Improved cylinder

A cylinder and cylinder barrel technology is applied in the field of improvement of the cylinder structure of a piston engine, which can solve the problems of increased energy consumption, reduced engine service life, blue smoke and the like, and achieves increased energy consumption, reduced service life, and sealing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

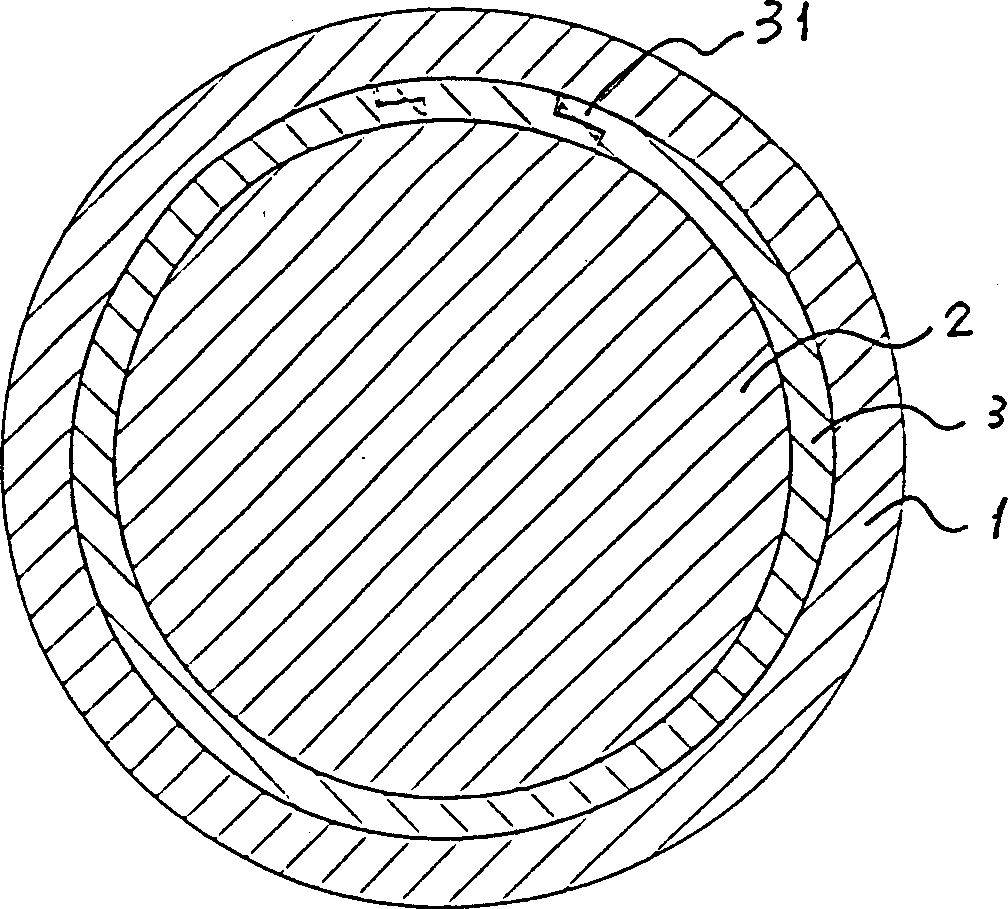

[0032] figure 1 yes figure 2 A-A direction view in ;

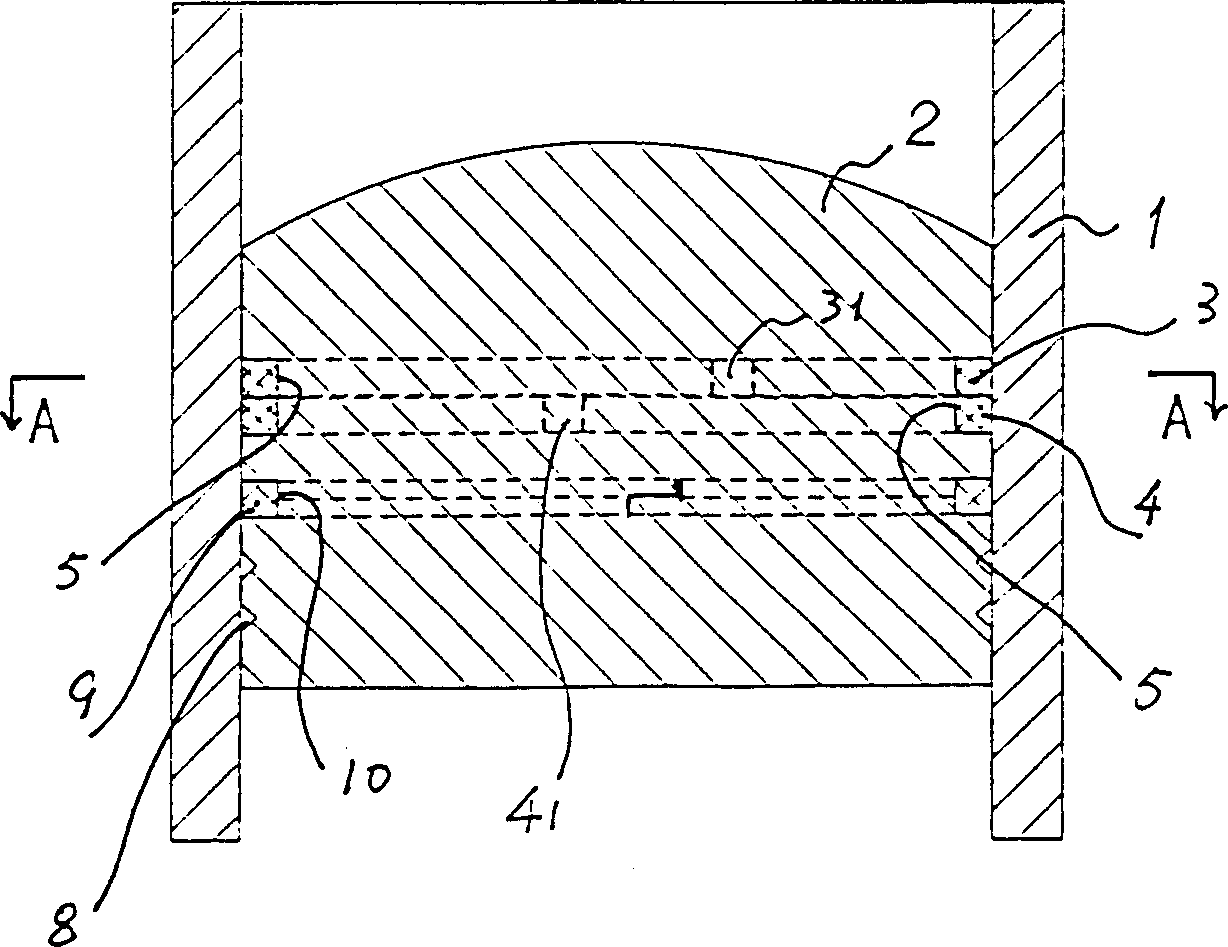

[0033] figure 2 It is a schematic diagram of the structure (part) section front view of the improved cylinder described in Embodiment 1 of the first technical solution of the present invention;

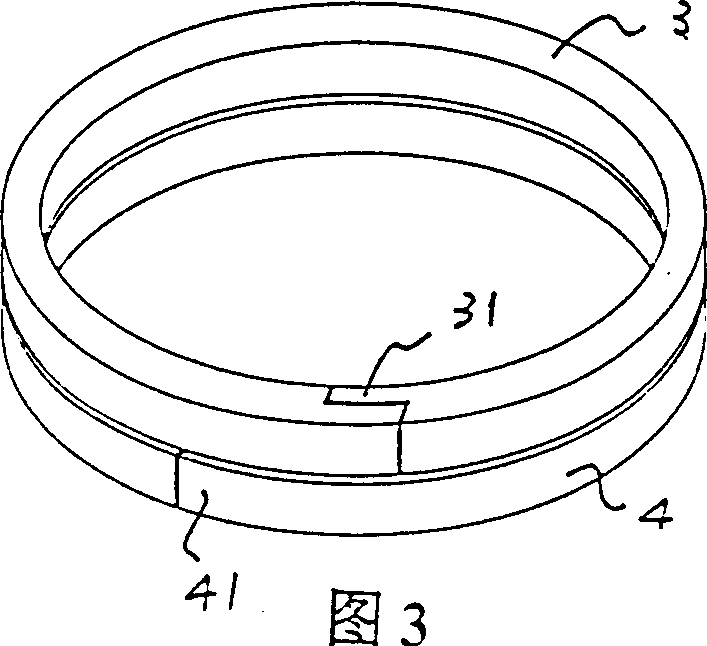

[0034] Fig. 3 is a structural schematic diagram of the piston ring included in the improved cylinder mentioned in Embodiment 1 of the first technical solution of the present invention.

[0035] An improved cylinder, comprising a cylinder barrel (1), a piston (2), a piston ring (3) and an oil ring (9), the piston ring (3) is located in the piston ring groove (5) of the piston, and the oil ring (9 ) is located in the oil ring groove (10) of the piston, which is characterized in that two parallel piston rings (3, 4) are arranged in the said piston ring groove (5), and the piston ring joints (31, 41) are in diameter Upwards, the outer and inner stepped butt joint structures are opposite. The two parallel piston ring joints (31, ...

Embodiment 2

[0037] Figure 4 yes Figure 5 A'-A' in the view;

[0038] Figure 5 It is a schematic diagram of the structure (part) section front view of the said improved cylinder of the second technical solution embodiment 2 of the present invention;

[0039] Image 6 It is a structural schematic diagram of the piston ring included in the improved cylinder mentioned in Embodiment 2 of the second technical solution of the present invention.

[0040]Another improved cylinder comprises a cylinder barrel (1), a piston (2), a piston ring (6) and an oil ring (11), the piston ring (6) is located in the piston ring groove (12) of the piston, and the oil ring ( 11) Located in the oil ring groove (14) of the piston, it is characterized in that two piston rings (6, 7) nested together are arranged in the said piston ring groove (12), and a piston ring joint (61) In the axial direction, it is a stepped butt joint structure facing up and down. The other piston ring joint (71) is a disconnected fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com