Carbide drill and machining process thereof

A cemented carbide and drill technology, which is used in wood drilling tools, wood processing appliances, manufacturing tools, etc., can solve the problems of rough hole shape, easy blockage, poor chip removal performance, etc., to increase strength and impact resistance. , entry and exit for a brisk, beautifully shaped hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

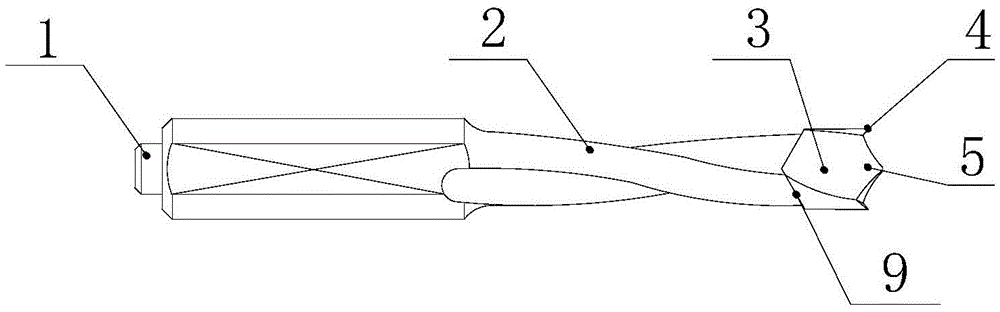

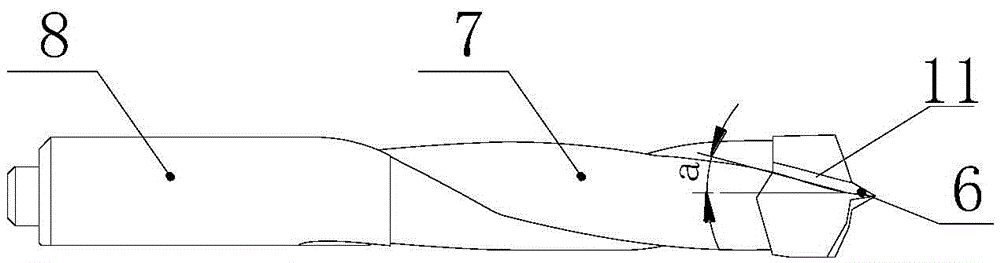

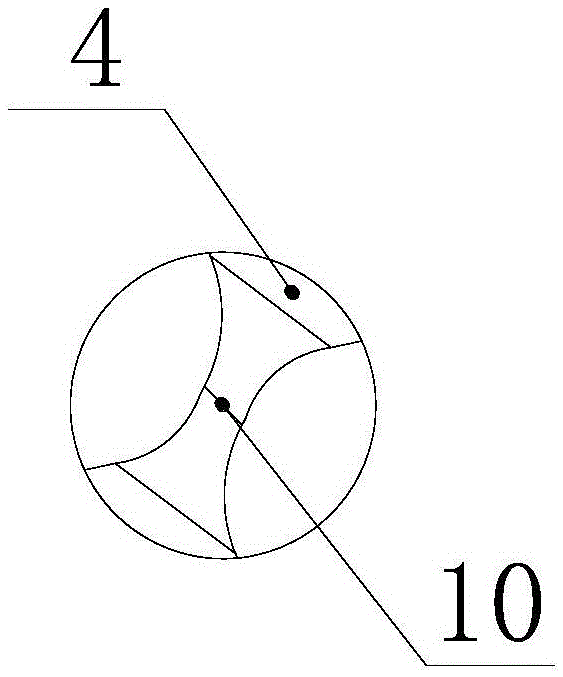

[0029] Further explain below in conjunction with accompanying drawing:

[0030] as attached Figure 1-6 Shown: the present invention comprises drill tip, cutter body, handle of a knife successively, wherein: described cutter body and handle of a knife are integrally formed, and described cutter body is provided with several helical grooves, and is set between the helical grooves and the horizontal plane. There is an included angle, the angle of the included angle is 10°-15°, the left end section of the drill tip is a tapered surface, and the end face of the cutter body close to the drill tip is the same taper as the left end section of the drill tip The inner cone angle of the cutter body is fixed by V-shaped butt welding on the end face of the drill tip. The drill tip includes a drill tip body and a drill tip tip. The surface shape of the drill tip body is It is W-shaped, the tip of the drill point is provided with a chisel edge, the drill point is provided with two cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com