Special exhaust device for integrated cooker

An exhaust device and integrated stove technology, applied in the field of integrated stoves, can solve problems such as blockage of air outlet channels, oil stains, and reduced smoke exhaust effects, and achieve the effects of reducing sulfide, saving space, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

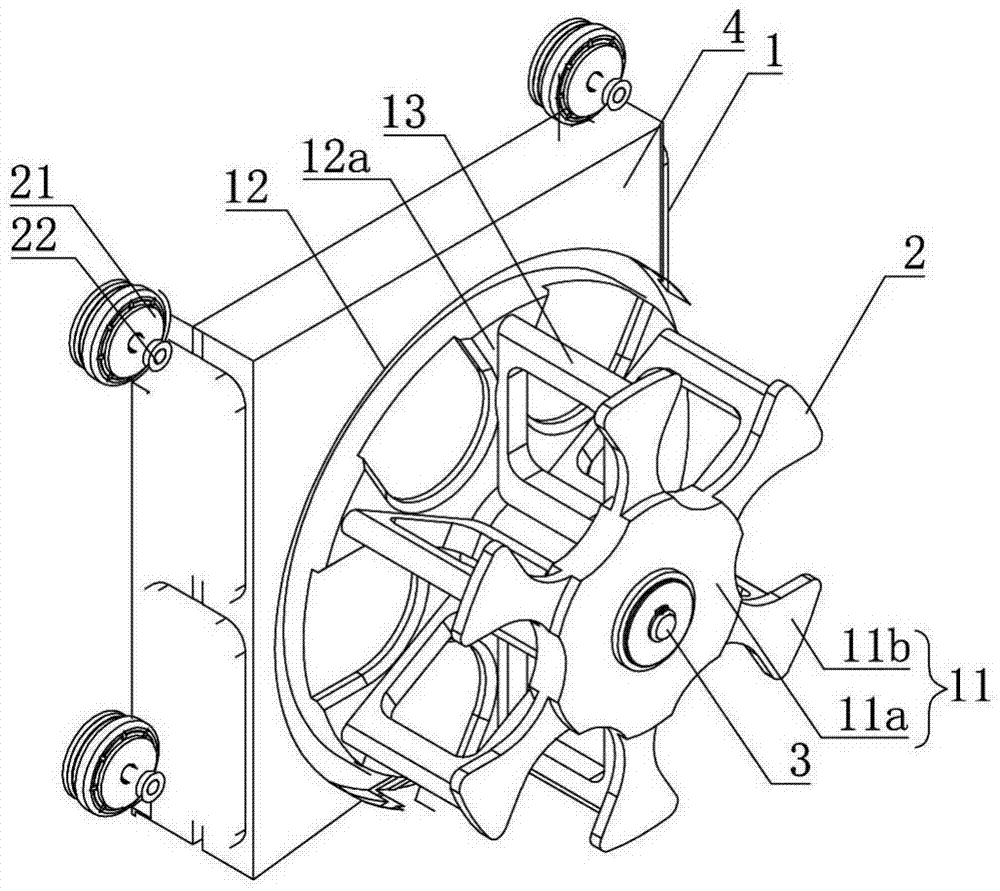

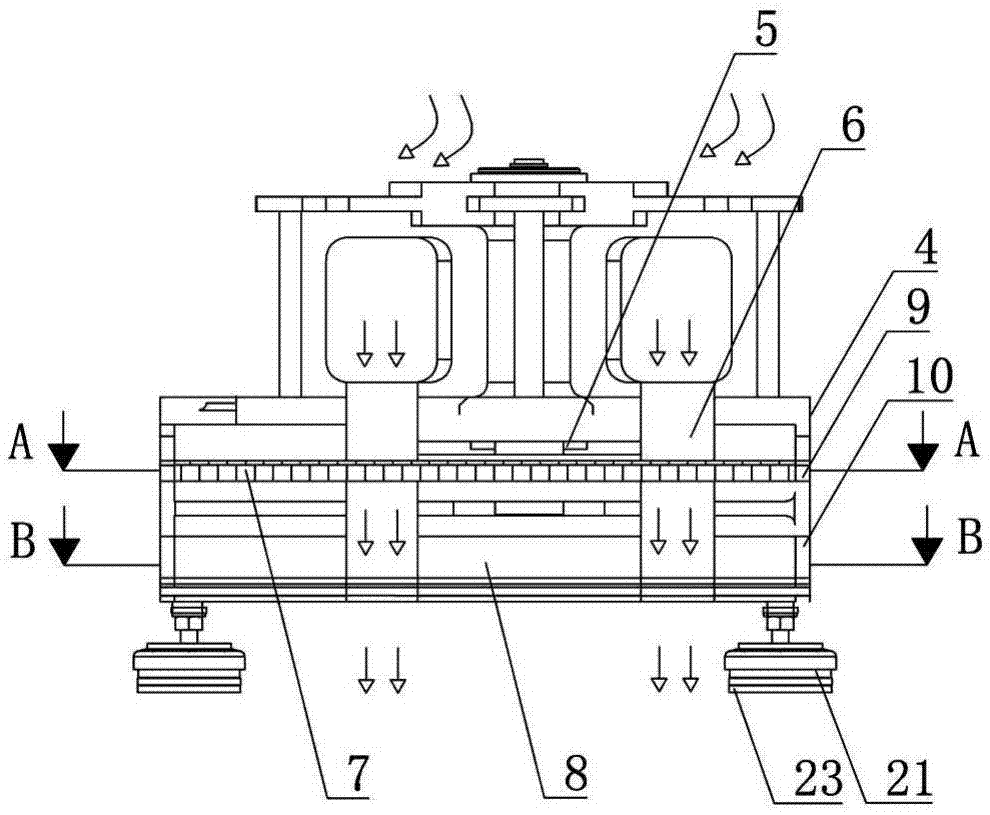

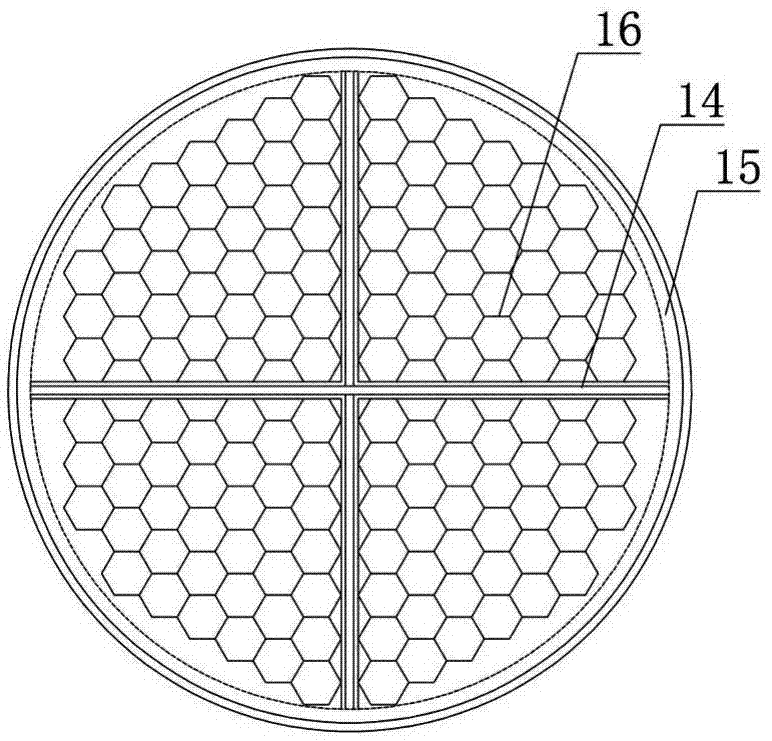

[0033] Such as figure 1 , figure 2 , image 3 As shown, the dedicated exhaust device for integrated stoves includes a mounting bracket assembly 1, an exhaust structure 2 located on the mounting bracket assembly 1, a movable shaft 3 for connecting the mounting bracket assembly 1 and the exhaust structure 2, and a mounting bracket The assembly 1 includes a rectangular frame 4. The central axis of the rectangular frame 4 is provided with a first groove 5 for inserting the movable shaft 3. The outer ring of the movable shaft 3 is provided with 6 exhaust channels 6. The rectangular frame 4 is arranged along the direction of the exhaust channel 6. A filter layer 7 is provided, a drainage grid frame 8 located below the filter layer 7, a first card slot 9 is provided on the inner wall of the rectangular frame 4, a second card slot 10 is located below the first card slot 9, and the filter layer 7 is movable Placed in the first slot 9, the upper end of the filter layer 7 is fixedly c...

Embodiment 2

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the dedicated exhaust device for integrated stoves includes a mounting bracket assembly 1, an exhaust structure 2 located on the mounting bracket assembly 1, a movable shaft 3 for connecting the mounting bracket assembly 1 and the exhaust structure 2, and a mounting bracket The assembly 1 includes a rectangular frame 4. The central axis of the rectangular frame 4 is provided with a first groove 5 for inserting the movable shaft 3. The outer ring of the movable shaft 3 is provided with 6 exhaust channels 6. The rectangular frame 4 is arranged along the direction of the exhaust channel 6. A filter layer 7 is provided, a drainage grid frame 8 located below the filter layer 7, a first card slot 9 is provided on the inner wall of the rectangular frame 4, a second card slot 10 is located below the first card slot 9, and the filter layer 7 is movable Placed in the first slot 9, the upper end of the filter layer 7...

Embodiment 3

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the dedicated exhaust device for integrated stoves includes a mounting bracket assembly 1, an exhaust structure 2 located on the mounting bracket assembly 1, a movable shaft 3 for connecting the mounting bracket assembly 1 and the exhaust structure 2, and a mounting bracket The assembly 1 includes a rectangular frame 4. The central axis of the rectangular frame 4 is provided with a first groove 5 for inserting the movable shaft 3. The outer ring of the movable shaft 3 is provided with 6 exhaust channels 6. The rectangular frame 4 is arranged along the direction of the exhaust channel 6. A filter layer 7 is provided, a drainage grid frame 8 located below the filter layer 7, a first card slot 9 is provided on the inner wall of the rectangular frame 4, a second card slot 10 is located below the first card slot 9, and the filter layer 7 is movable Placed in the first slot 9, the upper end of the filter layer 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com