Friction material, long-life friction lining and preparation method thereof

A technology of friction materials and raw materials, applied in the field of brake materials, can solve the problem that the service life of friction linings cannot reach more than 100,000 kilometers, and achieve the effect of normal wear, technical requirements, and beautiful car wheels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

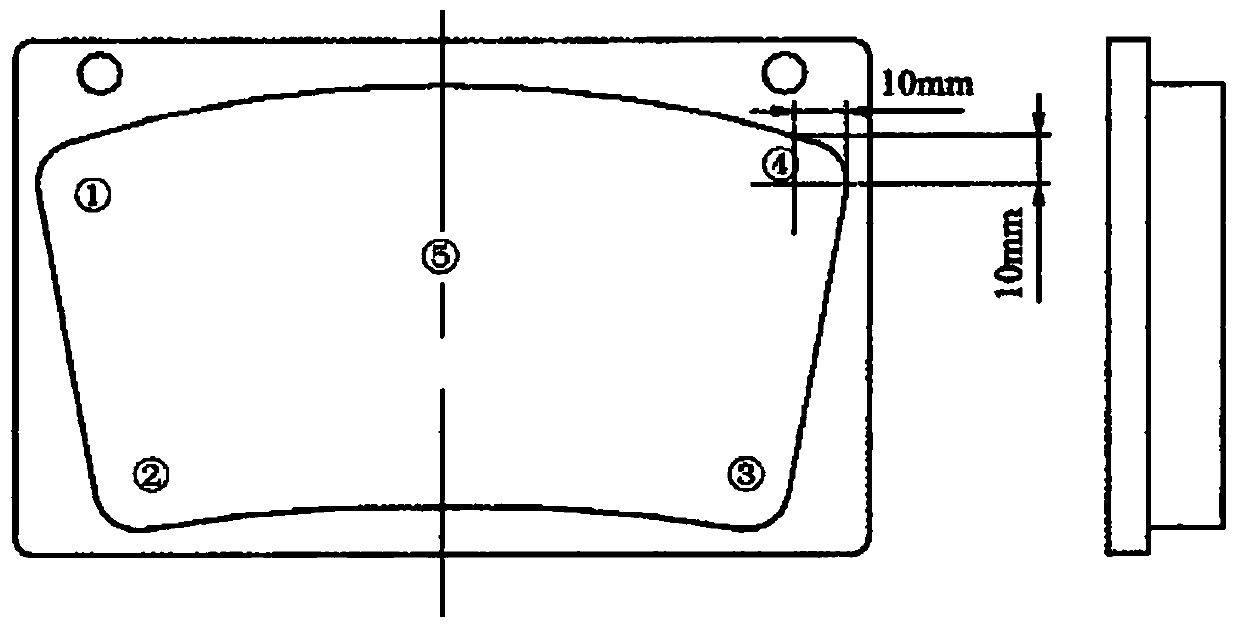

Image

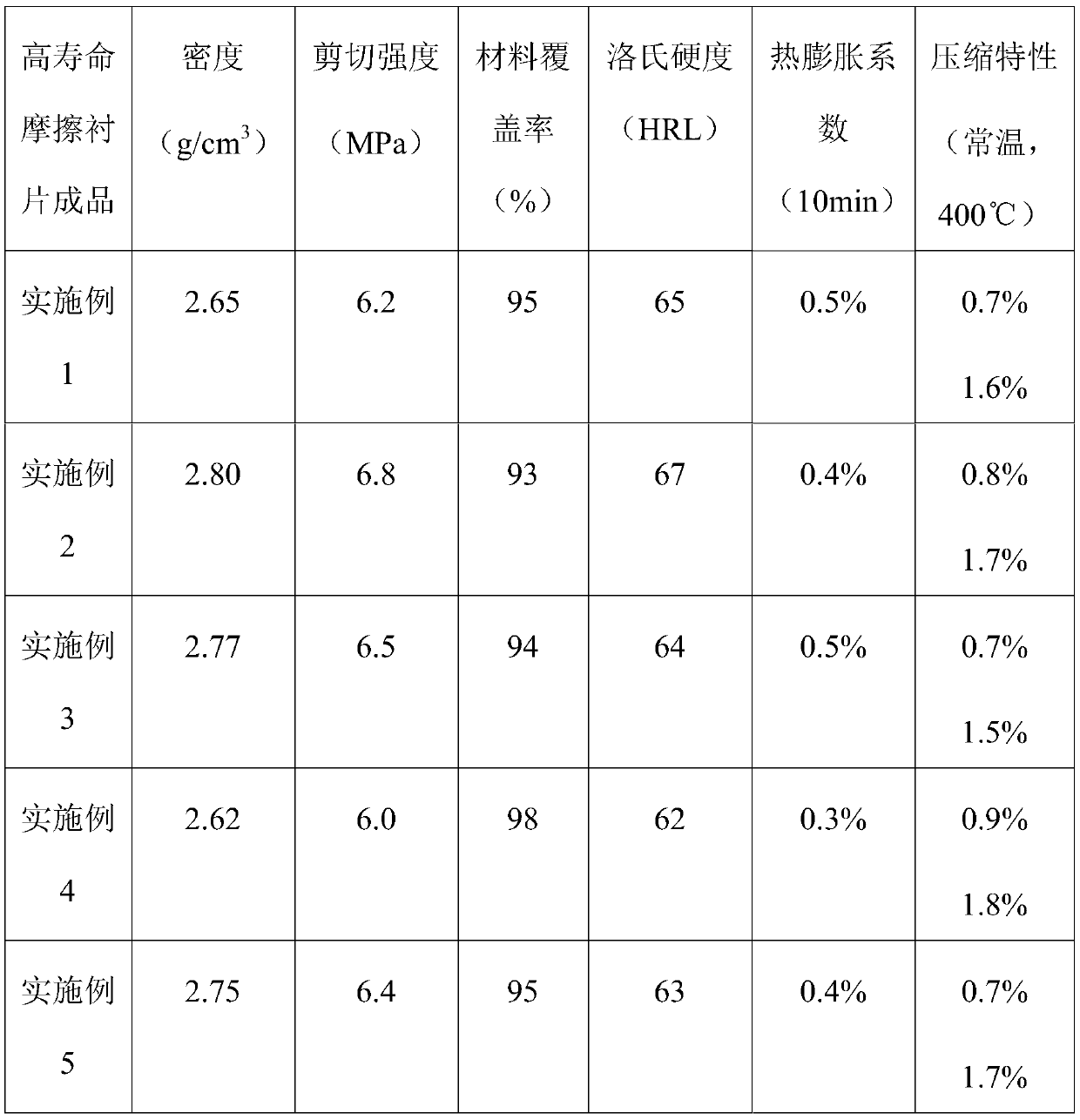

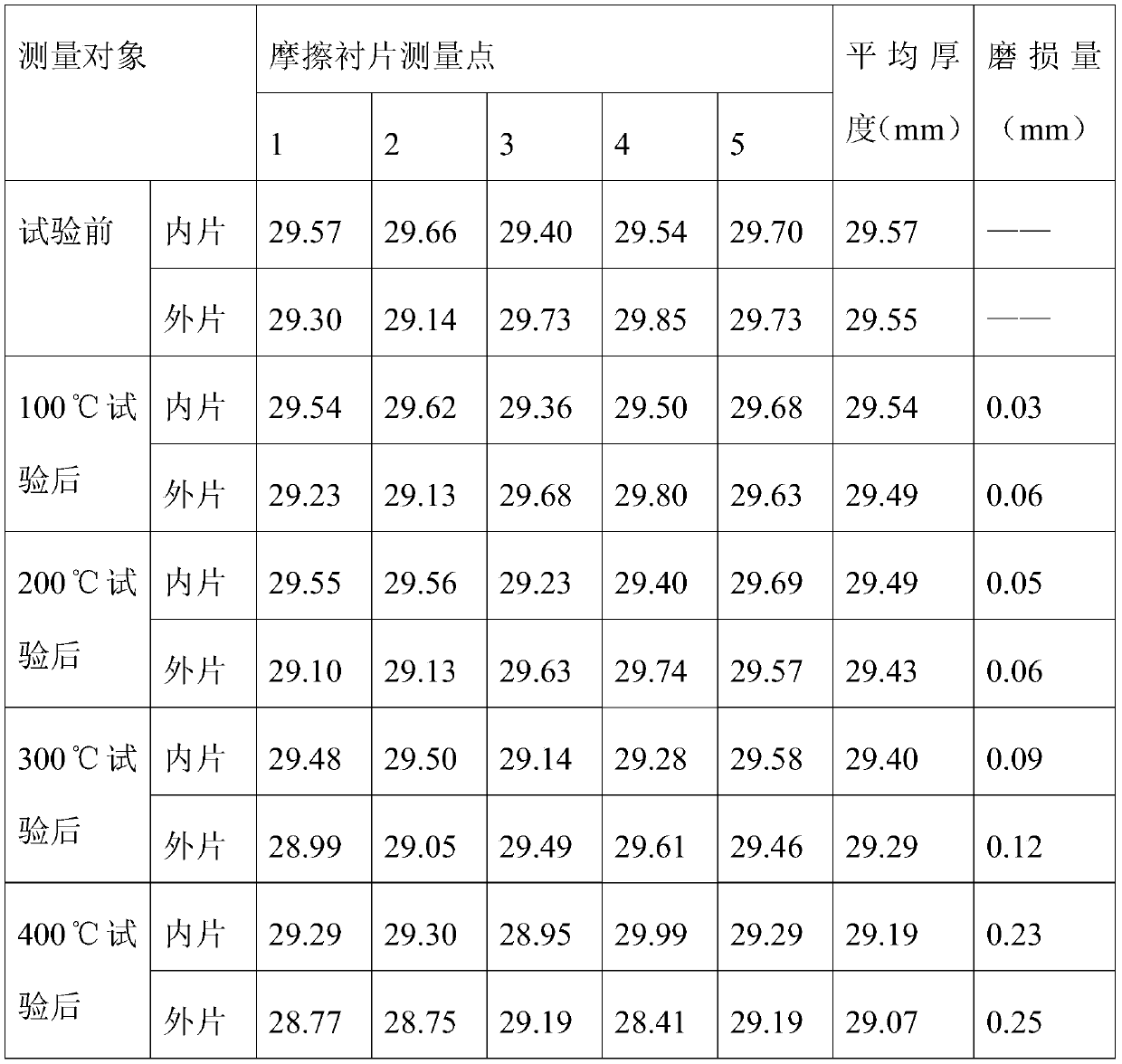

Examples

Embodiment 1

[0029] A friction material consisting of the following raw materials: 5kg of basalt fiber, 10kg of steel fiber, 5kg of composite mineral fiber, 7kg of nitrile modified phenolic resin, 4kg of powdered nitrile rubber, 6kg of graphite, 10kg of precipitated barium sulfate, and 2kg of aramid pulp , Titanate platelets 7kg, light calcium carbonate 9kg, magnesium oxide 7kg, calcined alumina 3kg, copper fiber 8kg, ferrous sulfide 5kg, fluorite 12kg.

[0030] A high-life friction lining, the preparation method is as follows:

[0031] (1) Take the above-mentioned basalt fiber, steel fiber, composite mineral fiber, nitrile modified phenolic resin, powdered nitrile rubber, graphite, precipitated barium sulfate, and mix for 8 minutes to obtain mixture A;

[0032] (2) Take the above-mentioned aramid pulp, titanate platelets, light calcium carbonate, magnesium oxide, calcined alumina, copper fiber, ferrous sulfide, and fluorite respectively, and mix for 8 minutes to obtain mixture B;

[0033] (3) Mix...

Embodiment 2

[0038] A friction material consisting of the following raw materials: 8kg of basalt fiber, 11kg of steel fiber, 5kg of composite mineral fiber, 6kg of nitrile modified phenolic resin, 5kg of powdered nitrile rubber, 7kg of graphite, 15kg of precipitated barium sulfate, 4kg of aramid pulp , Titanate platelets 5kg, light calcium carbonate 10kg, magnesium oxide 8kg, calcined alumina 6kg, copper fiber 7kg, ferrous sulfide 9kg, fluorite 9kg.

[0039] A high-life friction lining, the preparation method is as follows:

[0040] (1) Take the above-mentioned basalt fiber, steel fiber, composite mineral fiber, nitrile modified phenolic resin, powdered nitrile rubber, graphite, precipitated barium sulfate, and mix for 5 minutes to obtain mixture A;

[0041] (2) Take the above-mentioned aramid pulp, titanate platelets, light calcium carbonate, magnesium oxide, calcined alumina, copper fiber, ferrous sulfide, and fluorite respectively, and mix for 10 minutes to obtain mixture B;

[0042] (3) Mixing...

Embodiment 3

[0047] A friction material composed of the following raw materials: 6kg of basalt fiber, 15kg of steel fiber, 6kg of composite mineral fiber, 9kg of nitrile modified phenolic resin, 8kg of powdered nitrile rubber, 8kg of graphite, 10kg of precipitated barium sulfate, and 3kg of aramid pulp , Titanate flakes 6kg, light calcium carbonate 15kg, magnesium oxide 10kg, calcined alumina 4kg, copper fiber 8kg, ferrous sulfide 6kg, fluorite 10kg.

[0048] A high-life friction lining, the preparation method is as follows:

[0049] (1) Take the above-mentioned basalt fiber, steel fiber, composite mineral fiber, nitrile modified phenolic resin, powdered nitrile rubber, graphite, and precipitated barium sulfate, and mix for 7 minutes to obtain mixture A;

[0050] (2) Take the above-mentioned aramid pulp, titanate platelet, light calcium carbonate, magnesium oxide, calcined alumina, copper fiber, ferrous sulfide, and fluorite respectively, and mix for 6 minutes to obtain mixture B;

[0051] (3) Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com