure 10, the present invention uses the principle of dry distillation to crack biomass. The whole equipment is composed of cracking box 12, oil and gas collection and delivery system, stove 11, metal shell 13, incubator 2, support frame 17, feeding and discharging system, air supply system, cooling system and temperature measuring system.

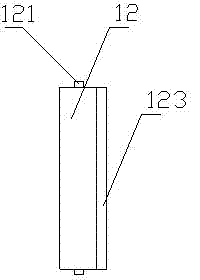

[0034] The cracking box 12 is in the shape of a wide flat box and folds and stretches in the up-down direction. The upper opening of the cracking box 12 is connected with the feed hopper 10, and the outlet at the lower end of the cracking box 12 is connected with the discharge conveyor 3. On each fold of the cracking box 12 Oil and gas outlet holes 122 are arranged on the surface, and a semicircular tube 14 is sealed and covered above the oil and gas outlet holes 122. One end of the semicircular tube 14 is closed, and the other end is connected with the oil and gas collection and delivery pipe 15. The oil and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com