High-purity duplex stainless steel smelting process with precise control of n content

A duplex stainless steel, precise control technology, applied in the field of stainless steel smelting, can solve the problems of low cost, high cost of ferrochromium nitride, unstable N recovery rate, etc., and achieve low cost, energy saving and production cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with specific embodiments.

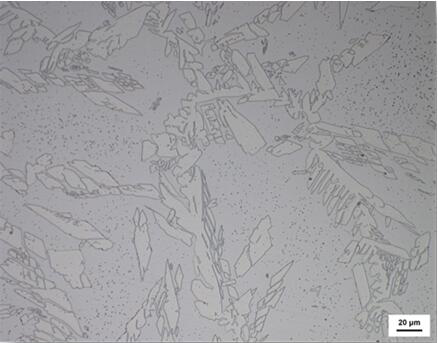

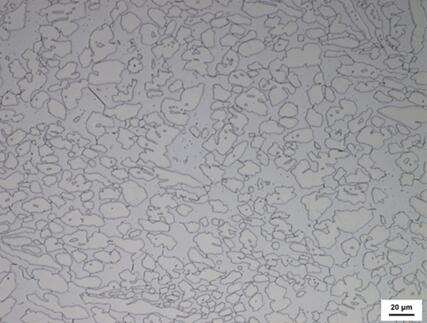

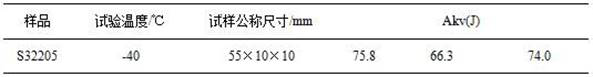

[0047] The smelting workshop of a certain company implements the high-purity duplex stainless steel smelting process with precise control of N content described in the present invention, adopts the 10-ton "electric arc furnace + AOD furnace refining" smelting method, continuously produces 5 furnaces of S32205 duplex stainless steel, and casts them into 3.2 1 ton and 4.2 tons of steel ingots of two different ingot shapes, the content of the components of the prepared duplex stainless steel according to the mass percentage is: C<0.03%, Si 0.4-0.6%, Mn 1.0-1.4%, P≤0.015 %, S≤0.002%, Cr 22.0-22.5%, Ni 5.0-5.5%, Mo 3.0-3.5%, N 0.16-0.18%, gas elements [O]≤25ppm, [H]≤2ppm, and the rest are Fe elements. The chemical composition of the steel ingot meets the requirements of the internal control composition. The inclusions of the five categories of A, B, C, D, and DS are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com