Injection molding method and system

A technology of injection molding and mould, which is applied in the field of injection molding methods and systems, can solve problems such as poor exhaust, poor surface appearance, and low safety, and achieve the elimination of deformation and post-deformation, good product surface appearance, and stable product dimensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

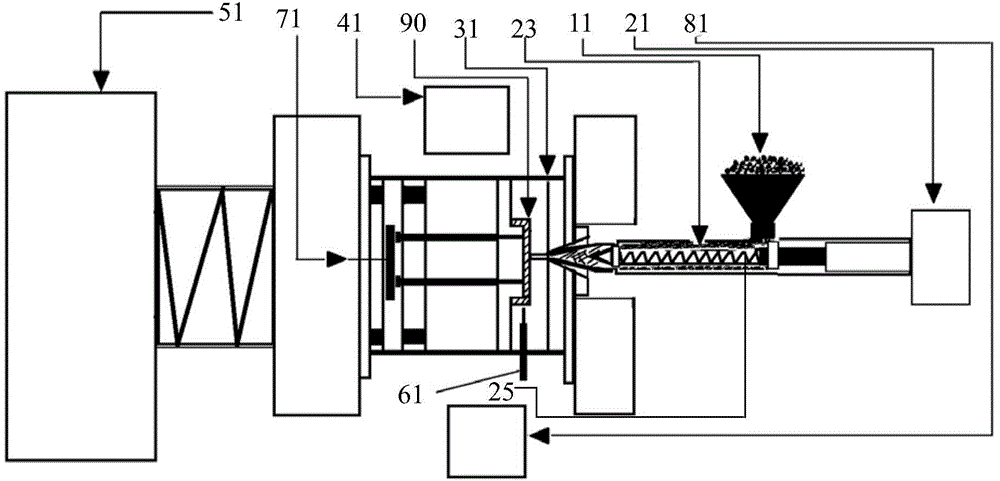

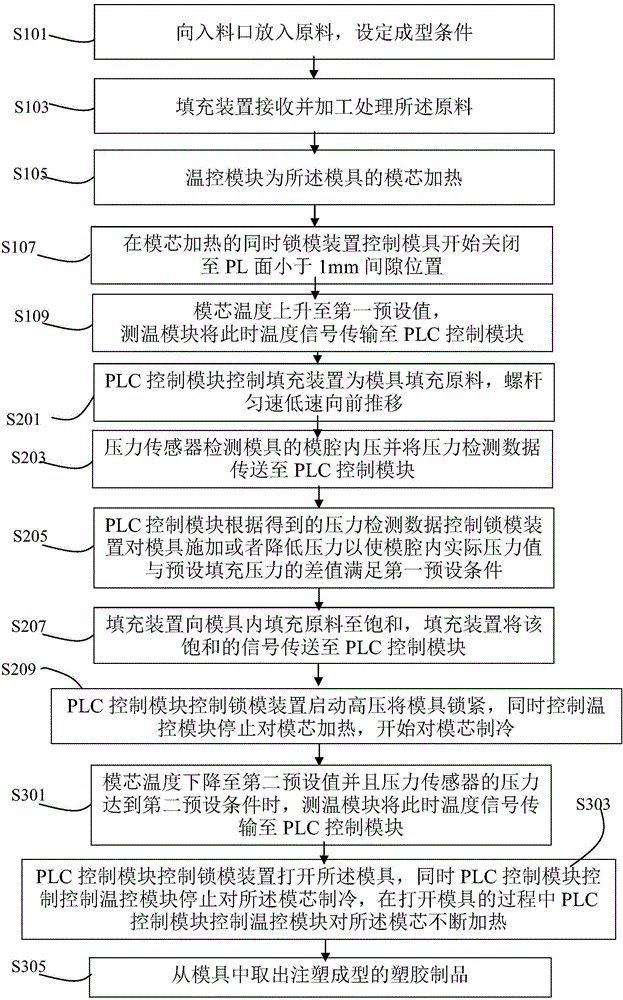

[0030] refer to figure 1 , an injection molding system provided by an embodiment of the present invention includes: a material inlet 11, a filling device 21, a mold 31, a temperature control module 41, a mold clamping device 51, a temperature measurement module 61, a pressure sensor 71 and a PLC control mold Fast 81.

[0031] The material inlet 11 is used to put raw materials into, and is connected to the filling device 21. The filling device 21 receives and processes the raw material and injects the raw material into the mold 31. In the present embodiment, the filling device 21 includes a barrel 23 and a Inside the barrel 23 is a screw 25 for propelling the raw material. The mold 31 is connected to the filling device 21 for injection molding to form a plastic product. The temperature control module 41 is connected to the mold 31 for heating or cooling the mold core of the mold 31 . The temperature control module 41 includes a hot water pump 43, a cold water pump 45 and a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com